sensor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1021 of 5621

![INFINITI M35 2006 Factory Service Manual BL-82

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

CAUTION:

When CAN COMM 1 [U1000] and CAN COMM 2 [U1010] are displayed, give priority to performing trouble diagnosis.

DATA MONITOR

INTEL INFINITI M35 2006 Factory Service Manual BL-82

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

CAUTION:

When CAN COMM 1 [U1000] and CAN COMM 2 [U1010] are displayed, give priority to performing trouble diagnosis.

DATA MONITOR

INTEL](/img/42/57023/w960_57023-1020.png)

BL-82

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

CAUTION:

When CAN COMM 1 [U1000] and CAN COMM 2 [U1010] are displayed, give priority to performing trouble diagnosis.

DATA MONITOR

INTELLIGENT KEY

[B2552]Internal malfunction is detected in Intelligent Key unitReplace Intelligent Key

unit.BL-163

IGN POWER CIRCUIT

[B2553]It continues for 2 seconds or more that ON power sup-

ply input to Intelligent Key unit is excessively low when

the power supply position is in ON positionCheck Intelligent Key

unit ON power supply

inputBL-163

ACC POWER CIRCUIT

[B2554]It continues for 2 seconds or more that ACC power

supply input to Intelligent Key unit is excessively low

when the power supply position is in ACC or ON posi-

tionCheck Intelligent Key

unit ACC power supply

inputBL-164

STOP LAMP CIRCUIT

[B2555]5V or less is detected at both the stop lamp switch sig-

nal input circuit that is input to Intelligent Key unit and

the monitor input before stop lamp switchCheck stop lamp switchBL-167

ENG START SW

[B2556]Condition that push-button ignition switch is pushed is

detected continuously for 100 seconds or moreCheck push-button igni-

tion switchBL-168

VEHICLE SPEED

[B2557]Some differences occur on one or more vehicle speed

inputs of Intelligent Key unitCheck vehicle speed sig-

nalBL-169

SHIFT POSITION

[B2558]

There is a difference between the shift position input

via CAN communication and the P position input by

detent switch

Vehicle speed (5 km/h or more) is detected continu-

ously for 10 seconds or more even if the shift posi-

tion is detected in P position when the power supply

position is in ON positionCheck shift position inputBL-172

PDU

[B2559]Internal malfunction is detected in PDU Replace PDUBL-174

START POW SUP CIRC

[B2560]Though the engine start operation is not performed,

starter relay in IPDM E/R is ONCheck starter power sup-

plyBL-174

LOW VOLTAGE

[B2562]Battery power supply input to Intelligent Key unit (8.8V

or less) is detected continuously for 1.5 seconds or

moreCheck battery low volt-

ageBL-177

HI VOLTAGE

[B2563]Battery power supply input to Intelligent Key unit (18V

or more) is detected continuously for 90 seconds or

moreCheck for battery high

voltageBL-178

NATS MALFUNCTION

[B2590]Malfunction is detected in immobilizer systemCheck (IVIS) NATS trou-

ble diagnosis procedureBL-248

Suspect Systems

[DTC]Diagnostic item is detected when... Repair work Reference page

Monitor item Content

DR REQ SW Indicates [ON/OFF] condition of door request switch (driver side).

AS REQ SW Indicates [ON/OFF] condition of door request switch (passenger side).

BD/TR REQ SW Indicates [ON/OFF] condition of trunk opener request switch.

ON POS Indicates [ON/OFF] condition of ignition switch in ON position.

ACC POS Indicates [ON/OFF] condition of ignition switch in ACC position.

DOOR STAT SW Indicates [ON/OFF] condition of door unlock sensor.

STOP LAMP SW Indicates [ON/OFF] condition of stop lamp switch.

P RANGE SW Indicates [ON/OFF] condition of park position switch.

TR CANCEL SW* Indicates [ON/OFF] condition of trunk cancel switch.

DOOR LOCK SIG* Indicates [ON/OFF] condition of door lock signal from Intelligent Key remote controller button.

DOOR UNLOCK SIG* Indicates [ON/OFF] condition of door unlock signal from Intelligent Key remote controller button.

KEYLESS TRUNK* Indicates [ON/OFF] condition of trunk open signal from Intelligent Key remote controller button.

Page 1026 of 5621

INTELLIGENT KEY SYSTEM

BL-87

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

REMOTE KEYLESS ENTRY FUNCTION MALFUNCTION

NOTE:

Before performing the diagnosis in the following table, check “Trouble Diagnosis Procedure”. Refer to BL-

78, "Trouble Diagnosis Procedure" .

Make sure that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis,

and check each symptom.

If the following “symptoms” are detected, check systems shown in the “Diagnosis/service procedure” col-

umn in this order.

Conditions of Vehicle (Operating Conditions)

Intelligent Key is out of key slot.

Ignition switch is not ON position.

All doors are closed.

Selective unlock function does not operate by

door request switch (passenger side) (other

door lock function operate).1.Check “SELECT UNLOCK FUNCTION” setting in

“WORK SUPPORT”.BL-83

2. Replace Intelligent Key unit.BL-125

Auto lock function does not operate.1.Check “AUTO RELOCK TIMER” setting in “WORK

SUPPORT”.BL-832. Check door switch.BL-96

3. Check key slot.BL-94

4. Replace BCM.BCS-17

Key reminder function does not operate.1.Check “ANTI KEY LOCK IN FUNCTION” setting in

“WORK SUPPORT”.BL-83

2. Check door switch.BL-96

3. Check inside key antenna.BL-112

4. Check unlock sensor.BL-105

5. Check Intelligent Key battery inspection.BL-126

6. Replace Intelligent Key unit.BL-125

Symptom Diagnosis/service procedure Reference page

Symptom Diagnosis/service procedureReference

page

All of the remote keyless entry functions

do not operate.1. Check Intelligent Key battery inspection.BL-126

2. Replace Intelligent Key unit.BL-125

Selective unlock function does not operate

by Intelligent Key.1.Check “SELECT UNLOCK FUNCTION” setting in “WORK SUP-

PORT”.BL-83

2. Check Intelligent Key battery inspection.BL-126

3. Replace Intelligent Key unit.BL-125

Auto lock function does not operate prop-

erly.1. Check “AUTO RELOCK TIMER” setting in “WORK SUPPORT”.BL-832. Check door switch.BL-96

3. Check key slot.BL-94

4. Replace BCM.BCS-17

Key reminder function does not operate.1.Check “ANTI KEY LOCK IN FUNCTION” setting in “WORK SUP-

PORT”.BL-83

2. Check door switch.BL-96

3. Check inside key antenna.BL-112

4. Check unlock sensor.BL-105

5. Check Intelligent Key battery inspection.BL-126

6. Replace Intelligent Key unit.BL-125

Page 1044 of 5621

INTELLIGENT KEY SYSTEM

BL-105

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

5. CHECK INTELLIGENT KEY UNIT OUTPUT SIGNAL

1. Connect Intelligent Key unit connector.

2. Check voltage between Intelligent Key unit connector and ground.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Replace Intelligent Key unit.

Check Unlock SensorNIS001XS

1. CHECK UNLOCK SENSOR POWER SUPPLY

With CONSULT-II

Check unlock sensor (“DOOR STAT SW”) in “DATA MONITOR” mode.

Without CONSULT-II

Check voltage between Intelligent Key unit connector and ground.

OK or NG

OK >> Unlock sensor is OK.

NG >> GO TO 2.

Terminals

Voltage (V)

(Approx.) (+)

(–)

Intelligent Key unit

connectorTerminal

M32 25 Ground 5

PIIB6334E

Monitor item Condition

DOOR STAT SWFront door lock (driver side) LOCK : ON

Front door lock (driver side) UNLOCK : OFF

PIIB6399E

Terminals

Front door

lock

(driver side )

conditionVoltage (V)

(Approx.) (+)

(–)

Intelligent Key

unit connectorTerminal

M32 26 GroundLocked Battery voltage

Unlocked 0

PIIB6338E

Page 1045 of 5621

BL-106

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

2. CHECK UNLOCK SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect Intelligent Key unit and front door lock assembly (driver side) connector.

3. Check continuity between Intelligent Key unit connector and front door lock assembly (driver side) con-

nector.

4. Check continuity between Intelligent Key unit connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between Intelligent Key unit and front door lock assembly (driver side).

3. CHECK UNLOCK SENSOR GROUND CIRCUIT

Check continuity between front door lock assembly (driver side) connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK INTELLIGENT KEY UNIT OUTPUT SIGNAL

1. Connect Intelligent Key unit harness connector.

2. Check voltage between Intelligent Key unit connector and ground.

OK or NG

OK >> Replace front door lock assembly (driver side).

NG >> Replace Intelligent Key unit.

AB

Continuity

Intelligent Key

unit connectorTe r m i n a l Front door lock

assembly (driver

side) connectorTerminal

M32 26 D14 3 Yes

A

GroundContinuity

Intelligent Key unit

connectorTerminal

M32 26 No

PIIB6339E

Front door lock

assembly (driver side)

connectorTerminal

GroundContinuity

D14 4 Yes

PIIB6340E

Terminals

Voltage (V)

(Approx.) (+)

(–)

Intelligent Key unit

connectorTerminal

M32 26 Ground Battery voltage

PIIB6338E

Page 1060 of 5621

INTELLIGENT KEY SYSTEM

BL-121

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Check Trunk Lid Opener Cancel SwitchNIS001Y0

1. CHECK TRUNK LID OPENER CANCEL SWITCH

With CONSULT-II

Check trunk lid opener cancel sensor (“TR CANCEL SW”) in “DATA MONITOR” mode.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between Intelligent Key unit connector and ground.

OK or NG

OK >> Trunk lid opener cancel switch is OK.

NG >> GO TO 2.

2. CHECK TRUNK LID OPENER CANCEL SWITCH CIRCUIT

1. Disconnect Intelligent Key unit and trunk lid opener cancel switch connector.

2. Check continuity between Intelligent Key unit connector and trunk lid opener cancel switch connector.

3. Check continuity between Intelligent Key unit connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between Intelligent Key unit and trunk lid opener cancel switch.

Monitor item Condition

TR CANCEL SWTrunk lid opener cancel switch ON : ON

Trunk lid opener cancel switch OFF : OFF

PIIB6400E

Terminals

Trunk lid

opener cancel

switch condi-

tionVoltage (V)

(Approx.) (+)

(–)

Intelligent Key

unit connectorTerminal

M32 23 GroundON 0

OFF (Cancel) 5

PIIB6390E

AB

Continuity

Intelligent Key

unit connectorTe r m i n a l Trunk lid opener

cancel switch

connectorTerminal

M32 23 M99 1 Yes

A

GroundContinuity

Intelligent Key unit

connectorTerminal

M32 23 No

PIIB6393E

Page 1092 of 5621

![INFINITI M35 2006 Factory Service Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-153

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

CAUTION:

When CAN COMM 1 [U1000] and CAN COMM 2 [U1010] are displayed, give priority to INFINITI M35 2006 Factory Service Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-153

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

CAUTION:

When CAN COMM 1 [U1000] and CAN COMM 2 [U1010] are displayed, give priority to](/img/42/57023/w960_57023-1091.png)

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-153

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

CAUTION:

When CAN COMM 1 [U1000] and CAN COMM 2 [U1010] are displayed, give priority to performing trouble diagnosis.

DATA MONITOR

ENG START SW

[B2556]Condition that push-button ignition switch is pushed is

detected continuously for 100 seconds or moreCheck push-button igni-

tion switchBL-168

VEHICLE SPEED

[B2557]Some differences occur on one or more vehicle speed

inputs of Intelligent Key unitCheck vehicle speed sig-

nalBL-169

SHIFT POSITION

[B2558]

There is a difference between the shift position input

via CAN communication and the P position input by

detent switch

Vehicle speed (5 km/h or more) is detected continu-

ously for 10 seconds or more even if the shift posi-

tion is detected in P position when the power supply

position is in ON positionCheck shift position inputBL-172

PDU

[B2559]Internal malfunction is detected in PDU Replace PDUBL-174

START POW SUP CIRC

[B2560]Though the engine start operation is not performed,

starter relay in IPDM E/R is ONCheck starter power sup-

plyBL-174

LOW VOLTAGE

[B2562]Battery power supply input to Intelligent Key unit (8.8V

or less) is detected continuously for 1.5 seconds or

moreCheck battery low volt-

ageBL-177

HI VOLTAGE

[B2563]Battery power supply input to Intelligent Key unit (18V

or more) is detected continuously for 90 seconds or

moreCheck for battery high

voltageBL-178

NATS MALFUNCTION

[B2590]Malfunction is detected in immobilizer systemCheck (IVIS) NATS trou-

ble diagnosis procedureBL-268

Suspect Systems

[DTC]Diagnostic item is detected when... Repair work Reference page

Monitor item Content

DR REQ SW Indicates [ON/OFF] condition of door request switch (driver side).

AS REQ SW Indicates [ON/OFF] condition of door request switch (passenger side).

BD/TR REQ SW Indicates [ON/OFF] condition of trunk opener request switch.

ON POS Indicates [ON/OFF] condition of ignition switch in ON position.

ACC POS Indicates [ON/OFF] condition of ignition switch in ACC position.

DOOR STAT SW Indicates [ON/OFF] condition of door unlock sensor.

STOP LAMP SW Indicates [ON/OFF] condition of stop lamp switch.

P RANGE SW Indicates [ON/OFF] condition of park position switch.

TR CANCEL SW* Indicates [ON/OFF] condition of trunk cancel switch.

DOOR LOCK SIG* Indicates [ON/OFF] condition of door lock signal from Intelligent Key remote controller button.

DOOR UNLOCK SIG* Indicates [ON/OFF] condition of door unlock signal from Intelligent Key remote controller button.

KEYLESS TRUNK* Indicates [ON/OFF] condition of trunk open signal from Intelligent Key remote controller button.

KEYLESS PANIC* Indicates [ON/OFF] condition of panic alarm signal from Intelligent Key remote controller button.

DOOR SW DR*Indicates [OPEN/CLOSE] condition of front door switch driver side from BCM via CAN communica-

tion line.

DOOR SW AS*Indicates [OPEN/CLOSE] condition of front door switch passenger side from BCM via CAN commu-

nication line.

DOOR SW RR* Indicates [OPEN/CLOSE] condition of rear door switch LH from BCM via CAN communication line.

DOOR SW RL* Indicates [OPEN/CLOSE] condition of rear door switch RH from BCM via CAN communication line.

DOOR BK SW* Indicates [OPEN/CLOSE] condition of back door switch from BCM via CAN communication line.

Page 1283 of 5621

BR-8

BRAKE PEDAL

Revision: 2006 January2006 M35/M45

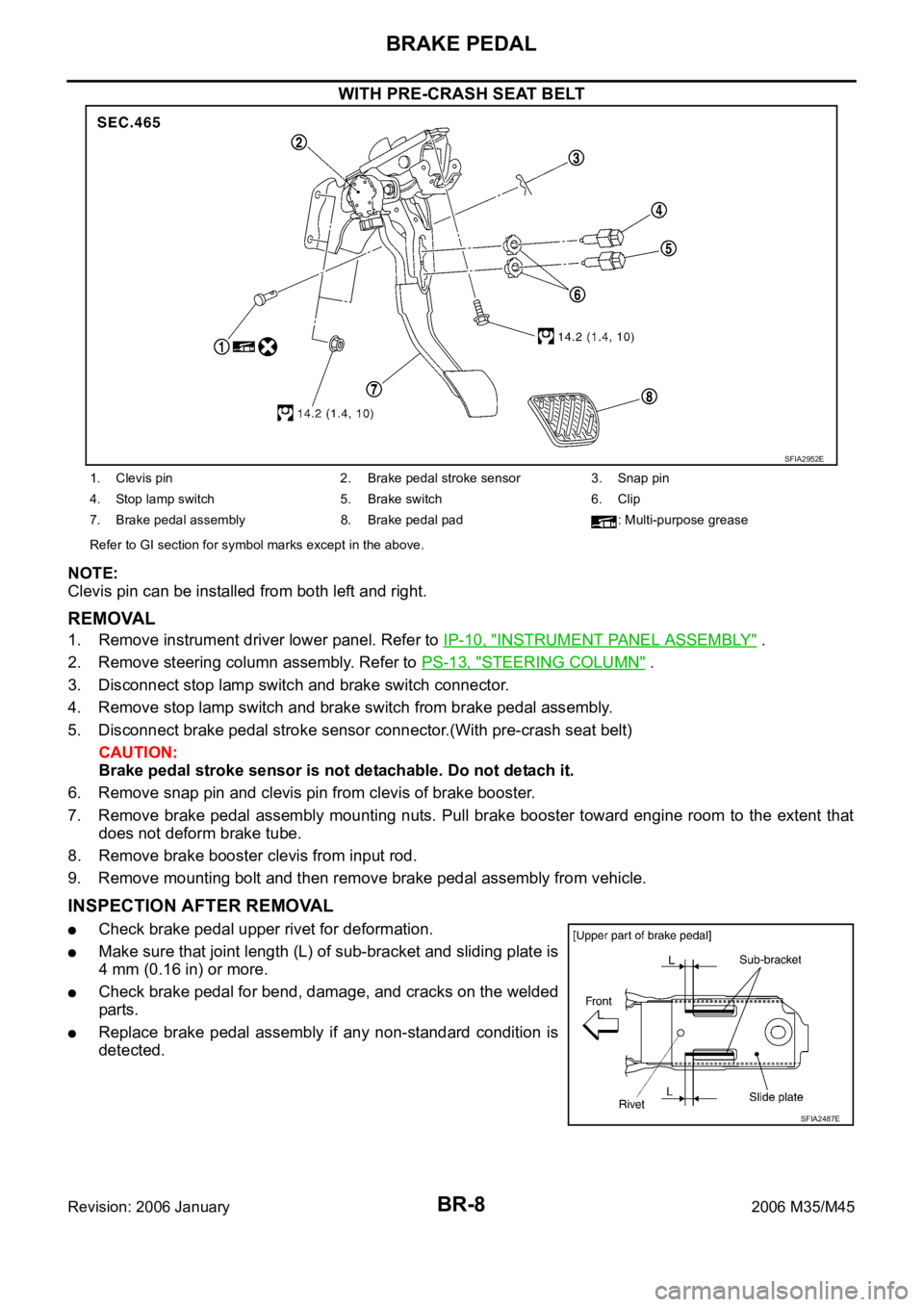

WITH PRE-CRASH SEAT BELT

NOTE:

Clevis pin can be installed from both left and right.

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove steering column assembly. Refer to PS-13, "

STEERING COLUMN" .

3. Disconnect stop lamp switch and brake switch connector.

4. Remove stop lamp switch and brake switch from brake pedal assembly.

5. Disconnect brake pedal stroke sensor connector.(With pre-crash seat belt)

CAUTION:

Brake pedal stroke sensor is not detachable. Do not detach it.

6. Remove snap pin and clevis pin from clevis of brake booster.

7. Remove brake pedal assembly mounting nuts. Pull brake booster toward engine room to the extent that

does not deform brake tube.

8. Remove brake booster clevis from input rod.

9. Remove mounting bolt and then remove brake pedal assembly from vehicle.

INSPECTION AFTER REMOVAL

Check brake pedal upper rivet for deformation.

Make sure that joint length (L) of sub-bracket and sliding plate is

4 mm (0.16 in) or more.

Check brake pedal for bend, damage, and cracks on the welded

parts.

Replace brake pedal assembly if any non-standard condition is

detected.

SFIA2952E

1. Clevis pin 2. Brake pedal stroke sensor 3. Snap pin

4. Stop lamp switch 5. Brake switch 6. Clip

7. Brake pedal assembly 8. Brake pedal pad : Multi-purpose grease

Refer to GI section for symbol marks except in the above.

SFIA2487E

Page 1298 of 5621

FRONT DISC BRAKE

BR-23

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

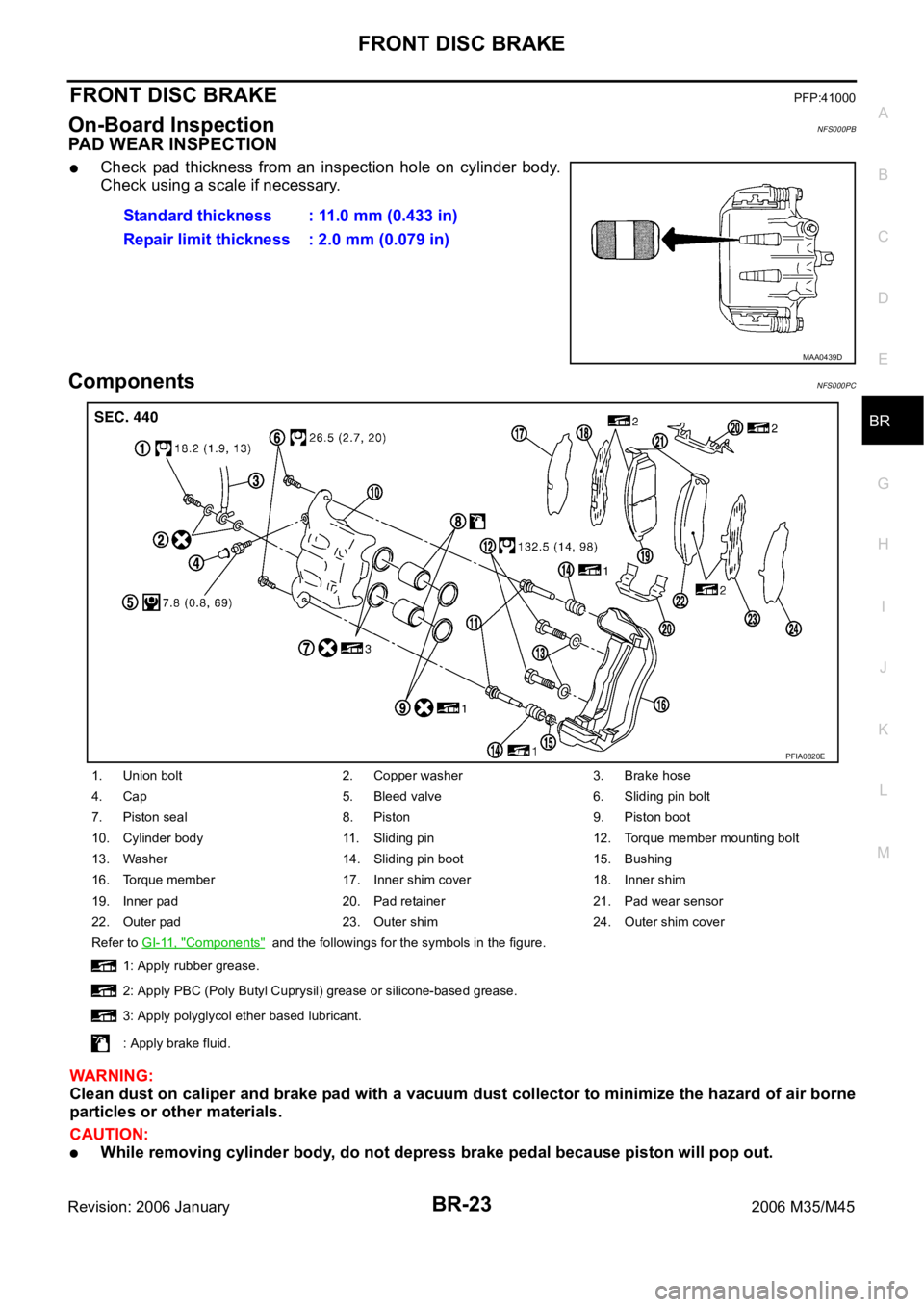

FRONT DISC BRAKEPFP:41000

On-Board InspectionNFS000PB

PAD WEAR INSPECTION

Check pad thickness from an inspection hole on cylinder body.

Check using a scale if necessary.

ComponentsNFS000PC

WAR NING :

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

While removing cylinder body, do not depress brake pedal because piston will pop out. Standard thickness : 11.0 mm (0.433 in)

Repair limit thickness : 2.0 mm (0.079 in)

MAA0439D

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

Refer to GI-11, "

Components" and the followings for the symbols in the figure.

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

3: Apply polyglycol ether based lubricant.

: Apply brake fluid.

PFIA0820E

Page 1299 of 5621

BR-24

FRONT DISC BRAKE

Revision: 2006 January2006 M35/M45

It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

Do not damage piston boot.

If any shim is subject to serious corrosion, replace it with a new one.

Always replace shim and shim cover as a set when replacing brake pads.

Keep rotor free from brake fluid.

Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage. Refer to BR-28, "

BRAKE

BURNISHING PROCEDURE" .

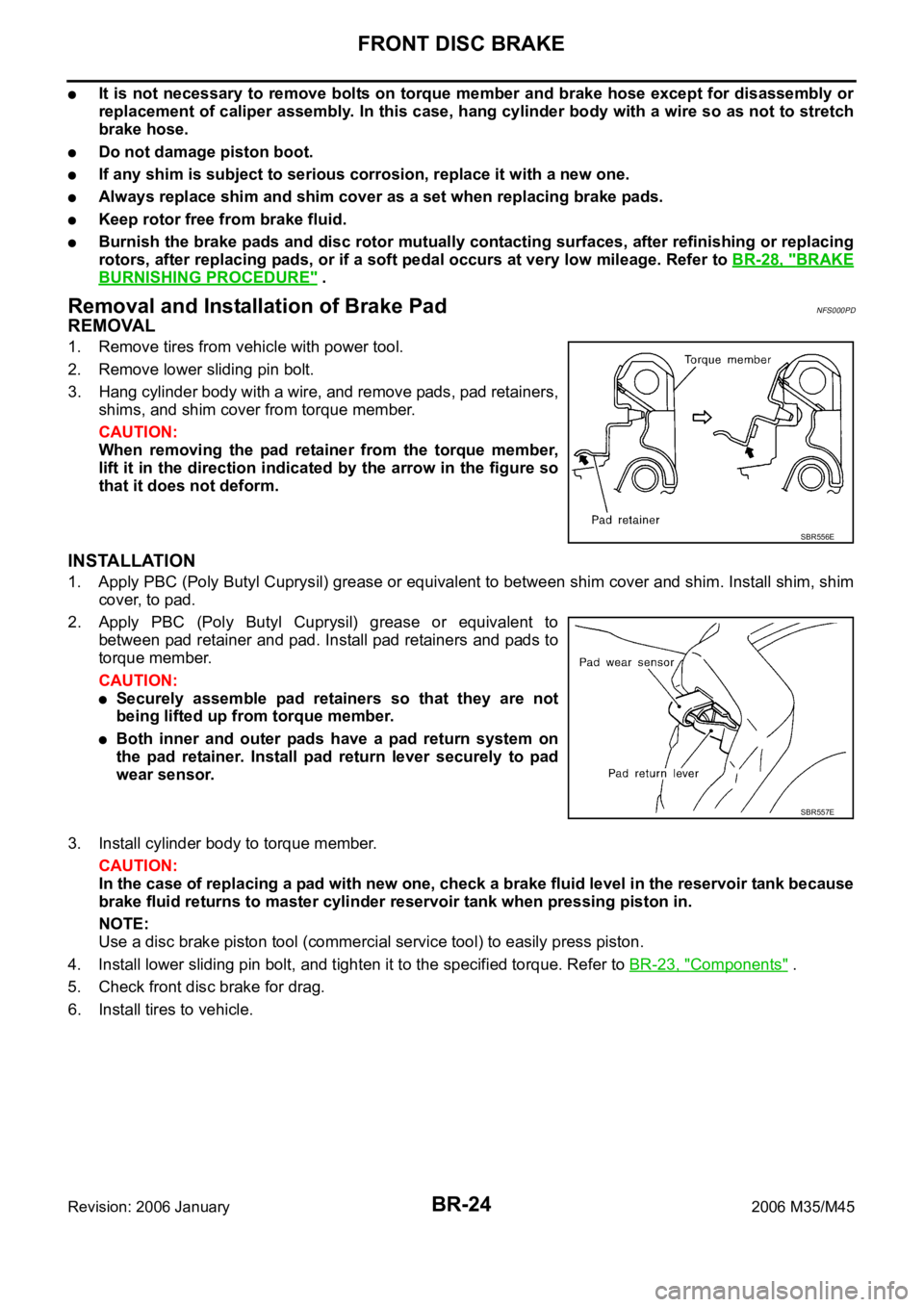

Removal and Installation of Brake PadNFS000PD

REMOVAL

1. Remove tires from vehicle with power tool.

2. Remove lower sliding pin bolt.

3. Hang cylinder body with a wire, and remove pads, pad retainers,

shims, and shim cover from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indicated by the arrow in the figure so

that it does not deform.

INSTALLATION

1. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to between shim cover and shim. Install shim, shim

cover, to pad.

2. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to

between pad retainer and pad. Install pad retainers and pads to

torque member.

CAUTION:

Securely assemble pad retainers so that they are not

being lifted up from torque member.

Both inner and outer pads have a pad return system on

the pad retainer. Install pad return lever securely to pad

wear sensor.

3. Install cylinder body to torque member.

CAUTION:

In the case of replacing a pad with new one, check a brake fluid level in the reservoir tank because

brake fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily press piston.

4. Install lower sliding pin bolt, and tighten it to the specified torque. Refer to BR-23, "

Components" .

5. Check front disc brake for drag.

6. Install tires to vehicle.

SBR556E

SBR557E

Page 1304 of 5621

REAR DISC BRAKE

BR-29

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

REAR DISC BRAKEPFP:44000

On-Board InspectionNFS000PG

PAD WEAR INSPECTION

Check pad thickness from an inspection hole on cylinder body.

Check using a scale if necessary.

ComponentsNFS000PH

Standard

Standard thickness : 8.5 mm (0.335 in)

Repair limit thickness : 2.0 mm (0.079 in)

BRA0010D

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Retaining ring 12. Inner shim cover

13. Inner shim 14. Inner pad 15. Pad retainer

16. Outer pad 17. Outer shim 18. Sliding pin boot

19. Bushing 20. Torque member mounting bolt 21. Washer

22. Torque member 23. Pad wear sensor 24. Inner pad (RH)

Refer to GI-11, "

Components" and the followings for the symbols in the figure.

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

PFIA0705J