display INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 506 of 5621

TROUBLE DIAGNOSIS

ATC-59

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

11 . CHECK INTAKE SENSOR

Press (DEF) switch for the third time. Temperature detected by

intake sensor is indicated on the display.

NOTE:

If the temperature indicated on the display greatly differs from the

actual temperature, check sensor circuit first, and then check sensor.

OK or NG

OK >> GO TO 12.

NG >> Go to Intake Sensor Circuit. Refer to ATC-122, "

Intake

Sensor Circuit" .

12. CHECK CAN COMMUNICATION ERROR

1. Press intake switch.

2. CAN communication error between the unified meter and A/C

amp. and the AV control unit or NAVI control unit can be

detected as self-diagnosis results. (If plural errors occur, the dis-

play of each error will blink twice for 0-5 second intervals.)

OK or NG

OK >> 1. Turn ignition switch OFF or AUTO switch ON.

2. INSPECTION END

NG >> Go to CAN communication. Refer to DI-36, "

DTC

[U1000] CAN Communication Circuit" .

Unified meter and A/C amp. - AV control unit or NAVI

control unit

RJIA1272E

RJIA4036E

Page 508 of 5621

TROUBLE DIAGNOSIS

ATC-61

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

14. CHECK MALFUNCTIONING DOOR MOTOR POSITION SWITCH

Mode and/or intake door motor PBR(s) is/are malfunctioning.

(If two or more mode or intake doors are out of order, corresponding code numbers blink respectively twice.)

*1: If mode door motor harness connector is disconnected, the following display pattern will appear.

31

3233343536Return to 31

*2: If intake door motor harness connector is disconnected, the following display pattern will appear.

37

3839Return to 37

*3: ATC-79, "

DIAGNOSIS PROCEDURE FOR MODE DOOR MOTOR" .

*4: ATC-82, "

DIAGNOSIS PROCEDURE FOR UPPER VENTILATOR DOOR MOTOR" .

*5: ATC-88, "

DIAGNOSIS PROCEDURE FOR INTAKE DOOR MOTOR" .

>> INSPECTION END

Code No. *1 *2Mode or intake door position Reference page

31 VENT (Driver side)

Mode door motor *3 32 DEF (Driver side)

33 VENT (Passenger side)

34 DEF (Passenger side)

35 UPPER VENT (Open)

Upper ventilator door

motor*4

36 UPPER VENT (Shut)

37 FRE

Intake door motor *5 38 20% FRE

39 REC

RJIA0228E

Page 509 of 5621

ATC-62

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

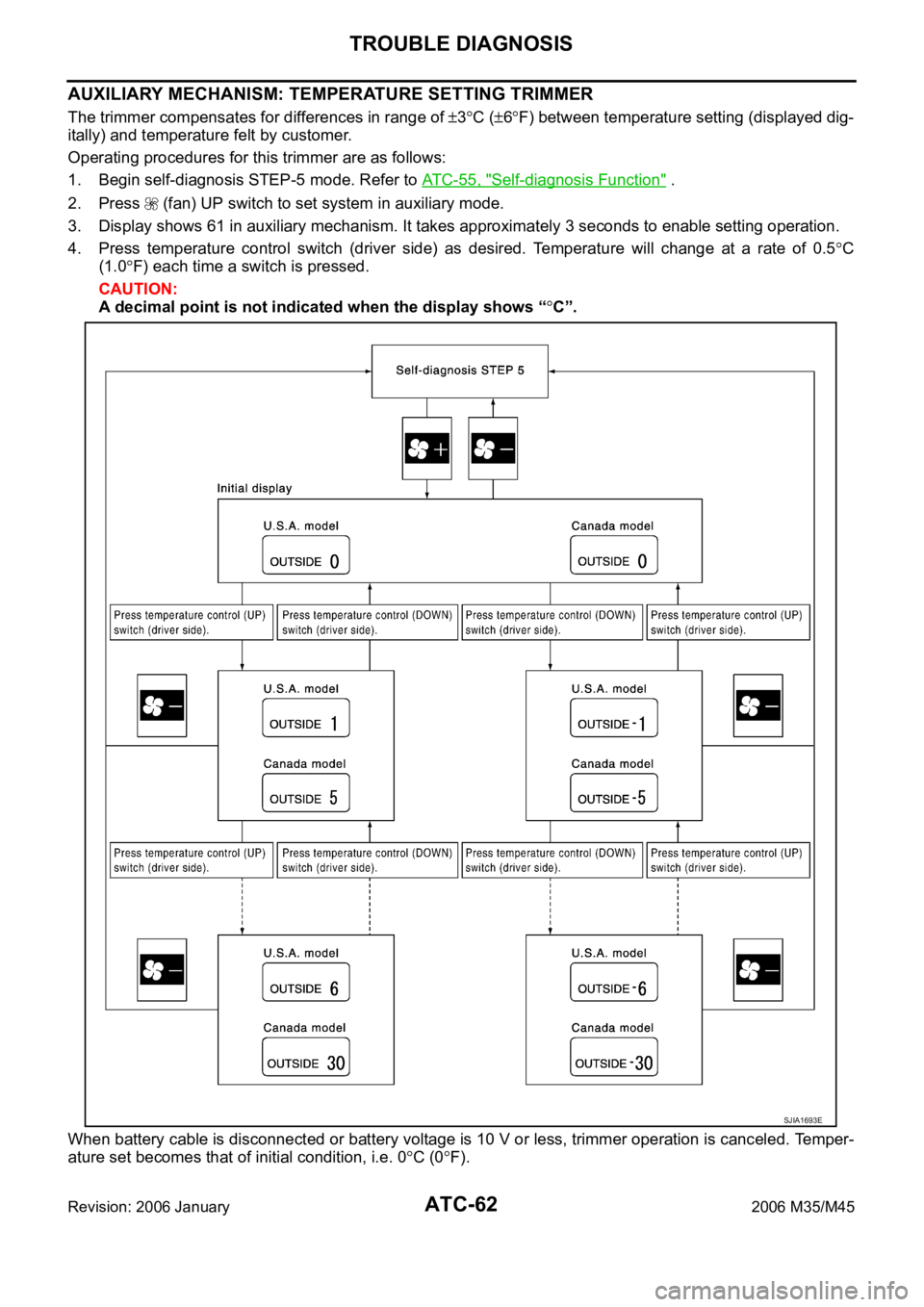

AUXILIARY MECHANISM: TEMPERATURE SETTING TRIMMER

The trimmer compensates for differences in range of 3C (6F) between temperature setting (displayed dig-

itally) and temperature felt by customer.

Operating procedures for this trimmer are as follows:

1. Begin self-diagnosis STEP-5 mode. Refer to ATC-55, "

Self-diagnosis Function" .

2. Press (fan) UP switch to set system in auxiliary mode.

3. Display shows 61 in auxiliary mechanism. It takes approximately 3 seconds to enable setting operation.

4. Press temperature control switch (driver side) as desired. Temperature will change at a rate of 0.5

C

(1.0

F) each time a switch is pressed.

CAUTION:

A decimal point is not indicated when the display shows “

C”.

When battery cable is disconnected or battery voltage is 10 V or less, trimmer operation is canceled. Temper-

ature set becomes that of initial condition, i.e. 0

C (0F).

SJIA1693E

Page 510 of 5621

TROUBLE DIAGNOSIS

ATC-63

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

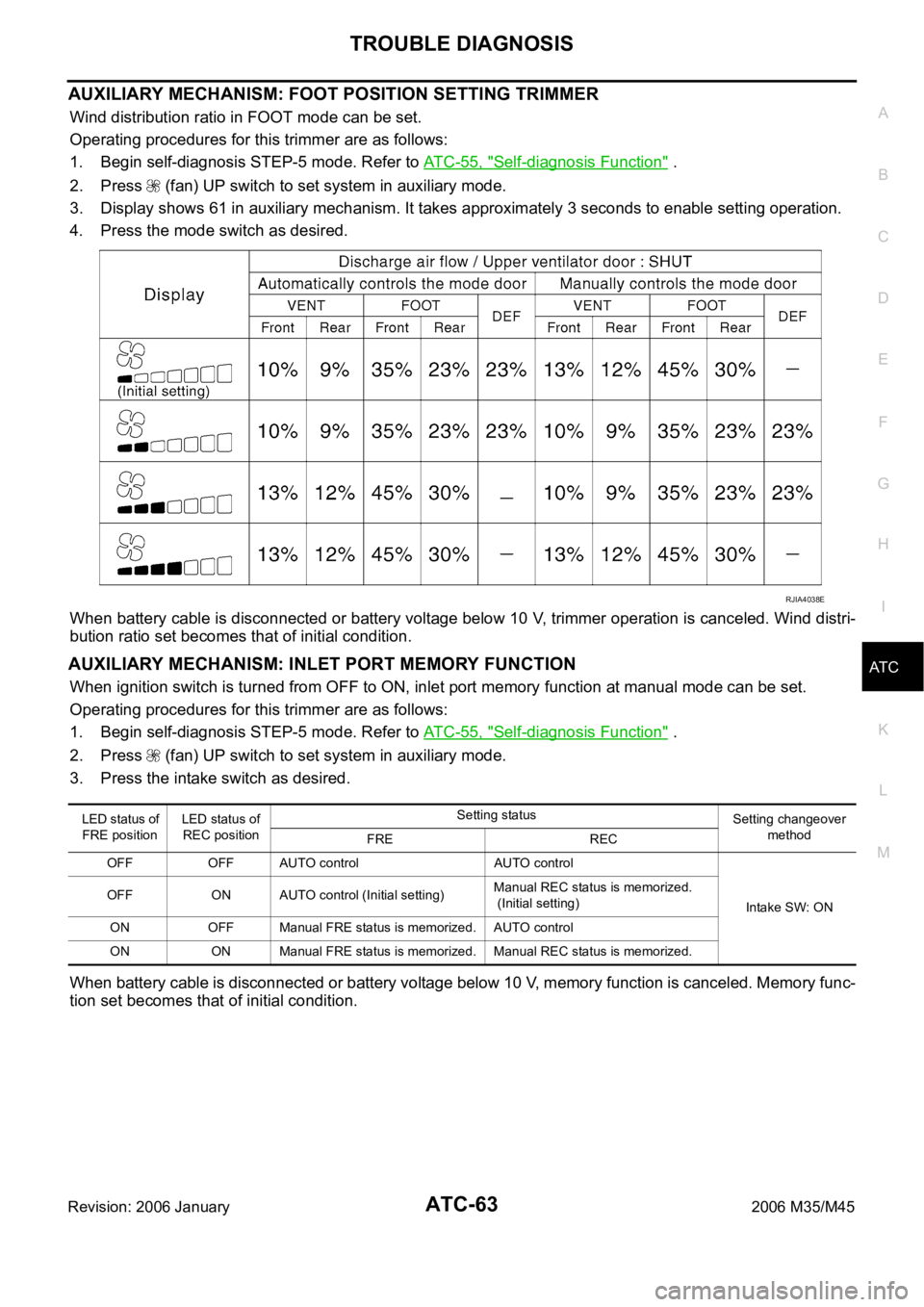

AUXILIARY MECHANISM: FOOT POSITION SETTING TRIMMER

Wind distribution ratio in FOOT mode can be set.

Operating procedures for this trimmer are as follows:

1. Begin self-diagnosis STEP-5 mode. Refer to AT C - 5 5 , "

Self-diagnosis Function" .

2. Press (fan) UP switch to set system in auxiliary mode.

3. Display shows 61 in auxiliary mechanism. It takes approximately 3 seconds to enable setting operation.

4. Press the mode switch as desired.

When battery cable is disconnected or battery voltage below 10 V, trimmer operation is canceled. Wind distri-

bution ratio set becomes that of initial condition.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION

When ignition switch is turned from OFF to ON, inlet port memory function at manual mode can be set.

Operating procedures for this trimmer are as follows:

1. Begin self-diagnosis STEP-5 mode. Refer to AT C - 5 5 , "

Self-diagnosis Function" .

2. Press (fan) UP switch to set system in auxiliary mode.

3. Press the intake switch as desired.

When battery cable is disconnected or battery voltage below 10 V, memory function is canceled. Memory func-

tion set becomes that of initial condition.

RJIA4038E

LED status o f

FRE positionLED status of

REC positionSetting status

Setting changeover

method

FRE REC

OFF OFF AUTO control AUTO control

Intake SW: ON OFF ON AUTO control (Initial setting)Manual REC status is memorized.

(Initial setting)

ON OFF Manual FRE status is memorized. AUTO control

ON ON Manual FRE status is memorized. Manual REC status is memorized.

Page 511 of 5621

ATC-64

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Operational CheckNJS000GK

The purpose of the operational check is to check if the individual system operates properly.

CHECKING MEMORY FUNCTION

1. Press the temperature control (UP) switch (driver side) until 32C (90F) is displayed.

2. Press OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for ATC-112, "

Memory Function" .

If OK, continue the check.

CHECKING BLOWER

1. Press fan (UP:+) switch. Blower should operate on low speed. The fan symbol should have one blade lit.

2. Press fan (UP:+) switch again, and continue checking blower speed and fan symbol until all speeds are

checked.

3. Leave blower on max. speed.

If NG, go to trouble diagnosis procedure for ATC-89, "

Blower Motor Circuit" .

If OK, continue the check.

CHECKING DISCHARGE AIR (MODE SWITCH AND DEF SWITCH)

1. Press MODE switch and DEF switch.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distribution table. Refer to AT C - 3 7 , "

Discharge

Air Flow" .

If NG, go to trouble diagnosis procedure for ATC-75, "

Mode Door Motor Circuit" .

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

FRESH when the D/F or DEF is selected.Conditions : Engine running at normal operating temperature

RJIA4035E

Page 512 of 5621

TROUBLE DIAGNOSIS

ATC-65

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

CHECKING DISCHARGE AIR (UPPER VENT SWITCH)

1. Press temperature control (DOWN) switch (driver side) until 18C (60F) is displayed.

2. Press fan (UP:+) switch until Max. speed.

3. Set MODE switch (driver side) to VENT position.

4. Press UPPER VENT switch.

AUTO indicator should illuminate.

5. Press temperature control (UP) switch (driver side) until 32

C (90F) is displayed.

6. Conform that discharger come out.

7. Press UPPER VENT switch again.

AUTO indicator should OFF.

If NG, go to trouble diagnosis procedure for ATC-80, "

Upper Ventilator Door Motor Circuit" .

If OK, continue the check.

CHECKING INTAKE AIR

1. Press intake switch. Recirculation indicator should illuminate.

2. Press intake switch again. Fresh indicator should illuminate.

3. Listen for intake door position change. (Slight change of blower sound can be heard.)

If NG, go to trouble diagnosis procedure for ATC-86, "

Intake Door Motor Circuit" .

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

FRESH when the D/F or DEF is selected.

CHECKING TEMPERATURE DECREASE

1. Press temperature control (DOWN) switch (driver side) until 18C (60F) is displayed.

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for ATC-99, "

Insufficient Cooling" .

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Press temperature control (UP) switch (driver side) until 32C (90F) is displayed.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for ATC-109, "

Insufficient Heating" .

If OK, continue the check.

CHECKING A/C SWITCH

1. Press AUTO switch and A/C switch.

2. A/C switch indicator will turn ON.

Confirm that the compressor clutch engages (sound or visual inspection).

CHECKING AUTO MODE

1. Press AUTO switch and A/C switch.

2. Display should indicate AUTO.

Discharge air and blower speed will depend on ambient, in-vehicle, and set temperatures.

If NG, go to trouble diagnosis procedure for AT C - 6 6 , "

Power Supply and Ground Circuit for Auto Amp." , then

if necessary, trouble diagnosis procedure for AT C - 9 4 , "

Magnet Clutch Circuit" .

If all operational checks are OK (symptom cannot be duplicated), go to Incident Simulation Tests in GI-28,

"How to Perform Efficient Diagnosis for an Electrical Incident" and perform tests as outlined to simulate driv-

ing conditions environment. If symptom appears, refer to AT C - 4 1 , "

SYMPTOM TABLE" and perform applica-

ble trouble diagnosis procedures.

Page 514 of 5621

TROUBLE DIAGNOSIS

ATC-67

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

COMPONENT DESCRIPTION

Unified Meter and A/C Amp. (Automatic Amplifier)

The unified meter and A/C amp. has a built-in microcomputer which

processes information sent from various sensors needed for air con-

ditioner operation. The air mix door motor, mode door motor, upper

ventilator door motor, intake door motor, blower motor and compres-

sor are then controlled.

When the various switches and temperature control switch are oper-

ated, data is input to the unified meter and A/C amp. from the AV

control unit / NAVI control unit using CAN communication.

Self-diagnosis functions are also built into unified meter and A/C

amp. to provide quick check of malfunctions in the auto air condi-

tioner system.

Potentio Temperature Control (PTC)

The PTC is built into the multifunction switch. It can be set at an

interval of 0.5

C (1.0F) in the 18C (60F) to 32C (90F) tempera-

ture range by pressing temperature control switch. The set tempera-

ture is displayed.

DIAGNOSIS PROCEDURE FOR A/C SYSTEM

SYMPTOM: A/C system does not come on.

RJIA4032E

RJIA4048E

RJIA4049E

Page 561 of 5621

ATC-114

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK CIRCUIT CONTINUITY BETWEEN AMBIENT SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between ambient sensor harness connector

E62 terminal 2 and unified meter and A/C amp. harness connec-

tor M65 terminal 61.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK AMBIENT SENSOR

Refer to AT C - 11 5 , "

Ambient Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace ambient sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN AMBIENT SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between ambient sensor harness connector

E62 terminal 1 and unified meter and A/C amp. harness connec-

tor M65 terminal 45.

4. Check continuity between ambient sensor harness connector

E62 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.2 – 61 : Continuity should exist.

RJIA4089E

1 – 45 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4090E

Page 564 of 5621

TROUBLE DIAGNOSIS

ATC-117

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

DIAGNOSIS PROCEDURE FOR IN-VEHICLE SENSOR

SYMPTOM: In-vehicle sensor circuit is open or shorted. (22 or 22 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN IN-VEHICLE SENSOR AND GROUND

1. Disconnect in-vehicle sensor connector.

2. Turn ignition switch ON.

3. Check voltage between in-vehicle sensor harness connector

M54 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector

M54 terminal 2 and unified meter and A/C amp. harness con-

nector M65 terminal 60.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK IN-VEHICLE SENSOR

Refer to AT C - 11 8 , "

In-vehicle Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace in-vehicle sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

RJIA4094E

1 – Ground : Approx. 5 V

RJIA2022E

2 – 60 : Continuity should exist.

RJIA4095E

Page 565 of 5621

ATC-118

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

4. CHECK CIRCUIT CONTINUITY BETWEEN IN-VEHICLE SENSOR AND UNIFIED METER AND A/C

AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between in-vehicle sensor harness connector

M54 terminal 1 and unified meter and A/C amp. harness con-

nector M65 terminal 44.

4. Check continuity between in-vehicle sensor harness connector

M54 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

In-vehicle Sensor

After disconnecting in-vehicle sensor connector M54, measure resis-

tance between terminals 1 and 2 at sensor side, using the table

below.

If NG, replace in-vehicle sensor.1 – 44 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4096E

Temperature C (F) Resistance k

15 (5) 12.73

10 (14) 9.92

5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

RJIA4097E