check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1126 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-187

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

2. CHECK POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect key slot connector.

3. Check voltage between key slot connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Check key slot power supply circuit for open or short.

3. CHECK HARNESS CONTINUITY 1

1. Disconnect Intelligent Key unit connector.

2. Check continuity between Intelligent Key unit connector and key slot connector.

3. Check continuity between Intelligent Key unit connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK KEY SLOT

Check key slot.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Replace key slot.

Terminals

Voltage (V)

(Approx.) (+)

(–)

Key slot connector Terminal

M14 1 Ground Battery voltage

PIIB6258E

AB

Continuity

Intelligent Key

unit connectorTerminal Key slot connector Terminal

M32 19 M14 2 Yes

A

GroundContinuity

Intelligent Key unit connector Terminal

M32 19 No

PIIB6259E

Terminal

Condition Continuity

Key slot

12Keyslot inserted Yes

Keyslot removed No

PIIB6260E

Page 1127 of 5621

BL-188

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Revision: 2006 January2006 M35/M45

5. CHECK HARNESS CONTINUITY 2

1. Disconnect BCM connector.

2. Check continuity between BCM connector and key slot connector.

3. Check continuity between BCM connector and ground.

OK or NG

OK >> Replace BCM. Refer to "C/U INITIALIZATION", and then perform the registration again after

replacing BCM.

NG >> Repair or replace harness.

Check NATS Antenna Amp. Built In Key SlotNIS001Z8

For the circuit information of this diagnosis, refer to Engine Immobilizer System Circuit Diagram.

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect key slot connector.

3. Check voltage between key slot connector and ground.

OK or NG

OK >> GO TO 2.

NG >> Check key slot power supply circuit for open or short.

2. CHECK GROUND CIRCUIT

Check continuity between key slot connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

AB

Continuity

BCM connector Terminal Key slot connector Terminal

M1 37 M14 2 Yes

A

GroundContinuity

BCM connector Terminal

M1 37 No

PIIB6261E

Terminals

Voltage (V)

(Approx.) (+)

(–)

Key slot connector Terminal

M14 1 Ground Battery voltage

PIIB6258E

Key slot connector Terminal

GroundContinuity

M14 8 Yes

PIIB6262E

Page 1128 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-189

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

3. CHECK KEY SLOT SIGNAL

1. Connect key slot connector.

2. Check voltage between key slot connector and ground.

OK or NG

OK >> Check the condition of harness and connector.

NG >> Repair or replace harness between BCM and key slot.

Terminals

ConditionVoltage (V)

(Approx.) (+)

(–)

Key slot

connectorTerminal

M146

GroundCheck the voltage just

after the Intelligent Key

is inserted into the key

slot and the ignition

switch is turned to

START.The pointer of

the analog

tester fluctu-

ates. 7

PIIB6263E

Page 1130 of 5621

DOOR

BL-191

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

2. Accessing from inside the vehicle, loosen the mounting nuts. Open the rear door, and raise the rear door

at rear end to adjust.

STRIKER ADJUSTMENT

1. Adjust the striker so that it becomes parallel with the lock inser-

tion direction.

Removal and Installation of Front DoorNIS001ZA

CAUTION:

When removing and installing the front door assembly, support the door with a jack and cloth to

protect the door and body.

When removing and installing front door assembly, be sure to carry out the fitting adjustment.

Refer to BL-190, "

Fitting Adjustment" .

After installing, apply touch-up paint (the body color) onto the head of the hinge mounting nuts.

Check the hinge rotating part for poor lubrication. If necessary, apply “body grease”.

Operate with two workers, because of its heavy weight.

Check rear door open/close operation after installation.

REMOVAL

1. Pull the lever and disconnect the door harness connector while

removing tabs of door harness connector.

2. Remove the mounting bolts of the check link on the vehicle.

PIIB2804J

PIIB3884J

PIIB2865J

Page 1131 of 5621

BL-192

DOOR

Revision: 2006 January2006 M35/M45

3. Remove the door-side hinge mounting nuts, then remove the

door assembly.

INSTALLATION

Install in the reverse order of removal.

Removal and Installation of Rear DoorNIS001ZB

CAUTION:

When removing and installing the rear door assembly, support the door with a jack and cloth to

protect the door and body.

When removing and installing rear door assembly, be sure to carry out the fitting adjustment.

Refer to BL-190, "

Fitting Adjustment" .

Check the hinge rotating part for poor lubrication. If necessary, apply “body grease”.

After installing, apply touch-up paint (the body color) onto the head of the hinge mounting nuts.

Operate with two workers, because of its heavy weight.

Check rear door open/close operation after installation.

REMOVAL

1. Pull out grommet and disconnect rear door harness connector.

2. Remove the mounting bolts of the check link on the vehicle.

PIIB3912J

PIIB3913J

PIIB2865J

Page 1133 of 5621

BL-194

DOOR

Revision: 2006 January2006 M35/M45

Door WeatherstripNIS001ZC

FRONT DOOR

REMOVAL

1. Remove the mounting bolts of the check link on the vehicle. Refer to BL-191, "Removal and Installation of

Front Door" or BL-192, "Removal and Installation of Rear Door" .

2. Remove the weatherstrip clips and remove weatherstrip.

CAUTION:

After removal, do not pull strongly on the weatherstrip.

INSTALLATION

Install in the reverse order of removal.

Install the door weatherstrip (A) and along the arrow direction.

1. Door weatherstrip 2. Front door 3. Door sash molding

PIIB3878J

Page 1134 of 5621

DOOR

BL-195

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

REAR DOOR

REMOVAL

1. Remove the mounting bolts of the check link on the vehicle. Refer to BL-191, "Removal and Installation of

Front Door" or BL-192, "Removal and Installation of Rear Door" .

2. Remove the weatherstrip clips and remove weatherstrip.

CAUTION:

After removal, do not pull strongly on the weatherstrip.

INSTALLATION

Install in the reverse order of removal.

Install the door weatherstrip (A) and along the arrow direction.

1. Door weatherstrip 2. Rear door 3. Door sash molding

PIIB3879J

Page 1142 of 5621

TRUNK LID

BL-203

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

TRUNK LIDPFP:H4300

Fitting AdjustmentNIS001ZH

1. Check the clearance and the evenness between the trunk lid and eack part by visual and tactile feeling.

(Fitting standard dimension in the table below should be satisfied.)

* Unit: mm (in)

2. In case out of specification, adjust them according to the procedures shown below.

Loosen the bumper rubber.

1. Trunk lid assembly 2. Rear fender 3. Rear combination lamp

4. Rear bumper fascia 5. Bumper rubber 6. Trunk lid hinge

7. Trunk lid striker

Parts Standard Parallelism (MAX) Right/left clearance (MAX)

A – Aa 2.5 - 4.5 (01.0 - 0.18) 1.5 (0.06) 1.5 (0.06)

b -1.0 - 1.0 (-0.04 - 0.04) 1.5 (0.06) 1.5 (0.06)

B – Ba 2.5 - 5.5 (0.10 - 0.22) — 2.0 (0.08)

b -1.5 - 1.5 (-0.06 - 0.06) — 2.0 (0.08)

C – C a 2.4 - 6.6 (0.09 - 0.26) 2.5 (0.10) —

PIIB5817E

Page 1143 of 5621

BL-204

TRUNK LID

Revision: 2006 January2006 M35/M45

Loosen the striker mounting bolts.

Lift up the trunk lid approx. 100 - 150 mm (3.94 - 5.91 in) height then close it lightly and make sure it

engaged firmly with the trunk lid closed.

Check the clearance and evenness.

Finally tighten the trunk lid striker.

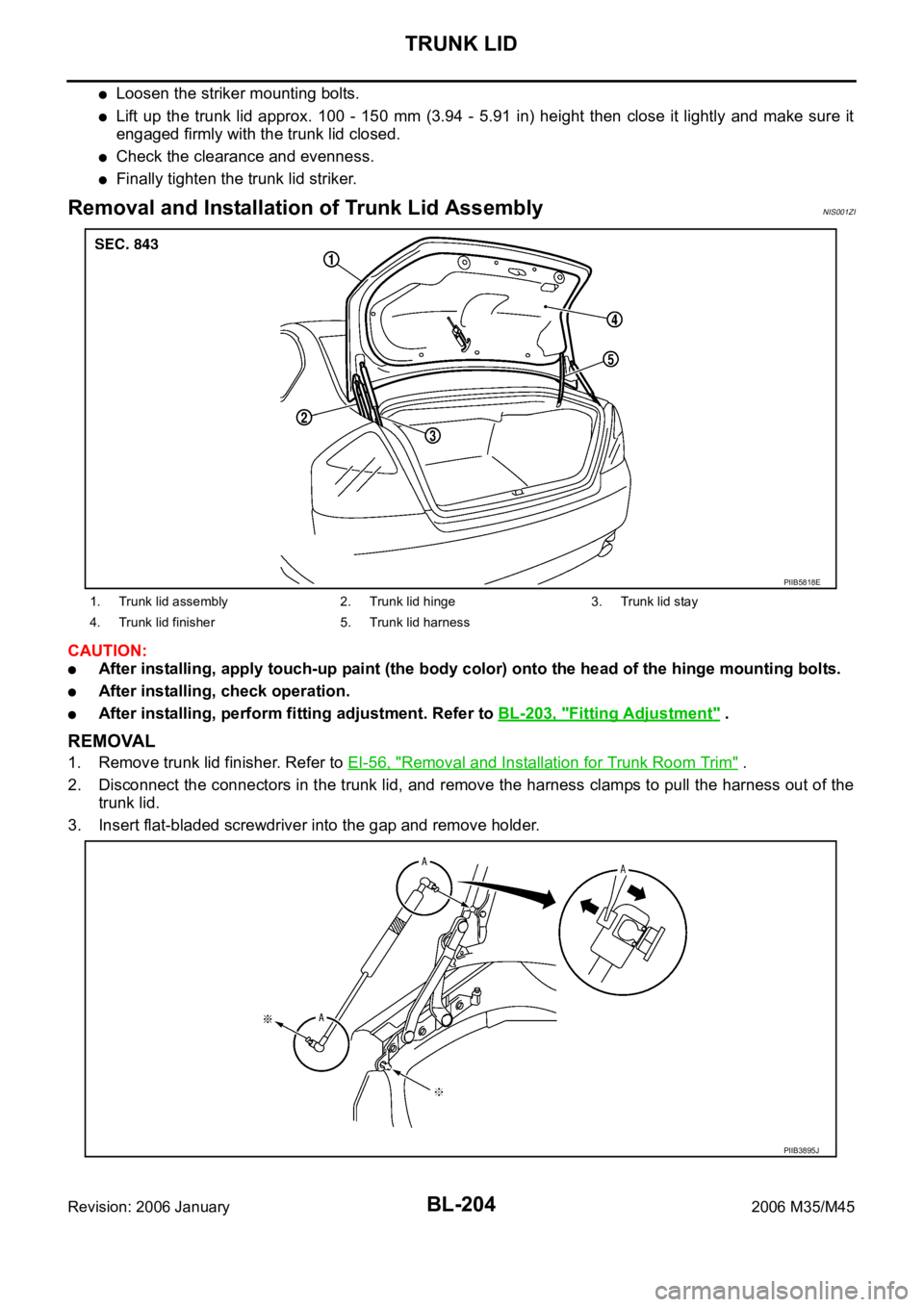

Removal and Installation of Trunk Lid AssemblyNIS001ZI

CAUTION:

After installing, apply touch-up paint (the body color) onto the head of the hinge mounting bolts.

After installing, check operation.

After installing, perform fitting adjustment. Refer to BL-203, "Fitting Adjustment" .

REMOVAL

1. Remove trunk lid finisher. Refer to EI-56, "Removal and Installation for Trunk Room Trim" .

2. Disconnect the connectors in the trunk lid, and remove the harness clamps to pull the harness out of the

trunk lid.

3. Insert flat-bladed screwdriver into the gap and remove holder.

1. Trunk lid assembly 2. Trunk lid hinge 3. Trunk lid stay

4. Trunk lid finisher 5. Trunk lid harness

PIIB5818E

PIIB3895J

Page 1144 of 5621

TRUNK LID

BL-205

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

4. Remove trunk lid stay (gas stay).

WAR NING :

Body injury may occur if no supporting rod is holding the

trunk lid open when removing the damper stay.

5. Remove the mounting bolts, and remove the trunk lid assembly.

INSTALLATION

Install in the reverse order of removal.

Removal and Installation of Trunk Lid StayNIS001ZJ

REMOVAL

1. Insert flat-bladed screwdriver into the gap and remove holder.

2. Remove trunk lid stay on the trunk lid.

3. Remove the stud balls, and trunk lid stay.

INSTALLATION

1. Install in the reverse order of removal.

2. After installing, check the operation.

PIIB4909J

PIIB3895J