Oil INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3335 of 5621

![INFINITI M35 2006 Factory Service Manual EM-272

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

If out of the standard, measure the main bearing oil clearance. Then use undersize bearing. Refer to EM-

274, "MAIN BEARING OIL CL INFINITI M35 2006 Factory Service Manual EM-272

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

If out of the standard, measure the main bearing oil clearance. Then use undersize bearing. Refer to EM-

274, "MAIN BEARING OIL CL](/img/42/57023/w960_57023-3334.png)

EM-272

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

If out of the standard, measure the main bearing oil clearance. Then use undersize bearing. Refer to EM-

274, "MAIN BEARING OIL CLEARANCE" .

CRANKSHAFT PIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft pin journal with

micrometer.

If out of the standard, measure the connecting rod bearing oil

clearance. Then use undersize bearing. Refer to EM-273,

"CONNECTING ROD BEARING OIL CLEARANCE" .

CRANKSHAFT OUT-OF-ROUND AND TAPER

Measure the dimensions at four different points as shown in the

figure on each main journal and pin journal with micrometer.

Out-of-round is indicated by the difference in the dimensions

between “X” and “Y” at “A” and “B”.

Taper is indicated by the difference in the dimensions between

“A” and “B” at “X” and “Y”.

If the measured value exceeds the limit, correct or replace crankshaft.

If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then

select the main bearing and/or connecting rod bearing. Refer to EM-274, "

MAIN BEARING OIL CLEAR-

ANCE" and/or EM-273, "CONNECTING ROD BEARING OIL CLEARANCE" .

CRANKSHAFT RUNOUT

Place V-block on precise flat table, and support the journals on

the both end of crankshaft.

Place dial indicator straight up on the No. 3 journal.

While rotating crankshaft, read the movement of the pointer on

dial indicator (total indicator reading).

If it exceeds the limit, replace crankshaft.Standard : 63.940 - 63.964 mm (2.5173 - 2.5183 in) dia.

Standard : 51.956 - 51.974 mm (2.0455 - 2.0462 in) dia.

PBIC0127E

Limit:

Out-of-round (Difference between “X” and “Y”)

: 0.015 mm (0.0006 in)

Taper (Difference between “A” and “B”)

: 0.010 mm (0.0004 in)

PBIC1685E

Standard : Less than 0.05 mm (0.002 in)

Limit : 0.10 mm (0.004 in)

PBIC2378E

Page 3336 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-273

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connectin INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-273

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connectin](/img/42/57023/w960_57023-3335.png)

CYLINDER BLOCK

EM-273

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Install connecting rod bearings to connecting rod and cap, and

tighten connecting rod bolts to the specified torque. Refer to

EM-254, "

ASSEMBLY" for the tightening procedure.

Measure the inner diameter of connecting rod bearing with

inside micrometer.

(Bearing oil clearance) = (Connecting rod bearing inner diameter) –

(Crankshaft pin journal diameter)

If the calculated value exceeds the limit, select proper connecting rod bearing according to connecting rod

big end diameter and crankshaft pin journal diameter to obtain the specified bearing oil clearance. Refer

to EM-261, "

HOW TO SELECT CONNECTING ROD BEARING" .

Method of Using Plastigage

Remove oil and dust on crankshaft pin journal and the surfaces of each bearing completely.

Cut plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

Install connecting rod bearings to connecting rod and cap, and tighten connecting rod bolts to the speci-

fied torque. Refer to EM-254, "

ASSEMBLY" for the tightening procedure.

CAUTION:

Do not rotate crankshaft.

Remove connecting rod bearing cap and bearing, and using

scale on plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.Standard : 0.020 - 0.045 mm (0.0008 - 0.0018 in)

(actual clearance)

Limit : 0.055 mm (0.0022 in)

PBIC1642E

PBIC1149E

Page 3337 of 5621

![INFINITI M35 2006 Factory Service Manual EM-274

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings to cylinder block and main bearing caps,

and tighten INFINITI M35 2006 Factory Service Manual EM-274

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings to cylinder block and main bearing caps,

and tighten](/img/42/57023/w960_57023-3336.png)

EM-274

[VK45DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

MAIN BEARING OIL CLEARANCE

Method by Calculation

Install main bearings to cylinder block and main bearing caps,

and tighten main bearing cap bolts with main bearing to the

specified torque. Refer to EM-254, "

ASSEMBLY" for the tighten-

ing procedure.

Measure the inner diameter of main bearing with bore gauge.

(Bearing clearance) = (Main bearing inner diameter) – (Crankshaft main journal diameter)

If the calculated value exceeds the limit, select proper main bearing according to main bearing inner diam-

eter and crankshaft main journal diameter to obtain the specified bearing oil clearance. Refer to EM-262,

"HOW TO SELECT MAIN BEARING" .

Method of Using Plastigage

Remove oil and dust on crankshaft main journal and the surfaces of each bearing completely.

Cut plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

Install main bearings to cylinder block and main bearing caps, and tighten main bearing bolts with main

bearing to the specified torque. Refer to EM-254, "

ASSEMBLY" for the tightening procedure.

CAUTION:

Do not rotate crankshaft.

Remove main bearing caps and bearings, and using scale on

plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

PBIC1644E

Standard

No . 1 and 5 journal : 0.001 - 0.011 mm (0.00004 - 0.0004 in)

No. 2, 3 and 4 journal : 0.007 - 0.017 mm (0.0003 - 0.0007 in)

Limit

No. 1 and 5 journal : 0.021 mm (0.0008 in)

No. 2, 3 and 4 journal : 0.027 mm (0.0011 in)

PBIC1149E

Page 3339 of 5621

![INFINITI M35 2006 Factory Service Manual EM-276

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004PQ

GENERAL SPECIFICATIONS

DRIVE BELTS

IN INFINITI M35 2006 Factory Service Manual EM-276

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004PQ

GENERAL SPECIFICATIONS

DRIVE BELTS

IN](/img/42/57023/w960_57023-3338.png)

EM-276

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004PQ

GENERAL SPECIFICATIONS

DRIVE BELTS

INTAKE MANIFOLD AND EXHAUST MANIFOLD

Unit: mm (in) Cylinder arrangementV-8

Displacement cm

3 (cu in)4,494 (274.22)

Bore and stroke mm (in)93 x 82.7 (3.66 x 3.256)

Valve arrangementDOHC

Firing order1-8-7-3-6-5-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio10.5

Compression pressure

kPa (kg/cm

2 , psi)/300 rpmStandard 1,320 (13.5, 191)

Minimum 1,130 (11.5, 164)

Differential limit

between cylinders98 (1.0, 14)

Cylinder number

Va l v e t i m i n g

Unit: degree

abcde f

228 240 -2 62 4 44

SEM957C

PBIC0187E

Tension of drive belts Auto adjustment by auto tensioner

Items Limit

Surface distortionIntake manifold (upper) 0.1 (0.004)

Intake manifold (lower) 0.1 (0.004)

Exhaust manifold 0.3 (0.012)

Page 3346 of 5621

![INFINITI M35 2006 Factory Service Manual SERVICE DATA AND SPECIFICATIONS (SDS)

EM-283

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

PISTON, PISTON RING AND PISTON PIN

Ava ilable Piston

Unit: mm (in)

Piston Ring

Unit: INFINITI M35 2006 Factory Service Manual SERVICE DATA AND SPECIFICATIONS (SDS)

EM-283

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

PISTON, PISTON RING AND PISTON PIN

Ava ilable Piston

Unit: mm (in)

Piston Ring

Unit:](/img/42/57023/w960_57023-3345.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-283

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

PISTON, PISTON RING AND PISTON PIN

Ava ilable Piston

Unit: mm (in)

Piston Ring

Unit: mm (in)

Piston Pin

Unit: mm (in) Items Standard Oversize [0.2 (0.008)]

Piston skirt diameter “A”Grade No. 1 92.980 - 92.990 (3.6606 - 3.6610) —

Grade No. 2 92.990 - 93.000 (3.6610 - 3.6614) —

Grade No. 3 93.000 - 93.010 (3.6614 - 3.6618) —

Service — 93.180 - 93.210 (3.6685 - 3.6697)

“H” dimension42 (1.65)

Piston pin hole diameterGrade No. 0 21.993 - 21.999 (0.8659 - 0.8661)

Grade No. 1 21.999 - 22.005 (0.8661 - 0.8663)

Piston to cylinder bore

clearanceStandard 0.010 - 0.030 (0.0004 - 0.0012)

Limit 0.08 (0.0031)

PBIC0188E

Standard Limit

Side clearanceTop 0.045 - 0.080 (0.0018 - 0.0031) 0.11 (0.0043)

2nd 0.030 - 0.070 (0.0012 - 0.0028) 0.1 (0.004)

Oil ring 0.065 - 0.135 (0.0026 - 0.0053) —

End gapTop 0.22 - 0.32 (0.0087 - 0.0126) 0.56 (0.0220)

2nd 0.22 - 0.32 (0.0087 - 0.0126) 0.56 (0.0220)

Oil (rail ring) 0.20 - 0.50 (0.0079 - 0.0197) 0.96 (0.0378)

Items Standard Limit

Piston pin outer diameterGrade No. 0 21.989 - 21.995 (0.8657 - 0.8659) —

Grade No. 1 21.995 - 22.001 (0.8659 - 0.8662) —

Piston to piston pin oil clearance 0.002 - 0.006 (0.0001 - 0.0002) —

Connecting rod bushing oil clearance 0.005 - 0.017 (0.0002 - 0.0007) 0.030 (0.0012)

Page 3351 of 5621

![INFINITI M35 2006 Factory Service Manual EM-288

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Main Bearing Oil Clearance

Unit: mm (in)

CONNECTING ROD BEARING

Unit: mm (in)

Undersize

Unit: mm (in)

Connectin INFINITI M35 2006 Factory Service Manual EM-288

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Main Bearing Oil Clearance

Unit: mm (in)

CONNECTING ROD BEARING

Unit: mm (in)

Undersize

Unit: mm (in)

Connectin](/img/42/57023/w960_57023-3350.png)

EM-288

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Main Bearing Oil Clearance

Unit: mm (in)

CONNECTING ROD BEARING

Unit: mm (in)

Undersize

Unit: mm (in)

Connecting Rod Bearing Oil Clearance

Unit: mm (in) Main bearing oil clearanceStandardNo.1 and 5 0.001 - 0.011 (0.00004 - 0.0004)

No.2, 3 and 4 0.007 - 0.017 (0.0003 - 0.0007)

LimitNo.1 and 5 0.021 (0.0008)

No.2, 3 and 4 0.027 (0.0011)

Grade number Thickness Identification color (mark)

0 1.500 - 1.503 (0.0591 - 0.0592) No color

1 1.503 - 1.506 (0.0592 - 0.0593) Brown

2 1.506 - 1.509 (0.0593 - 0.0594) Green

Undersize Thickness Pin journal diameter

0.25 (0.0098) 1.626 - 1.634 (0.0640 - 0.0643) Grind so that bearing clearance is the specified value.

Connecting rod bearing oil clearanceStandard 0.020 - 0.045 (0.0008 - 0.0018)

Limit 0.055 (0.0022)

Page 3371 of 5621

FAX-12

FRONT DRIVE SHAFT

Revision: 2006 January2006 M35/M45

8. Remove cotter pin (1), and then loosen the nut.

9. Remove steering outer socket (2) from steering knuckle (3) so

as not to damage ball joint boot (4) using the ball joint remover

(suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover (suitable tool) from

suddenly coming off.

10. Remove drive shaft from wheel hub and bearing assembly.

11. Remove fixing nuts and bolts, and then remove shock absorber

arm. Refer to FSU-25, "

Components" .

12. Remove drive shaft from transaxle. (right side)

Remove drive shaft from transaxle using the drive shaft

attachment [SST] and a drive shaft puller (suitable tool) while

inserting tip of the drive shaft attachment [SST] between

housing and transaxle as shown in the figure.

CAUTION:

Do not place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

13. Remove fixing nuts and bolts, and then remove drive shaft from

vehicle. (left side)

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in the axial directions. Check for motion that is not smooth and for sig-

nificant looseness.

Check boot for cracks, damage, and leakage of grease.

Disassemble drive shaft and exchange malfunctioning part if

there is a non-standard condition.

INSTALLATION

CAUTION:

Always replace transaxle side oil seal with new one when installing drive shaft. Refer to FFD-11, "

SIDE

OIL SEAL" .

Installation is the reverse order of removal. For tightening torque refer to FA X - 11 , "COMPONENT" .

Place the protector [SST: KV38107900 ( – )] onto transaxle

to prevent damage to the oil seal while inserting drive shaft.

Slide drive shaft sliding joint and tap with a hammer to install

securely. (right side)

SGIA1183E

SDIA1504E

SDIA1163J

SDIA0593E

Page 3378 of 5621

FFD-1

FRONT FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION FFD

A

B

FFD

Revision: 2006 January2006 M35/M45

FRONT FINAL DRIVE

PRECAUTIONS .......................................................... 2

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 2

OPERATION PROCEDURE ................................. 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Sectional View ............................................... 7

DIFFERENTIAL GEAR OIL ........................................ 8

Changing Differential Gear Oil ................................. 8

DRAINING ............................................................. 8

FILLING ................................................................. 8

Checking Differential Gear Oil .................................. 8

OIL LEAKAGE AND OIL LEVEL ........................... 8

FRONT OIL SEAL .................................................

..... 9

Removal and Installation .......................................... 9

REMOVAL ........................................................

..... 9

INSTALLATION ................................................... 10SIDE OIL SEAL ......................................................... 11

Removal and Installation ........................................ 11

REMOVAL ........................................................

... 11

INSTALLATION ................................................... 11

FRONT FINAL DRIVE ASSEMBLY .......................... 13

Removal and Installation ........................................ 13

COMPONENTS ................................................... 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 14

Disassembly and Assembly .................................... 15

COMPONENTS ................................................... 15

ASSEMBLY INSPECTION AND ADJUSTMENT ... 16

DISASSEMBLY ................................................... 20

INSPECTION AFTER DISASSEMBLY ................ 24

ADJUSTMENT AND SELECTION OF ADJUST-

ING WASHERS (SHIMS) .................................... 25

ASSEMBLY ......................................................... 28

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

General Specifications ......................................... ... 35

Inspection and Adjustment ..................................... 35

DRIVE GEAR RUNOUT ...................................... 35

DIFFERENTIAL SIDE GEAR CLEARANCE ....... 35

PRELOAD TORQUE ........................................... 35

BACKLASH ......................................................... 35

COMPANION FLANGE RUNOUT ....................... 35

SELECTIVE PARTS ............................................ 35

Page 3379 of 5621

FFD-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions Necessary for Steering Wheel Rotation after Battery DisconnectNDS000EK

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK

position, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-II.

Service Notice or PrecautionsNDS000EL

Check for the correct installation status prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of the parts when applied.

Overhaul should be done in a clean work area, it is preferable to work in dustproof area.

Before disassembly, using steam or white gasoline, completely remove sand and mud from the exterior of

the unit, preventing them from entering into the unit during disassembly or assembly.

Check appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with a new ones if necessary.

Gaskets, seals and O-rings should be replaced any time when the unit is disassembled.

In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, observe it.

Clean and flush the parts sufficiently and blow-dry them.

Be careful not to damage sliding surfaces and mating surfaces.

When applying sealant, remove the old sealant from the mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

Always use shop paper for cleaning the inside of components.

Avoid using cotton gloves or shop rags to prevent entering of lint.

During assembly, observe the specified tightening torque, and apply new gear oil, petroleum jelly, or multi-

purpose grease as specified for each vehicle, if necessary.

Page 3380 of 5621

PREPARATION

FFD-3

C

E

F

G

H

I

J

K

L

MA

B

FFD

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

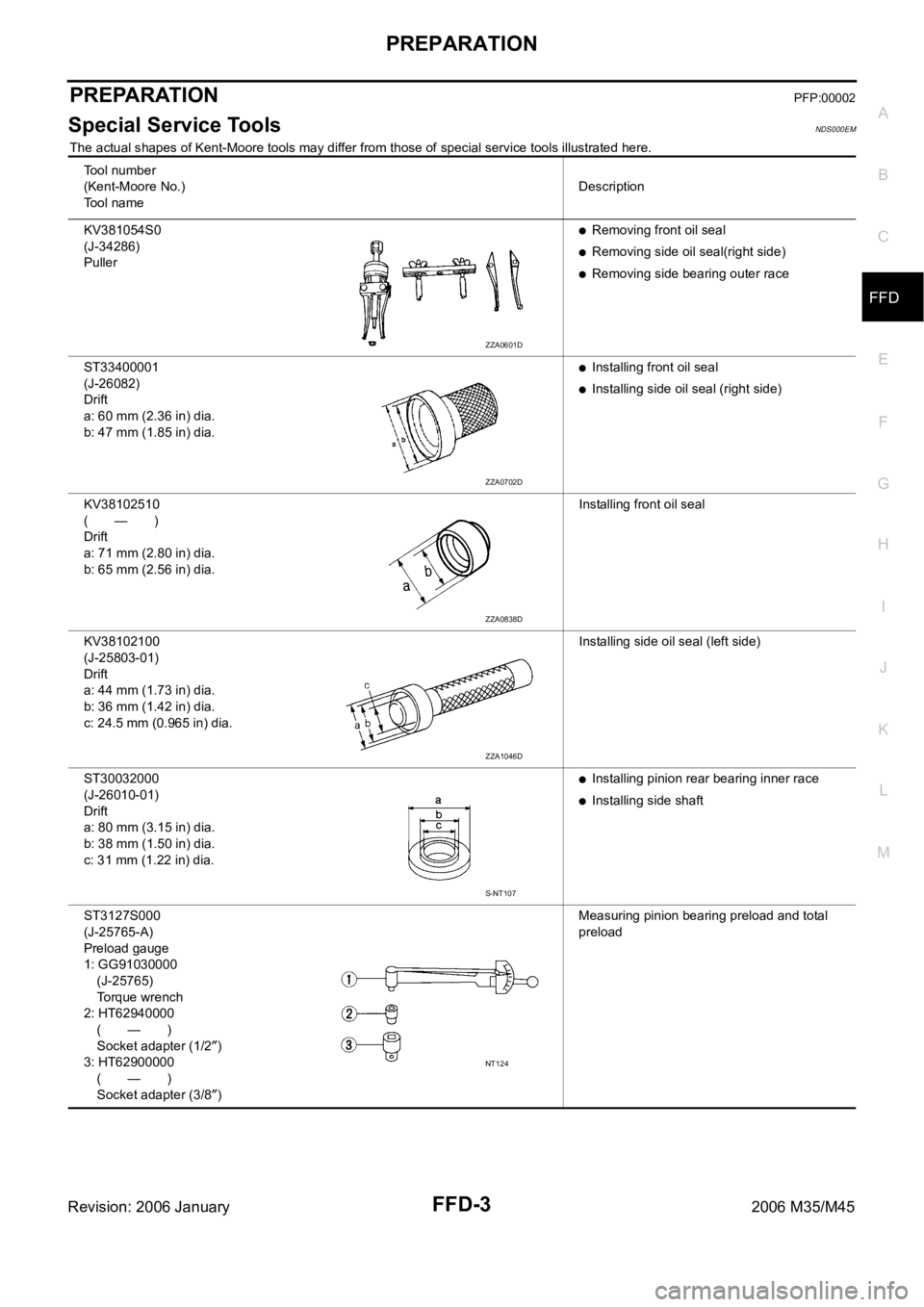

Special Service ToolsNDS000EM

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

To o l n u m b e r

(Kent-Moore No.)

To o l n a m eDescription

KV381054S0

(J-34286)

Puller

Removing front oil seal

Removing side oil seal(right side)

Removing side bearing outer race

ST33400001

(J-26082)

Drift

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing front oil seal

Installing side oil seal (right side)

KV38102510

(—)

Drift

a: 71 mm (2.80 in) dia.

b: 65 mm (2.56 in) dia.Installing front oil seal

KV38102100

(J-25803-01)

Drift

a: 44 mm (1.73 in) dia.

b: 36 mm (1.42 in) dia.

c: 24.5 mm (0.965 in) dia.Installing side oil seal (left side)

ST30032000

(J-26010-01)

Drift

a: 80 mm (3.15 in) dia.

b: 38 mm (1.50 in) dia.

c: 31 mm (1.22 in) dia.

Installing pinion rear bearing inner race

Installing side shaft

ST3127S000

(J-25765-A)

Preload gauge

1: GG91030000

(J-25765)

Torque wrench

2: HT62940000

(—)

Socket adapter (1/2

)

3: HT62900000

(—)

Socket adapter (3/8

)Measuring pinion bearing preload and total

preload

ZZA0601D

ZZA0702D

ZZA0838D

ZZA1046D

S-NT107

NT124