installation INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3779 of 3924

SRS-42

< SERVICE INFORMATION >

CRASH ZONE SENSOR

CRASH ZONE SENSOR

Removal and InstallationINFOID:0000000001327768

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove front grille. Refer to EI-22, "Component Parts Location".

2. Remove crash zone sensor connector.

3. Remove crash zone sensor fixing nuts.

CAUTION:

Replace crash zone sensor if it has b een dropped or sustained an impact.

Do not disassemble crash zone sensor.

Do not use old fixing nuts afte r removal; replace with new nuts.

Replace the crash zone sensor of deployed SRS dr iver air bag and deployed SRS front passenger air

bag.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the crash zone sensor harness.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT −III.

In case that malfunction is still de tected after the above operation, perform self-diagnosis to repair

malfunctions. Refer to SRS-23, "

SRS Operation Check".

PHIA0316E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3780 of 3924

SIDE AIR BAG (SATELLITE) SENSOR

SRS-43

< SERVICE INFORMATION >

C

D E

F

G

I

J

K L

M A

B

SRS

N

O P

SIDE AIR BAG (S ATELLITE) SENSOR

Removal and InstallationINFOID:0000000001327769

WARNING:

Before servicing SRS, turn igniti on switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove seat belt pre-tensioner. Refer to SB-3, "Removal and Installation of Front Seat Belt".

2. Remove side air bag (Satellite) sensor fixing nuts.

3. Remove the side air bag (Satellite) sensor connector.

CAUTION:

Do not use old nuts; replace with new ones.

Check side air bag (Satellite) senso r to ensure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of da mage, replace it with new one.

Do not disassemble side ai r bag (Satellite) sensor.

Replace side air bag (Satellite) sensor if it has been dropped or sustained an impact.

Replace the satellite sensor of de ployed SRS front side air bag and deployed SRS side curtain air

bag.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the satellite sensor harness.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT −III.

In case that malfunction is still detected after th e above operation, perform self-diagnosis to repair

malfunctions. Refer to SRS-23, "

SRS Operation Check".

PHIA0314E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3781 of 3924

SRS-44

< SERVICE INFORMATION >

DIAGNOSIS SENSOR UNIT

DIAGNOSIS SENSOR UNIT

Removal and InstallationINFOID:0000000001327771

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Disconnect each harness connector for the ai r bag module and seat belt pre-tensioner.

2. Remove center console. Refer to IP-11, "

Removal and Installation".

3. Disconnect diagnosis sensor unit connector.

4. Remove TORX bolts from the diagnosis sensor unit.

CAUTION:

Do not use old TORX bolts. Replace with new ones.

Check diagnosis sensor unit bracket to ensure it is free of deformities, dents, cracks or rust. If it

shows any visible things of damage, replace with new one.

Replace diagnosis sensor unit if it has been dropped or sustained an impact.

Replace the diagnosis sensor unit of deployed SRS air bag and deployed SRS front seat belt pre-ten-

sioner.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the diagnosis sensor harness.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT −III.

In case that malfunction is still de tected after the above operation, perform self-diagnosis to repair

malfunctions. Refer to SRS-23, "

SRS Operation Check".

ECU DISCRIMINATED NO.

After replacing the diagnosis sensor unit, confirm that t he diagnosis sensor unit identification is correct for the

vehicle as equipped.

PHIA0315E

Specification ECU DISCRIMINATED No.

Models with driver and passenger air bags, seat belt pre-tensioner, side air bags and curtain air bags FB04

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3782 of 3924

FRONT SEAT BELT PRE-TENSIONERSRS-45

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

FRONT SEAT BELT PRE-TENSIONER

Removal and InstallationINFOID:0000000001327770

For removal and installation procedures, refer to SB-3, "Removal and Installation of Front Seat Belt".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3783 of 3924

SRS-46

< SERVICE INFORMATION >

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNIT

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNIT

Removal and InstallationINFOID:0000000001327772

The occupant classification system c ontrol unit, seat pressure sensor, and bladder are an integral part of the

front passenger seat cushion and are replaced as an assembly. Refer to SE-89, "

Removal and Installation".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3787 of 3924

TF-1

DRIVELINE/AXLE

CEF

G H

I

J

K L

M

SECTION TF

A

B

TF

N

O P

CONTENTS

TRANSFER

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

C1201-C1210, U1000 ......................................... ......3

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution .................................................................4

Service Notice or Precaution .....................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................7

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

9

NVH Troubleshooting Chart ................................ ......9

TRANSFER FLUID .............................................10

Replacement ....................................................... ....10

Inspection ................................................................10

AWD SYSTEM ................................................ ....11

Power Transfer Diagram ..................................... ....11

System Description .................................................11

Schematic ...............................................................13

CAN Communication ...............................................13

TROUBLE DIAGNOSIS .....................................14

Fail-Safe Function ............................................... ....14

How to Perform Trouble Diagnosis .........................14

Location of Electrical Parts ......................................15

Circuit Diagram .......................................................16

Wiring Diagram - AWD - ..........................................17

Trouble Diagnosis Chart by Symptom ....................20

AWD Control Unit Input/Output Signal Reference

Value ................................................................... ....

20

CONSULT-III Function (ALL MODE AWD/4WD) ....21

TROUBLE DIAGNOSIS FOR SYSTEM .............24

DTC C1201 CONTROLLER FAILURE ................ ....24

DTC C1203 ABS SYSTEM ......................................24

DTC C1204 4WD SOLENOID ............................. ....25

DTC C1205 4WD ACTUATOR RLY ........................27

DTC C1210 ENGINE SIGNAL 1 ..............................28

DTC U1000 CAN COMM CIRCUIT .........................28

Power Supply Circuit for AWD Control Unit .............28

TROUBLE DIAGNOSIS FOR SYMPTOMS ......30

AWD Warning Lamp Does Not Turn ON When the

Ignition Switch Is Turned to ON ...............................

30

AWD Warning Lamp Does Not Turn OFF Several

Seconds after Engine Started ..................................

30

Heavy Tight-Corner Braking Symptom Occurs

When the Vehicle Is Driven and the Steering

Wheel Is Turned Fully to Either Side after the En-

gine Is Started .........................................................

32

Vehicle Does Not Enter AWD Mode Even Though

AWD Warning Lamp Turned to OFF .......................

33

While Driving, AWD Warning Lamp Flashes Rap-

idly (When Flashing in Approx. 1 Minute and Then

Turning OFF) ....................................................... ....

33

While Driving, AWD Warning Lamp Flashes Slow-

ly (When Continuing to Flash until Turning Ignition

Switch OFF) .............................................................

33

AWD CONTROL UNIT ......................................35

Removal and Installation .........................................35

FRONT OIL SEAL .............................................36

Removal and Installation .........................................36

REAR OIL SEAL ...............................................37

Removal and Installation .........................................37

AIR BREATHER HOSE ....................................39

Removal and Installation .........................................39

TRANSFER ASSEMBLY ..................................40

Removal and Installation .........................................40

Disassembly and Assembly .....................................40

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3790 of 3924

TF-4

< SERVICE INFORMATION >

PRECAUTIONS

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612930

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PrecautionINFOID:0000000001327424

Before connecting or disconnect ing the AWD control unit har-

ness connector, turn ignition switch “OFF” and disconnect

battery ground cable. Because battery voltage is applied to

AWD control unit even if igni tion switch is turned “OFF”.

When connecting or disconnect ing pin connectors into or

from AWD control unit, take care not to damage pin terminals

(bend or break).

When connecting pin connectors, make sure that there are no

bends or breaks on AWD control unit pin terminal.

SEF289H

SEF291H

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3791 of 3924

PRECAUTIONSTF-5

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

Before replacing AWD control unit, perform AWD control unit

input/output signal inspection and make sure whether AWD

control unit functions properly or not. Refer to TF-20, "

AW D

Control Unit Input/Output Signal Reference Value".

Service Notice or PrecautionINFOID:0000000001327425

Do not reuse transfer fluid, once it has been drained.

Check the fluid level or replace the fluid only with the vehicle parked on level ground.

During removal or installation, keep inside of transfer clear of dust or dirt.

Replace all tires at the same time. Always use tires of the proper size and the same brand and pattern. Fit-

ting improper size and unusual wear tires applies excessive force to vehicle mechanism and can cause lon-

gitudinal vibration.

Disassembly should be done in a clean work area, it is preferable to work in dustproof area.

Before proceeding with disassembly, thoroughly clean the tr ansfer. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign matter.

All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

Check for the correct installation status prior to remo val or disassembly. If matching marks are required, be

certain they do not interfere with t he function of the parts when applied.

Check appearance of the disassembled parts for dam age, deformation, and unusual wear. Replace them

with a new ones if necessary.

Gaskets, seals and O-rings should be replaced any time when the transfer is disassembled.

In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If tight-

ening sequence is specified, use it.

Observe the specified torque when assembling.

Clean and flush the parts sufficiently and blow-dry them.

Be careful not to damage sliding surfaces and mating surfaces.

Clean innerparts with lint-free cloth or towels. Do not use cotton work gloves and rags to prevent adhering

fibers.

SDIA1848E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3821 of 3924

AWD CONTROL UNITTF-35

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

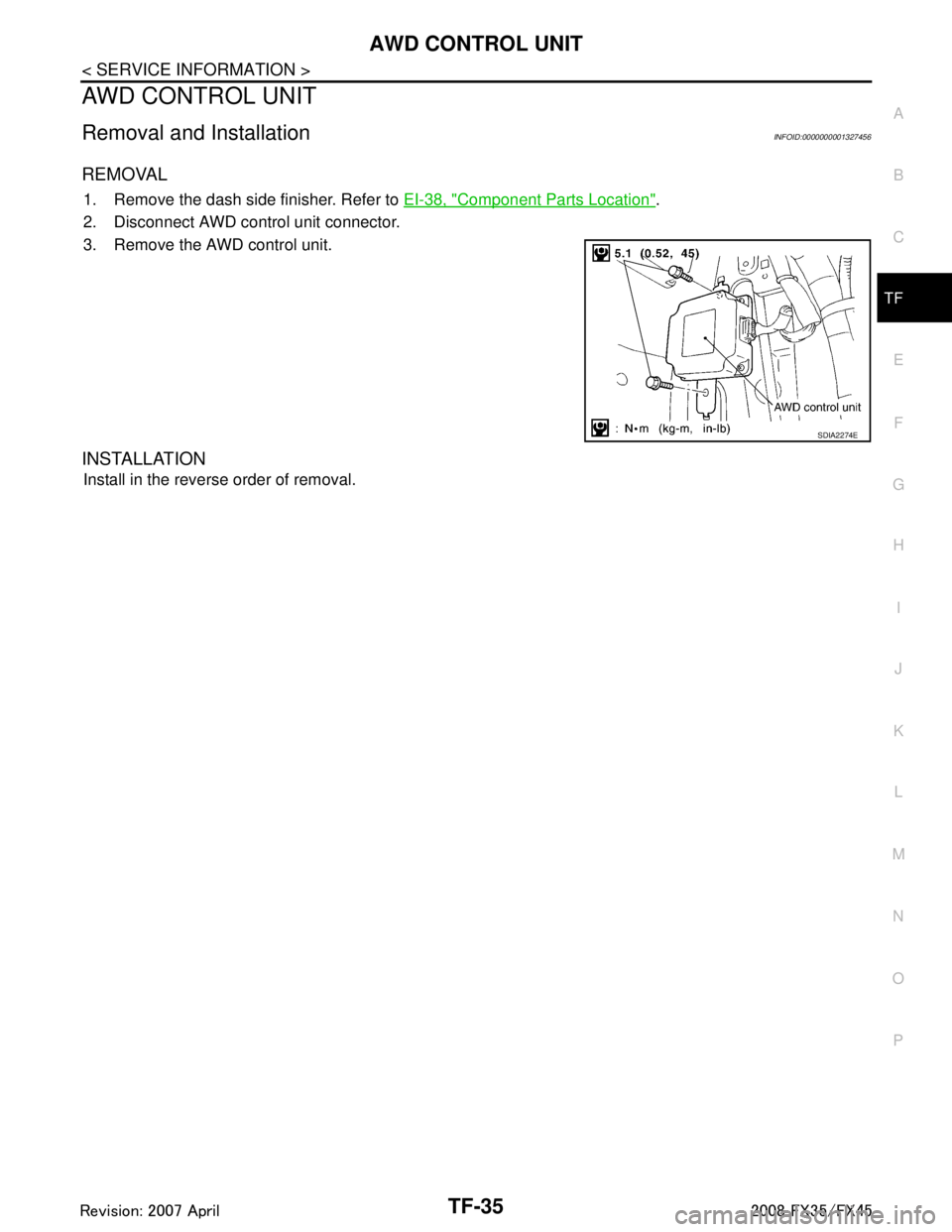

AWD CONTROL UNIT

Removal and InstallationINFOID:0000000001327456

REMOVAL

1. Remove the dash side finisher. Refer to EI-38, "Component Parts Location".

2. Disconnect AWD control unit connector.

3. Remove the AWD control unit.

INSTALLATION

Install in the reverse order of removal.

SDIA2274E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3822 of 3924

TF-36

< SERVICE INFORMATION >

FRONT OIL SEAL

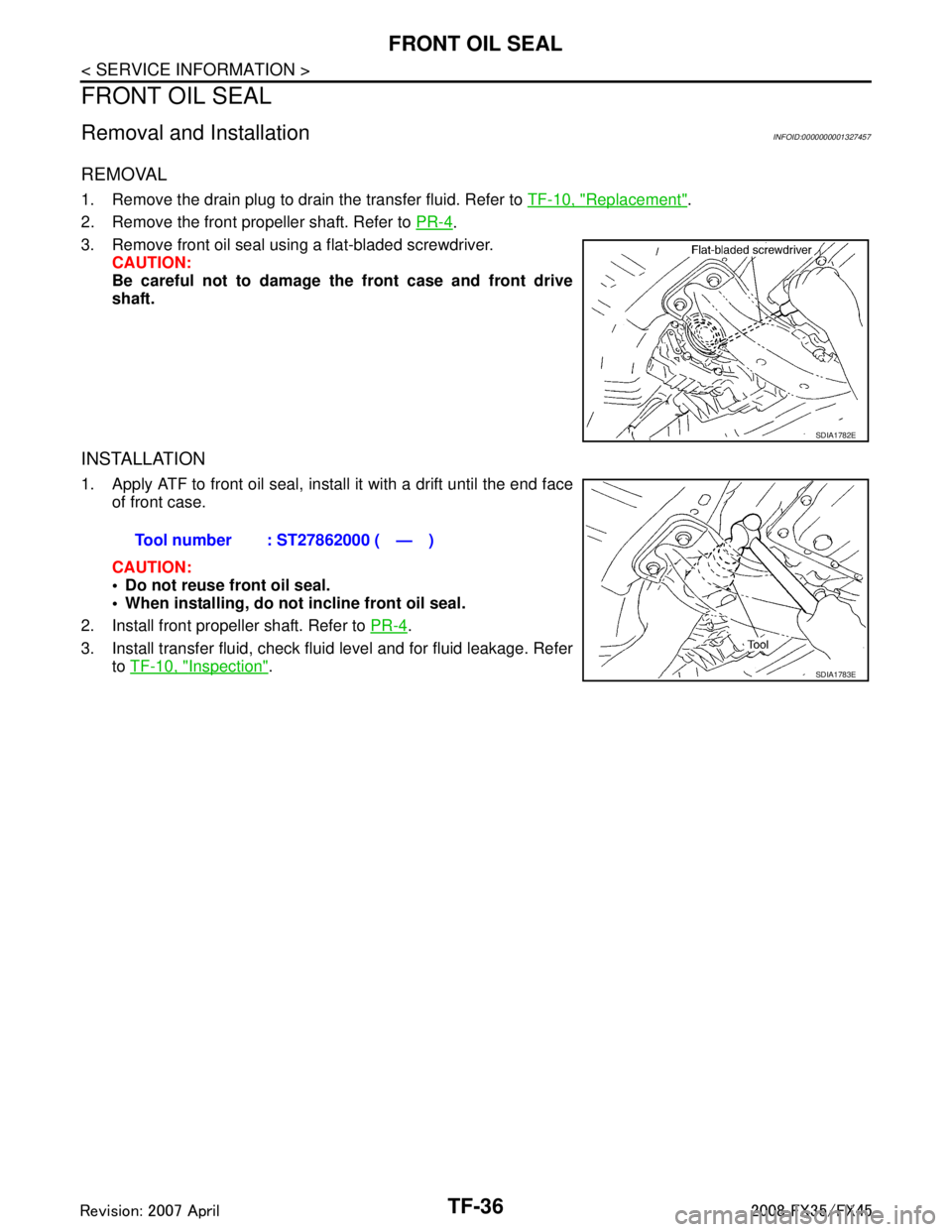

FRONT OIL SEAL

Removal and InstallationINFOID:0000000001327457

REMOVAL

1. Remove the drain plug to drain the transfer fluid. Refer to TF-10, "Replacement".

2. Remove the front propeller shaft. Refer to PR-4

.

3. Remove front oil seal using a flat-bladed screwdriver. CAUTION:

Be careful not to damage the front case and front drive

shaft.

INSTALLATION

1. Apply ATF to front oil seal, install it with a drift until the end faceof front case.

CAUTION:

Do not reuse front oil seal.

When installing, do no t incline front oil seal.

2. Install front propeller shaft. Refer to PR-4

.

3. Install transfer fluid, check fluid level and for fluid leakage. Refer to TF-10, "

Inspection".

SDIA1782E

Tool number : ST27862000 ( — )

SDIA1783E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C