sensor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1373 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-62

[VDC/TCS/ABS]

G-SENSOR

Revision: 2006 January2006 M35/M45

G-SENSORPFP:47930

Removal and InstallationNFS000RD

CAUTION:

Do not drop or strike yaw rate/side G sensor, because it has little enduran INFINITI M35 2006 Factory Service Manual BRC-62

[VDC/TCS/ABS]

G-SENSOR

Revision: 2006 January2006 M35/M45

G-SENSORPFP:47930

Removal and InstallationNFS000RD

CAUTION:

Do not drop or strike yaw rate/side G sensor, because it has little enduran](/img/42/57023/w960_57023-1372.png)

BRC-62

[VDC/TCS/ABS]

G-SENSOR

Revision: 2006 January2006 M35/M45

G-SENSORPFP:47930

Removal and InstallationNFS000RD

CAUTION:

Do not drop or strike yaw rate/side G sensor, because it has little endurance to impact.

Do not use power tool etc., because yaw rate/side G sensor is sensitive for the impact.

REMOVAL

1. Remove center console. Refer to IP-10, "Component Parts

Drawing" .

2. Disconnect yaw rate/side G sensor harness connector.

3. Remove mounting bolts. Remove yaw rate/side G sensor.

(Shown in the figure 1).

INSTALLATION

Installation is the reverse order of removal.

SFIA2725J

Yaw rate/side G sensor mounting bolt

: 6.5 Nꞏm (0.66 kgꞏm, 58 in-lb)

Page 1374 of 5621

![INFINITI M35 2006 Factory Service Manual STEERING ANGLE SENSOR

BRC-63

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

STEERING ANGLE SENSORPFP:25554

Removal and InstallationNFS000RE

REMOVAL

1. Remove spiral cable INFINITI M35 2006 Factory Service Manual STEERING ANGLE SENSOR

BRC-63

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

STEERING ANGLE SENSORPFP:25554

Removal and InstallationNFS000RE

REMOVAL

1. Remove spiral cable](/img/42/57023/w960_57023-1373.png)

STEERING ANGLE SENSOR

BRC-63

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

STEERING ANGLE SENSORPFP:25554

Removal and InstallationNFS000RE

REMOVAL

1. Remove spiral cable assembly. Refer to SRS-40, "SPIRAL CABLE" .

2. Remove steering angle sensor from spiral cable assembly.

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

After work, make sure to adjust neutral position of steering angle sensor. Refer to BRC-6, "

Adjustment

of Steering Angle Sensor Neutral Position" .

SFIA1404E

Page 1375 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-64

[VDC/TCS/ABS]

STEERING ANGLE SENSOR

Revision: 2006 January2006 M35/M45 INFINITI M35 2006 Factory Service Manual BRC-64

[VDC/TCS/ABS]

STEERING ANGLE SENSOR

Revision: 2006 January2006 M35/M45](/img/42/57023/w960_57023-1374.png)

BRC-64

[VDC/TCS/ABS]

STEERING ANGLE SENSOR

Revision: 2006 January2006 M35/M45

Page 1406 of 5621

![INFINITI M35 2006 Factory Service Manual WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REM INFINITI M35 2006 Factory Service Manual WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REM](/img/42/57023/w960_57023-1405.png)

WATER OUTLET AND WATER PIPING

CO-31

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER OUTLET AND WATER PIPINGPFP:11060

ComponentsNBS004R5

Removal and InstallationNBS004R6

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-19, "

INTAKE MANIFOLD COLLECTOR" .

3. Remove air duct (inlet) and air cleaner case assembly. Refer to EM-17, "

AIR CLEANER AND AIR DUCT"

.

4. Remove front engine undercover with power tool.

5. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-11, "

Changing Engine Coolant" and CO-24, "WATER PUMP" .

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

6. Remove radiator hose (upper) and heater hose.

7. Remove the following parts, when remove water outlet.

A/T fluid charging pipe: Refer to AT-271, "TRANSMISSION ASSEMBLY" .

Intake manifold collectors (upper and lower): Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Rocker cover (right bank): Refer to EM-51, "ROCKER COVER" .

8. Remove engine coolant temperature sensor as necessary.

CAUTION:

Be careful not to damage engine coolant temperature sensor.

1. Harness bracket 2. Water hose 3. Water bypass hose

4. Engine coolant temperature sensor 5. Gasket 6. Water outlet

7. Heater hose 8. Water pipe 9. Radiator hose (upper)

10. Heater pipe 11. Washer 12. O-ring

SBIA0484E

Page 1434 of 5621

DI-1

DRIVER INFORMATION SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION DI

A

B

DI

Revision: 2006 January2006 M35/M45

DRIVER INFORMATION SYSTEM

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Commercial Service Tools ........................................ 4

COMBINATION METERS ........................................... 5

System Description .................................................. 5

UNIFIED METER CONTROL UNIT ...................... 5

UNIFIED METER AND A/C AMP. ......................... 5

POWER SUPPLY AND GROUND CIRCUIT ........ 5

SPEEDOMETER ................................................... 6

TACHOMETER ..................................................... 6

WATER TEMPERATURE GAUGE ........................ 6

FUEL GAUGE ....................................................... 7

ODO/TRIP METER ............................................... 7

METER ILLUMINATION CONTROL ..................... 8

FAIL-SAFE ............................................................ 9

Arrangement of Combination Meter ....................... 10

Component Parts and Harness Connector Location .... 11

Internal Circuit ........................................................ 12

Wiring Diagram — METER — ................................ 13

Terminals and Reference Value for Combination

Meter ...................................................................... 15

Terminals and Reference Value for Unified Meter

and A/C Amp. ......................................................... 16

Self-Diagnosis Mode of Combination Meter ........... 17

SELF-DIAGNOSIS FUNCTION .......................... 17

OPERATION PROCEDURE ............................... 17

CONSULT-II Function (METER A/C AMP) ............. 18

Trouble Diagnosis .................................................. 18

HOW TO PERFORM TROUBLE DIAGNOSIS ... 18

PRELIMINARY CHECK ...................................... 18

Symptom Chart ...................................................... 18

Power Supply and Ground Circuit Inspection ........ 19

Vehicle Speed Signal Inspection ............................ 20

Engine Speed Signal Inspection ............................ 21

Engine Coolant Temperature Signal Inspection ..... 22

Fuel Level Sensor Signal Inspection ...................... 22

Fuel Gauge Pointer Fluctuates, Indicator Wrong Value or Varies ....................................................... 25

Fuel Gauge Does Not Move to FULL Position ....... 25

Electrical Components Inspection .......................... 26

CHECK FUEL LEVEL SENSOR UNIT ................ 26

Removal and Installation of Combination Meter ..... 27

REMOVAL ........................................................

... 27

INSTALLATION ................................................... 27

Disassembly and Assembly of Combination Meter ... 27

DISASSEMBLY ................................................... 27

ASSEMBLY ......................................................... 27

UNIFIED METER AND A/C AMP ...........................

... 28

System Description ................................................. 28

COMBINATION METER CONTROL FUNCTION ... 28

A/C AUTO AMP. FUNCTION ............................... 29

OTHER FUNCTIONS .......................................... 29

Schematic ............................................................... 30

CONSULT-II Function (METER A/C AMP) ............. 31

CONSULT-II BASIC OPERATION ....................... 31

SELF-DIAG RESULTS ........................................ 32

DATA MONITOR ................................................. 33

Power Supply and Ground Circuit Inspection ......... 35

DTC [U1000] CAN Communication Circuit ............. 36

DTC [B2202] Meter Communication Circuit ........... 36

DTC [B2205] Vehicle Speed Circuit ........................ 39

Removal and Installation of Unified Meter and A/C

Amp. ....................................................................... 39

REMOVAL ........................................................

... 39

INSTALLATION ................................................... 39

WARNING LAMPS .................................................... 40

System Description ................................................. 40

OIL PRESSURE WARNING LAMP ..................... 40

Component Parts and Harness Connector Location ... 41

Schematic ............................................................... 42

Wiring Diagram — WARN — .................................. 43

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) ............................................................. 53

Oil Pressure Warning Lamp Does Not Turn Off (Oil

Pressure Is Normal) ................................................ 54

Electrical Component Inspection ............................ 55

OIL PRESSURE SWITCH ................................... 55

Page 1439 of 5621

DI-6

COMBINATION METERS

Revision: 2006 January2006 M35/M45

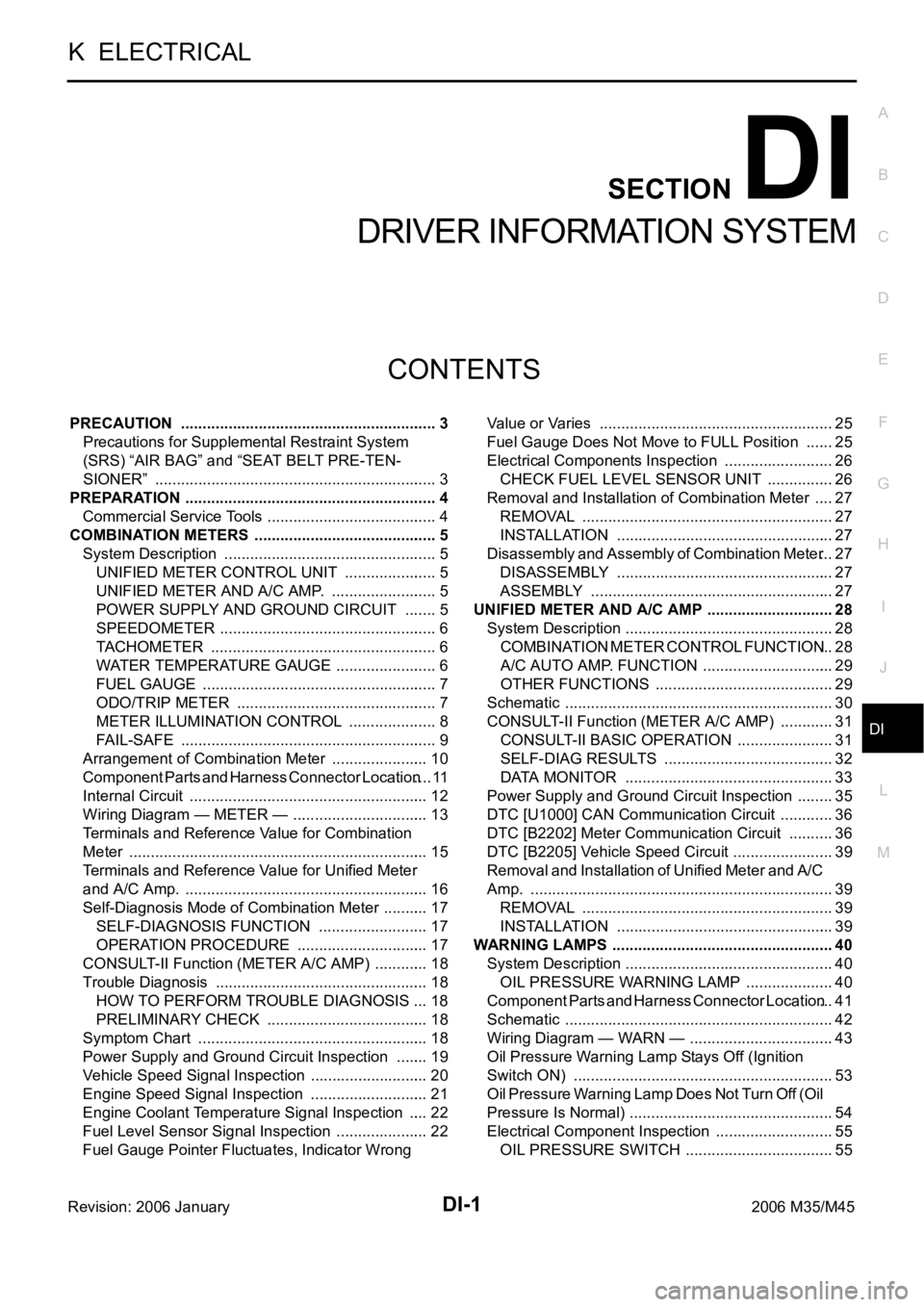

SPEEDOMETER

The speedometer indicates the vehicle speed.

ABS actuator and electric unit (control unit) converses a pulse signal from wheel sensor to vehicle speed

signal, and transmit vehicle speed signal to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits vehicle speed signal to combination meter with communication line.

Combination meter converses vehicle speed signal to the angle signal, and commands to speedometer.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

ECM converses a signal from crankshaft position sensor to engine speed signal, and transmits to unified

meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits engine speed signal to combination meter with communication line.

Combination meter converses engine speed signal to the angle signal, and commands to tachometer.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

ECM converses a signal from engine coolant temperature sensor to engine coolant temperature signal,

and transmits to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. transmits engine coolant temperature signal to combination meter with com-

munication line.

Combination meter converses engine coolant temperature signal to the angle signal, and commands to

water temperature gauge.

PKIC0696E

PKIB7631E

PKIB7632E

Page 1440 of 5621

COMBINATION METERS

DI-7

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

from unified meter and A/C amp. terminal 58

through the fuel level sensor unit and fuel pump (main) terminals 5 and 2, and

through the fuel level sensor unit (sub) terminals 2 and 1

to unified meter and A/C amp. terminal 42.

Unified meter and A/C amp. provides a fuel level signal to combination meter for fuel gauge with communica-

tion line between unified meter and A/C amp. and combination meter.

ODO/TRIP METER

ABS actuator and electric unit (control unit) converses a pulse signal from wheel sensor to vehicle speed

signal, and transmits vehicle speed signal to unified meter and A/C amp. with CAN communication.

Unified meter and A/C amp. converses vehicle speed signal to 8 pulse signal, and transmits to combina-

tion meter.

Combination meter processes the 8 pulse signal and the memory signals from the meter memory circuit.

Then the mileage is displayed.

How to Change The Display For Odo/trip Meter

Operating the odo/trip meter switch allows switching the mode in the following order.

The odo/trip meter display switching and trip display resetting

can be identified by the time from pressing the odo/trip meter

switch (1) to releasing it.

When resetting with “trip A” displayed, only “trip A” display is

reset. (The same way for “trip B”.)

SEL175W

PKIB7633E

Page 1449 of 5621

DI-16

COMBINATION METERS

Revision: 2006 January2006 M35/M45

Terminals and Reference Value for Unified Meter and A/C Amp.NKS003U1

Te r m i n a l

No.Wire

colorItemCondition

Reference value

(Approx.) Ignition

switchOperation or condition

7RTX communication line

(To combination meter)ON —

27 GRX communication line

(From combination meter)ON —

28 LGVehicle speed signal output

(8-pulse)ONSpeedometer operated

[When vehicle speed is

approx. 40 km/h (25 MPH)]NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

41 V Ignition switch ACC or ON ACC — Battery voltage

42 P/L Fuel level sensor signal — —Refer to DI-26, "

CHECK FUEL

LEVEL SENSOR UNIT" .

53 W/G Ignition switch ON or START ON — Battery voltage

54 W/G Battery power supply OFF — Battery voltage

55 B Ground ON — 0 V

56 L CAN H — — —

58 B Fuel level sensor ground ON — 0 V

71 B Ground (power) ON — 0 V

72 P CAN L — — —

SKIA3362E

SKIA3361E

PKIA1935E

Page 1451 of 5621

DI-18

COMBINATION METERS

Revision: 2006 January2006 M35/M45

CONSULT-II Function (METER A/C AMP)NKS003U3

Refer to DI-31, "CONSULT-II Function (METER A/C AMP)" in “UNIFIED METER AND A/C AMP”.

Trouble DiagnosisNKS003U4

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom or customer complaint.

2. Perform preliminary check. Refer to DI-18, "

PRELIMINARY CHECK" .

3. According to the symptom chart, make sure the cause of the symptom and repair or replace applicable

parts. Refer to DI-18, "

Symptom Chart" .

4. Does the meter operate normally? If yes, GO TO 5. If no, GO TO 2.

5. INSPECTION END

PRELIMINARY CHECK

1. CHECK OPERATION SELF-DIAGNOSIS MODE OF COMBINATION METER

Perform self-diagnosis mode of combination meter. Refer to DI-17, "

OPERATION PROCEDURE" .

Does self

-diagnosis mode operate?

YES >> GO TO 2.

NO >> GO TO 3.

2. CHECK UNIFIED METER AND A/C AMP. (CONSULT-II)

Perform self-diagnosis of unified meter and A/C amp. Refer to DI-31, "

CONSULT-II Function (METER A/C

AMP)" .

Self

-diagnostic results content

No malfunction detected>>INSPECTION END

Malfunction detected>>Check applicable parts, and repair or replace corresponding parts.

3. CHECK POWER SUPPLY AND GROUND CIRCUIT OF COMBINATION METER

Check power supply and ground circuit of combination meter. Refer to DI-19, "

Power Supply and Ground Cir-

cuit Inspection" .

OK or NG

OK >> Replace combination meter.

NG >> Repair power supply and ground circuit of combination meter.

Symptom ChartNKS003U5

Symptom Diagnosis/Service procedure

Speedometer or odo/trip meter indication is malfunction. Refer to DI-20, "

Vehicle Speed Signal Inspection" .

Tachometer indication is malfunction. Refer to DI-21, "

Engine Speed Signal Inspection" .

Water temperature gauge indication is malfunction. Refer to DI-22, "

Engine Coolant Temperature Signal Inspection" .

Fuel gauge indication is malfunction.

Refer to DI-22, "

Fuel Level Sensor Signal Inspection" .

Low-fuel warning lamp indication is irregular.

A/T position indicator is malfunction. Refer to DI-59, "

A/T Indicator Is Malfunction" .

Page 1455 of 5621

DI-22

COMBINATION METERS

Revision: 2006 January2006 M35/M45

Engine Coolant Temperature Signal InspectionNKS003U9

Symptom: Water temperature gauge indication is malfunction.

1. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Start engine and select “METER A/C AMP” on CONSULT-II.

2. Using “W TEMP METER” on “DATA MONITOR”, compare the

value of “DATA MONITOR” to the indication of water tempera-

ture gauge of combination meter.

Is the indication of water temperature gauge same as the value in

the monitor?

OK >> GO TO 2.

NG >> Replace combination meter. [Perform self-diagnosis of ECM when the value in the monitor indi-

cates 215

C (419F). Then repair or replace the malfunction part.]

2. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Select “ENGINE” on CONSULT-II.

2. Using “COOLAN TEMP/S” on “DATA MONITOR”, print out the

CONSULT-II screen.

3. Select “METER A/C AMP” on CONSULT-II.

4. Using “W TEMP METER” on “DATA MONITOR”, compare the

value of “DATA MONITOR” to that of the “COOLAN TEMP/S”.

OK or NG

OK >> Perform self-diagnosis of ECM. Refer to EC-133, "CON-

SULT-II Function (ENGINE)" (for VQ35DE) or EC-846,

"CONSULT-II Function (ENGINE)" (for VK45DE).

NG >> Replace unified meter and A/C amp.

Fuel Level Sensor Signal InspectionNKS003UA

Symptom:

Fuel gauge indication is malfunction.

Low-fuel warning lamp indication is irregular.

NOTE:

The following symptoms are not malfunction.

Fuel level sensor unit

Depending on vehicle position or driving circumstance, the fuel level in the tank varies, and the pointer

may fluctuate.

If the vehicle is fueled with the ignition switch ON, the pointer will move slowly.

Low-fuel warning lamp

Depending on vehicle position or driving circumstance, the fuel in the tank flows and the warning lamp ON

timing may change.

Water temperature gauge pointer Reference value of data monitor C (F)

Hot Approx. 130 (266)

Middle Approx. 70 - 105 (158 - 221)

Cold Approx. 50 (122)

PKIA2091E

SKIA4368E