brake sensor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3713 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-44

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

AW D m o del s

T: Transmit R: Receive

Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure w INFINITI M35 2006 Factory Service Manual LAN-44

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

AW D m o del s

T: Transmit R: Receive

Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure w](/img/42/57023/w960_57023-3712.png)

LAN-44

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

AW D m o del s

T: Transmit R: Receive

Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure warning control unit

Steering angle sensor

Intelligent Key unit

Unified meter and A/C amp.

AV (NAVI) control unit

Pre-crash seat belt control unit*3

Driver seat control unit

ABS actuator and electric unit (control unit)

ICC sensor integrated unit*4

IPDM E/R

A/C compressor request signal TR

Accelerator pedal position signal T R R R R

ASCD CRUISE lamp signal T R

ASCD OD cancel request signal T R

ASCD operation signal T R

ASCD SET lamp signal T R

Battery voltage signal T R

Closed throttle position signal T R R

Cooling fan speed request signal TR

Engine coolant temperature signal T R

Engine speed signal T R R R R R R

Engine status signal T R R R

Fuel consumption monitor signal T R R

ICC brake switch signal T R

ICC prohibition signal T R

ICC steering switch signal T R

Malfunctioning indicator lamp signal T R

Power generation command value signal TR

Wide open throttle position signal T R

A/T CHECK indicator lamp signal T R

A/T position indicator signal T R R R R

A/T self-diagnosis signal R T

Current gear position signal T R R

Manual mode indicator signal T R R

N range signal T R R

Output shaft revolution signal R T R R

P range signal T R R R R

R range signal T R R R

Turbine revolution signal R T R

AWD signal T R

AWD warning lamp signal T R

AFS OFF indicator signal T R

A/C switch signal R T

Page 3715 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-46

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

A/C evaporator temperature signal R T

Distance to empty signalTR

Fuel level low warning signalTR

Fuel level sensor signal R T

Manual m INFINITI M35 2006 Factory Service Manual LAN-46

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

A/C evaporator temperature signal R T

Distance to empty signalTR

Fuel level low warning signalTR

Fuel level sensor signal R T

Manual m](/img/42/57023/w960_57023-3714.png)

LAN-46

[CAN]

CAN COMMUNICATION

Revision: 2006 January2006 M35/M45

A/C evaporator temperature signal R T

Distance to empty signalTR

Fuel level low warning signalTR

Fuel level sensor signal R T

Manual mode shift down signal R T

Manual mode shift up signal R T

Manual mode signal R T

Not manual mode signal R T

Parking brake switch signal R R T

Seat belt buckle switch signal R T

Snow mode switch signalRT

TRR

Stop lamp switch signalRR T

TR

TR

Target A/C evaporator temperature signal R T

A/C switch/indicator signalRT

TR

System setting signalRTR

TRT

A/T shift schedule change demand signal R T

ABS malfunction signalTR

ABS operation signal TR

ABS warning lamp signalRT

Brake pressure control signalTR

Brake warning lamp signalRT

Side G sensor signal R T

SLIP indicator lamp signalRT

TCS malfunction signalTR

TCS operation signal TR

VDC malfunction signalTR

VDC OFF indicator lamp signal R T

VDC OFF switch signalTR

VDC operation signalTR Signals

ECM

TCM

AWD control unit

AFS control unit*1

BCM

LDW camera unit*2

Low tire pressure warning control unit

Steering angle sensor

Intelligent Key unit

Unified meter and A/C amp.

AV (NAVI) control unit

Pre-crash seat belt control unit*3

Driver seat control unit

ABS actuator and electric unit (control unit)

ICC sensor integrated unit*4

IPDM E/R

Page 4429 of 5621

LT-2Revision: 2006 January2006 M35/M45 ACTIVE TEST ..................................................... 59

CONSULT-II Functions (IPDM E/R) ........................ 60

CONSULT-II BASIC OPERATION ....................... 60

DATA MONITOR .................................................. 61

ACTIVE TEST ..................................................... 61

Headlamp High Beam Does Not Illuminate (Both

Sides) ..................................................................... 62

Headlamp High Beam Does Not Illuminate (One

Side) ....................................................................... 65

High Beam Indicator Lamp Does Not Illuminate ..... 66

Headlamp Low Beam Does Not Illuminate (Both

Sides) ..................................................................... 67

Headlamp Low Beam Does Not Illuminate (One

Side) ....................................................................... 70

Headlamps Do Not Turn OFF ................................. 72

General Information for Xenon Headlamp Trouble

Diagnosis ................................................................ 73

Caution: .................................................................. 73

Xenon Headlamp Trouble Diagnosis ...................... 73

Aiming Adjustment .................................................. 74

PREPARATION BEFORE ADJUSTING .............. 74

LOW BEAM AND HIGH BEAM ........................... 74

ADJUSTMENT USING AN ADJUSTMENT

SCREEN (LIGHT/DARK BORDERLINE) ............ 75

Bulb Replacement ...............................................

... 75

HEADLAMP (INNER) HIGH BEAM ..................... 75

HEADLAMP (OUTER) LOW BEAM .................... 76

PARKING LAMP (CLEARANCE LAMP) .............. 76

FRONT TURN SIGNAL LAMP ............................ 76

FRONT SIDE MARKER LAMP ............................ 76

Removal and Installation ........................................ 76

Disassembly and Assembly .................................... 77

DISASSEMBLY ................................................... 77

ASSEMBLY ......................................................... 78

HEADLAMP (FOR CANADA) - DAYTIME LIGHT

SYSTEM - .................................................................. 79

Component Parts and Harness Connector Location ... 79

System Description ................................................. 79

OUTLINE ............................................................. 80

HEADLAMP OPERATION ................................... 81

DAYTIME LIGHT OPERATION ........................... 82

COMBINATION SWITCH READING FUNCTION ... 82

AUTO LIGHT OPERATION ................................. 82

CAN Communication System Description .............. 82

Schematic ............................................................... 83

Wiring Diagram — DTRL — ................................... 84

Terminals and Reference Values for BCM .............. 89

Terminals and Reference Values for IPDM E/R ...... 91

How to Perform Trouble Diagnosis ......................... 91

Preliminary Check .................................................. 92

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ............................................. 92

INSPECTION FOR PARKING BRAKE SWITCH

CIRCUIT .............................................................. 93

CONSULT-II Functions (BCM) ................................ 94

CONSULT-II BASIC OPERATION ....................... 94

DATA MONITOR .................................................. 95

ACTIVE TEST ..................................................... 96

CONSULT-II Functions (IPDM E/R) ........................ 97CONSULT-II BASIC OPERATION ....................... 97

DATA MONITOR .................................................. 98

ACTIVE TEST ...................................................... 98

Daytime Light Control Does Not Operate Properly

(Normal Headlamps Operate Properly) .................. 99

Headlamp High Beam Does Not Illuminate (Both

Sides) ....................................................................102

RH High Beam Does Not Illuminate But LH High

Beam Illuminates ..................................................105

LH High Beam Does Not Illuminate But RH High

Beam Illuminates ..................................................107

Headlamp Low Beam Does Not Illuminate (Both

Sides) ....................................................................109

Headlamp Low Beam Does Not Illuminate (One

Side) ......................................................................112

Headlamps Do Not Turn OFF ...............................114

General Information for Xenon Headlamp Trouble

Diagnosis ..............................................................115

CAUTION: .............................................................115

Xenon Headlamp Trouble Diagnosis ....................115

Aiming Adjustment ................................................115

Bulb Replacement .................................................115

Removal and Installation .......................................115

Disassembly and Assembly ..................................115

AUTO LIGHT SYSTEM ...........................................116

Component Parts and Harness Connector Location .116

System Description ...............................................116

OUTLINE ...........................................................116

COMBINATION SWITCH READING FUNCTION .117

EXTERIOR LAMP BATTERY SAVER CONTROL .117

DELAY TIMER FUNCTION ................................117

CAN Communication System Description ............117

CAN Communication Unit .....................................117

Major Components and Functions ........................117

Schematic .............................................................118

Wiring Diagram — AUTO/L — ..............................119

Terminals and Reference Values for BCM ............123

Terminals and Reference Values for IPDM E/R ....125

How to Perform Trouble Diagnoses ......................125

Preliminary Check .................................................126

SETTING CHANGE FUNCTIONS .....................126

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ...................................................................126

CONSULT-II Functions (BCM) .............................

.127

CONSULT-II BASIC OPERATION .....................127

WORK SUPPORT .............................................128

DATA MONITOR ................................................129

ACTIVE TEST ....................................................130

Symptom Chart .....................................................130

Lighting Switch Inspection ....................................131

Optical Sensor System Inspection ........................131

Removal and Installation for Optical Sensor .........133

REMOVAL ..........................................................133

INSTALLATION ..................................................133

ACTIVE AFS ............................................................134

Component Parts and Harness Connector Location .134

System Description ...............................................135

AFS (ADAPTIVE FRONT-LIGHTING SYSTEM) .135

HEADLAMP AUTO AIMING ..............................136

Page 4523 of 5621

LT-96

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

NOTE:

This item is displayed, but cannot be monitored.

ACTIVE TEST

Operation Procedure

1. Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch item to be tested and check operation of the selected item.

4. During the operation check, touching “BACK” deactivates the operation.

Display Item List

DOOR SW - RL “ON/OFF”Displays status of the rear door as judged from the rear door switch (LH) signal. (door is open:

ON/door is closed: OFF)

BACK DOOR SW

NOTE “OFF” —

PKB SW “ON/OFF”Displays status (parking brake released: ON/ parking brake applied: OFF) of parking brake

switch judged from parking brake switch signal.

ENGINE RUN “ON/OFF”Displays status (engine running: ON/ engine stopped: OFF) of engine judged from engine run

signal.

OPTICAL SENSOR “0 - 5V” Displays “outside brightness (close to 5V when light/close to 0V when dark)” judged from opti-

cal sensor signal.

VEHICLE SPEED “km/h” Displays vehicle speed as judged from vehicle speed signal. Monitor item Contents

Test item Description

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows front fog lamp relay to operate by switching ON-OFF.

DAYTIME RUNNING LIGHT Allows daytime relay to operate by switching ON-OFF.

HEAD LAMP (HI, LO) Allows headlamp relay to operate by switching ON-OFF.

Page 4920 of 5621

HARNESS

PG-93

C

D

E

F

G

H

I

J

L

MA

B

PG

Revision: 2006 January2006 M35/M45

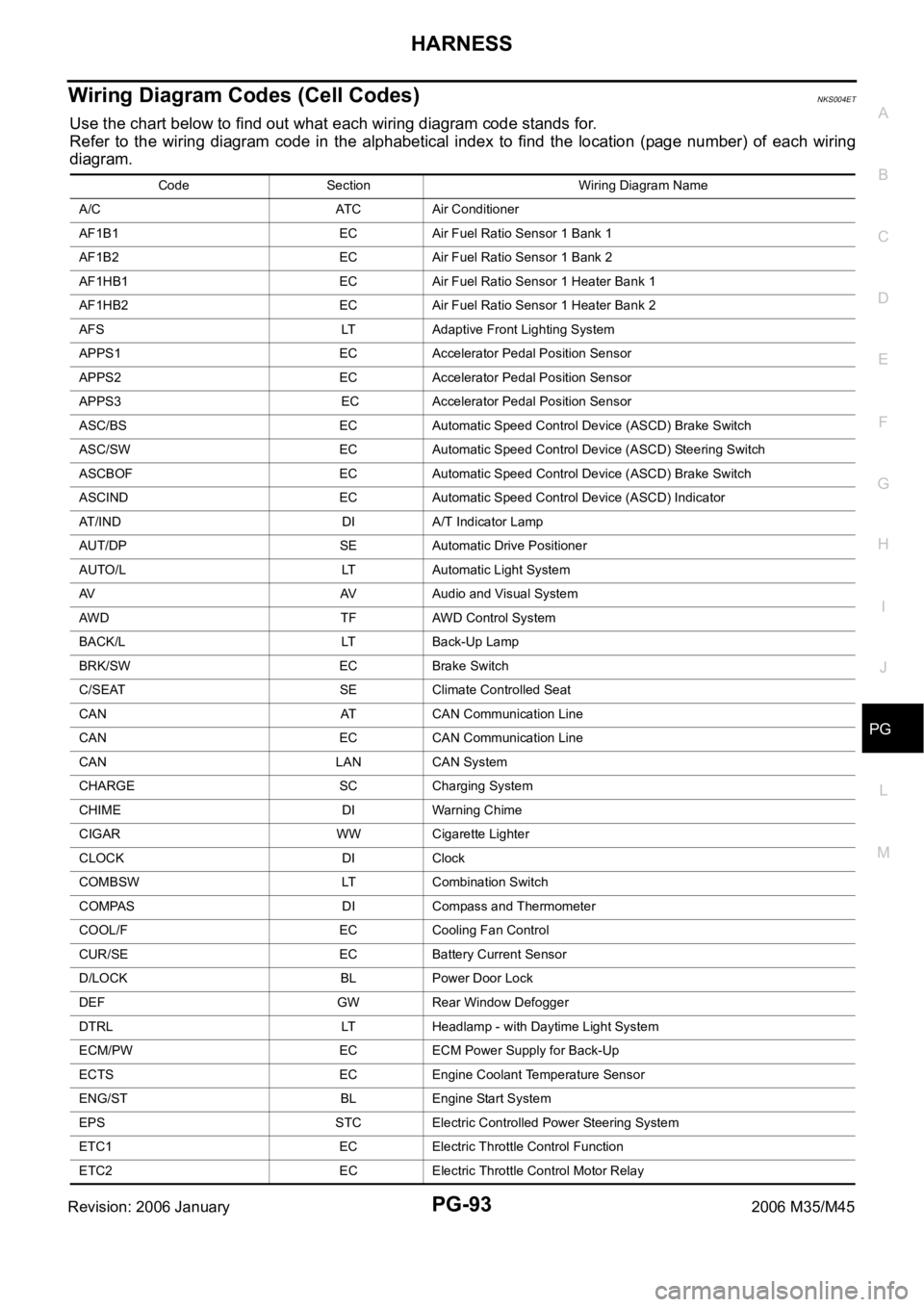

Wiring Diagram Codes (Cell Codes) NKS004ET

Use the chart below to find out what each wiring diagram code stands for.

Refer to the wiring diagram code in the alphabetical index to find the location (page number) of each wiring

diagram.

Code Section Wiring Diagram Name

A/C ATC Air Conditioner

AF1B1 EC Air Fuel Ratio Sensor 1 Bank 1

AF1B2 EC Air Fuel Ratio Sensor 1 Bank 2

AF1HB1 EC Air Fuel Ratio Sensor 1 Heater Bank 1

AF1HB2 EC Air Fuel Ratio Sensor 1 Heater Bank 2

AFS LT Adaptive Front Lighting System

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC Automatic Speed Control Device (ASCD) Brake Switch

ASC/SW EC Automatic Speed Control Device (ASCD) Steering Switch

ASCBOF EC Automatic Speed Control Device (ASCD) Brake Switch

ASCIND EC Automatic Speed Control Device (ASCD) Indicator

AT/IND DI A/T Indicator Lamp

AUT/DP SE Automatic Drive Positioner

AUTO/L LT Automatic Light System

AV AV Audio and Visual System

AWD TF AWD Control System

BACK/L LT Back-Up Lamp

BRK/SW EC Brake Switch

C/SEAT SE Climate Controlled Seat

CAN AT CAN Communication Line

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CIGAR WW Cigarette Lighter

CLOCK DI Clock

COMBSW LT Combination Switch

COMPAS DI Compass and Thermometer

COOL/F EC Cooling Fan Control

CUR/SE EC Battery Current Sensor

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - with Daytime Light System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ENG/ST BL Engine Start System

EPS STC Electric Controlled Power Steering System

ETC1 EC Electric Throttle Control Function

ETC2 EC Electric Throttle Control Motor Relay

Page 4921 of 5621

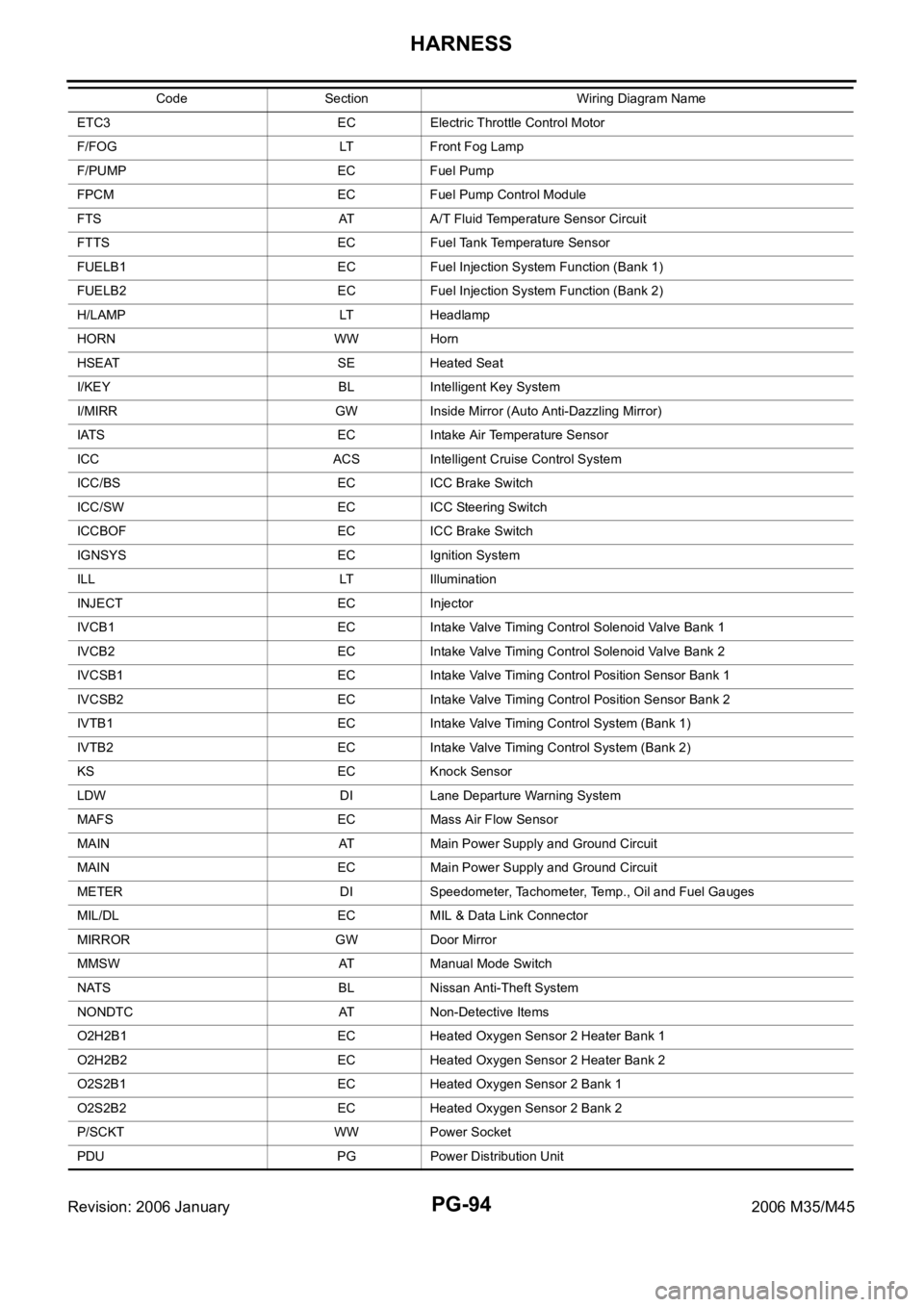

PG-94

HARNESS

Revision: 2006 January2006 M35/M45

ETC3 EC Electric Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FPCM EC Fuel Pump Control Module

FTS AT A/T Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Function (Bank 1)

FUELB2 EC Fuel Injection System Function (Bank 2)

H/LAMP LT Headlamp

HORN WW Horn

HSEAT SE Heated Seat

I/KEY BL Intelligent Key System

I/MIRR GW Inside Mirror (Auto Anti-Dazzling Mirror)

IATS EC Intake Air Temperature Sensor

ICC ACS Intelligent Cruise Control System

ICC/BS EC ICC Brake Switch

ICC/SW EC ICC Steering Switch

ICCBOF EC ICC Brake Switch

IGNSYS EC Ignition System

ILL LT Illumination

INJECT EC Injector

IVCB1 EC Intake Valve Timing Control Solenoid Valve Bank 1

IVCB2 EC Intake Valve Timing Control Solenoid Valve Bank 2

IVCSB1 EC Intake Valve Timing Control Position Sensor Bank 1

IVCSB2 EC Intake Valve Timing Control Position Sensor Bank 2

IVTB1 EC Intake Valve Timing Control System (Bank 1)

IVTB2 EC Intake Valve Timing Control System (Bank 2)

KS EC Knock Sensor

LDW DI Lane Departure Warning System

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp., Oil and Fuel Gauges

MIL/DL EC MIL & Data Link Connector

MIRROR GW Door Mirror

MMSW AT Manual Mode Switch

NATS BL Nissan Anti-Theft System

NONDTC AT Non-Detective Items

O2H2B1 EC Heated Oxygen Sensor 2 Heater Bank 1

O2H2B2 EC Heated Oxygen Sensor 2 Heater Bank 2

O2S2B1 EC Heated Oxygen Sensor 2 Bank 1

O2S2B2 EC Heated Oxygen Sensor 2 Bank 2

P/SCKT WW Power Socket

PDU PG Power Distribution Unit Code Section Wiring Diagram Name

Page 5089 of 5621

RSU-8

REAR SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

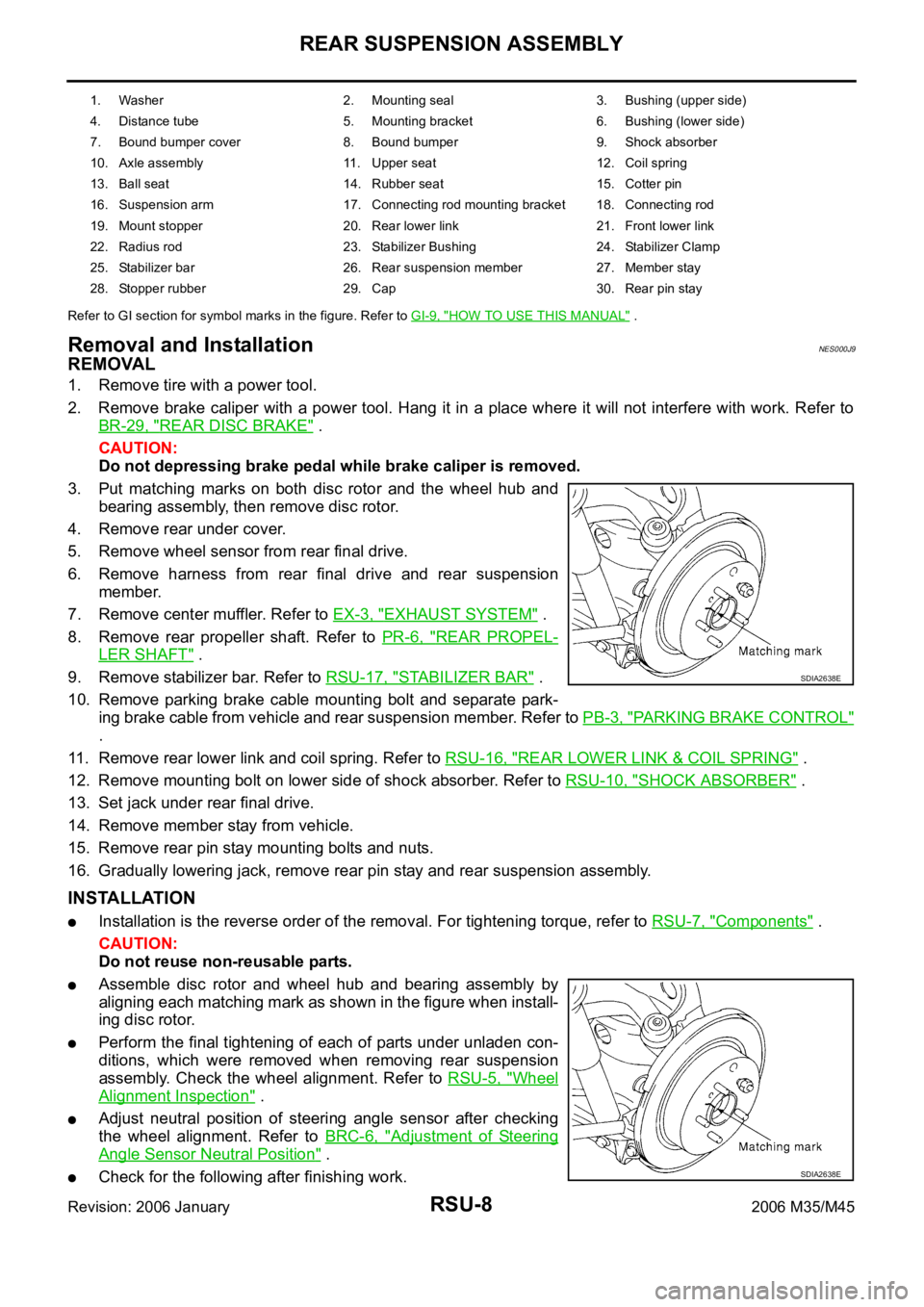

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and InstallationNES000J9

REMOVAL

1. Remove tire with a power tool.

2. Remove brake caliper with a power tool. Hang it in a place where it will not interfere with work. Refer to

BR-29, "

REAR DISC BRAKE" .

CAUTION:

Do not depressing brake pedal while brake caliper is removed.

3. Put matching marks on both disc rotor and the wheel hub and

bearing assembly, then remove disc rotor.

4. Remove rear under cover.

5. Remove wheel sensor from rear final drive.

6. Remove harness from rear final drive and rear suspension

member.

7. Remove center muffler. Refer to EX-3, "

EXHAUST SYSTEM" .

8. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPEL-

LER SHAFT" .

9. Remove stabilizer bar. Refer to RSU-17, "

STABILIZER BAR" .

10. Remove parking brake cable mounting bolt and separate park-

ing brake cable from vehicle and rear suspension member. Refer to PB-3, "

PARKING BRAKE CONTROL"

.

11. Remove rear lower link and coil spring. Refer to RSU-16, "

REAR LOWER LINK & COIL SPRING" .

12. Remove mounting bolt on lower side of shock absorber. Refer to RSU-10, "

SHOCK ABSORBER" .

13. Set jack under rear final drive.

14. Remove member stay from vehicle.

15. Remove rear pin stay mounting bolts and nuts.

16. Gradually lowering jack, remove rear pin stay and rear suspension assembly.

INSTALLATION

Installation is the reverse order of the removal. For tightening torque, refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and wheel hub and bearing assembly by

aligning each matching mark as shown in the figure when install-

ing disc rotor.

Perform the final tightening of each of parts under unladen con-

ditions, which were removed when removing rear suspension

assembly. Check the wheel alignment. Refer to RSU-5, "

Wheel

Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

the wheel alignment. Refer to BRC-6, "

Adjustment of Steering

Angle Sensor Neutral Position" .

Check for the following after finishing work.

1. Washer 2. Mounting seal 3. Bushing (upper side)

4. Distance tube 5. Mounting bracket 6. Bushing (lower side)

7. Bound bumper cover 8. Bound bumper 9. Shock absorber

10. Axle assembly 11. Upper seat 12. Coil spring

13. Ball seat 14. Rubber seat 15. Cotter pin

16. Suspension arm 17. Connecting rod mounting bracket 18. Connecting rod

19. Mount stopper 20. Rear lower link 21. Front lower link

22. Radius rod 23. Stabilizer Bushing 24. Stabilizer Clamp

25. Stabilizer bar 26. Rear suspension member 27. Member stay

28. Stopper rubber 29. Cap 30. Rear pin stay

SDIA2638E

SDIA2638E

Page 5090 of 5621

REAR SUSPENSION ASSEMBLY

RSU-9

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

–Parking brake operation (stroke): Refer to PB-2, "PEDAL STROKE" .

–Wheel sensor harness for proper connection: Refer to BRC-57, "WHEEL SENSOR" .

Page 5095 of 5621

RSU-14

RADIUS ROD

Revision: 2006 January2006 M35/M45

RADIUS RODPFP:55110

Removal and InstallationNES000JD

REMOVAL

1. Remove tire with a power tool.

2. Remove brake caliper with a power tool. Hang it in a place where it will not interfere with work. Refer to

BR-29, "

REAR DISC BRAKE" .

CAUTION:

Do not depressing brake pedal while brake caliper is removed.

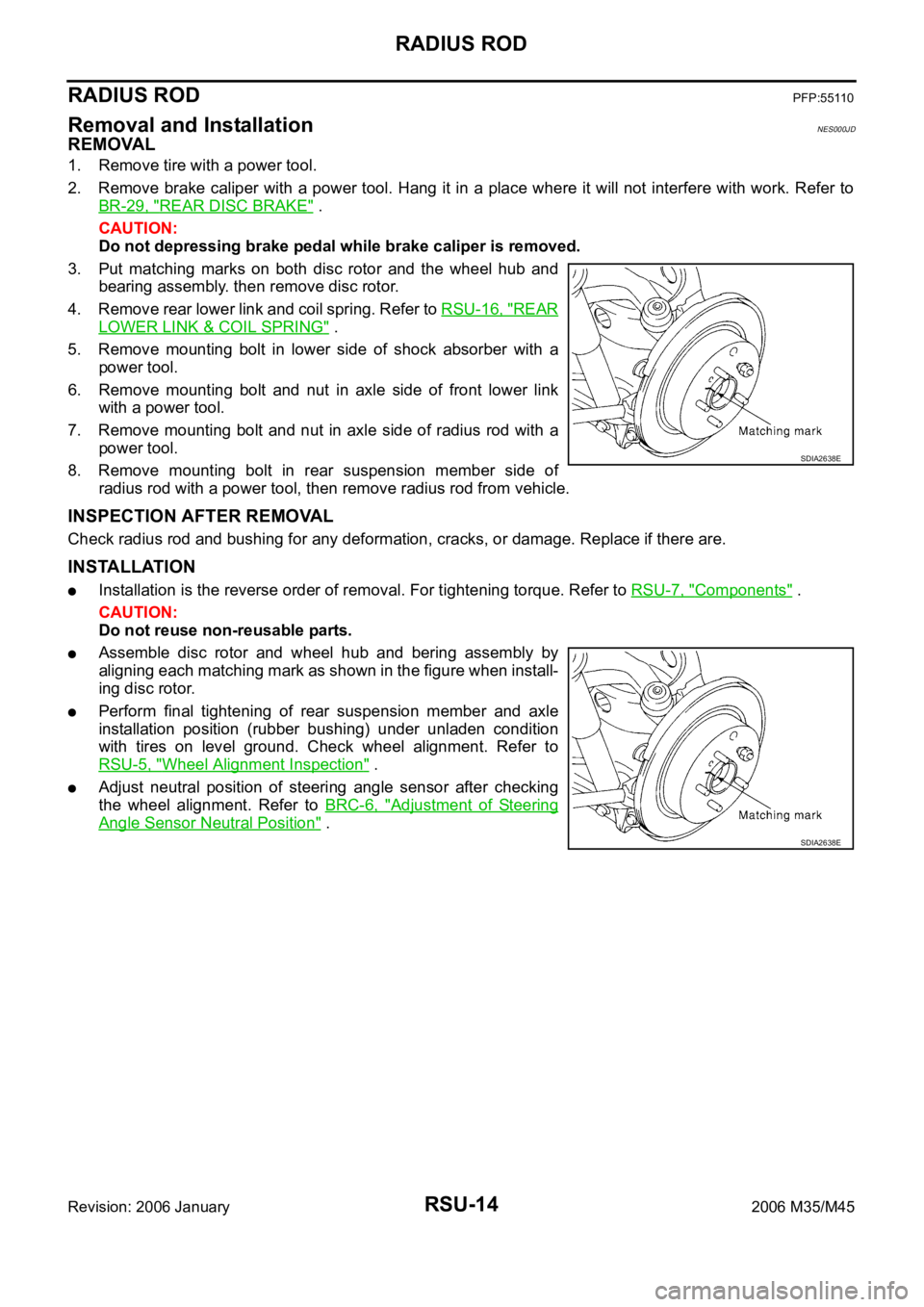

3. Put matching marks on both disc rotor and the wheel hub and

bearing assembly. then remove disc rotor.

4. Remove rear lower link and coil spring. Refer to RSU-16, "

REAR

LOWER LINK & COIL SPRING" .

5. Remove mounting bolt in lower side of shock absorber with a

power tool.

6. Remove mounting bolt and nut in axle side of front lower link

with a power tool.

7. Remove mounting bolt and nut in axle side of radius rod with a

power tool.

8. Remove mounting bolt in rear suspension member side of

radius rod with a power tool, then remove radius rod from vehicle.

INSPECTION AFTER REMOVAL

Check radius rod and bushing for any deformation, cracks, or damage. Replace if there are.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and wheel hub and bering assembly by

aligning each matching mark as shown in the figure when install-

ing disc rotor.

Perform final tightening of rear suspension member and axle

installation position (rubber bushing) under unladen condition

with tires on level ground. Check wheel alignment. Refer to

RSU-5, "

Wheel Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

the wheel alignment. Refer to BRC-6, "

Adjustment of Steering

Angle Sensor Neutral Position" .

SDIA2638E

SDIA2638E

Page 5100 of 5621

SB-1

SEAT BELTS

H RESTRAINTS

CONTENTS

C

D

E

F

G

I

J

K

L

M

SECTION SB

A

B

SB

Revision: 2006 January2006 M35/M45

SEAT BELTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precaution for Seat Belt Service .............................. 2

AFTER A COLLISION ........................................... 2

PRE-CRASH SEAT BELT .......................................... 3

Component Parts and Harness Connector Location ..... 3

System Description .................................................. 3

FUNCTION DESCRIPTION .................................. 4

FAIL-SAFE MODE ................................................ 4

CAN Communication System Description ................ 5

CAN Communication Unit ........................................ 5

Schematic ................................................................ 6

Wiring Diagram — PSB — ....................................... 7

Terminals and Reference Value for Pre-Crash Seat

Belt Control Unit ..................................................... 13

Work Flow .............................................................. 13

CONSULT-II Function (PRECRASH SEATBELT) ... 14

CONSULT-II INSPECTION PROCEDURE ......... 14

HOW TO READ SELF-DIAGNOSTIC RESULTS ... 15

SELF-DIAGNOSTIC RESULTS ITEM CHART ... 15

DATA MONITOR ITEM CHART .......................... 15

Preliminary Check .................................................. 16

PRE-CRASH SEAT BELT OPERATION

INSPECTION ...................................................... 16

Diagnoses Symptom Chart .................................... 16

Check CAN Communication System Inspection

[U1000] ................................................................... 16

Ignition Power Supply Circuit Check ...................... 17

Motor Power Supply and Ground Circuit Check

[B2454] ................................................................... 17

Seat Belt Buckle Switch (Driver Side) Circuit Check ... 19

Seat Belt Buckle Switch (Passenger Side) Circuit

Check ..................................................................... 21

Brake Pedal Stroke Sensor Circuit Check [B2453] ... 22

Pre-Crash Seat Belt Motor LH Circuit Check [B2452]

... 25

Pre-Crash Seat Belt Motor RH Circuit Check [B2451] ................................................................... 27

Brake Pedal Stroke Sensor Shield Wire Circuit

Check ..................................................................... 28

Removal and Installation of Pre-Crash Seat Belt

Control Unit ............................................................. 29

REMOVAL ........................................................

... 29

INSTALLATION ................................................... 29

SEAT BELTS ............................................................. 30

System Description ................................................. 30

SEAT BELT WARNING CHIME ........................... 30

SEAT BELT WARNING LAMP ............................. 30

Removal and Installation of Front Seat Belt ........... 30

REMOVAL OF SEAT BELT RETRACTOR .......... 30

INSTALLATION OF SEAT BELT RETRACTOR ... 31

REMOVAL OF SEAT BELT BUCKLE .................. 31

INSTALLATION OF SEAT BELT BUCKLE .......

... 31

Removal and Installation of Rear Seat Belt ............ 32

REMOVAL OF SEAT BELT RETRACTOR .......... 32

INSTALLATION OF SEAT BELT RETRACTOR ... 32

REMOVAL OF SEAT BELT BUCKLE .................. 32

INSTALLATION OF SEAT BELT BUCKLE .......... 33

Seat Belt Inspection ................................................ 33

AFTER A COLLISION ......................................... 33

PRELIMINARY CHECKS .................................... 33

SEAT BELT RETRACTOR ON-VEHICLE

CHECK ................................................................ 34

SEAT BELT RETRACTOR OFF-VEHICLE

CHECK (FRONT SEAT BELT) ............................ 35

SEAT BELT RETRACTOR OFF-VEHICLE

CHECK (REAR SEAT BELT) ............................... 35

LATCH (LOWER ANCHORS AND TETHER FOR

CHILDREN) SYSTEM ............................................... 36

Removal and Installation ........................................ 36

REMOVAL ........................................................

... 36

INSTALLATION ................................................... 36

TOP TETHER STRAP CHILD RESTRAINT ............. 37

Removal and Installation ........................................ 37

REMOVAL ........................................................

... 37

INSTALLATION ................................................... 37