brake sensor INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 54 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-45

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

9. CHECK HARNESS BETWEEN ICC BRAKE SWITCH AND ECM

1. Turn ignition switch OFF.

2. INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-45

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

9. CHECK HARNESS BETWEEN ICC BRAKE SWITCH AND ECM

1. Turn ignition switch OFF.

2.](/img/42/57023/w960_57023-53.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-45

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

9. CHECK HARNESS BETWEEN ICC BRAKE SWITCH AND ECM

1. Turn ignition switch OFF.

2. Disconnect ECM connector.

3. Check continuity between ICC brake switch harness connector

(A) and ECM harness connector (B).

4. Check continuity between ICC brake switch harness connector

(A) and ground.

OK or NG

OK >> GO TO 10.

NG >> 1. Repair or replace harness between ICC brake switch and ECM.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or

EC-846, "

CONSULT-II Function (ENGINE)" (for VK45DE).

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

11 . CHECK STOP LAMP SWITCH INSTALLATION AND ADJUSTMENT

Check stop lamp switch for proper installation, and adjust the switch if necessary. Refer to BR-6, "

BRAKE

PEDAL" .

OK or NG

OK >> GO TO 12.

NG >> 1. Adjust stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

12. CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to ACS-68, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK >> GO TO 13.

NG >> 1. Replace stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

AB

Continuity

Connector Terminal Connector Terminal

E111 2 M71 108 Yes

A

GroundContinuity

Connector Terminal

E 111 2 N o

PKIB9336E

Page 58 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-49

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 13 STOP LAMP RLY FIXNKS004D7

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGN INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-49

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 13 STOP LAMP RLY FIXNKS004D7

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGN](/img/42/57023/w960_57023-57.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-49

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 13 STOP LAMP RLY FIXNKS004D7

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if “CAN COMM CIRCUIT [U1000]” (DTC 100) other than “STOP LAMP RLY FIX [C1A13]” (DTC 13)

is indicated in self-diagnosis item in the display.

Is it indicated?

YES >> 1. CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2. CHECK CONNECTOR FOR ECM

1. Turn ignition switch OFF.

2. Disconnect ECM connector, and connect it securely again.

3. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system again.

4. Check if “STOP LAMP RLY FIX [C1A13]” (DTC 13) is indicated in self-diagnosis item in the display.

Is it indicated?

YES >> GO TO 3.

NO >> Poor connector connection

1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-

minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

3. CHECK STOP LAMP SWITCH WITH ICC DATA MONITOR

With CONSULT-II

With “ICC” “DATA MONITOR”, check if “STOP LAMP SW” operates normally.

OK or NG

OK >> GO TO 11.

NG >> GO TO 4.

4. CHECK STOP LAMP SWITCH INSTALLATION AND ADJUSTMENT

Check stop lamp switch for proper installation, and adjust the switch if necessary. Refer to BR-6, "

BRAKE

PEDAL" .

OK or NG

OK >> GO TO 5.

NG >> 1. Adjust stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

5. CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to ACS-68, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK >> GO TO 6.

NG >> 1. Replace stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Page 60 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-51

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diag INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-51

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diag](/img/42/57023/w960_57023-59.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-51

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

10. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ENGINE” self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or

EC-846, "

CONSULT-II Function (ENGINE)" (for VK45DE).

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

11 . CHECK HARNESS BETWEEN ICC SENSOR INTEGRATED UNIT AND ICC BRAKE HOLD RELAY

1. Turn ignition switch OFF.

2. Disconnect ICC sensor integrated unit connector and ICC brake hold relay.

3. Check continuity between ICC sensor integrated unit harness

connector (A) and ICC brake hold relay harness connector (B).

4. Check continuity between ICC sensor integrated unit harness

connector (A) and ground.

OK or NG

OK >> GO TO 12.

NG >> 1. Repair harness between ICC sensor integrated unit and ICC brake hold relay.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

12. CHECK ICC BRAKE HOLD RELAY GROUND CIRCUIT

Check continuity between ICC brake hold relay harness connector

and ground.

OK or NG

OK >> GO TO 13.

NG >> 1. Repair or replace harness between ICC brake hold

relay and ground.

2. Erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

AB

Continuity

Connector Terminal Connector Terminal

E61 2 E80 2 Yes

A

GroundContinuity

Connector Terminal

E61 2 No

PKIB9338E

ICC brake hold relay

connectorTerminal

GroundContinuity

E80 1 Yes

PKIB9341E

Page 61 of 5621

![INFINITI M35 2006 Factory User Guide ACS-52

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

13. CHECK ICC SENSOR INTEGRATED UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect ICC sensor integrated uni INFINITI M35 2006 Factory User Guide ACS-52

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

13. CHECK ICC SENSOR INTEGRATED UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect ICC sensor integrated uni](/img/42/57023/w960_57023-60.png)

ACS-52

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

13. CHECK ICC SENSOR INTEGRATED UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect ICC sensor integrated unit connector.

2. Turn ignition switch ON.

3. Perform “ACTIVE TEST” (“STOP LAMP”: “STP LMP DRIVE

ON”) with CONSULT-II, check voltage between ICC brake hold

relay harness connector and ground.

OK or NG

OK >> GO TO 14.

NG >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

14. CHECK ICC BRAKE HOLD RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between ICC brake hold relay harness connector

and ground.

OK or NG

OK >> GO TO 15.

NG >> 1. Repair or replace harness or fuse.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Terminals

ConditionVoltage

(Approx.) (+)

(–)

ICC brake hold

relay connectorTerminal

E80 2 GroundDuring

“ACTIVE TEST”12 V

PKIB9342E

Terminals

Voltage

(Approx.) (+)

(–)

ICC brake hold relay

connectorTe r m i n a l

E80 3 Ground Battery voltage

PKIB9343E

Page 63 of 5621

![INFINITI M35 2006 Factory User Guide ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS� INFINITI M35 2006 Factory User Guide ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS�](/img/42/57023/w960_57023-62.png)

ACS-54

[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

19. PERFORM ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

With CONSULT-II

1. Perform “ABS” self-diagnosis. Refer to BRC-22, "

CONSULT-II Functions (ABS)" .

2. Check if malfunction is indicated.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

20. CHECK STOP LAMP SWITCH INSTALLATION AND ADJUSTMENT

Check stop lamp switch for proper installation, and adjust the switch if necessary. Refer to BR-6, "

BRAKE

PEDAL" .

OK or NG

OK >> GO TO 21.

NG >> 1. Adjust stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

21. CHECK STOP LAMP SWITCH

Check stop lamp switch. Refer to ACS-68, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK >> GO TO 22.

NG >> 1. Replace stop lamp switch.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

22. CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch connector.

3. Turn ignition switch ON.

4. Check voltage between stop lamp switch harness connector and

ground.

OK or NG

OK >> GO TO 23.

NG >> 1. Repair or replace harness or fuse.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Te r m i n a l s

Voltage

(Approx.) (+)

(–)

Stop lamp switch

connectorTerminal

E124 3 Ground Battery voltage

PKIC0833E

Page 72 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-63

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

Symptom 2: ICC System Cannot Be Set (MAIN Switch Turns ON/OFF)NKS004DL

The ICC system cannot b INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-63

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

Symptom 2: ICC System Cannot Be Set (MAIN Switch Turns ON/OFF)NKS004DL

The ICC system cannot b](/img/42/57023/w960_57023-71.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-63

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

Symptom 2: ICC System Cannot Be Set (MAIN Switch Turns ON/OFF)NKS004DL

The ICC system cannot be set in the following cases.

When the vehicle speed is not in range of approx. 25 MPH (40 km/h) to 90 MPH (144 km/h).

When the A/T selector lever is in “N”.

When A/T mode switch is at the snow mode position.

While the brake is in operation.

When wiper switch is at LOW/HI position.

1. CHECK CAUSE OF AUTOMATIC CANCELLATION

With CONSULT-II

With “CAUSE OF AUTO-CANCEL” in “WORK SUPPORT” at “ICC”, check if any cause of cancellation is

found.

Is any cause found?

YES >> Cancel with appropriate cause, and go to specified diagnosis.

“OPE SW VOLT CIRC”: Refer to ACS-47, "DTC 6 OPERATION SW CIRC" .

“VHCL SPD UNMATCH”: Refer to ACS-42, "DTC 3 VHCL SPEED SE CIRC" .

“IGN LOW VOLT”: Refer to ACS-41, "DTC 1 POWER SUPPLY CIR, DTC 2 POWER SUPPLY

CIR 2" .

“ECM CIRCUIT”: Refer to ACS-55, "DTC 14 ECM CIRCUIT" .

NO >> GO TO 2.

2. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

With CONSULT-II

Perform self-diagnosis to check for malfunctioning items.

Is malfunction indicated?

YES >> 1. Repair or replace applicable item. Refer to ACS-39, "Diagnostic Trouble Code (DTC) Chart" .

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 3.

3. CHECK SWITCHES AND VEHICLE SPEED SIGNAL

With CONSULT-II

With “ICC” “DATA MONITOR”, check if switches and vehicle speed signal operate normally. Refer to ACS-30,

"DATA MONITOR" .

VHCL SPEED SE

D RANGE SW

BRAKE SW

SET/COAST SW

OK or NG

OK >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and Perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> Check items which do not function normally.

VHCL SPEED SE. Refer to ACS-42, "DTC 3 VHCL SPEED SE CIRC" .

D RANGE SW. Refer to ACS-64, "Symptom 4: ICC System Is Not Cancelled When the A/T

Selector Lever Is In Other Than “D” and “M”" .

BRAKE SW. Refer to ACS-43, "DTC 5 BRAKE SW/STOP L SW" .

SET/COAST SW. Refer to ACS-47, "DTC 6 OPERATION SW CIRC" .

Page 81 of 5621

AT-2Revision: 2006 January2006 M35/M45 On Board Diagnosis Logic ....................................113

Possible Cause .....................................................113

DTC Confirmation Procedure ...............................113

Wiring Diagram — AT — PNP/SW .......................114

Diagnostic Procedure ...........................................115

DTC P0717 TURBINE REVOLUTION SENSOR ....117

Description ............................................................117

CONSULT-II Reference Value ..............................117

On Board Diagnosis Logic ....................................117

Possible Cause .....................................................117

DTC Confirmation Procedure ...............................117

Diagnostic Procedure ...........................................118

DTC P0720 VEHICLE SPEED SENSOR A/T (REV-

OLUTION SENSOR) ...............................................119

Description ............................................................119

CONSULT-II Reference Value ..............................119

On Board Diagnosis Logic ....................................119

Possible Cause .....................................................119

DTC Confirmation Procedure ...............................119

Wiring Diagram — AT — VSSA/T .........................121

Diagnostic Procedure ...........................................122

DTC P0725 ENGINE SPEED SIGNAL ...................124

Description ............................................................124

CONSULT-II Reference Value ..............................124

On Board Diagnosis Logic ....................................124

Possible Cause .....................................................124

DTC Confirmation Procedure ...............................124

Diagnostic Procedure ...........................................125

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE .................................................126

Description ............................................................126

CONSULT-II Reference Value ..............................126

On Board Diagnosis Logic ....................................126

Possible Cause .....................................................126

DTC Confirmation Procedure ...............................126

Diagnostic Procedure ...........................................127

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) . 128

Description ............................................................128

CONSULT-II Reference Value ..............................128

On Board Diagnosis Logic ....................................128

Possible Cause .....................................................128

DTC Confirmation Procedure ...............................128

Diagnostic Procedure ...........................................129

DTC P0745 LINE PRESSURE SOLENOID VALVE .130

Description ............................................................130

CONSULT-II Reference Value ..............................130

On Board Diagnosis Logic ....................................130

Possible Cause .....................................................130

DTC Confirmation Procedure ...............................130

Diagnostic Procedure ...........................................131

DTC P1705 THROTTLE POSITION SENSOR .......132

Description ............................................................132

CONSULT-II Reference Value ..............................132

On Board Diagnosis Logic ....................................132

Possible Cause .....................................................132

DTC Confirmation Procedure ...............................132

Diagnostic Procedure ...........................................133

DTC P1710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................135Description ............................................................135

CONSULT-II Reference Value ...............................135

On Board Diagnosis Logic ....................................135

Possible Cause .....................................................135

DTC Confirmation Procedure ................................135

Wiring Diagram — AT — FTS ...............................136

Diagnostic Procedure ............................................137

Component Inspection ..........................................139

DTC P1721 VEHICLE SPEED SENSOR MTR .......140

Description ............................................................140

CONSULT-II Reference Value ...............................140

On Board Diagnosis Logic ....................................140

Possible Cause .....................................................140

DTC Confirmation Procedure ................................140

Diagnostic Procedure ............................................141

DTC P1730 A/T INTERLOCK .................................142

Description ............................................................142

On Board Diagnosis Logic ....................................142

Possible Cause .....................................................142

DTC Confirmation Procedure ................................142

Judgement of A/T Interlock ...................................143

Diagnostic Procedure ............................................143

DTC P1731 A/T 1ST ENGINE BRAKING ...............145

Description ............................................................145

CONSULT-II Reference Value ...............................145

On Board Diagnosis Logic ....................................145

Possible Cause .....................................................145

DTC Confirmation Procedure ................................145

Diagnostic Procedure ............................................146

DTC P1752 INPUT CLUTCH SOLENOID VALVE ..147

Description ...................................................

.........147

CONSULT-II Reference Value ...............................147

On Board Diagnosis Logic ....................................147

Possible Cause .....................................................147

DTC Confirmation Procedure ................................147

Diagnostic Procedure ............................................148

DTC P1754 INPUT CLUTCH SOLENOID VALVE

FUNCTION ..............................................................149

Description ............................................................149

CONSULT-II Reference Value ...............................149

On Board Diagnosis Logic ....................................149

Possible Cause .....................................................149

DTC Confirmation Procedure ................................149

Diagnostic Procedure ............................................150

DTC P1757 FRONT BRAKE SOLENOID VALVE ...151

Description ............................................................151

CONSULT-II Reference Value ...............................151

On Board Diagnosis Logic ....................................151

Possible Cause .....................................................151

DTC Confirmation Procedure ................................151

Diagnostic Procedure ............................................152

DTC P1759 FRONT BRAKE SOLENOID VALVE

FUNCTION ..............................................................153

Description ............................................................153

CONSULT-II Reference Value ...............................153

On Board Diagnosis Logic ....................................153

Possible Cause .....................................................153

DTC Confirmation Procedure ................................153

Diagnostic Procedure ............................................154

Page 83 of 5621

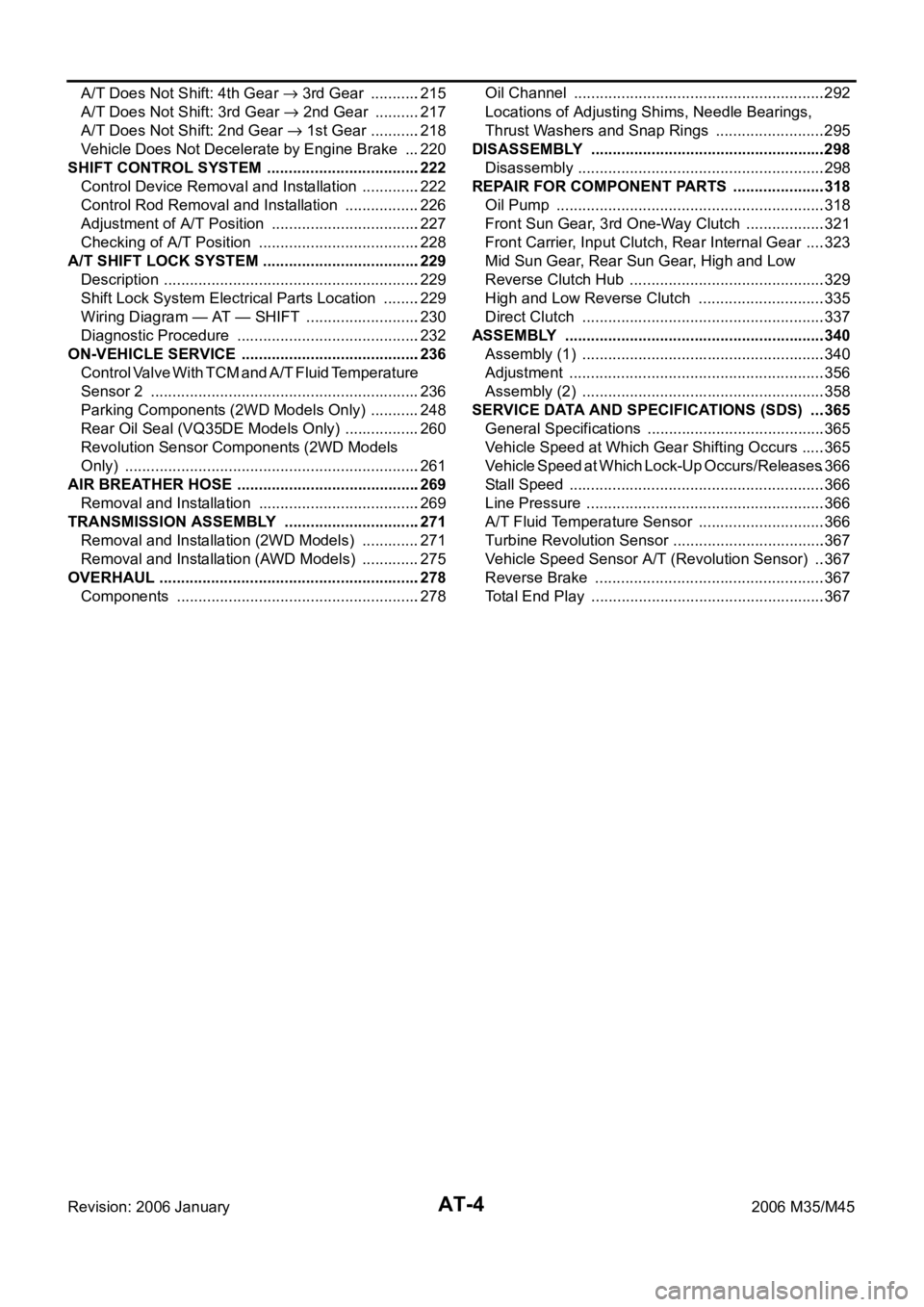

AT-4Revision: 2006 January2006 M35/M45 A/T Does Not Shift: 4th Gear

3rd Gear ............215

A/T Does Not Shift: 3rd Gear

2nd Gear ...........217

A/T Does Not Shift: 2nd Gear

1st Gear ............218

Vehicle Does Not Decelerate by Engine Brake ....220

SHIFT CONTROL SYSTEM ....................................222

Control Device Removal and Installation ..............222

Control Rod Removal and Installation ..................226

Adjustment of A/T Position ...................................227

Checking of A/T Position ......................................228

A/T SHIFT LOCK SYSTEM .....................................229

Description ............................................................229

Shift Lock System Electrical Parts Location .........229

Wiring Diagram — AT — SHIFT ...........................230

Diagnostic Procedure ...........................................232

ON-VEHICLE SERVICE ..........................................236

C o n t r o l V a l v e W i t h T C M a n d A / T F l u i d Te m p e r a t u r e

Sensor 2 ...............................................................236

Parking Components (2WD Models Only) ............248

Rear Oil Seal (VQ35DE Models Only) ..................260

Revolution Sensor Components (2WD Models

Only) .....................................................................261

AIR BREATHER HOSE ...........................................269

Removal and Installation ......................................269

TRANSMISSION ASSEMBLY ................................271

Removal and Installation (2WD Models) ..............271

Removal and Installation (AWD Models) ..............275

OVERHAUL .............................................................278

Components .........................................................278Oil Channel ...........................................................292

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................295

DISASSEMBLY .......................................................298

Disassembly ..........................................................298

REPAIR FOR COMPONENT PARTS ......................318

Oil Pump ...............................................................318

Front Sun Gear, 3rd One-Way Clutch ...................321

Front Carrier, Input Clutch, Rear Internal Gear .....323

Mid Sun Gear, Rear Sun Gear, High and Low

Reverse Clutch Hub ..............................................329

High and Low Reverse Clutch ..............................335

Direct Clutch .........................................................337

ASSEMBLY .............................................................340

Assembly (1) .........................................................340

Adjustment ............................................................356

Assembly (2) .........................................................358

SERVICE DATA AND SPECIFICATIONS (SDS) ....365

General Specifications ......................................... .365

Vehicle Speed at Which Gear Shifting Occurs ......365

Vehicle Speed at Which Lock-Up Occurs/Releases .366

Stall Speed ............................................................366

Line Pressure ........................................................366

A/T Fluid Temperature Sensor ..............................366

Turbine Revolution Sensor ....................................367

Vehicle Speed Sensor A/T (Revolution Sensor) ...367

Reverse Brake ......................................................367

Total End Play .......................................................367

Page 110 of 5621

A/T CONTROL SYSTEM

AT-31

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

TCM FunctionNCS001JP

The function of the TCM is to:

Receive input signals sent from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

Send required output signals to the respective solenoids.

CONTROL SYSTEM OUTLINE

The A/T senses vehicle operating conditions through various sensors or signals. It always controls the opti-

mum shift position and reduces shifting and lock-up shocks.

CONTROL SYSTEM DIAGRAM

SENSORS (or SIGNAL)TCMACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Turbine revolution sensor

ATF pressure switchShift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN systemInput clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch

solenoid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Back-up lamp relay

Sta r te r re l a y

SCIA5325E

Page 111 of 5621

AT-32

A/T CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

CAN CommunicationNCS001JQ

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. Refer to LAN-34, "

CAN

Communication Unit" .

Input/Output Signal of TCMNCS001JR

*1: Spare for vehicle speed sensorꞏA/T (revolution sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: Used as a condition for starting self-diagnostics; if self-diagnostics are not started, it is judged that there is some kind of error.

*5: Input by CAN communications.

*6: Output by CAN communications.Control itemLine

pressure

controlVehicle

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

function

(*3)Self-diag-

nostics

function

InputAccelerator pedal position signal

(*5)XXXXXXX

Vehicle speed sensor A/T

(revolution sensor)XXXXXXX

Vehicle speed sensor MTR

(*1) (*5)X

Closed throttle position signal

(*5)X(*2) X X X X(*4)

Wide open throttle position signal

(*5)XX(*4)

Turbine revolution sensor 1 X X X X X

Turbine revolution sensor 2

(for 4th speed only)X XXXX

Engine speed signals

(*5)XXXXXXX

Stop lamp switch signal

(*5)XXX X(*4)

A/T fluid temperature sensors 1, 2XXXX XX

ASCD or ICC

sensor inte-

grated unitOperation signal

(*5)XXX

Overdrive cancel

signal

(*5)X

Out-

putDirect clutch solenoid

(ATF pressure switch 5)XX XX

Input clutch solenoid

(ATF pressure switch 3)XX XX

High and low reverse clutch solenoid

(ATF pressure switch 6)XX XX

Front brake solenoid

(ATF pressure switch 1)XX XX

Low coast brake solenoid

(ATF pressure switch 2)XX XXX

Line pressure solenoidXXXXXXX

TCC solenoid X X X

Self-diagnostics table

(*6)X

Starter relayXX