bulb INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 122 of 5621

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-43

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-103, "

OBD-II SELF-DIAGNOSTIC PROCEDURE (WITH GST)" . (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Select Mode 4 with GST (Generic Scan Tool). For details, refer to EC-146, "

Generic Scan Tool (GST)

Function" (for VQ35DE engine), EC-859, "Generic Scan Tool (GST) Function" (for VK45DE engine).

HOW TO ERASE DTC (NO TOOLS)

The A/T CHECK indicator lamp is located on the instrument panel.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform AT-103, "

TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)" . (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Perform “OBD-II SELF-DIAGNOSTIC PROCEDURE (No tools)”. Refer to EC-67, "

How to Erase DTC"

(for VQ35DE engine), EC-778, "How to Erase DTC" (for VK45DE engine).

Malfunction Indicator Lamp (MIL)NCS001K1

DESCRIPTION

The MIL is located on the combination meters.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-40, "WARNING LAMPS" ,

or see EC-722, "

MIL AND DATA LINK CONNECTOR" (for

VQ35DE engine), EC-1459, "

MIL AND DATA LINK CONNEC-

TOR" (for VK45DE engine).

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

SEF217U

Page 1612 of 5621

![INFINITI M35 2006 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-69

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

–Te s t v a l u e s

Actual work procedures are explained using a DTC as an example. Be INFINITI M35 2006 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-69

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

–Te s t v a l u e s

Actual work procedures are explained using a DTC as an example. Be](/img/42/57023/w960_57023-1611.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-69

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

–Te s t v a l u e s

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)NBS004SO

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-40, "

WARNING LAMPS" ,

or see EC-722, "

MIL AND DATA LINK CONNECTOR" .

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

SEF217U

Diagnostic Test

ModeKEY and ENG.

StatusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MIL bulb for damage (blown,

open circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When a malfunction is

detected twice in two consecutive driving cycles (two trip

detection logic), the MIL will light up to inform the driver

that a malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

Misfire (Possible three way catalyst damage)

One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Page 1613 of 5621

![INFINITI M35 2006 Factory Service Manual EC-70

[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

MIL Flashing Without DTC

When any SRT codes are not set, MIL may flash without DTC. For the details, refer to EC-62, INFINITI M35 2006 Factory Service Manual EC-70

[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

MIL Flashing Without DTC

When any SRT codes are not set, MIL may flash without DTC. For the details, refer to EC-62,](/img/42/57023/w960_57023-1612.png)

EC-70

[VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

MIL Flashing Without DTC

When any SRT codes are not set, MIL may flash without DTC. For the details, refer to EC-62, "How to Display

SRT Status" .

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

It is better to count the time accurately with a clock.

It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MIL starts

blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL may start blinking on the halfway of this

10 seconds. This blinking is displaying SRT status and is continued for another 10 seconds. For

the details, refer to EC-62, "

How to Display SRT Status" .

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

NOTE:

Wait until the same DTC (or 1st trip DTC) appears to confirm all DTCs certainly.

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer to EC-70, "How to Set Diagnostic Test

Mode II (Self-diagnostic Results)" .

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MIL on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to DI-

40, "WARNING LAMPS" or see EC-722, "MIL AND DATA LINK CONNECTOR" .

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

This DTC number is clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

PBIB0092E

MIL Condition

ON When the malfunction is detected.

OFF No malfunction.

Page 2323 of 5621

![INFINITI M35 2006 Factory Service Manual EC-780

[VK45DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

–Test values

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, INFINITI M35 2006 Factory Service Manual EC-780

[VK45DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

–Test values

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC,](/img/42/57023/w960_57023-2322.png)

EC-780

[VK45DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Revision: 2006 January2006 M35/M45

–Test values

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)NBS005A4

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-40, "

WARNING LAMPS" ,

or see EC-1459, "

MIL AND DATA LINK CONNECTOR" .

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

SEF217U

Diagnostic Test

ModeKEY and ENG.

Sta tusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MIL bulb for damage (blown,

open circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When a malfunction is

detected twice in two consecutive driving cycles (two trip

detection logic), the MIL will light up to inform the driver

that a malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

Misfire (Possible three way catalyst damage)

One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Page 2324 of 5621

![INFINITI M35 2006 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-781

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

MIL Flashing Without DTC

When any SRT codes are not set, MIL may flash without DTC. For th INFINITI M35 2006 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-781

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

MIL Flashing Without DTC

When any SRT codes are not set, MIL may flash without DTC. For th](/img/42/57023/w960_57023-2323.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-781

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

MIL Flashing Without DTC

When any SRT codes are not set, MIL may flash without DTC. For the details, refer to EC-773, "How to Dis-

play SRT Status" .

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

It is better to count the time accurately with a clock.

It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MIL starts

blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL may start blinking on the halfway of this

10 seconds. This blinking is displaying SRT status and is continued for another 10 seconds. For

the details, refer to EC-773, "

How to Display SRT Status" .

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

NOTE:

Wait until the same DTC (or 1st trip DTC) appears to confirm all DTCs certainly.

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer to EC-781, "How to Set Diagnostic

Test Mode II (Self-diagnostic Results)" .

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MIL on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to DI-

40, "WARNING LAMPS" or see EC-1459, "MIL AND DATA LINK CONNECTOR" .

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

This DTC number is clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MIL as shown below.

PBIB0092E

MIL Condition

ON When the malfunction is detected.

OFF No malfunction.

Page 3497 of 5621

GI-34

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Revision: 2006 January2006 M35/M45

If repairs are needed always use wire that is of the same or larger gauge.

MEASURING VOLTAGE DROP — ACCUMULATED METHOD

Connect the DMM across the connector or part of the circuit you want to check. The positive lead of the

DMM should be closer to power and the negative lead closer to ground.

Operate the circuit.

The DMM will indicate how many volts are being used to “push” current through that part of the circuit.

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

MEASURING VOLTAGE DROP — STEP-BY-STEP

The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those in

“Computer Controlled Systems”).

Circuits in the “Computer Controlled System” operate on very low amperage.

The (Computer Controlled) system operations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

SGI974

SAIA0258E

Page 3643 of 5621

IDX-2

ALPHABETICAL INDEX

A

A/C air flow ...................................................... ATC-37

A/C component layout ..................................... ATC-25

A/C compressor mounting ........... ATC-155, ATC-158,

ATC-159

, ATC-160, ATC-162, ATC-164, ATC-165,

ATC-167

, ATC-168, ATC-169

A/C compressor precaution ............................. ATC-12

A/C compressor special service tool ................ ATC-16

A/C control operation (auto A/C) ...................... ATC-33

A/C diagnostic work flow (auto A/C) .............. ATC-111

A/C evaporator ............................................... ATC-168

A/C HFC134a (R134a) system precaution ........ ATC-6

A/C HFC134a (R134a) system service procedure .......

ATC-151

A/C HFC134a (R134a) system service tools ... ATC-17

A/C HFC134a system service equipment precaution ...

ATC-13

A/C lubricant (R134a) ...................................... ATC-26

A/C lubrication oil ........................................... ATC-174

A/C operational check ...................................... ATC-64

A/C self-diagnoses (auto A/C) ........ ATC-55, ATC-111

A/C service data specification ........................ ATC-174

A/C system description (auto A/C) ................... ATC-29

A/C trouble diagnoses (auto A/C) .................... ATC-40

A/C, A - Wiring diagram ................................... ATC-46

A/T fluid checking ...................... AT-13, AT-53, MA-29

A/T fluid cooler cleaning .................................... AT-14

A/T fluid replacement ............................. AT-12, MA-31

A/T fluid temperature sensor ........................... AT-135

A/T IND - Wiring diagram .................................... DI-57

A/T self-diagnoses ............................... AT-92, AT-103

A/T shift lock system ........................................ AT-229

A/T shift lock system - Wiring diagram ............ AT-230

A/T trouble diagnoses ........................................ AT-44

Accelerator control system ............................... ACC-3

Accelerator pedal position (APP) sensor ........ EC-626,

EC-633

, EC-647, EC-1358, EC-1365, EC-1379

Accelerator pedal released position learning .... EC-95,

EC-806

AF1B1-Wiring diagram ...... EC-249, EC-258, EC-267,

EC-277

, EC-657, EC-972, EC-981, EC-990, EC-1000,

EC-1389

AF1B2-Wiring diagram ...... EC-251, EC-260, EC-269,

EC-279

, EC-659, EC-974, EC-983, EC-992, EC-1002,

EC-1391

AF1HB1-Wiring diagram .................... EC-183, EC-905

AF1HB2-Wiring diagram .................... EC-185, EC-907

Air bag .............................................................. SRS-3

Air bag precautions ........................................... SRS-3

Air cleaner and air duct(VK45DE) ................... EM-177

Air cleaner and air duct(VQ35DE) .................... EM-17

Air cleaner filter replacement ............................ MA-25

Air cleaner filter replacement(VQ35DE) ........... MA-18

Air cleaner filter(VQ35DE) ................................ EM-18

Air conditioner cut control .................... EC-35, EC-745

Air flow meter - See Mass air flow sensor ...... EC-205,

EC-214

, EC-927, EC-936

Air fuel ratio sensor 1 ......... EC-246, EC-256, EC-265, EC-274

, EC-655, EC-969, EC-979, EC-988, EC-997,

EC-1387

Air fuel ratio sensor 1 heater ............. EC-182, EC-904

Air mix. door motor ......................... ATC-83, ATC-141

Alternator ........................................................... SC-23

Ambient sensor ............................. ATC-113, ATC-126

Angular tightening application ............................. EM-6

Angular tightening application(VK45DE) ........ EM-164

APPS1 - Wiring diagram ................. EC-628, EC-1360

APPS2 - Wiring diagram ................. EC-635, EC-1367

APPS3 - Wiring diagram ................. EC-649, EC-1381

ASC/BS - Wiring diagram ............... EC-587, EC-1313

ASC/SW - Wiring diagram .............. EC-570, EC-1296

ASCBOF - Wiring diagram .............. EC-708, EC-1450

ASCD .................................................. EC-36, EC-746

ASCD (automatic speed control device) ........... ACS-3

ASCIND - Wiring diagram ............... EC-715, EC-1457

AT indicator lamp ................................................ DI-56

Auto air conditioner - Wiring diagram ............. ATC-46

Auto amp ...................................................... ATC-125

Auto anti-dazzling inside mirror .......... GW-71, GW-72

Automatic amplifier ........... ATC-53, ATC-66, ATC-125

Automatic transmission fluid replacement ........ MA-32

AWD - Wiring diagram ....................................... TF-17

Axle ................................................................... MA-37

B

Back-up lamp ................................................... LT-246

Basic inspection .................................. EC-77, EC-788

Battery ................................................................. SC-4

Battery current sensor ....... EC-537, EC-543, EC-549,

EC-555

, EC-1263, EC-1269, EC-1275, EC-1281

Battery/Starting/Charging System Tester .......... SC-28

Battery/Starting/Charging System Tester(Battery) SC-7

Battery/Starting/Charging System Tester(Starting

system) .............................................................. SC-13

BCM (Body control module) .............................. BCS-3

Block heater(VK45DE) .................................... EM-249

Block heater(VQ35DE) ................................... EM-123

Blower motor ................................... ATC-89, ATC-132

Blower unit .................................................... ATC-130

Brake fluid level ................................................ MA-35

Brake hydraulic line ........................................... BR-12

Brake inspection ............................................... MA-36

Brake lines and cables inspection .................... MA-35

Brake pedal .......................................................... BR-6

Brake switch ................................... EC-598, EC-1329

BRK/SW - Wiring diagram .............. EC-600, EC-1331

Bulb specifications ........................................... LT-315

Bumper, front ...................................................... EI-11

Bumper, rear ....................................................... EI-14

C

Camshaft inspection(VK45DE) ....................... EM-216

Camshaft inspection(VQ35DE) ......................... EM-86

Camshaft position sensor (PHASE) EC-383, EC-1106

Camshaft(VK45DE) ........................................ EM-215

Page 4428 of 5621

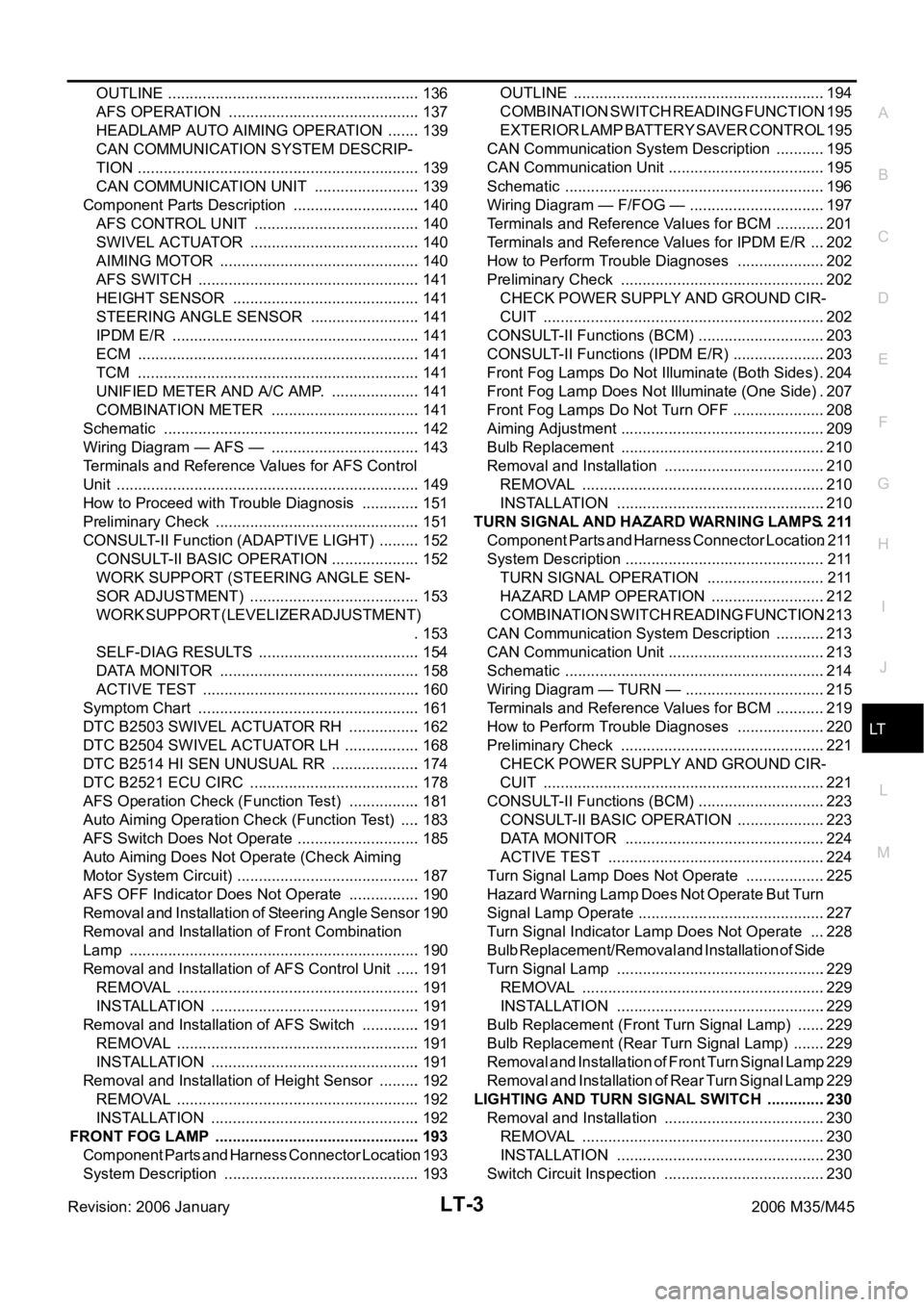

LT-1

LIGHTING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION LT

A

B

LT

Revision: 2006 January2006 M35/M45

LIGHTING SYSTEM

PRECAUTIONS .......................................................... 6

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 6

General Precautions for Service Operations ............ 7

HEADLAMP (FOR USA) - CONVENTIONAL TYPE - ..... 8

Component Parts and Harness Connector Location ..... 8

System Description .................................................. 8

OUTLINE ............................................................... 9

HEADLAMP OPERATION .................................. 10

COMBINATION SWITCH READING FUNCTION .... 11

EXTERIOR LAMP BATTERY SAVER CONTROL .... 11

AUTO LIGHT OPERATION .................................. 11

CAN Communication System Description ............... 11

CAN Communication Unit ....................................... 11

Schematic .............................................................. 12

Wiring Diagram — H/LAMP — ............................... 13

Terminals and Reference Values for BCM ............. 18

Terminals and Reference Values for IPDM E/R ..... 20

How to Perform Trouble Diagnoses ....................... 20

Preliminary Check .................................................. 20

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 20

CONSULT-II Functions (BCM) ............................... 22

CONSULT-II BASIC OPERATION ....................... 22

DATA MONITOR ................................................. 23

ACTIVE TEST ..................................................... 24

CONSULT-II Functions (IPDM E/R) ....................... 25

CONSULT-II BASIC OPERATION ....................... 25

DATA MONITOR ................................................. 26

ACTIVE TEST ..................................................... 26

Headlamp High Beam Does Not Illuminate (Both

Sides) ..................................................................... 27

Headlamp High Beam Does Not Illuminate (One

Side) ....................................................................... 30

High Beam Indicator Lamp Does Not Illuminate .... 31

Headlamp Low Beam Does Not Illuminate (Both

Sides) ..................................................................... 32

Headlamp Low Beam Does Not Illuminate (One

Side) ....................................................................... 35Headlamps Do Not Turn OFF ................................. 37

Aiming Adjustment .................................................. 38

PREPARATION BEFORE ADJUSTING .............. 38

LOW BEAM AND HIGH BEAM ........................... 38

ADJUSTMENT USING AN ADJUSTMENT

SCREEN (LIGHT/DARK BORDERLINE) ............ 39

Bulb Replacement .................................................. 39

HEADLAMP (INNER) HIGH BEAM ..................... 39

HEADLAMP (OUTER) LOW BEAM .................... 40

PARKING LAMP (CLEARANCE) LAMP .............. 40

FRONT TURN SIGNAL LAMP ............................ 40

FRONT SIDE MARKER LAMP ........................... 40

Removal and Installation ........................................ 41

REMOVAL ........................................................

... 41

INSTALLATION ................................................... 41

Disassembly and Assembly .................................... 42

DISASSEMBLY ................................................... 42

ASSEMBLY ......................................................... 42

HEADLAMP (FOR USA) - XENON TYPE - .............. 43

Component Parts and Harness Connector Location ... 43

System Description ................................................. 43

OUTLINE ............................................................. 44

HEADLAMP OPERATION ................................... 45

COMBINATION SWITCH READING FUNCTION ... 46

EXTERIOR LAMP BATTERY SAVER CONTROL ... 46

AUTO LIGHT OPERATION ................................. 46

XENON HEADLAMP ........................................... 46

CAN Communication System Description .............. 46

CAN Communication Unit ....................................... 46

Schematic ............................................................... 47

Wiring Diagram — H/LAMP — ............................... 48

Terminals and Reference Values for BCM .............. 53

Terminals and Reference Values for IPDM E/R ...... 55

How to Perform Trouble Diagnoses ....................... 55

Preliminary Check .................................................. 55

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 55

CONSULT-II Functions (BCM) ................................ 57

CONSULT-II BASIC OPERATION ....................... 57

DATA MONITOR ................................................. 58

Page 4429 of 5621

LT-2Revision: 2006 January2006 M35/M45 ACTIVE TEST ..................................................... 59

CONSULT-II Functions (IPDM E/R) ........................ 60

CONSULT-II BASIC OPERATION ....................... 60

DATA MONITOR .................................................. 61

ACTIVE TEST ..................................................... 61

Headlamp High Beam Does Not Illuminate (Both

Sides) ..................................................................... 62

Headlamp High Beam Does Not Illuminate (One

Side) ....................................................................... 65

High Beam Indicator Lamp Does Not Illuminate ..... 66

Headlamp Low Beam Does Not Illuminate (Both

Sides) ..................................................................... 67

Headlamp Low Beam Does Not Illuminate (One

Side) ....................................................................... 70

Headlamps Do Not Turn OFF ................................. 72

General Information for Xenon Headlamp Trouble

Diagnosis ................................................................ 73

Caution: .................................................................. 73

Xenon Headlamp Trouble Diagnosis ...................... 73

Aiming Adjustment .................................................. 74

PREPARATION BEFORE ADJUSTING .............. 74

LOW BEAM AND HIGH BEAM ........................... 74

ADJUSTMENT USING AN ADJUSTMENT

SCREEN (LIGHT/DARK BORDERLINE) ............ 75

Bulb Replacement ...............................................

... 75

HEADLAMP (INNER) HIGH BEAM ..................... 75

HEADLAMP (OUTER) LOW BEAM .................... 76

PARKING LAMP (CLEARANCE LAMP) .............. 76

FRONT TURN SIGNAL LAMP ............................ 76

FRONT SIDE MARKER LAMP ............................ 76

Removal and Installation ........................................ 76

Disassembly and Assembly .................................... 77

DISASSEMBLY ................................................... 77

ASSEMBLY ......................................................... 78

HEADLAMP (FOR CANADA) - DAYTIME LIGHT

SYSTEM - .................................................................. 79

Component Parts and Harness Connector Location ... 79

System Description ................................................. 79

OUTLINE ............................................................. 80

HEADLAMP OPERATION ................................... 81

DAYTIME LIGHT OPERATION ........................... 82

COMBINATION SWITCH READING FUNCTION ... 82

AUTO LIGHT OPERATION ................................. 82

CAN Communication System Description .............. 82

Schematic ............................................................... 83

Wiring Diagram — DTRL — ................................... 84

Terminals and Reference Values for BCM .............. 89

Terminals and Reference Values for IPDM E/R ...... 91

How to Perform Trouble Diagnosis ......................... 91

Preliminary Check .................................................. 92

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ............................................. 92

INSPECTION FOR PARKING BRAKE SWITCH

CIRCUIT .............................................................. 93

CONSULT-II Functions (BCM) ................................ 94

CONSULT-II BASIC OPERATION ....................... 94

DATA MONITOR .................................................. 95

ACTIVE TEST ..................................................... 96

CONSULT-II Functions (IPDM E/R) ........................ 97CONSULT-II BASIC OPERATION ....................... 97

DATA MONITOR .................................................. 98

ACTIVE TEST ...................................................... 98

Daytime Light Control Does Not Operate Properly

(Normal Headlamps Operate Properly) .................. 99

Headlamp High Beam Does Not Illuminate (Both

Sides) ....................................................................102

RH High Beam Does Not Illuminate But LH High

Beam Illuminates ..................................................105

LH High Beam Does Not Illuminate But RH High

Beam Illuminates ..................................................107

Headlamp Low Beam Does Not Illuminate (Both

Sides) ....................................................................109

Headlamp Low Beam Does Not Illuminate (One

Side) ......................................................................112

Headlamps Do Not Turn OFF ...............................114

General Information for Xenon Headlamp Trouble

Diagnosis ..............................................................115

CAUTION: .............................................................115

Xenon Headlamp Trouble Diagnosis ....................115

Aiming Adjustment ................................................115

Bulb Replacement .................................................115

Removal and Installation .......................................115

Disassembly and Assembly ..................................115

AUTO LIGHT SYSTEM ...........................................116

Component Parts and Harness Connector Location .116

System Description ...............................................116

OUTLINE ...........................................................116

COMBINATION SWITCH READING FUNCTION .117

EXTERIOR LAMP BATTERY SAVER CONTROL .117

DELAY TIMER FUNCTION ................................117

CAN Communication System Description ............117

CAN Communication Unit .....................................117

Major Components and Functions ........................117

Schematic .............................................................118

Wiring Diagram — AUTO/L — ..............................119

Terminals and Reference Values for BCM ............123

Terminals and Reference Values for IPDM E/R ....125

How to Perform Trouble Diagnoses ......................125

Preliminary Check .................................................126

SETTING CHANGE FUNCTIONS .....................126

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ...................................................................126

CONSULT-II Functions (BCM) .............................

.127

CONSULT-II BASIC OPERATION .....................127

WORK SUPPORT .............................................128

DATA MONITOR ................................................129

ACTIVE TEST ....................................................130

Symptom Chart .....................................................130

Lighting Switch Inspection ....................................131

Optical Sensor System Inspection ........................131

Removal and Installation for Optical Sensor .........133

REMOVAL ..........................................................133

INSTALLATION ..................................................133

ACTIVE AFS ............................................................134

Component Parts and Harness Connector Location .134

System Description ...............................................135

AFS (ADAPTIVE FRONT-LIGHTING SYSTEM) .135

HEADLAMP AUTO AIMING ..............................136

Page 4430 of 5621

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45 OUTLINE ...........................................................136

AFS OPERATION .............................................137

HEADLAMP AUTO AIMING OPERATION ........139

CAN COMMUNICATION SYSTEM DESCRIP-

TION ..................................................................139

CAN COMMUNICATION UNIT .........................139

Component Parts Description ..............................140

AFS CONTROL UNIT .......................................140

SWIVEL ACTUATOR ........................................140

AIMING MOTOR ...............................................140

AFS SWITCH ....................................................141

HEIGHT SENSOR ............................................141

STEERING ANGLE SENSOR ..........................141

IPDM E/R ..........................................................141

ECM ..................................................................141

TCM ..................................................................141

UNIFIED METER AND A/C AMP. .....................141

COMBINATION METER ...................................141

Schematic ............................................................142

Wiring Diagram — AFS — ...................................143

Terminals and Reference Values for AFS Control

Unit .......................................................................149

How to Proceed with Trouble Diagnosis ..............151

Preliminary Check ................................................151

CONSULT-II Function (ADAPTIVE LIGHT) ..........152

CONSULT-II BASIC OPERATION .....................152

WORK SUPPORT (STEERING ANGLE SEN-

SOR ADJUSTMENT) ........................................153

WORK SUPPORT (LEVELIZER ADJUSTMENT)

.153

SELF-DIAG RESULTS ......................................154

DATA MONITOR ...............................................158

ACTIVE TEST ...................................................160

Symptom Chart ....................................................161

DTC B2503 SWIVEL ACTUATOR RH .................162

DTC B2504 SWIVEL ACTUATOR LH ..................168

DTC B2514 HI SEN UNUSUAL RR .....................174

DTC B2521 ECU CIRC ........................................178

AFS Operation Check (Function Test) .................181

Auto Aiming Operation Check (Function Test) .....183

AFS Switch Does Not Operate .............................185

Auto Aiming Does Not Operate (Check Aiming

Motor System Circuit) ..........................................

.187

AFS OFF Indicator Does Not Operate .................190

Removal and Installation of Steering Angle Sensor .190

Removal and Installation of Front Combination

Lamp ....................................................................190

Removal and Installation of AFS Control Unit ......191

REMOVAL ........................................................

.191

INSTALLATION .................................................191

Removal and Installation of AFS Switch ..............191

REMOVAL ........................................................

.191

INSTALLATION .................................................191

Removal and Installation of Height Sensor ..........192

REMOVAL ........................................................

.192

INSTALLATION .................................................192

FRONT FOG LAMP ................................................193

Component Parts and Harness Connector Location .193

System Description ..............................................193OUTLINE ...........................................................194

COMBINATION SWITCH READING FUNCTION .195

EXTERIOR LAMP BATTERY SAVER CONTROL .195

CAN Communication System Description ............195

CAN Communication Unit .....................................195

Schematic .............................................................196

Wiring Diagram — F/FOG — ................................197

Terminals and Reference Values for BCM ............201

Terminals and Reference Values for IPDM E/R ....202

How to Perform Trouble Diagnoses .....................202

Preliminary Check ................................................202

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................202

CONSULT-II Functions (BCM) ..............................203

CONSULT-II Functions (IPDM E/R) ......................203

Front Fog Lamps Do Not Illuminate (Both Sides) . 204

Front Fog Lamp Does Not Illuminate (One Side) . 207

Front Fog Lamps Do Not Turn OFF ......................208

Aiming Adjustment ................................................209

Bulb Replacement ................................................210

Removal and Installation ......................................210

REMOVAL ........................................................

.210

INSTALLATION .................................................210

TURN SIGNAL AND HAZARD WARNING LAMPS .211

Component Parts and Harness Connector Location .211

System Description ...............................................211

TURN SIGNAL OPERATION ............................211

HAZARD LAMP OPERATION ...........................212

COMBINATION SWITCH READING FUNCTION .213

CAN Communication System Description ............213

CAN Communication Unit .....................................213

Schematic .............................................................214

Wiring Diagram — TURN — .................................215

Terminals and Reference Values for BCM ............219

How to Perform Trouble Diagnoses .....................220

Preliminary Check ................................................221

CHECK POWER SUPPLY AND GROUND CIR-

CUIT ..................................................................221

CONSULT-II Functions (BCM) ..............................223

CONSULT-II BASIC OPERATION .....................223

DATA MONITOR ...............................................224

ACTIVE TEST ...................................................224

Turn Signal Lamp Does Not Operate ...................225

H a z a r d W a r n i n g L a m p D o e s N o t O p e r a t e B u t T u r n

Signal Lamp Operate ............................................227

Turn Signal Indicator Lamp Does Not Operate ....228

Bulb Replacement/Removal and Installation of Side

Turn Signal Lamp .................................................229

REMOVAL ........................................................

.229

INSTALLATION .................................................229

Bulb Replacement (Front Turn Signal Lamp) .......229

Bulb Replacement (Rear Turn Signal Lamp) ........229

Removal and Installation of Front Turn Signal Lamp .229

Removal and Installation of Rear Turn Signal Lamp .229

LIGHTING AND TURN SIGNAL SWITCH ..............230

Removal and Installation ......................................230

REMOVAL ........................................................

.230

INSTALLATION .................................................230

Switch Circuit Inspection ......................................230