ABS INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 63 of 5621

![INFINITI M35 2006 Factory User Guide ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS� INFINITI M35 2006 Factory User Guide ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS�](/img/42/57023/w960_57023-62.png)

ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS” self-diagnosis. Refer to BRC-22, "

CONSULT-II Functions (ABS)" .

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

20. CHECK STOP LAMP SWITCH INSTALLATION AND ADJUSTMENT

Check stop lamp switch for proper installation, and adjust the switch if necessary. Refer to BR-6, "

BRAKE

PEDAL" .

OK or NG

OK >> GO TO 21.

NG >> 1. Adjust stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

21. CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to ACS-68, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK >> GO TO 22.

NG >> 1. Replace stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

22. CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

3. Turn ignition switch ON.

4. Check voltage between stop lamp switch harness connector and

ground.

OK or NG

OK >> GO TO 23.

NG >> 1. Repair or replace harness or fuse.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Te r m i n a l s

Voltage

(Approx.) (+)

(–)

Stop lamp switch

connectorTerminal

E124 3 Ground Battery voltage

PKIC0833E

Page 64 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-55

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

23. CHECK HARNESS BETWEEN STOP LAMP SWITCH AND ABS ACTUATOR AND ELECTRIC UNIT

(C INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-55

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

23. CHECK HARNESS BETWEEN STOP LAMP SWITCH AND ABS ACTUATOR AND ELECTRIC UNIT

(C](/img/42/57023/w960_57023-63.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-55

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

23. CHECK HARNESS BETWEEN STOP LAMP SWITCH AND ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT)

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) connector.

3. Check continuity between stop lamp switch harness connector

(A) and ABS actuator and electric unit (control unit) harness

connector (B).

4. Check continuity between stop lamp switch harness connector

(A) and ground.

OK or NG

OK >> 1. Perform “ABS” self-diagnosis. Refer to BRC-22, "CONSULT-II Functions (ABS)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NG >> 1. Repair or replace harness between stop lamp switch and ABS actuator and electric unit (control

unit).

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 14 ECM CIRCUITNKS004D8

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if “CAN COMM CIRCUIT [U1000]” (DTC 100) other than “ECM CIRCUIT [C1A14]” (DTC 14) is indi-

cated in self-diagnosis item in the display.

Is it indicated?

YES >> 1. CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or

EC-846, "

CONSULT-II Function (ENGINE)" (for VK45DE).

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

AB

Continuity

Connector Terminal Connector Terminal

E124 4 E30 30 Yes

A

GroundContinuity

Connector Terminal

E124 4 No

PKIC0834E

Page 65 of 5621

![INFINITI M35 2006 Factory User Guide ACS-56

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

DTC 15 GEAR POSITIONNKS004D9

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis. INFINITI M35 2006 Factory User Guide ACS-56

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

DTC 15 GEAR POSITIONNKS004D9

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.](/img/42/57023/w960_57023-64.png)

ACS-56

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

DTC 15 GEAR POSITIONNKS004D9

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if “VHCL SPEED SE CIRC [C1A03]” (DTC 3), “ABS/TCS/VDC CIRC [C1A04]” (DTC 4) or “CAN

COMM CIRCUIT [U1000]” (DTC100) other than “GEAR POSITION [C1A15]” (DTC 15) is indicated in self-

diagnosis item in the display.

Is any indicated?

YES >> 1. Repair or replace applicable item. Refer to ACS-39, "Diagnostic Trouble Code (DTC) Chart" .

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2. CHECK VEHICLE SPEED SIGNAL

With CONSULT-II

With “ICC” “DATA MONITOR”, check if “VHCL SPEED SE” operates normally.

OK or NG

OK >> GO TO 3.

NG >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

3. CHECK SHIFT GEAR POSITION

Check if gear positions are correct in A/T.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4. CHECK TCM GEAR POSITION SIGNAL

With CONSULT-II

With “A/T” “DATA MONITOR”, check if gear positions are correct.

OK or NG

OK >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform “A/T” self-diagnosis. Refer to AT- 9 0 , "

CONSULT-II Function (A/T)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

5. CHECK TCM TURBINE REVOLUTION

With CONSULT-II

With TCM diagnosis, check if turbine revolution sensor is normal. Refer to AT- 11 7 , "

DTC P0717 TURBINE

REVOLUTION SENSOR" .

OK or NG

OK >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform “A/T” self-diagnosis. Refer to AT- 9 0 , "

CONSULT-II Function (A/T)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

Page 68 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-59

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 26 ECD MODE MALFNKS004DF

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-59

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 26 ECD MODE MALFNKS004DF

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS](/img/42/57023/w960_57023-67.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-59

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 26 ECD MODE MALFNKS004DF

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if “CAN COMM CIRCUIT [U1000]” (DTC 100) other than “ECD MODE MALF [C1A26]” (DTC 26) is

indicated in self-diagnosis item in the display.

Is it indicated?

YES >> 1. CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS” self-diagnosis. Refer to BRC-22, "

CONSULT-II Functions (ABS)" .

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 27 ECD PWR SUPLY CIRNKS004DG

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if “CAN COMM CIRCUIT [U1000]” (DTC 100) other than “ECD PWR SUPLY CIR [C1A27]” (DTC

27) is indicated in self-diagnosis item in the display.

Is it indicated?

YES >> 1. CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY CIRCUIT

With CONSULT-II

Check ABS actuator and electric unit (control unit) power supply circuit. Refer to BRC-37, "

Inspection 4: ABS

Actuator and Electric Unit (Control Unit) Power Supply and Ground Circuit" .

OK or NG

OK >> 1. Perform “ABS” self-diagnosis. Refer to BRC-22, "CONSULT-II Functions (ABS)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NG >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Page 115 of 5621

AT-36

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

Shift Change System Diagram

ASC (ADOPTIVE SHIFT CONTROL)

ASC automatically shifts or hold at the 3rd or 4th gear on certain roads (up/down slope and curve) and driving

condition.

When Driving on an Up/down Slope

ASC judges up/down slope according to the angle of accelerator pedal and vehicle speed. Holding gear at

the 3rd or 4th on an up-slope prevents shift hunting and controls the vehicle to gain maximum driving

force. On a down-slope, automatic shift-down to the 3rd or 4th gear controls to gain maximum engine

brake.

When Driving on a Curve

TCM receives side G sensor signal from ABS actuator and electric unit (control unit). Holding gear at the

3rd or 4th based on the signal prevents shift-up and kick-down and controls to drive smoothly.

SCIA6483E

SCIA6469E

Page 116 of 5621

A/T CONTROL SYSTEM

AT-37

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

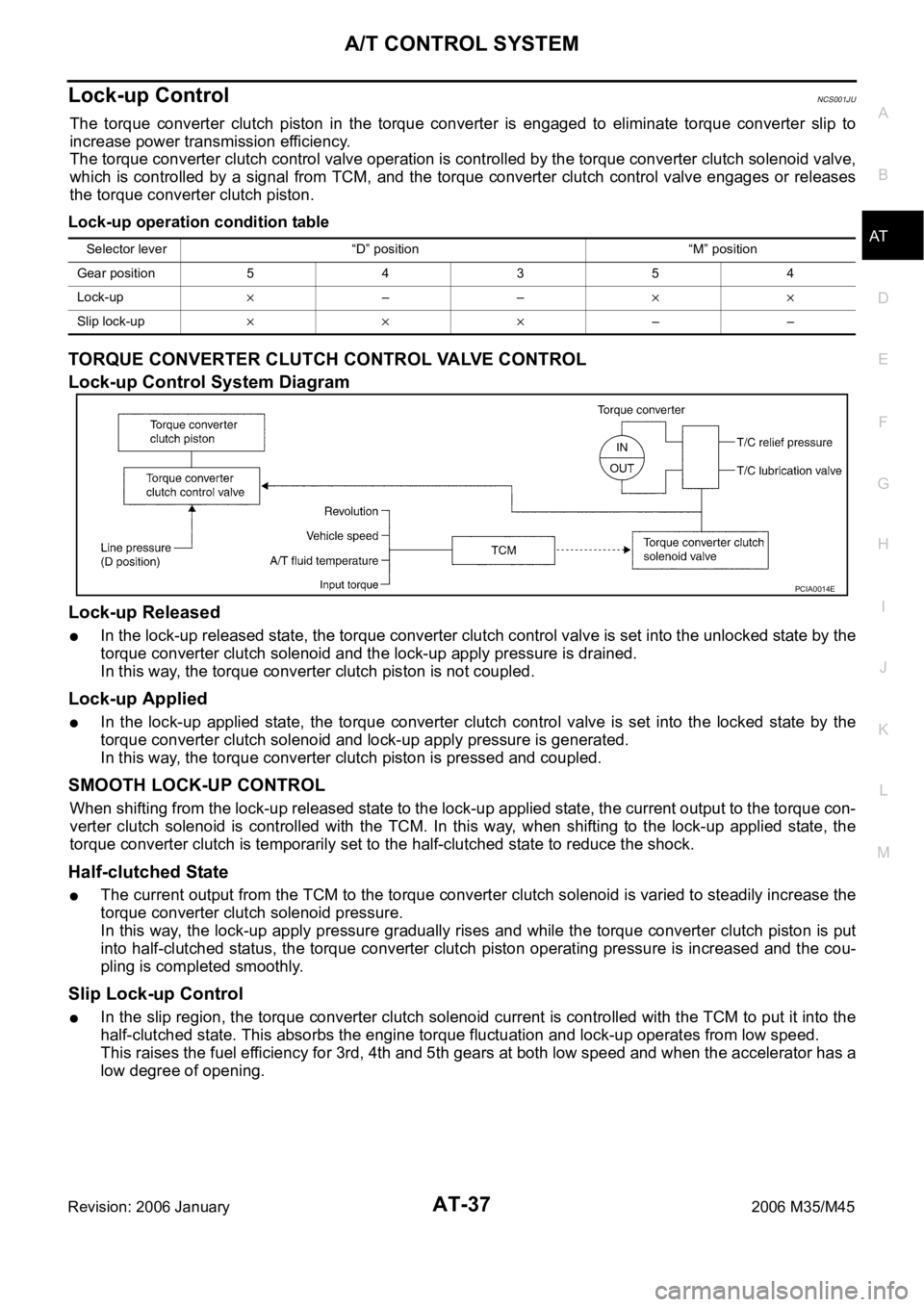

Lock-up ControlNCS001JU

The torque converter clutch piston in the torque converter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is controlled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the torque converter clutch control valve engages or releases

the torque converter clutch piston.

Lock-up operation condition table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the

torque converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converter clutch solenoid is varied to steadily increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put

into half-clutched status, the torque converter clutch piston operating pressure is increased and the cou-

pling is completed smoothly.

Slip Lock-up Control

In the slip region, the torque converter clutch solenoid current is controlled with the TCM to put it into the

half-clutched state. This absorbs the engine torque fluctuation and lock-up operates from low speed.

This raises the fuel efficiency for 3rd, 4th and 5th gears at both low speed and when the accelerator has a

low degree of opening.

Selector lever “D” position “M” position

Gear position 5 4 3 5 4

Lock-up

––

Slip lock-up––

PCIA0014E

Page 177 of 5621

AT-98

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

SFT UP ST SW (ON/OFF) — —

Not mounted but displayed.

SFT DWN ST SW (ON/OFF) — —

ASCDꞏOD CUT (ON/OFF) — —

ASCDꞏCRUISE (ON/OFF) — —

ABS SIGNAL (ON/OFF) — —

ACC OD CUT (ON/OFF) — —

Intelligent cruise control (ICC) system

ACC SIGNAL (ON/OFF) — —

TCS GR/P KEEP (ON/OFF) — —

TCS SIGNAL 2 (ON/OFF) — —

TCS SIGNAL 1 (ON/OFF) — —

TCC SOLENOID (A) — X

LINE PRES SOL (A) — X

I/C SOLENOID (A) — X

FR/B SOLENOID (A) — X

D/C SOLENOID (A) — X

HLR/C SOL (A) — X

ON OFF SOL (ON/OFF) — — LC/B solenoid

TCC SOL MON (A) — —

L/P SOL MON (A) — —

I/C SL MON (A) — —

FR/B SOL MON (A) — —

D/C SOL MON (A) — —

HLR/C SOL MON (A) — —

ON OFF SOL MON (ON/OFF) — — LC/B solenoid

P POSI IND (ON/OFF) — —

R POSI IND (ON/OFF) — —

N POSI IND (ON/OFF) — —

D POSI IND (ON/OFF) — —

4TH POSI IND (ON/OFF) — —

3RD POSI IND (ON/OFF) — —

2ND POSI IND (ON/OFF) — —

1ST POSI IND (ON/OFF) — —

MANU MODE IND (ON/OFF) — —

POWER M LAMP (ON/OFF) — —

F-SAFE IND/L (ON/OFF) — —Monitored item (Unit)Monitor Item Selection

Remarks ECU

INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

Page 453 of 5621

ATC-6

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Procedures without Cowl Top CoverNJS000FP

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions for Working with HFC-134a (R-134a)NJS000FQ

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. If the refrigerants

are mixed and compressor malfunction is likely to occur, refer to “CONTAMINATED REFRIGER-

ANT” below. To determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use

Refrigerant Recovery/Recycling Recharging equipment and Refrigerant Identifier.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor malfunction is likely to occur.

The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

–When removing refrigerant components from a vehicle, immediately the cap (seal) the component

to minimize the entry of moisture from the atmosphere.

–When installing refrigerant components to a vehicle, never remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possi-

ble to minimize the entry of moisture into system.

–Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

–Never allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrene foam parts.

Damage may result.

PIIB3706J

Page 758 of 5621

![INFINITI M35 2006 Factory User Guide REMOVAL AND INSTALLATION

AV-137

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

Front Display Unit (BOSE System)NKS0049W

REMOVAL

1. Remove upper vent INFINITI M35 2006 Factory User Guide REMOVAL AND INSTALLATION

AV-137

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

Front Display Unit (BOSE System)NKS0049W

REMOVAL

1. Remove upper vent](/img/42/57023/w960_57023-757.png)

REMOVAL AND INSTALLATION

AV-137

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

Front Display Unit (BOSE System)NKS0049W

REMOVAL

1. Remove upper ventilator grille. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove multifunction switch. Refer to ATC-124, "

Removal and Installation of Multifunction Switch" .

3. Remove screw (A).

4. Remove screws (B) and disconnect connector, and remove dis-

play (1).

5. Remove screws (A) separate front display (1) unit from bracket

(2).

INSTALLATION

Installation is the reverse order of removal.

Multifunction SwitchNKS0049X

REMOVAL

1. Remove instrument panel finisher B and C. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove screw (A).

3. Disengage tabs (B) and connector to separate multifunction

switch (1) from instrument panel.

INSTALLATION

Installation is the reverse order of removal.

Preset SwitchNKS0049Y

REMOVAL

1. Remove cluster lid C. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

SKIB4373E

SKIB4391E

SKIB4276E

Page 759 of 5621

![INFINITI M35 2006 Factory User Guide AV-138

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

2. Disengage tabs (A) to separate preset switch (1) from cluster lid

C (2).

INSTALLATION

Instal INFINITI M35 2006 Factory User Guide AV-138

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

2. Disengage tabs (A) to separate preset switch (1) from cluster lid

C (2).

INSTALLATION

Instal](/img/42/57023/w960_57023-758.png)

AV-138

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

2. Disengage tabs (A) to separate preset switch (1) from cluster lid

C (2).

INSTALLATION

Installation is the reverse order of removal.

Steering SwitchNKS0049Z

REMOVAL

1. Refer to SRS-38, "DRIVER AIR BAG MODULE" .

INSTALLATION

Installation is the reverse order of removal.

DVD PlayerNKS004A0

REMOVAL

1. Remove cup holder. Refer to IP-11, "Removal and Installation of Instrument Panel & Pad" .

2. Disconnect sub harness connector.

SKIB4277E

1. Air bag 2. Steering switch 3. Screw

4. Spring 5. Bracket 6. Screw

SKIB4278E