bulb INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4431 of 5621

LT-4Revision: 2006 January2006 M35/M45 HAZARD SWITCH ..................................................231

Removal and Installation ......................................231

REMOVAL ........................................................

.231

COMBINATION SWITCH ........................................232

Wiring Diagram — COMBSW — ..........................232

Combination Switch Reading Function .................233

Terminals and Reference Values for BCM ............233

CONSULT-II Functions (BCM) ..............................238

CONSULT-II BASIC OPERATION .....................238

DATA MONITOR ................................................239

Combination Switch Inspection ............................240

Removal and Installation ......................................242

STOP LAMP ............................................................243

Wiring Diagram — STOP LAMP — ......................243

High-Mounted Stop Lamp .....................................245

BULB REPLACEMENT, REMOVAL AND

INSTALLATION ..................................................245

Stop Lamp ............................................................245

BULB REPLACEMENT .....................................245

BULB REPLACEMENT .....................................245

BACK-UP LAMP .....................................................246

Wiring Diagram — B/LAMP — .............................246

Bulb Replacement ...............................................

.247

Removal and Installation ......................................248

REMOVAL ........................................................

.248

INSTALLATION ..................................................248

PARKING, LICENSE PLATE AND TAIL LAMPS ....249

Component Parts and Harness Connector Location .249

System Description ...............................................249

OUTLINE ...........................................................249

OPERATION BY LIGHTING SWITCH ...............250

COMBINATION SWITCH READING FUNCTION .250

EXTERIOR LAMP BATTERY SAVER CONTROL .250

CAN Communication System Description ............250

CAN Communication Unit .....................................250

Schematic .............................................................251

Wiring Diagram — TAIL/L — ................................252

Terminals and Reference Values for BCM ............257

Terminals and Reference Values for IPDM E/R ....258

How to Perform Trouble Diagnoses ......................258

Preliminary Check ................................................258

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................258

CONSULT-II Functions (BCM) ..............................259

CONSULT-II Functions (IPDM E/R) ......................259

Parking, License Plate and Tail Lamps Do Not Illu-

minate ...................................................................260

Parking, License Plate and Tail Lamps Do Not Turn

OFF (After Approx. 10 Minutes) ...........................264

License Plate Lamp ..............................................265

BULB REPLACEMENT .....................................265

Removal and Installation ......................................265

REMOVAL ........................................................

.265

INSTALLATION ..................................................265

Front Parking (Clearance) Lamp ..........................265

BULB REPLACEMENT .....................................265

REMOVAL AND INSTALLATION .......................265

REAR COMBINATION LAMP .................................266

Bulb Replacement ...............................................

.266REAR TURN SIGNAL LAMP BULB, STOP/TAIL

LAMP BULB ...................................................... .266

Removal and Installation .......................................266

REMOVAL ..........................................................266

INSTALLATION ..................................................266

INTERIOR ROOM LAMP ........................................267

Component Parts and Harness Connector Location .267

System Description ...............................................267

ROOM LAMP TIMER BASIC OPERATION .......267

POWER SUPPLY AND GROUND .....................268

SWITCH OPERATION .......................................269

ROOM LAMP TIMER OPERATION ...................270

CONDITIONS FOR CANCELING TIMER ..........271

ROOM LAMP TIMER INAPPLICABLE LAMPS

OPERATION ......................................................271

INTERIOR ROOM LAMP BATTERY SAVER

FUNCTION .......................................................

.271

Schematic .............................................................272

Wiring Diagram — ROOM/L — .............................274

Terminals and Reference Values for BCM ............281

How to Perform Trouble Diagnoses ......................282

Preliminary Check .................................................283

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ...................................................................283

CONSULT-II Functions (BCM) ..............................284

CONSULT-II BASIC OPERATION .....................284

WORK SUPPORT (INT LAMP) .........................285

DATA MONITOR (INT LAMP) ............................286

ACTIVE TEST (INT LAMP) ................................287

WORK SUPPORT (BATTERY SAVER) .............287

DATA MONITOR (BATTERY SAVER) ...............287

ACTIVE TEST (BATTERY SAVER) ...................288

Interior Room Lamp Control Does Not Operate ....289

Map Lamp .............................................................291

BULB REPLACEMENT ......................................291

REMOVAL AND INSTALLATION .......................291

Personal Lamp ......................................................291

BULB REPLACEMENT ......................................291

REMOVAL AND INSTALLATION .......................291

Foot Lamp (Driver Side) .......................................

.292

BULB REPLACEMENT ......................................292

REMOVAL AND INSTALLATION .......................292

Foot Lamp (Passenger Side) ................................293

BULB REPLACEMENT ......................................293

REMOVAL AND INSTALLATION .......................293

Vanity Mirror Lamp ................................................293

BULB REPLACEMENT ......................................293

Step Lamp .............................................................294

BULB REPLACEMENT ......................................294

REMOVAL AND INSTALLATION .......................294

Kicking Plate Illumination .....................................

.294

BULB REPLACEMENT ......................................294

REMOVAL AND INSTALLATION .......................294

Trunk Room Lamp (Upper/Lower) ........................294

BULB REPLACEMENT ......................................294

REMOVAL AND INSTALLATION .......................294

ILLUMINATION ........................................................295

System Description ...............................................295

OUTLINE ...........................................................295

Page 4432 of 5621

LT-5

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45 ILLUMINATION OPERATION BY LIGHTING

SWITCH ............................................................296

EXTERIOR LAMP BATTERY SAVER CONTROL .297

CAN Communication System Description ............297

CAN Communication Unit ....................................297

Schematic ............................................................298

Wiring Diagram — ILL — .....................................300

Glove Box Lamp ...................................................313

BULB REPLACEMENT, REMOVAL AND

INSTALLATION .................................................313

Cigarette Lighter Illumination ...............................313

BULB REPLACEMENT, REMOVAL AND INSTALLATION .................................................313

Front Ashtray Illumination .....................................314

BULB REPLACEMENT, REMOVAL AND

INSTALLATION .................................................314

Rear Ashtray Illumination .....................................314

REMOVAL AND INSTALLATION ......................314

INSTALLATION .................................................314

BULB SPECIFICATIONS ........................................315

Headlamp .............................................................315

Exterior Lamp .......................................................315

Interior Lamp/Illumination .....................................315

Page 4434 of 5621

PRECAUTIONS

LT-7

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

General Precautions for Service OperationsNKS003NX

Never work with wet hands.

Xenon headlamp includes high voltage generating part. Be sure

to disconnect battery negative cable (negative terminal) or

power fuse before removing, installing, or touching the xenon

headlamp (including lamp bulb).

Turn the lighting switch OFF before disconnecting and connect-

ing the connector.

When turning the xenon headlamp on and while it is illuminated,

never touch the harness, bulb, and socket of the headlamp.

When checking the headlamp on/off operation, check it on vehi-

cle and with the power connected to the vehicle-side connector.

Do not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not

touch the headlamp bulb just after the headlamp is turned off, because it is very hot.

Install the xenon headlamp bulb socket correctly. If it is installed

improperly, high-voltage leak or corona discharge may occur

that can melt the bulb, connector, and housing. Do not illuminate

the xenon headlamp bulb out of the headlamp housing. Doing

so can cause fire and harm your eyes.

When the bulb has burned out, wrap it in a thick vinyl bag and

discard. Do not break the bulb.

Leaving the bulb removed from the headlamp housing for a long

period of time can deteriorate the performance of the lens and

reflector (dirt, clouding). Always prepare a new bulb and have it

on hand when replacing the bulb.

When adjusting the headlamp aiming, turn the aiming adjust-

ment screw only in the tightening direction. (If it is necessary to loosen the screw, first fully loosen the

screw, and then turn it in the tightening direction.)

Do not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

PKIA0183E

EL-3422D

Page 4456 of 5621

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-29

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

6. CHECK BULB

Check bulbs of lamp (both side).

OK or NG

OK >> Check connecting condition headlamp harness connector.

NG >> Replace headlamp bulb.

7. CHECK CIRCUIT BETWEEN IPDM E/R AND FRONT COMBINATION LAMP

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector (A) and

front combination lamp (RH and LH) harness connector (B).

4. Check harness continuity between IPDM E/R harness connector

(A) and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and Installation of IPDM E/R" .

NG >> Repair harness or connector.

CircuitAB

Continuity

Connector Terminal Connector Terminal

RH

E727 E47 6

Ye s

LH 28 E54 6

A

GroundContinuity

Connector Terminal

RH

E727

No

LH 28

SKIB4753E

Page 4457 of 5621

LT-30

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

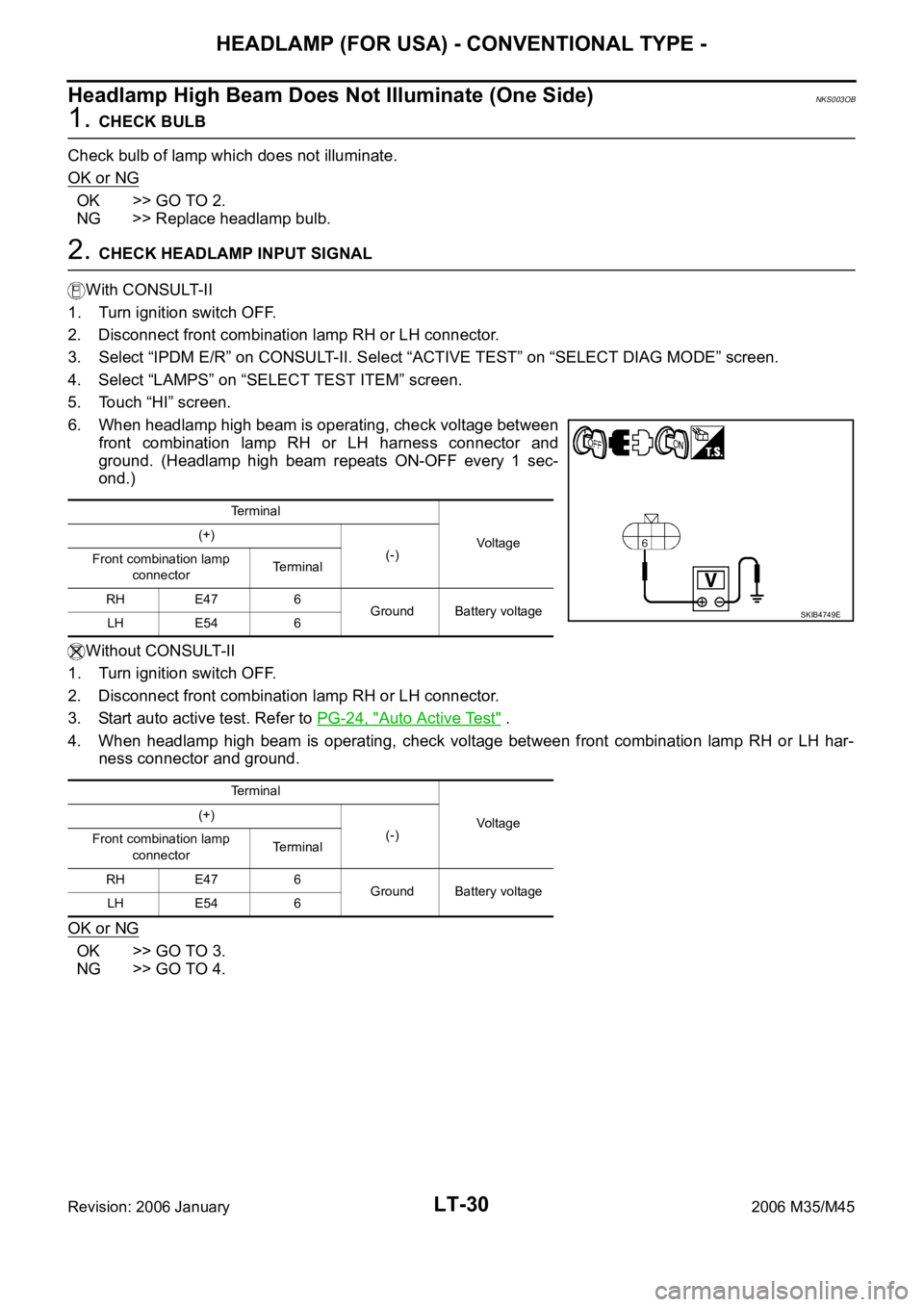

Headlamp High Beam Does Not Illuminate (One Side)NKS003OB

1. CHECK BULB

Check bulb of lamp which does not illuminate.

OK or NG

OK >> GO TO 2.

NG >> Replace headlamp bulb.

2. CHECK HEADLAMP INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “HI” screen.

6. When headlamp high beam is operating, check voltage between

front combination lamp RH or LH harness connector and

ground. (Headlamp high beam repeats ON-OFF every 1 sec-

ond.)

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Start auto active test. Refer to PG-24, "

Auto Active Test" .

4. When headlamp high beam is operating, check voltage between front combination lamp RH or LH har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

Terminal

Voltage (+)

(-)

Front combination lamp

connectorTerminal

RH E47 6

Ground Battery voltage

LH E54 6

Terminal

Voltage (+)

(-)

Front combination lamp

connectorTerminal

RH E47 6

Ground Battery voltage

LH E54 6

SKIB4749E

Page 4458 of 5621

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-31

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

3. CHECK HEADLAMP GROUND

1. Turn ignition switch OFF.

2. Check continuity between front headlamp RH or LH harness

connector and ground.

OK or NG

OK >> Check connecting condition headlamp harness and con-

nector.

NG >> Repair harness or connector.

4. CHECK CIRCUIT BETWEEN IPDM E/R AND FRONT COMBINATION LAMP

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front combination lamp RH or LH connector.

3. Check harness continuity between IPDM E/R harness connector

(A) and front combination lamp RH or LH harness connector (B).

4. Check harness continuity between IPDM E/R harness connector

(A) and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and Installation of IPDM E/R" .

NG >> Repair harness or connector.

High Beam Indicator Lamp Does Not IlluminateNKS003OC

1. CHECK BULB

Check bulb of high beam indicator lamp.

OK or NG

OK >> Replace combination meter.

NG >> Replace indicator bulb.

Front combination lamp

connectorTe r m i n a l

GroundContinuity

RH E47 2

Ye s

LH E54 2

SKIB4750E

CircuitAB

Continuity

Connector Terminal Connector Terminal

RH

E727 E47 6

Ye s

LH 28 E54 6

A

GroundContinuity

Connector Terminal

RH

E727

No

LH 28

SKIB4753E

Page 4462 of 5621

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-35

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Headlamp Low Beam Does Not Illuminate (One Side)NKS003OE

1. CHECK BULB

Check bulb of lamp which does not illuminate.

OK or NG

OK >> GO TO 2.

NG >> Replace headlamp bulb.

2. CHECK HEADLAMP INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “LO” screen.

6. When headlamp low beam is operating, check voltage between

headlamp RH or LH harness connector and ground.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp RH or LH connector.

3. Start auto active test. Refer to PG-24, "

Auto Active Test" .

4. When headlamp low beam is operating, check voltage between headlamp RH or LH harness connector

and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

Te r m i n a l

Voltage (+)

(-)

Front combination lamp

connectorterminal

RH E47 8

Ground Battery voltage

LH E54 8

Terminal

Voltag e (+)

(-)

Front combination lamp

connectorterminal

RH E47 8

Ground Battery voltage

LH E54 8

SKIB4758E

Page 4466 of 5621

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-39

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aiming.

Use the aiming chart shown in the figure.

Basic illumination area for adjustment should be within the range shown on the aiming chart.

Adjust headlamp accordingly.

Bulb ReplacementNKS003OH

HEADLAMP (INNER) HIGH BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

4. Remove washer tank inlet when replacing bulb RH. Refer to WW-47, "

Removal and Installation of Washer

Ta n k" .

5. Turn plastic cap counterclockwise and unlock it.

6. Turn bulb socket counterclockwise and unlock it.

7. Disconnect connector, and remove bulb.

SKIB4153E

Headlamp (inner) high beam : 12V - 60W (HB3)

Page 4467 of 5621

LT-40

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

HEADLAMP (OUTER) LOW BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove fender protector (front). Refer to EI-20, "

Removal and Installation" .

4. Turn plastic cap counterclockwise and unlock it.

5. Unlock retaining spring and remove bulb from headlamp.

6. Remove the socket connected the bulb.

PARKING LAMP (CLEARANCE) LAMP

1. Turn bulb socket counterclockwise and unlock it.

2. Remove bulb from its socket.

FRONT TURN SIGNAL LAMP

1. Remove washer tank inlet when replaced bulb RH. Refer to WW-47, "Removal and Installation of Washer

Ta n k" .

Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from its socket.

FRONT SIDE MARKER LAMP

1. Remove fender protector (front) to obtain work space between the fender protector and fender.

2. Turn bulb socket counterclockwise and unlock it.

3. Remove bulb from its socket.

CAUTION:

After installing bulb, be sure to install plastic cap and socket securely to insure watertightness. Headlamp (outer) low beam : 12V - 55W (H1)

Parking lamp (Clearance lamps) : 12V - 5W

Front turn signal lamp : 12V - 21W

Front side marker lamp : 12V - 5W

Page 4469 of 5621

LT-42

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

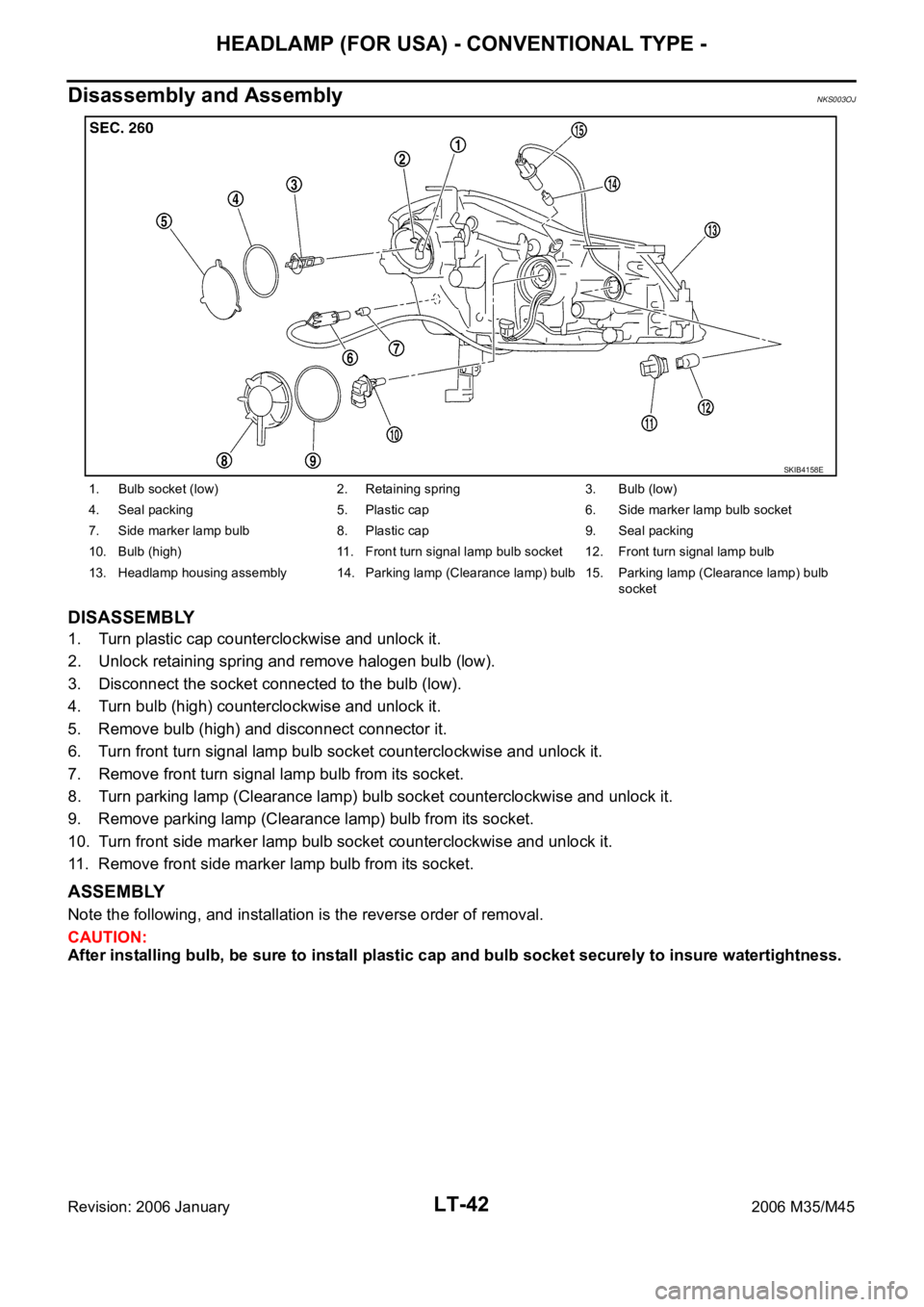

Disassembly and AssemblyNKS003OJ

DISASSEMBLY

1. Turn plastic cap counterclockwise and unlock it.

2. Unlock retaining spring and remove halogen bulb (low).

3. Disconnect the socket connected to the bulb (low).

4. Turn bulb (high) counterclockwise and unlock it.

5. Remove bulb (high) and disconnect connector it.

6. Turn front turn signal lamp bulb socket counterclockwise and unlock it.

7. Remove front turn signal lamp bulb from its socket.

8. Turn parking lamp (Clearance lamp) bulb socket counterclockwise and unlock it.

9. Remove parking lamp (Clearance lamp) bulb from its socket.

10. Turn front side marker lamp bulb socket counterclockwise and unlock it.

11. Remove front side marker lamp bulb from its socket.

ASSEMBLY

Note the following, and installation is the reverse order of removal.

CAUTION:

After installing bulb, be sure to install plastic cap and bulb socket securely to insure watertightness.

1. Bulb socket (low) 2. Retaining spring 3. Bulb (low)

4. Seal packing 5. Plastic cap 6. Side marker lamp bulb socket

7. Side marker lamp bulb 8. Plastic cap 9. Seal packing

10. Bulb (high) 11. Front turn signal lamp bulb socket 12. Front turn signal lamp bulb

13. Headlamp housing assembly 14. Parking lamp (Clearance lamp) bulb 15. Parking lamp (Clearance lamp) bulb

socket

SKIB4158E