flat tire INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5535 of 5621

WT-10

LOW TIRE PRESSURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

RECEIVER

The receiver receives the air pressure signal transmitted by the transmitter in each wheel.

LOW TIRE PRESSURE WARNING CONTROL UNIT

The low tire pressure warning control unit (1) reads the air pressure

signal received by the receiver, and controls the low tire pressure

warning lamp and the buzzer operations. It also has a judgement

function to detect a system malfunction.

LOW TIRE PRESSURE WARNING LAMP

The combination meter receives tire pressure status from the low tire

pressure warning control unit using CAN communication. When a

low tire pressure condition is sensed by the low tire pressure control

unit, the combination meter low tire pressure warning lamp and

buzzer are activated.

Low Tire Pressure Warning Lamp Indication

*: Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicle. 1. Tire pressure receiver front 2. Tire pressure receiver rear A. Front wheel house

B. Rear wheel house

Refer to GI-11, "

Components" , for the symbols in the figure.

SEIA0649E

SEIA0650E

SEIA0434E

ConditionLow tire pressure warning

lampBuzzer

Less than 186 kPa

(1.86 kg/cm

2 , 27 psi) [Flat tire]*ON Sounds for 10 sec.

Low tire pressure warning system malfunction [Other diagnostic item]Warning lamp flashes 1 min,

then turns ONOFF

Page 5545 of 5621

WT-20

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

ID REGISTRATION WITHOUT ACTIVATION TOOL

This procedure must be done after replacement of a tire pressure transmitter, low tire pressure warn-

ing control unit, or tire rotation.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunction might be detected

during self-diagnosis depending on control unit which performs CAN communication.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)” “AIR PRESSURE MONITOR”.

If “AIR PRESSURE MONITOR” is not displayed, print the “SELECT SYSTEM” screen. Then refer to

LAN-7, "

Precautions When Using CONSULT-II" .

NOTE:

Just after starting engine, or turning ignition switch ON, it may not be displayed even if “START (NIS-

SAN BASED VHCL)” is touched. In this case, reconnect CONSULT-II and CONSULT-II CONVERTER.

5. Touch “WORK SUPPORT” on “SELECT DIAG MODE” screen.

6. Touch “ID REGIST” on “SELECT WORK ITEM”.

7. Adjust the tire pressure to the values shown in the table below for ID registration, and drive the vehicle at

40 km/h (25 MPH) or more for a few minutes.

8. After completing all ID registrations, press “END” to complete the procedure.

9. Inflate all tires to proper pressure. Refer to WT-41, "

SERVICE DATA AND SPECIFICATIONS (SDS)" .

Tire position

Tire pressure kPa (kg/cm2 , psi)

Front

Left 240 (2.4, 34)

Front

Right 220 (2.2, 31)

Rear

Right 200 (2.0, 29)

Rear

Left 180 (1.8, 26)

Activation tire position CONSULT-II

Front LH

“YET”

“DONE” Front RH

Rear RH

Rear LH

Page 5547 of 5621

WT-22

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

WORK SUPPORT MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Perform the “ID Regist”. Refer to WT-19, "

ID Registration Procedure" .

SELF-DIAG RESULT MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. The self-diagnostic results are displayed. (Touch “PRINT” to print out the self-diagnostic results if neces-

sary.) Check low tire pressure warning lamp if “NO FAILURE” is displayed.

3. Perform the appropriate inspection from the display item list, and repair or replace the malfunctioning

component. Refer to WT-22, "

Display Item List" .

Display Item List

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-II.DTC Diagnostic item Diagnostic item is detected when ꞏꞏꞏ Check items

C1700 FLAT_TIRE_FLFront-left tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

— C1701 FLAT_TIRE_FRFront-right tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

C1702 FLAT_TIRE_RRRear-right tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

C1703 FLAT_TIRE_RLRear-left tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

C1708 [NO_DATA]_FL Data from front-left transmitter cannot be received.

WT-30

C1709 [NO_DATA]_FR Data from front-right transmitter cannot be received.

C1710 [NO_DATA]_RR Data from rear-right transmitter cannot be received.

C1711 [NO_DATA]_RL Data from rear-left transmitter cannot be received.

C1716 [PRESSDATA_ERR]_FL Air pressure data from front-left transmitter is malfunctioning.

WT-32

C1717 [PRESSDATA_ERR]_FR Air pressure data from front-right transmitter is malfunctioning.

C1718 [PRESSDATA_ERR]_RR Air pressure data from rear-right transmitter is malfunctioning.

C1719 [PRESSDATA_ERR]_RL Air pressure data from rear-left transmitter is malfunctioning.

C1720 [CODE_ERROR]_FL Function code data from front-left transmitter is malfunctioning.

WT-32

C1721 [CODE_ERROR]_FR Function code data from front-right transmitter is malfunctioning.

C1722 [CODE_ERROR]_RR Function code data from rear-right transmitter is malfunctioning.

C1723 [CODE_ERROR]_RL Function code data from rear-left transmitter is malfunctioning.

C1724 [BATT_VOLT_LOW]_FL Battery voltage of front-left transmitter drops.

WT-33

C1725 [BATT_VOLT_LOW]_FR Battery voltage of front-right transmitter drops.

C1726 [BATT_VOLT_LOW]_RR Battery voltage of rear-right transmitter drops.

C1727 [BATT_VOLT_LOW]_RL Battery voltage of rear-left transmitter drops.

C1728 RECEIVER_ID_NO_REG ID registration of receiver is not completed.WT-33

C1729 VHCL_SPEED_SIG_ERR Vehicle speed signal is error.WT-34

C1750 [RECEIVER_ERR]_FL Data from front-left receiver cannot be received.

WT-31

C1751 [RECEIVER_ERR]_FR Data from front-right receiver cannot be received.

C1752 [RECEIVER_ERR]_RR Data from rear-right receiver cannot be received.

C1753 [RECEIVER_ERR]_RL Data from rear-left receiver cannot be received.

U1000 CAN COMM CIRCUITWhen a control unit (except for low tire pressure) is not transmit-

ting or receiving CAN communication signal 2 seconds or less. WT-34

Page 5549 of 5621

WT-24

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

LOW TIRE PRESSURE WARNING CONTROL UNIT PART NUMBER

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. The part number described on low tire pressure warning control unit sticker is displayed.

Diagnosis Procedure with Warning Lamp Function (Without CONSULT-II)NES000K6

DESCRIPTION

During driving, the low tire pressure warning system receives the signal transmitted from the transmitter

installed in each wheel, and gives alarms when the tire pressure becomes low. The control unit (low tire pres-

sure warning control unit) of this system has pressure judgement and trouble diagnosis functions.

FUNCTION

When the low tire pressure warning system detects low inflation pressure or another unusual symptom, the

warning lamps in the combination meter comes on. To start the self-diagnostic results mode, ground terminal

of the tire pressure warning check connector. The malfunction location is indicated by the warning lamp flash-

ing and the buzzer sounds. Regarding location of tire pressure warning check connector, refer to PG-63,

"HARNESS" .

LOW TIRE PRESSURE WARNING LAMP DIAGNOSTIC CHART

Diagnosis

ItemSymptom

(Ignition switch ON)Low tire pressure warning lamp Cause Action

Low tire pres-

sure warning

lampWarning light comes

on immediately and

turns off after 1 sec-

ond.All wheel transmit-

ters are “activated”

(working).None (system OK)

Warning light blinks

on for 2 seconds,

then turns off for 0.2

seconds-repeats.All wheel transmit-

ters are not acti-

vated.Activate all wheel tire pres-

sure transmitters. Refer to

WT-21, "

Transmitter Wake Up

Operation" .

Warning light blinks

1 time.Tire pressure trans-

mitter front LH is not

activated.Activate tire pressure trans-

mitter front LH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light blinks

2 times.Tire pressure trans-

mitter front RH is not

activated.Activate tire pressure trans-

mitter front RH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light blinks

3 times.Tire pressure trans-

mitter rear RH is not

activated.Activate tire pressure trans-

mitter rear RH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

SEIA0592E

SEIA0593E

SEIA0594E

SEIA0595E

SEIA0596E

Page 5553 of 5621

WT-28

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

Trouble Diagnosis ChartNES000K9

SELF-DIAGNOSIS

NOTICE:

186 kPa (1.86 kg/cm2 , 27 psi): Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicles. Item

Reference Self-diagnosis function CONSULT-II

DTC (warning lamp blinks) Diagnosis item Diagnosis item

11Front-left tire pressure drops to * kPa

(* kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_FL

— 12Front-right tire pressure drops to * kPa

(* kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_FR

13Rear-right tire pressure drops to * kPa

(* kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_RR

14Rear-left tire pressure drops to * kPa (*

kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_RL

21 Transmitter no data (front - left) [NO_DATA]_FL

WT-30

22 Transmitter no data (front - right) [NO_DATA]_FR

23 Transmitter no data (rear - right) [NO_DATA]_RR

24 Transmitter no data (rear - left) [NO_DATA]_RL

25 Receiver data error (front - left) [RECEIVER_ERR]_FL

WT-31

26 Receiver data error (front - right) [RECEIVER_ERR]_FR

27 Receiver data error (rear - right) [RECEIVER_ERR]_RR

28 Receiver data error (rear - left) [RECEIVER_ERR]_RL

35Transmitter pressure data error (front -

left)[PRESSDATA_ERR]_FL

WT-32

36Transmitter pressure data error (front -

right)[PRESSDATA_ERR]_FR

37Transmitter pressure data error (rear -

right)[PRESSDATA_ERR]_RR

38Transmitter pressure data error (rear -

left)[PRESSDATA_ERR]_RL

41Transmitter function code error (front -

left)[CODE_ERROR]_FL

WT-32

42Transmitter function code error (front -

right)[CODE_ERROR]_FR

43Transmitter function code error (rear -

right)[CODE_ERROR]_RR

44Transmitter function code error (rear -

left)[CODE_ERROR]_RL

45Transmitter battery voltage low (front -

left)[BATT_VOLT_LOW]_FL

WT-33

46Transmitter battery voltage low (front -

right)[BATT_VOLT_LOW]_FR

47Transmitter battery voltage low (rear -

right)[BATT_VOLT_LOW]_RR

48Transmitter battery voltage low (rear -

left)[BATT_VOLT_LOW]_RL

51 Receiver ID no registration RECEIVER_ID_NO_REGWT-33

52 Vehicle speed signal VHCL_SPED_SIG_ERRWT-34

— CAN COMM CIRCUITWT-34

Page 5564 of 5621

REMOVAL AND INSTALLATION

WT-39

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

REMOVAL AND INSTALLATIONPFP:00000

Tr a n s m i t t e rNES000KM

REMOVAL

1. Deflate tire. Unscrew transmitter retaining nut and allow transmitter to fall into tire.

2. Gently bounce tire so that transmitter falls to bottom of tire.

Place on tire changing machine and break both tire beads

ensuring that the transmitter remains at the bottom of the tire.

3. Turn tire so that valve hole is at bottom and bounce so that

transmitter is near valve hole. Carefully lift tire onto turntable and

position valve hole (and transmitter) 270 degree from mounting/

dismounting head.

4. Lubricate tire well and remove first side of the tire. Reach inside

the tire and remove the transmitter.

INSTALLATION

1. Put first side of tire onto rim.

2. Mount transmitter on rim and tighten nut.

CAUTION:

Speed for tightening nut should be less than 40 rpm.

SEIA0047E

SEIA0048E

SEIA0049E

SEIA0521E

Page 5565 of 5621

WT-40

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

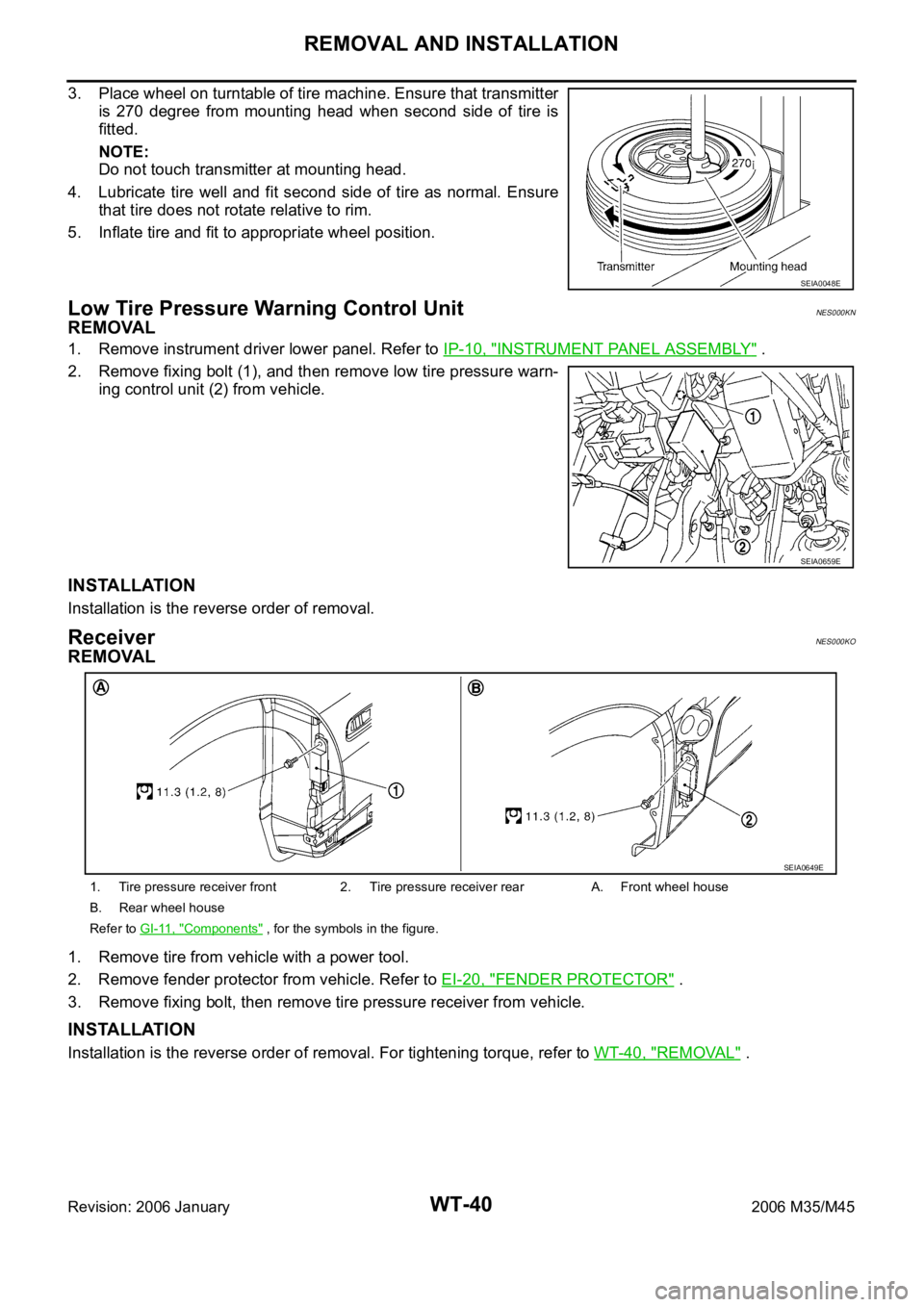

3. Place wheel on turntable of tire machine. Ensure that transmitter

is 270 degree from mounting head when second side of tire is

fitted.

NOTE:

Do not touch transmitter at mounting head.

4. Lubricate tire well and fit second side of tire as normal. Ensure

that tire does not rotate relative to rim.

5. Inflate tire and fit to appropriate wheel position.

Low Tire Pressure Warning Control UnitNES000KN

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove fixing bolt (1), and then remove low tire pressure warn-

ing control unit (2) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

ReceiverNES000KO

REMOVAL

1. Remove tire from vehicle with a power tool.

2. Remove fender protector from vehicle. Refer to EI-20, "

FENDER PROTECTOR" .

3. Remove fixing bolt, then remove tire pressure receiver from vehicle.

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer to WT-40, "REMOVAL" .

SEIA0048E

SEIA0659E

1. Tire pressure receiver front 2. Tire pressure receiver rear A. Front wheel house

B. Rear wheel house

Refer to GI-11, "

Components" , for the symbols in the figure.

SEIA0649E