torque INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 360 of 3924

REPAIR FOR COMPONENT PARTSAT-287

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

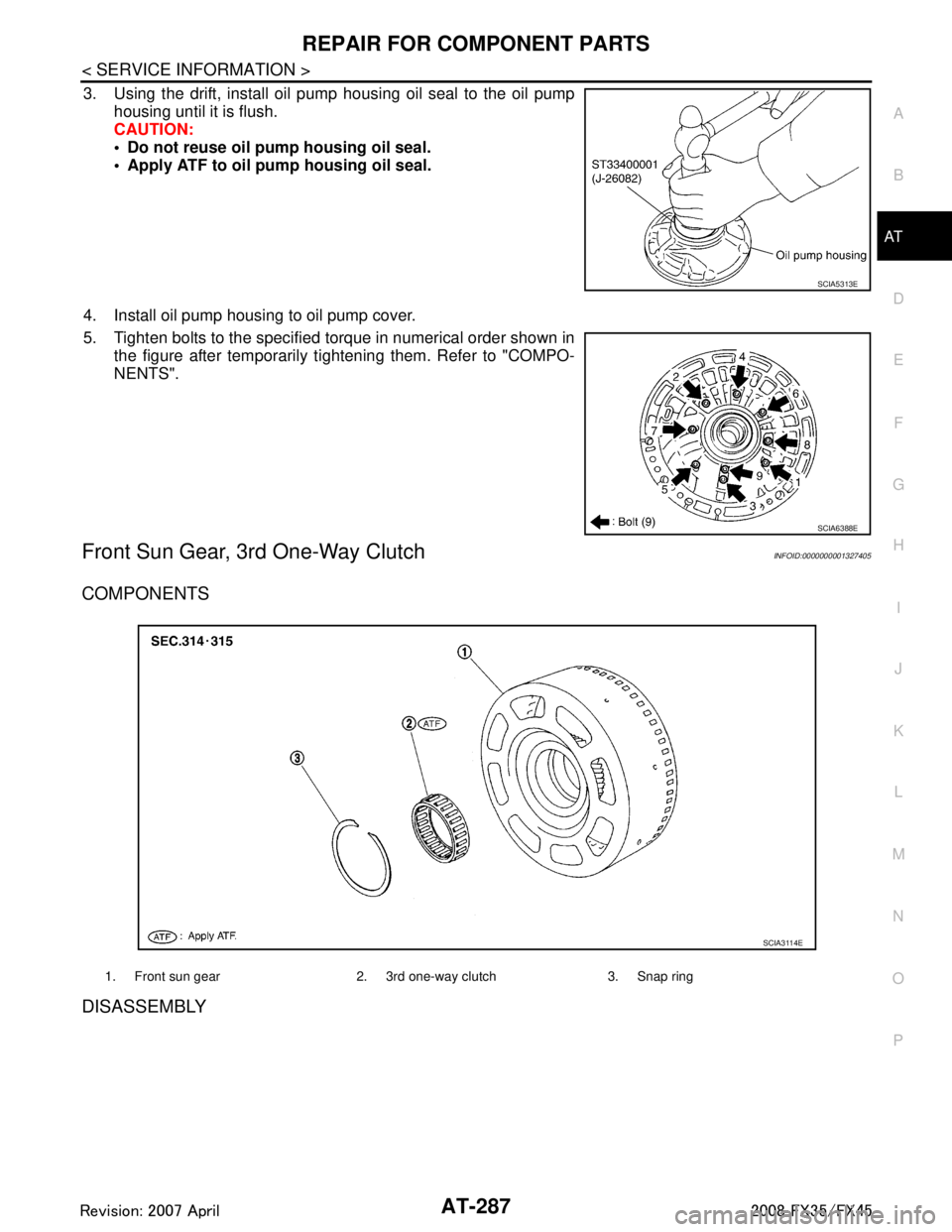

3. Using the drift, install oil pump housing oil seal to the oil pump housing until it is flush.

CAUTION:

Do not reuse oil pump housing oil seal.

Apply ATF to oil pump housing oil seal.

4. Install oil pump housing to oil pump cover.

5. Tighten bolts to the specified torque in numerical order shown in the figure after temporarily ti ghtening them. Refer to "COMPO-

NENTS".

Front Sun Gear, 3r d One-Way ClutchINFOID:0000000001327405

COMPONENTS

DISASSEMBLY

SCIA5313E

SCIA6388E

1. Front sun gear 2. 3rd one-way clutch 3. Snap ring

SCIA3114E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 379 of 3924

![INFINITI FX35 2008 Repair Manual

AT-306

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001327410

1. As shown in the figure, use a drift [commercial service tool: 22mm (0.87 in) dia.] to drive manual shaft oil se INFINITI FX35 2008 Repair Manual

AT-306

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001327410

1. As shown in the figure, use a drift [commercial service tool: 22mm (0.87 in) dia.] to drive manual shaft oil se](/img/42/57017/w960_57017-378.png)

AT-306

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000001327410

1. As shown in the figure, use a drift [commercial service tool: 22mm (0.87 in) dia.] to drive manual shaft oil seals into the trans-

mission case until it is flush.

CAUTION:

Do not reuse manual shaft oil seals.

Apply ATF to manual shaft oil seals.

2. Install detent spring and spacer in transmission case, and then tighten detent spring and spacer mounting bolt to the specified

torque. Refer to AT-249, "

Component".

3. Install manual shaft to transmission case.

4. Install parking rod to manual plate.

SCIA5259E

SCIA5248E

SCIA5716E

SCIA5220E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 385 of 3924

AT-312

< SERVICE INFORMATION >

ASSEMBLY

24. Install revolution sensor to transmission case, and then tightenrevolution sensor mounting bolt to the specified torque. Refer to

AT-249, "

Component".

CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings, etc. to get on the sensor's front

edge magnetic area.

Do not place in an area affected by magnetism.

25. As shown in the figure, use the drift to drive rear oil seal into the rear extension (2WD models) or adapter case (AWD models)

until it is flush.

CAUTION:

Do not reuse rear oil seal.

Apply ATF to rear oil seal.

26. Install return spring to parking pawl. VQ35DE models

SCIA2320E

SCIA5477E

SCIA2445E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 388 of 3924

ASSEMBLYAT-315

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

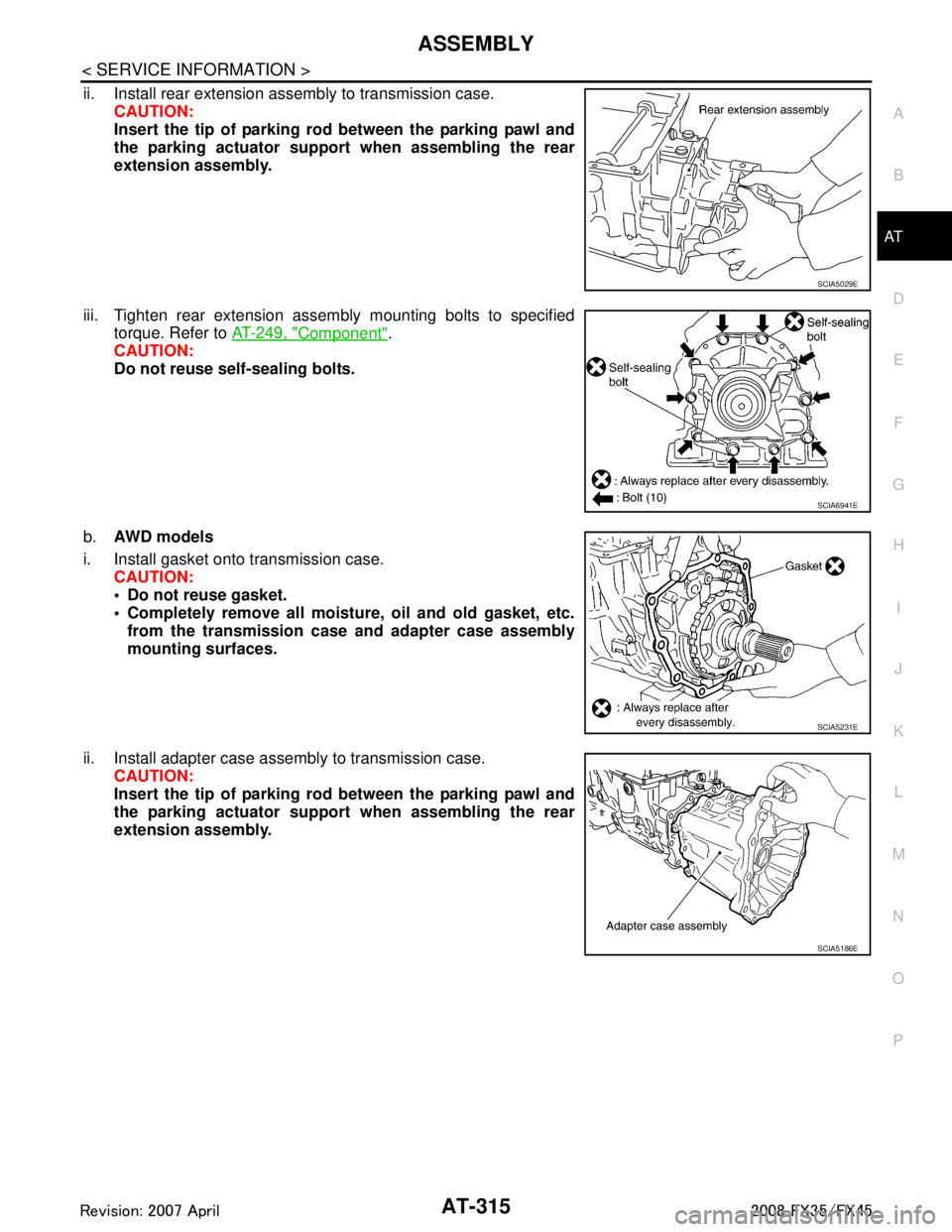

ii. Install rear extension assembly to transmission case. CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator suppor t when assembling the rear

extension assembly.

iii. Tighten rear extension assembly mounting bolts to specified torque. Refer to AT-249, "

Component".

CAUTION:

Do not reuse self-sealing bolts.

b. AWD m od e l s

i. Install gasket onto transmission case. CAUTION:

Do not reuse gasket.

Completely remove all moistu re, oil and old gasket, etc.

from the transmission case and adapter case assembly

mounting surfaces.

ii. Install adapter case assembly to transmission case. CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator suppor t when assembling the rear

extension assembly.

SCIA5029E

SCIA6941E

SCIA5231E

SCIA5186E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 389 of 3924

![INFINITI FX35 2008 Repair Manual

AT-316

< SERVICE INFORMATION >

ASSEMBLY

iii. Tighten adapter case assembly mounting bolts (1) to specifiedtorque. [With bracket (2).] Refer to AT-249, "

Component".

: Bolt (10)

CAUTION:

Do not reuse INFINITI FX35 2008 Repair Manual

AT-316

< SERVICE INFORMATION >

ASSEMBLY

iii. Tighten adapter case assembly mounting bolts (1) to specifiedtorque. [With bracket (2).] Refer to AT-249, "

Component".

: Bolt (10)

CAUTION:

Do not reuse](/img/42/57017/w960_57017-388.png)

AT-316

< SERVICE INFORMATION >

ASSEMBLY

iii. Tighten adapter case assembly mounting bolts (1) to specifiedtorque. [With bracket (2).] Refer to AT-249, "

Component".

: Bolt (10)

CAUTION:

Do not reuse self-sealing bolts (3).

Refer to GI section to mark sure icons (symbol marks) in the fig-

ure. Refer to GI-8, "

Component".

35. Install needle bearing in drum support. CAUTION:

Take care with the direction of needle bearing. Refer to

AT-264, "

Location of Adjusting Sh ims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

36. Install direct clutch assembly in reverse brake. CAUTION:

Make sure that drum support edge surface and direct clutch

inner boss edge surface come to almost same place.

37. Install high and low reverse clutch assembly in direct clutch.

SCIA7210E

SCIA5198E

SCIA5019E

SCIA2306E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 393 of 3924

AT-320

< SERVICE INFORMATION >

ASSEMBLY

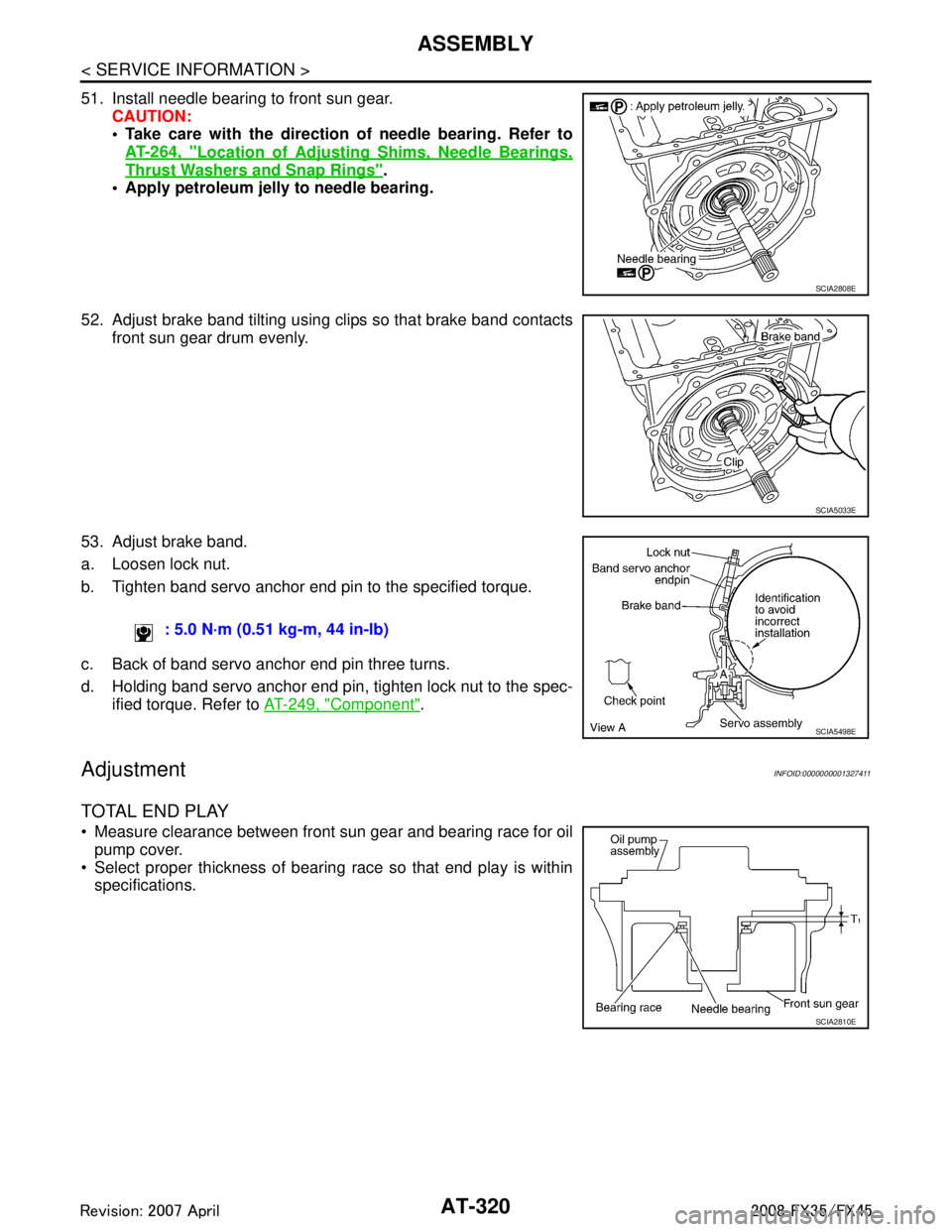

51. Install needle bearing to front sun gear.CAUTION:

Take care with the direction of needle bearing. Refer toAT-264, "

Location of Adjusting Sh ims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

52. Adjust brake band tilting using clips so that brake band contacts front sun gear drum evenly.

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to the specified torque.

c. Back of band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to the spec- ified torque. Refer to AT-249, "

Component".

AdjustmentINFOID:0000000001327411

TOTAL END PLAY

Measure clearance between front sun gear and bearing race for oil

pump cover.

Select proper thickness of bearing race so that end play is within specifications.

SCIA2808E

SCIA5033E

: 5.0 N·m (0.51 kg-m, 44 in-lb)

SCIA5498E

SCIA2810E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 397 of 3924

AT-324

< SERVICE INFORMATION >

ASSEMBLY

5. Tighten oil pump mounting bolts to specified torque. Refer to AT-

249, "Component".

CAUTION:

Apply ATF to oil pump bushing.

6. Install O-ring to input clutch assembly. CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

7. Install converter housing to transmission case, and then tighten converter housing mounting bolts (1) to the specified torque.

Refer to AT-249, "

Component".

: Bolt (8)

CAUTION:

Do not reuse self-sealing bolt (2).

8. Make sure that brake band does not close turbine revolution sensor hole.

9. Install control valve with TCM.

a. Connect TCM connector and park/neutral position switch con- nector.

SCIA2300E

SCIA5011E

SCIA7985E

SCIA5034E

SCIA5449E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 398 of 3924

ASSEMBLYAT-325

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

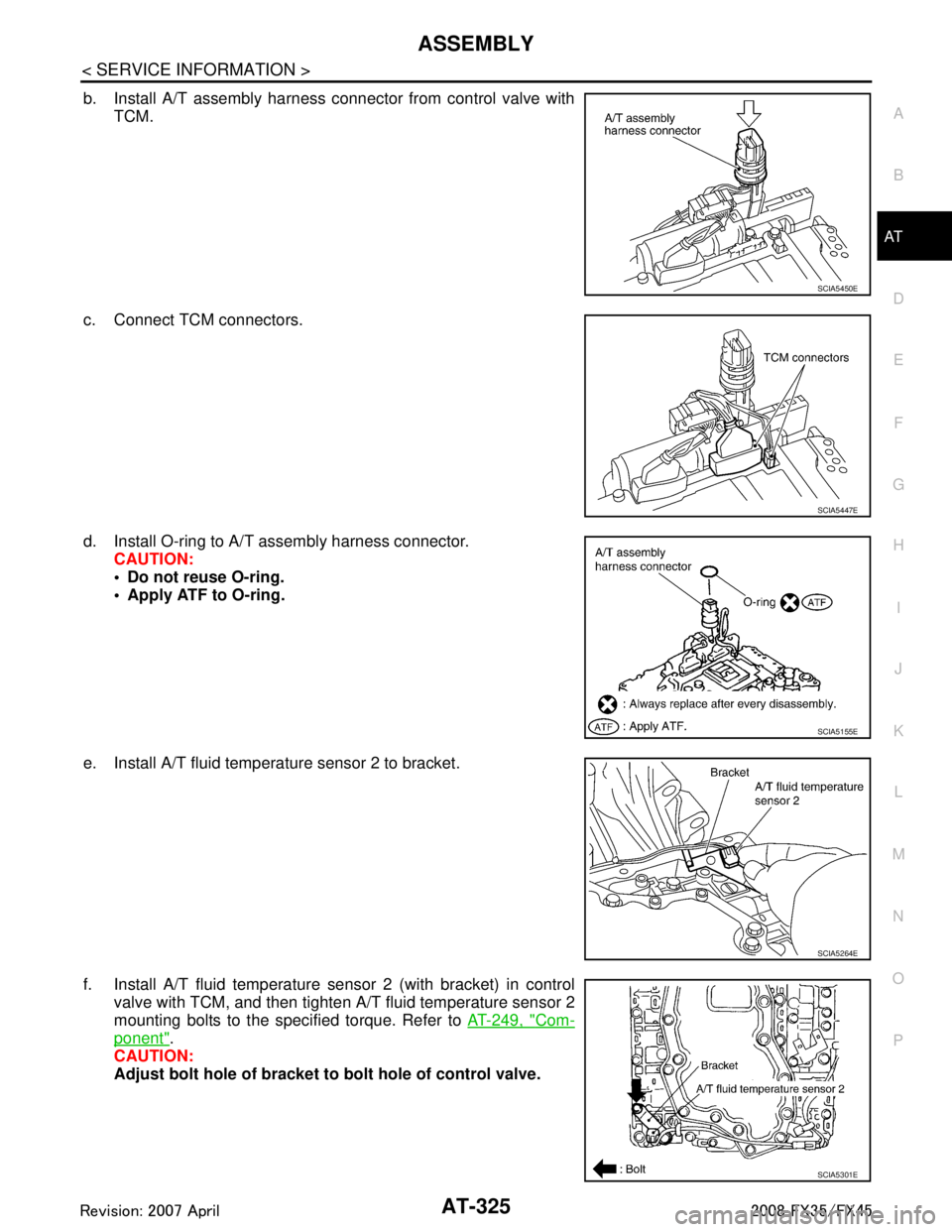

b. Install A/T assembly harness connector from control valve with TCM.

c. Connect TCM connectors.

d. Install O-ring to A/T assembly harness connector. CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

e. Install A/T fluid temperature sensor 2 to bracket.

f. Install A/T fluid temperature sens or 2 (with bracket) in control

valve with TCM, and then tighten A/T fluid temperature sensor 2

mounting bolts to the specified torque. Refer to AT-249, "

Com-

ponent".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve.

SCIA5450E

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5301E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 399 of 3924

AT-326

< SERVICE INFORMATION >

ASSEMBLY

g. Install control valve with TCM in transmission case.CAUTION:

Make sure that turbine revolu tion sensor securely installs

turbine revolution sensor hole.

Hang down revolution senso r harness toward outside so

as not to disturb installation of control valve with TCM.

Adjust A/T assembly harness co nnector of control valve

with TCM to terminal hole of transmission case.

Assemble it so that manual valve cutout is engaged with manual plate projection.

h. Install bolts A, B and C to control valve with TCM. : Front

i. Tighten bolt 1, 2 and 3 temporarily to prevent dislocation. After that tighten them in order (1 → 2 → 3), and then tighten other

bolts to the specified torque. Refer to AT-249, "

Component".

: Front

SCIA5034E

SCIA5035E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8077E

SCIA8078E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 401 of 3924

AT-328

< SERVICE INFORMATION >

ASSEMBLY

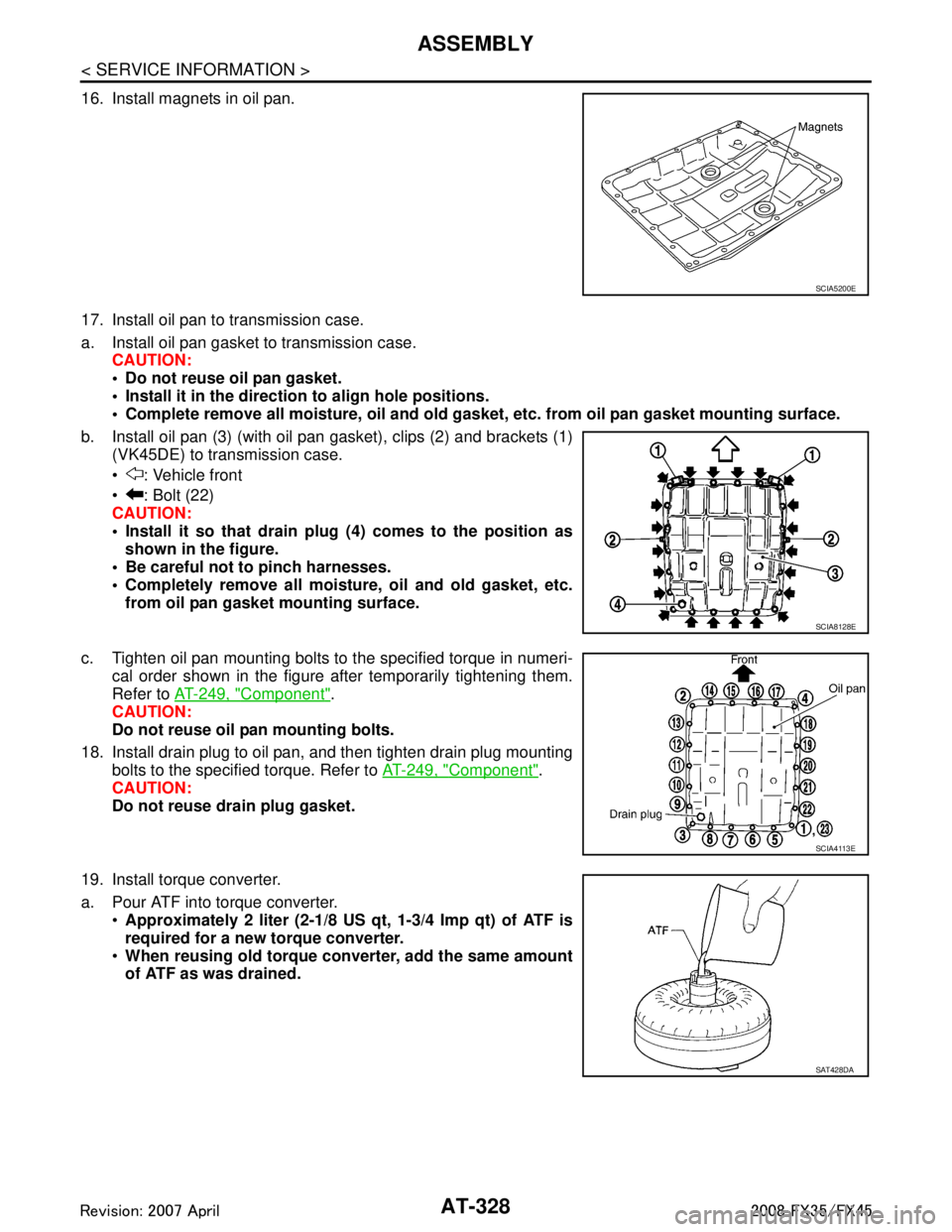

16. Install magnets in oil pan.

17. Install oil pan to transmission case.

a. Install oil pan gasket to transmission case.CAUTION:

Do not reuse oil pan gasket.

Install it in the direction to align hole positions.

Complete remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

b. Install oil pan (3) (with oil pan gasket), clips (2) and brackets (1) (VK45DE) to transmission case.

: Vehicle front

: Bolt (22)

CAUTION:

Install it so that drain plug (4) comes to the position as

shown in the figure.

Be careful not to pinch harnesses.

Completely remove all moisture, oil and old gasket, etc. from oil pan gasket mounting surface.

c. Tighten oil pan mounting bolts to the specified torque in numeri- cal order shown in the figure after temporarily tightening them.

Refer to AT-249, "

Component".

CAUTION:

Do not reuse oil pan mounting bolts.

18. Install drain plug to oil pan, and then tighten drain plug mounting bolts to the specified torque. Refer to AT-249, "

Component".

CAUTION:

Do not reuse drain plug gasket.

19. Install torque converter.

a. Pour ATF into torque converter. Approximately 2 liter (2-1/8 US qt, 1-3/4 Imp qt) of ATF is

required for a new torque converter.

When reusing old torque converter, add the same amount

of ATF as was drained.

SCIA5200E

SCIA8128E

SCIA4113E

SAT428DA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C