sensor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 567 of 5621

ATC-120

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector

M87 terminal 2 and unified meter and A/C amp. harness con-

nector M65 terminal 62.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK SUNLOAD SENSOR

1. Reconnect sunload sensor connector and unified meter and A/C amp. connector.

2. Refer to ATC-121, "

Sunload Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace sunload sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN SUNLOAD SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between sunload sensor harness connector

M87 terminal 1 and unified meter and A/C amp. harness con-

nector M65 terminal 46.

4. Check continuity between sunload sensor harness connector

M87 terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.2 – 62 : Continuity should exist.

RJIA4100E

1 – 46 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4101E

Page 568 of 5621

TROUBLE DIAGNOSIS

ATC-121

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

COMPONENT INSPECTION

Sunload Sensor

Measure voltage between unified meter and A/C amp. harness con-

nector M65 terminal 46 and ground.

When checking sunload sensor, select a place where sun shines directly on it.

If NG, replace sunload sensor.

RJIA4102E

SHA930E

Page 569 of 5621

ATC-122

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Intake Sensor CircuitNJS000H3

COMPONENT DESCRIPTION

Intake Sensor

The intake sensor is located on the heater & cooling unit assembly. It

converts temperature of air after it passes through the evaporator

into a resistance value which is then input to the unified meter and A/

C amp.

DIAGNOSIS PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. (24 or 24 is

indicated on unified meter and A/C amp. as a result of performing

self-diagnosis STEP-2.)

1. CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M82

terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M82

terminal 2 and unified meter and A/C amp. harness connector

M65 terminal 59.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

RJIA4103E

RJIA4104E

1 – Ground : Approx. 5 V

RJIA4215E

2 – 59 : Continuity should exist.

RJIA4106E

Page 570 of 5621

TROUBLE DIAGNOSIS

ATC-123

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

3. CHECK INTAKE SENSOR

Refer to ATC-123, "

Intake Sensor" .

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> 1. Replace intake sensor.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

4. CHECK CIRCUIT CONTINUITY BETWEEN INTAKE SENSOR AND UNIFIED METER AND A/C AMP.

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between intake sensor harness connector M82

terminal 1 and unified meter and A/C amp. harness connector

M65 terminal 43.

4. Check continuity between intake sensor harness connector M82

terminal 1 and ground.

OK or NG

OK >> 1. Replace unified meter and A/C amp.

2. Go to self-diagnosis AT C - 5 6 , "

FUNCTION CONFIRMATION PROCEDURE" and perform self-

diagnosis STEP-2. Confirm that code No. 20 is displayed.

NG >> Repair harness or connector.

COMPONENT INSPECTION

Intake Sensor

After disconnecting intake sensor connector M82, measure resis-

tance between terminals 1 and 2 at sensor side, using the table

below.

If NG, replace intake sensor.1 – 43 : Continuity should exist.

1 – Ground : Continuity should not exist.

RJIA4105E

Temperature C (F) Resistance k

15 (5) 12.34

10 (14) 9.62

5 (23) 7.56

0 (32) 6.00

5 (41) 4.80

10 (50) 3.87

15 (59) 3.15

20 (68) 2.57

25 (77) 2.12

30 (86) 1.76

35 (95) 1.47

40 (104) 1.23

45 (113) 1.04

RJIA4107E

Page 573 of 5621

ATC-126

AMBIENT SENSOR

Revision: 2006 January2006 M35/M45

AMBIENT SENSORPFP:27722

Removal and InstallationNJS000H6

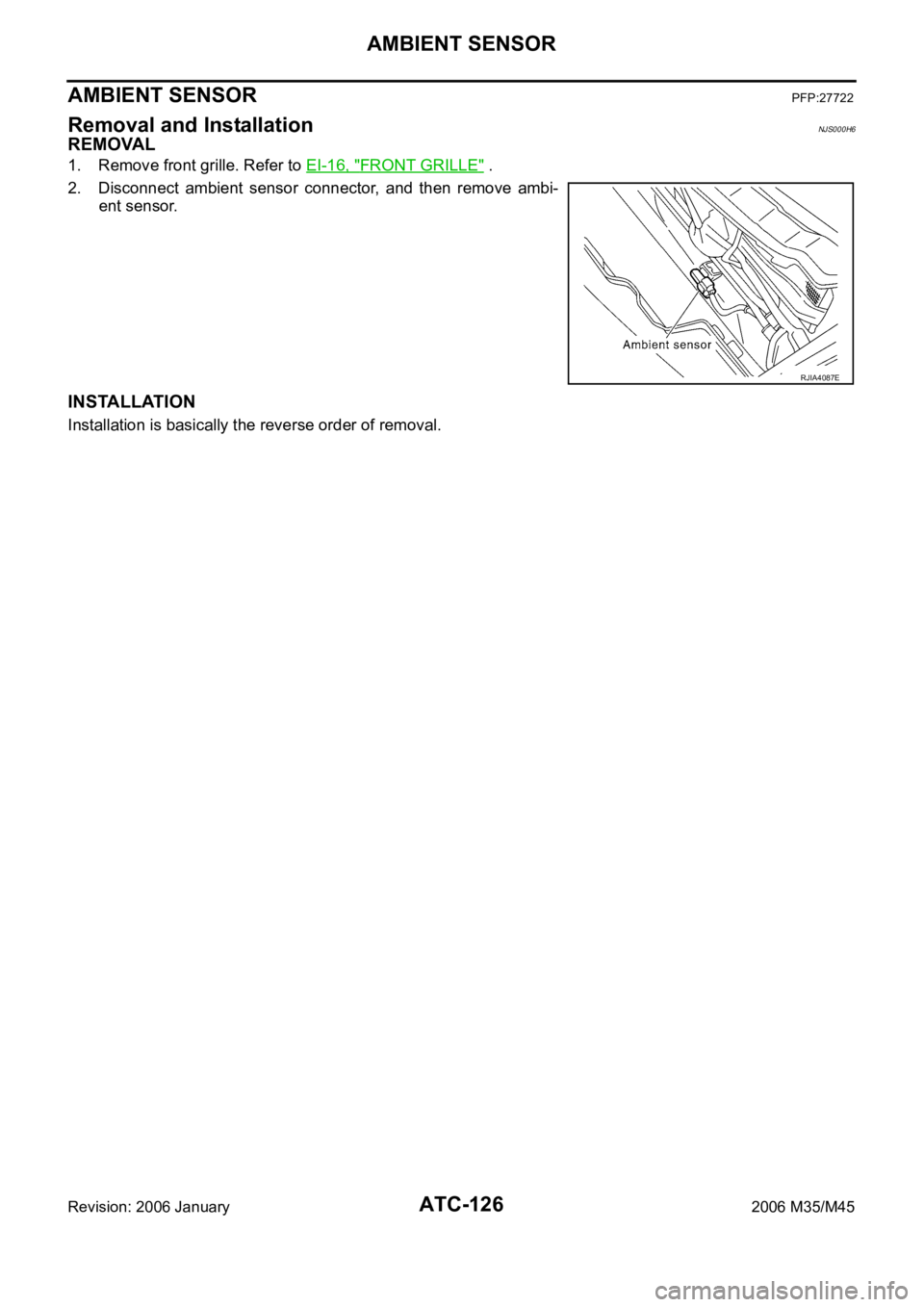

REMOVAL

1. Remove front grille. Refer to EI-16, "FRONT GRILLE" .

2. Disconnect ambient sensor connector, and then remove ambi-

ent sensor.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA4087E

Page 574 of 5621

IN-VEHICLE SENSOR

ATC-127

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

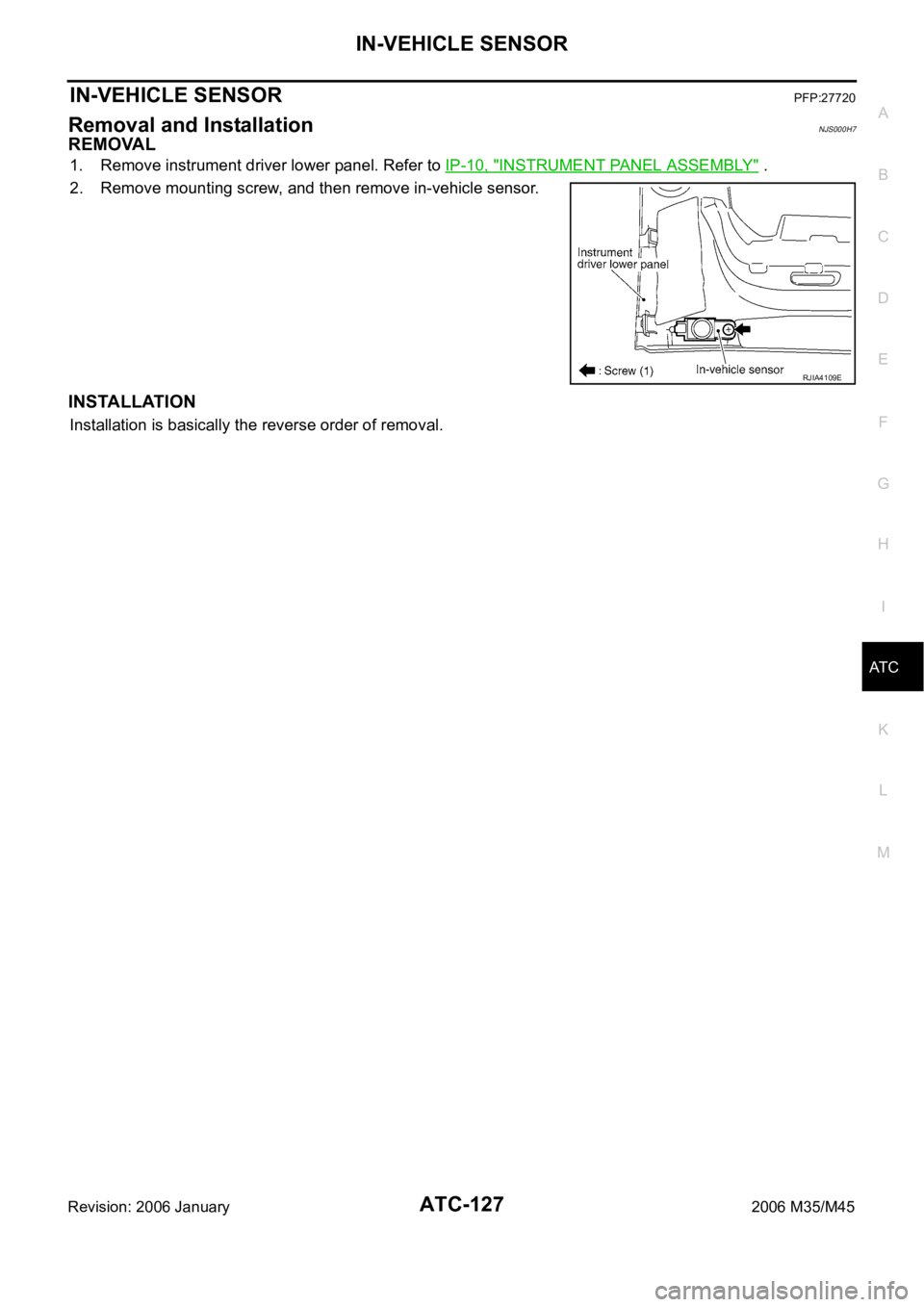

IN-VEHICLE SENSORPFP:27720

Removal and InstallationNJS000H7

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove mounting screw, and then remove in-vehicle sensor.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA4109E

Page 575 of 5621

ATC-128

SUNLOAD SENSOR

Revision: 2006 January2006 M35/M45

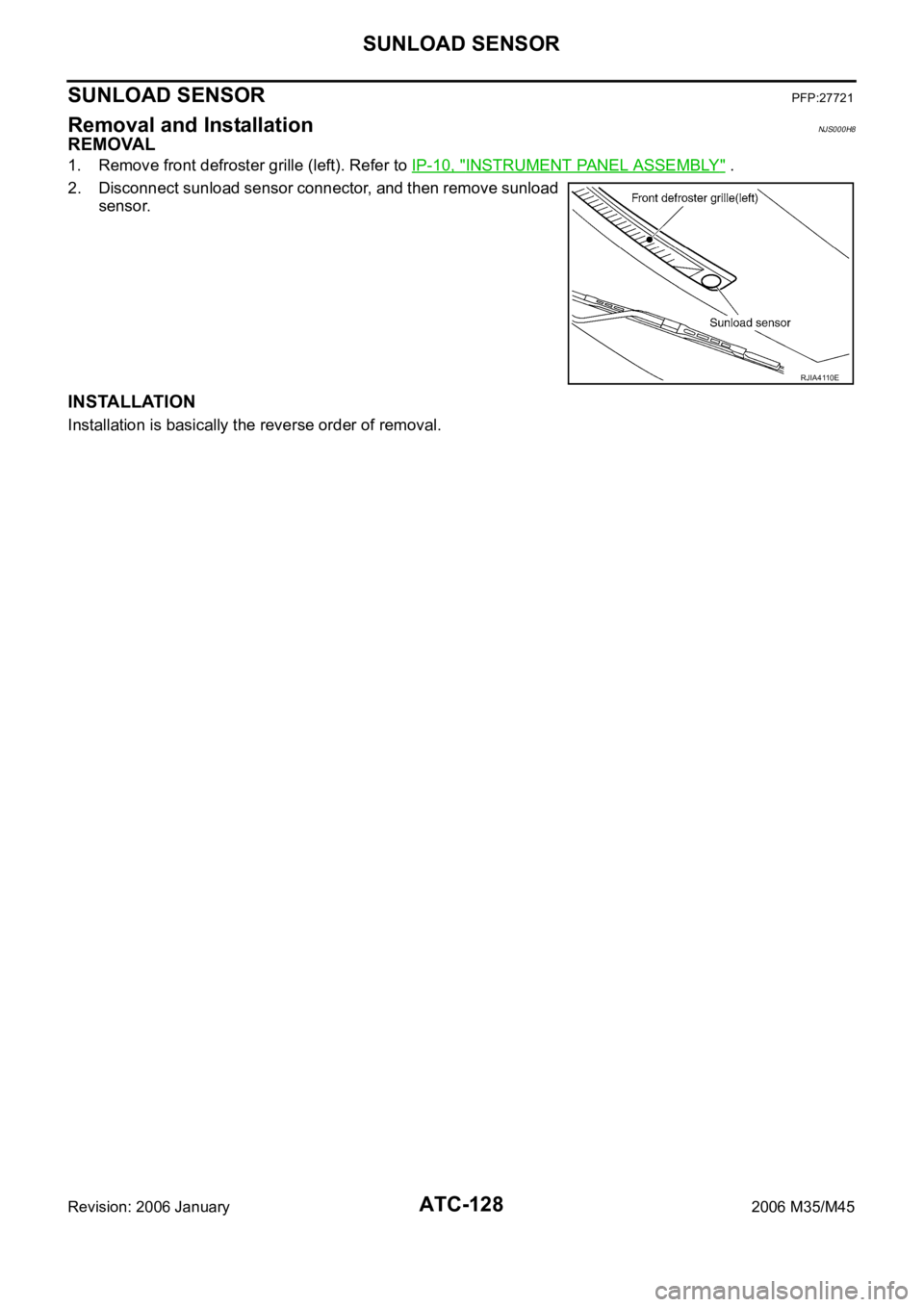

SUNLOAD SENSORPFP:27721

Removal and InstallationNJS000H8

REMOVAL

1. Remove front defroster grille (left). Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect sunload sensor connector, and then remove sunload

sensor.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA4110E

Page 576 of 5621

INTAKE SENSOR

ATC-129

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

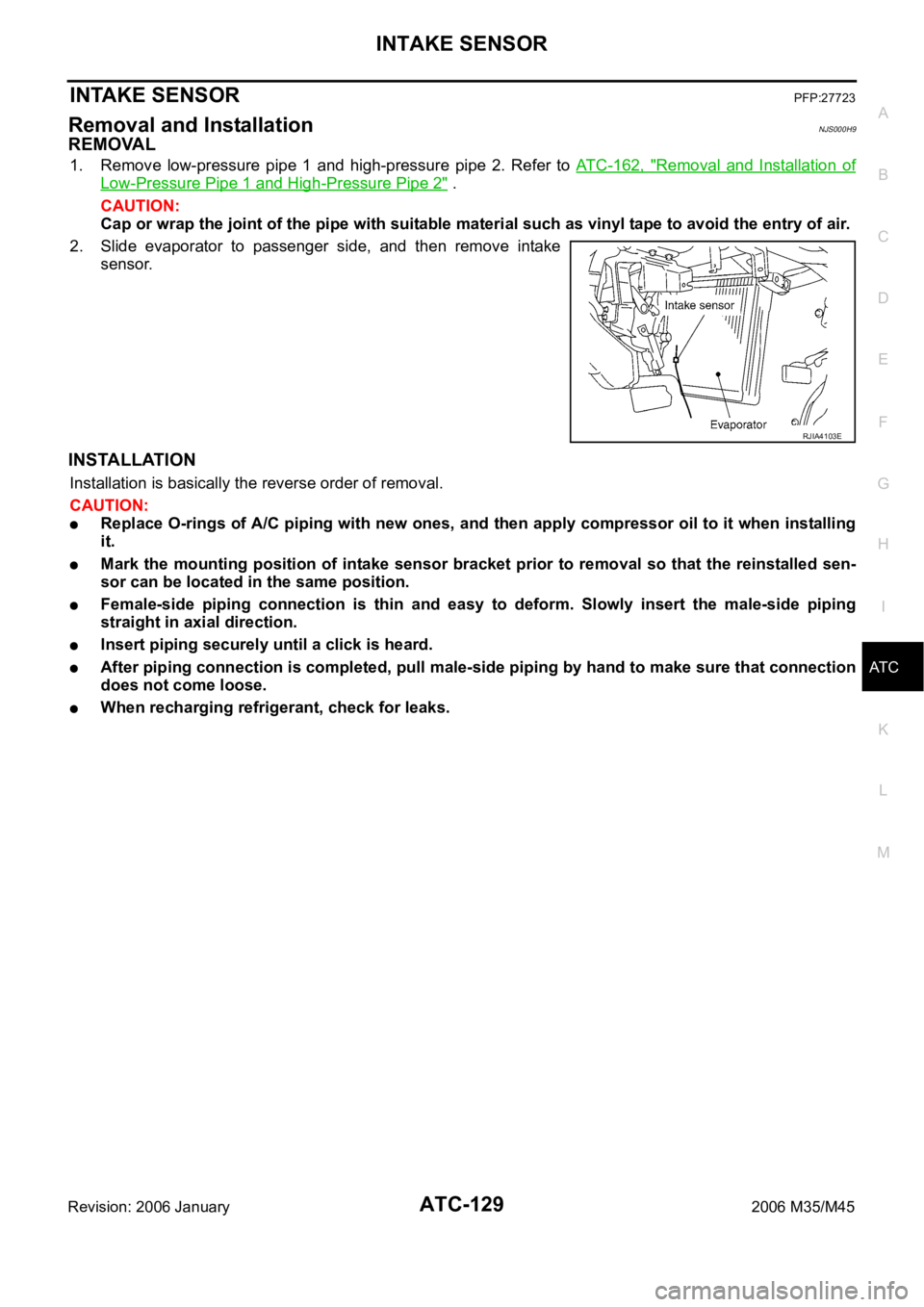

INTAKE SENSORPFP:27723

Removal and InstallationNJS000H9

REMOVAL

1. Remove low-pressure pipe 1 and high-pressure pipe 2. Refer to ATC-162, "Removal and Installation of

Low-Pressure Pipe 1 and High-Pressure Pipe 2" .

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

2. Slide evaporator to passenger side, and then remove intake

sensor.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of A/C piping with new ones, and then apply compressor oil to it when installing

it.

Mark the mounting position of intake sensor bracket prior to removal so that the reinstalled sen-

sor can be located in the same position.

Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

RJIA4103E

Page 585 of 5621

ATC-138

HEATER & COOLING UNIT ASSEMBLY

Revision: 2006 January2006 M35/M45

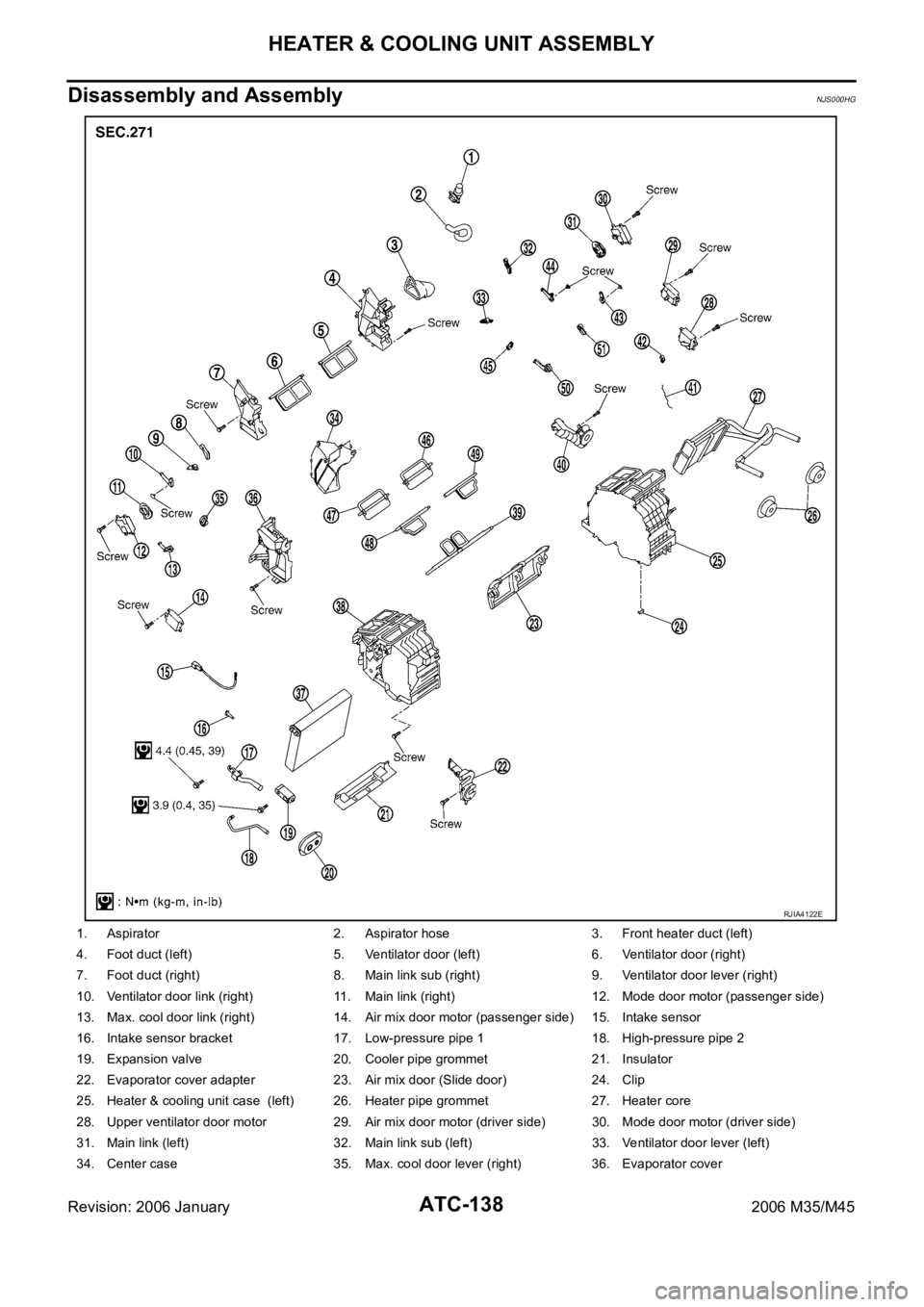

Disassembly and AssemblyNJS000HG

1. Aspirator 2. Aspirator hose 3. Front heater duct (left)

4. Foot duct (left) 5. Ventilator door (left) 6. Ventilator door (right)

7. Foot duct (right) 8. Main link sub (right) 9. Ventilator door lever (right)

10. Ventilator door link (right) 11. Main link (right) 12. Mode door motor (passenger side)

13. Max. cool door link (right) 14. Air mix door motor (passenger side) 15. Intake sensor

16. Intake sensor bracket 17. Low-pressure pipe 1 18. High-pressure pipe 2

19. Expansion valve 20. Cooler pipe grommet 21. Insulator

22. Evaporator cover adapter 23. Air mix door (Slide door) 24. Clip

25. Heater & cooling unit case (left) 26. Heater pipe grommet 27. Heater core

28. Upper ventilator door motor 29. Air mix door motor (driver side) 30. Mode door motor (driver side)

31. Main link (left) 32. Main link sub (left) 33. Ventilator door lever (left)

34. Center case 35. Max. cool door lever (right) 36. Evaporator cover

RJIA4122E

Page 611 of 5621

ATC-164

REFRIGERANT LINES

Revision: 2006 January2006 M35/M45

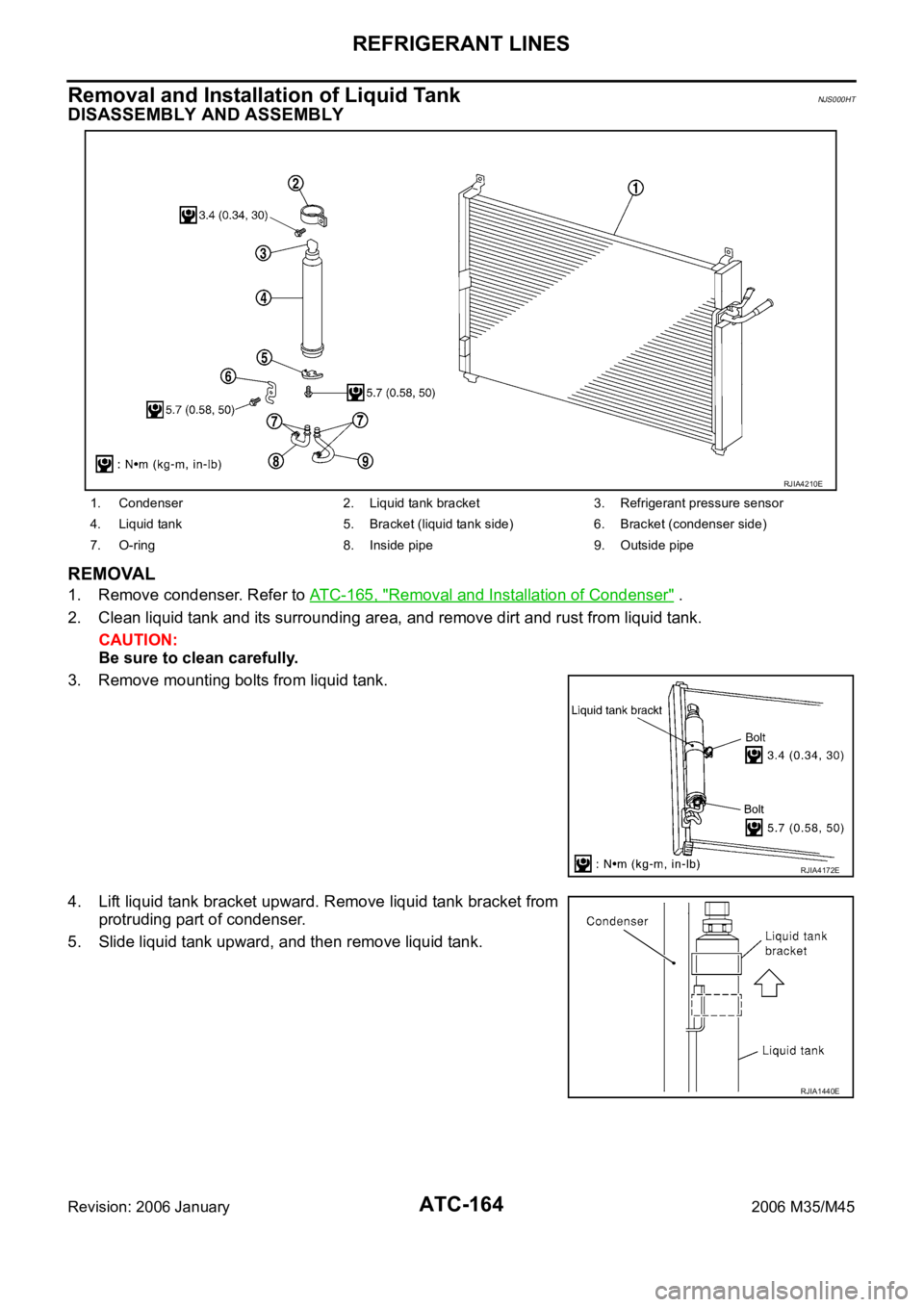

Removal and Installation of Liquid TankNJS000HT

DISASSEMBLY AND ASSEMBLY

REMOVAL

1. Remove condenser. Refer to ATC-165, "Removal and Installation of Condenser" .

2. Clean liquid tank and its surrounding area, and remove dirt and rust from liquid tank.

CAUTION:

Be sure to clean carefully.

3. Remove mounting bolts from liquid tank.

4. Lift liquid tank bracket upward. Remove liquid tank bracket from

protruding part of condenser.

5. Slide liquid tank upward, and then remove liquid tank.

1. Condenser 2. Liquid tank bracket 3. Refrigerant pressure sensor

4. Liquid tank 5. Bracket (liquid tank side) 6. Bracket (condenser side)

7. O-ring 8. Inside pipe 9. Outside pipe

RJIA4210E

RJIA4172E

RJIA1440E