light INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5461 of 5621

![INFINITI M35 2006 Factory Service Manual STC-46

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Diagnosis Chart by Symptom 1NGS000F1

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform RAS self-diagnosis.

With CONSULT-II: STC-28, "SELF-D INFINITI M35 2006 Factory Service Manual STC-46

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Diagnosis Chart by Symptom 1NGS000F1

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform RAS self-diagnosis.

With CONSULT-II: STC-28, "SELF-D](/img/42/57023/w960_57023-5460.png)

STC-46

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Diagnosis Chart by Symptom 1NGS000F1

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform RAS self-diagnosis.

With CONSULT-II: STC-28, "SELF-DIAG RESULT MODE"

Without CONSULT-II: STC-31, "Diagnosis Procedure with Self-Diagnosis Function (Without CONSULT-

II)"

Are malfunctioning items displayed in self-diagnosis results?

YES >> Repair or replace any malfunctioning items.

NO >> GO TO 2.

2. CHECK RAS STATIC/DYNAMIC CHARACTERISTICS

Check RAS static/dynamic characteristics. Refer to STC-48, "

Check RAS Static/Dynamic Characteristics" .

Is the malfunction corrected?

YES >> INSPECTION END

NO >> Perform the following check, and then check the symptom again.

Adjust neutral position of steering angle sensor. Refer to BRC-6, "Adjustment of Steering Angle

Sensor Neutral Position" .

Steering angle sensor mounting condition. Refer to BRC-63, "Removal and Installation" .

Diagnosis Chart by Symptom 2NGS000F2

The steering force does not change smoothly according to the vehicle speed (Heavy steering force with the

vehicle stopped/Light handle operation during high-speed driving)

1. CHECK (1): POWER STEERING SOLENOID VALVE SIGNAL

1. Start engine.

2. Change the vehicle speed from 0 to 100 km/h (0 to 62 MPH)

slowly, and then check voltage RAS control unit harness con-

nector B127.

OK or NG

OK >> GO TO 2.

NG >> GO TO 7.

2. CHECK (2): POWER STEERING SOLENOID VALVE SIGNAL

1. Activate fail-safe function by running engine speed at 1,500 rpm or higher for 10 seconds with the vehicle

stopped.

2. Change the engine speed to the idling speed, approx. 1,600

rpm, and approximately 3,000 rpm slowly, and then check volt-

age RAS control unit harness connector B127.

OK or NG

OK >> GO TO 3.

NG >> GO TO 7.Terminal 36 – 34 : The voltage has changed from

approximately 4.4 - 6.6 V to approxi-

mately 2.4 - 3.6 V.

SGIA1281E

Terminal 36 – 34 : The voltage is changed from

approximately 5.5 V to approximately

2.1 V step-by-step.

SGIA1281E

Page 5485 of 5621

TF-20

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Trouble Diagnosis Chart for SymptomsNDS000DK

If AWD warning lamp turns ON, perform self-diagnosis. Refer to TF-22, "SELF-DIAG RESULT MODE" .

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunction.

AWD Control Unit Input/Output Signal Reference ValuesNDS000DL

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

AWD warning lamp does not turn ON when

the ignition switch is turned to ON.

(AWD warning lamp check)Ignition switch: ONCAN communication line

TF-33

Unified meter and A/C amp.

Unified meter control unit

AWD warning lamp does not turn OFF sev-

eral seconds after engine started.Engine runningCAN communication line

TF-33

Power supply and ground for AWD con-

trol unit

Unified meter and A/C amp.

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

Heavy tight-corner braking symptom occurs

when the vehicle is driven and the steering

wheel is turned fully to either side after the

engine is started. (See NOTE.)

While driving

Steering wheel is

turned fully to either

sidesCAN communication line

TF-35Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF.While drivingCAN communication line

TF-36

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (Mechanical engage-

ment of clutch is not possible.)

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/secondWhile drivingProtection function is activated due to

heavy load to electric controlled cou-

pling. (AWD system is not malfunction-

ing. Also, optional distribution of torque

sometimes becomes rigid before lamp

flashes rapidly, but it is not malfunction.)TF-37

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turn-

ing ignition switch OFF)

Slow flashing: 1 time/2 secondsWhile driving

Vehicle speed: 20 km/h

(12 MPH) or moreTire size is different between front and

rear of vehicle.TF-37

Monitor item [Unit] Content Condition Display value

FR RH SENSOR [km/h] or [mph]Wheel speed (Front wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

FR LH SENSOR [km/h] or [mph]Wheel speed (Front wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

Page 5500 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-35

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

4. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >> GO TO 5.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

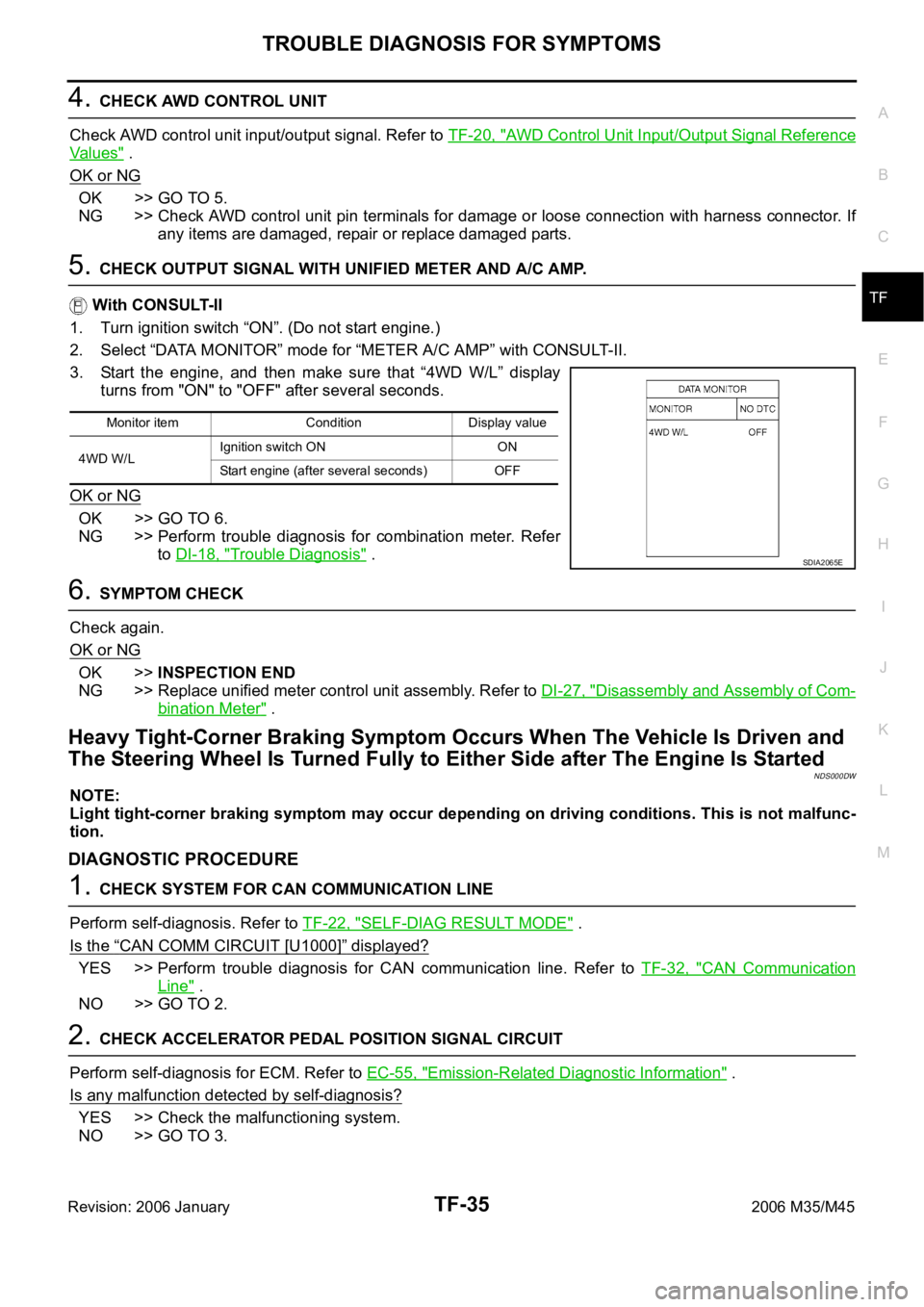

5. CHECK OUTPUT SIGNAL WITH UNIFIED METER AND A/C AMP.

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “METER A/C AMP” with CONSULT-II.

3. Start the engine, and then make sure that “4WD W/L” display

turns from "ON" to "OFF" after several seconds.

OK or NG

OK >> GO TO 6.

NG >> Perform trouble diagnosis for combination meter. Refer

to DI-18, "

Trouble Diagnosis" .

6. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-27, "

Disassembly and Assembly of Com-

bination Meter" .

Heavy Tight-Corner Braking Symptom Occurs When The Vehicle Is Driven and

The Steering Wheel Is Turned Fully to Either Side after The Engine Is Started

NDS000DW

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunc-

tion.

DIAGNOSTIC PROCEDURE

1. CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-22, "

SELF-DIAG RESULT MODE" .

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-32, "CAN Communication

Line" .

NO >> GO TO 2.

2. CHECK ACCELERATOR PEDAL POSITION SIGNAL CIRCUIT

Perform self-diagnosis for ECM. Refer to EC-55, "

Emission-Related Diagnostic Information" .

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

Monitor item Condition Display value

4WD W/LIgnition switch ON ON

Start engine (after several seconds) OFF

SDIA2065E

Page 5501 of 5621

TF-36

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

3. CHECK SYSTEM FOR AWD SOLENOID

Perform trouble diagnosis for AWD solenoid system. Refer to TF-28, "

AWD Solenoid" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. CHECK ELECTRIC CONTROLLED COUPLING

1. Turn ignition switch “OFF”.

2. Set the selector lever to “N” (neutral) position and disengage the parking brake.

3. Lift up the vehicle.

4. Rotate the rear propeller shaft by hand.

5. Hold front propeller shaft lightly.

Does front propeller shaft rotate?

YES >> Replace electric controlled coupling for mechanical malfunction (clutch sticking etc.). Refer to TF-

45, "Disassembly and Assembly" .

NO >> GO TO 5.

5. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >>INSPECTION END

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

Vehicle Does Not Enter AWD Mode Even Though AWD Warning Lamp Turned to

OFF

NDS000DX

DIAGNOSTIC PROCEDURE

1. CHECK AWD WARNING LANP

Turn ignition switch “ON”. (Do not start engine.)

Does AWD warning lamp turn on?

YES >> GO TO 2.

NO >> Go to TF-33, "

AWD Warning Lamp Does Not Turn ON When The Ignition Switch Is Turned to ON"

.

2. CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-22, "

SELF-DIAG RESULT MODE" .

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-32, "CAN Communication

Line" .

NO >> GO TO 3.

Page 5549 of 5621

WT-24

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

LOW TIRE PRESSURE WARNING CONTROL UNIT PART NUMBER

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. The part number described on low tire pressure warning control unit sticker is displayed.

Diagnosis Procedure with Warning Lamp Function (Without CONSULT-II)NES000K6

DESCRIPTION

During driving, the low tire pressure warning system receives the signal transmitted from the transmitter

installed in each wheel, and gives alarms when the tire pressure becomes low. The control unit (low tire pres-

sure warning control unit) of this system has pressure judgement and trouble diagnosis functions.

FUNCTION

When the low tire pressure warning system detects low inflation pressure or another unusual symptom, the

warning lamps in the combination meter comes on. To start the self-diagnostic results mode, ground terminal

of the tire pressure warning check connector. The malfunction location is indicated by the warning lamp flash-

ing and the buzzer sounds. Regarding location of tire pressure warning check connector, refer to PG-63,

"HARNESS" .

LOW TIRE PRESSURE WARNING LAMP DIAGNOSTIC CHART

Diagnosis

ItemSymptom

(Ignition switch ON)Low tire pressure warning lamp Cause Action

Low tire pres-

sure warning

lampWarning light comes

on immediately and

turns off after 1 sec-

ond.All wheel transmit-

ters are “activated”

(working).None (system OK)

Warning light blinks

on for 2 seconds,

then turns off for 0.2

seconds-repeats.All wheel transmit-

ters are not acti-

vated.Activate all wheel tire pres-

sure transmitters. Refer to

WT-21, "

Transmitter Wake Up

Operation" .

Warning light blinks

1 time.Tire pressure trans-

mitter front LH is not

activated.Activate tire pressure trans-

mitter front LH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light blinks

2 times.Tire pressure trans-

mitter front RH is not

activated.Activate tire pressure trans-

mitter front RH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light blinks

3 times.Tire pressure trans-

mitter rear RH is not

activated.Activate tire pressure trans-

mitter rear RH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

SEIA0592E

SEIA0593E

SEIA0594E

SEIA0595E

SEIA0596E

Page 5550 of 5621

TROUBLE DIAGNOSES

WT-25

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

NOTE:

If more than one wheel transmitter is NOT activated, the warning lamp blinking patterns for those wheels will combine. (Example: one

blink/OFF/three blinks = Tire pressure transmitter rear LH and rear RH are not activated.) Low tire pres-

sure warning

lampWarning light blinks

4 times.Tire pressure trans-

mitter rear LH is not

activated.Activate tire pressure trans-

mitter rear LH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light comes

on and does not turn

off.Tire pressure is low.Check tire pressure with

CONSULT-II. Refer to WT-23,

"DATA MONITOR MODE" .

The fuse for combi-

nation meter from

battery is pulled out.Check the fuse for combina-

tion meter from battery. Install

or replace (if needed).

Low tire pressure

warning control unit

connector pulled outCheck low tire pressure warn-

ing control unit connector. Re-

connect if needed.

Low tire pressure or

low tire pressure

warning system mal-

function.

Perform CONSULT-II Self-

Diagnosis. Refer to WT-22,

"SELF-DIAG RESULT

MODE" .

–Perform ID Registration if

needed. Refer to WT-19,

"ID Registration Procedure"

.

Turn signal

lampTurn signal lamp

does not flash 2

times or buzzer does

not sound after

transmitter activa-

tion.—1. Tool J-45295

[SST]

2. Ignition OFF dur-

ing activation.

3. Tool J-45295

[SST] not posi-

tioned correctly.

4. Transmitters

already activated.1. Install new battery.

2. Make sure ignition is ON

during activation.

3. Position tool correctly dur-

ing activation.

4. None Diagnosis

ItemSymptom

(Ignition switch ON)Low tire pressure warning lamp Cause Action

SEIA0597E

SEIA0598E

Page 5569 of 5621

WW-2Revision: 2006 January2006 M35/M45 CHECK VALVE INSPECTION ............................. 46

Inspection of Front Wiper and Washer Switch Circuit ... 46

Removal and Installation of Front Wiper and Washer

Switch ..................................................................... 46

REMOVAL ........................................................

... 46

INSTALLATION .................................................... 46

Removal and Installation of Washer Tank .............. 47

REMOVAL ........................................................

... 47

INSTALLATION .................................................... 47

Removal and Installation of Washer Pump ............. 48

REMOVAL ........................................................

... 48

INSTALLATION .................................................... 48

CIGARETTE LIGHTER ............................................. 49

Wiring Diagram — CIGAR — ................................. 49

Removal and Installation ........................................ 50

REMOVAL ........................................................

... 50

INSTALLATION .................................................... 50POWER SOCKET ..................................................... 51

Wiring Diagram — P/SCKT — ................................ 51

Removal and Installation of Center Console Box

Power Socket .......................................................... 52

REMOVAL ............................................................ 52

INSTALLATION .................................................... 52

Removal and Installation of Center Console Box

Rear Side Power Socket ......................................... 52

REMOVAL ............................................................ 52

INSTALLATION .................................................... 52

HORN ........................................................................ 53

Wiring Diagram — HORN — .................................. 53

Removal and Installation ......................................... 54

REMOVAL ............................................................ 54

INSTALLATION .................................................... 54

Page 5577 of 5621

WW-10

FRONT WIPER AND WASHER SYSTEM

Revision: 2006 January2006 M35/M45

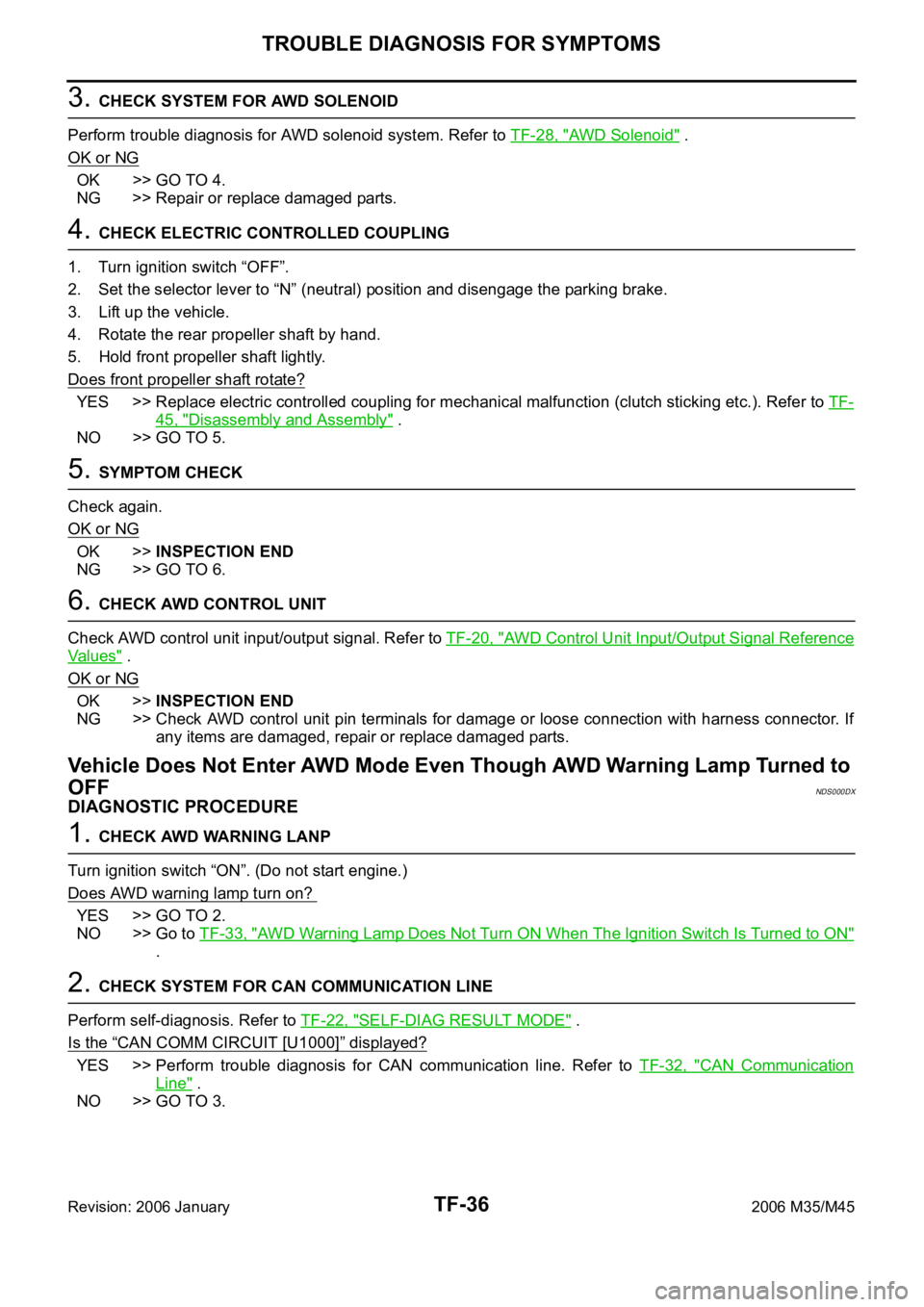

Operation Mode

Combination switch reading function has operation modes shown below.

1. Normal status

–When BCM is not in sleep status, OUTPUT terminals (1-5) each turn ON-OFF every 10 ms.

2. Sleep status

–When BCM is in sleep status, transistors of OUTPUT 1 and 5 stop the output, and BCM enters low current

consumption mode. OUTPUT 2, 3, and 4 turn ON-OFF every 60 ms, and only input from lighting switch

system is accepted.

PKIC0272E

Page 5584 of 5621

FRONT WIPER AND WASHER SYSTEM

WW-17

C

D

E

F

G

H

I

J

L

MA

B

WW

Revision: 2006 January2006 M35/M45

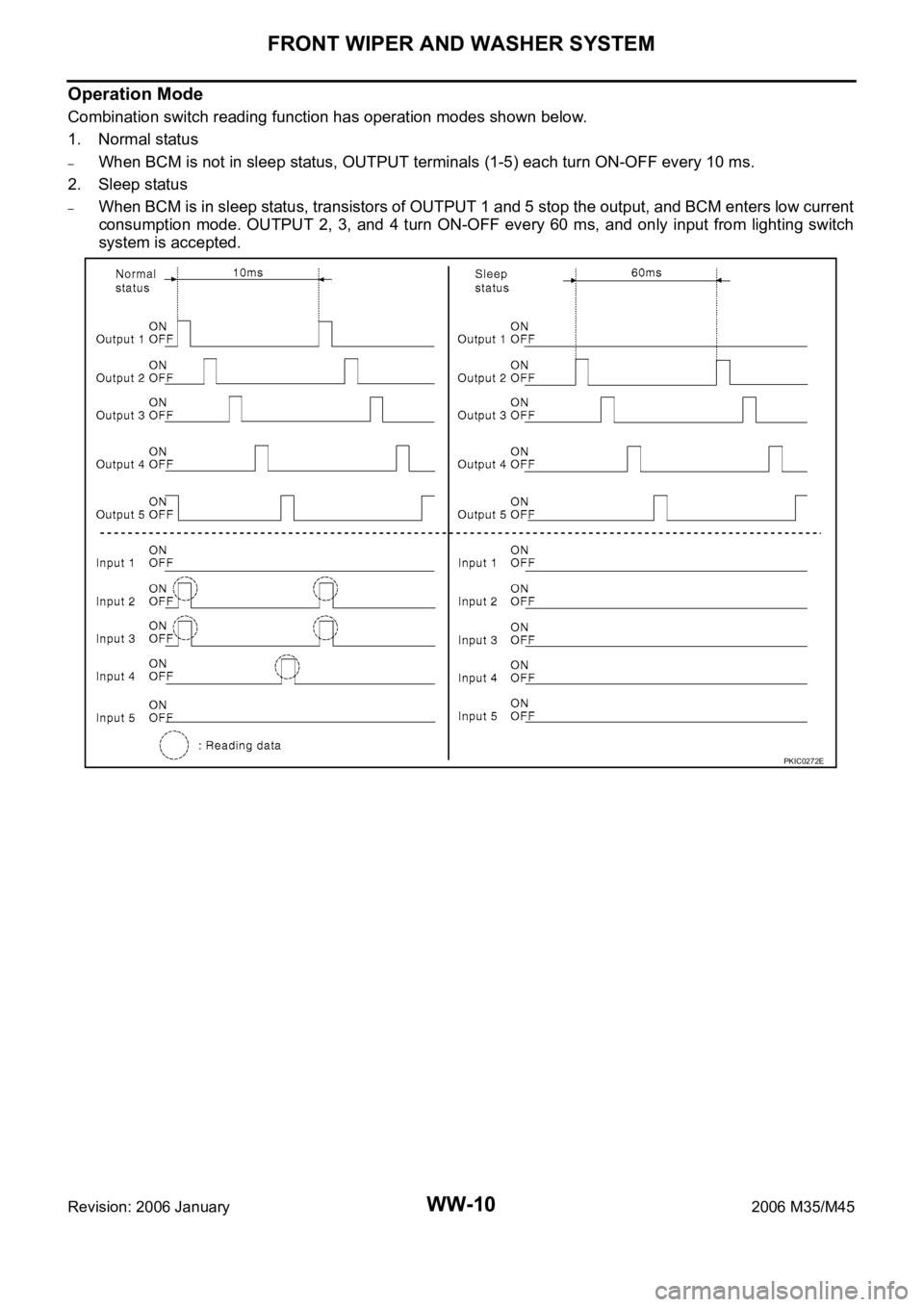

Terminals and Reference Values for BCMNKS003WH

CAUTION:

Check combination switch system terminal waveform under the loaded condition with lighting

switch, turn signal switch and wiper switch OFF not to be fluctuated by overloaded.

Turn wiper dial position to 4 except when checking waveform or voltage of wiper dial position.

Wiper dial position can be confirmed on CONSULT-II. Refer to WW-24, "

DATA MONITOR" .

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

4R/GCombination

switch input 3ONLighting, turn, wiper

OFF

(Wiper dial position 4)

Any of several con-

ditions below

Front wiper SW MIST

Front wiper SW INT

Front wiper SW LO

Approx. 1.0V

OFF Approx. 0V

5YCombination

switch input 2ONLighting, turn, wiper

OFF

Any of several con-

ditions below

Front washer switch

(Wiper dial position 4)

Wiper dial position 1

Wiper dial position 5

Wiper dial position 6

Approx. 1.0V

OFF

(Wiper dial position 4)Approx. 0V

PKIB4957J

PKIB4957J

Page 5585 of 5621

WW-18

FRONT WIPER AND WASHER SYSTEM

Revision: 2006 January2006 M35/M45

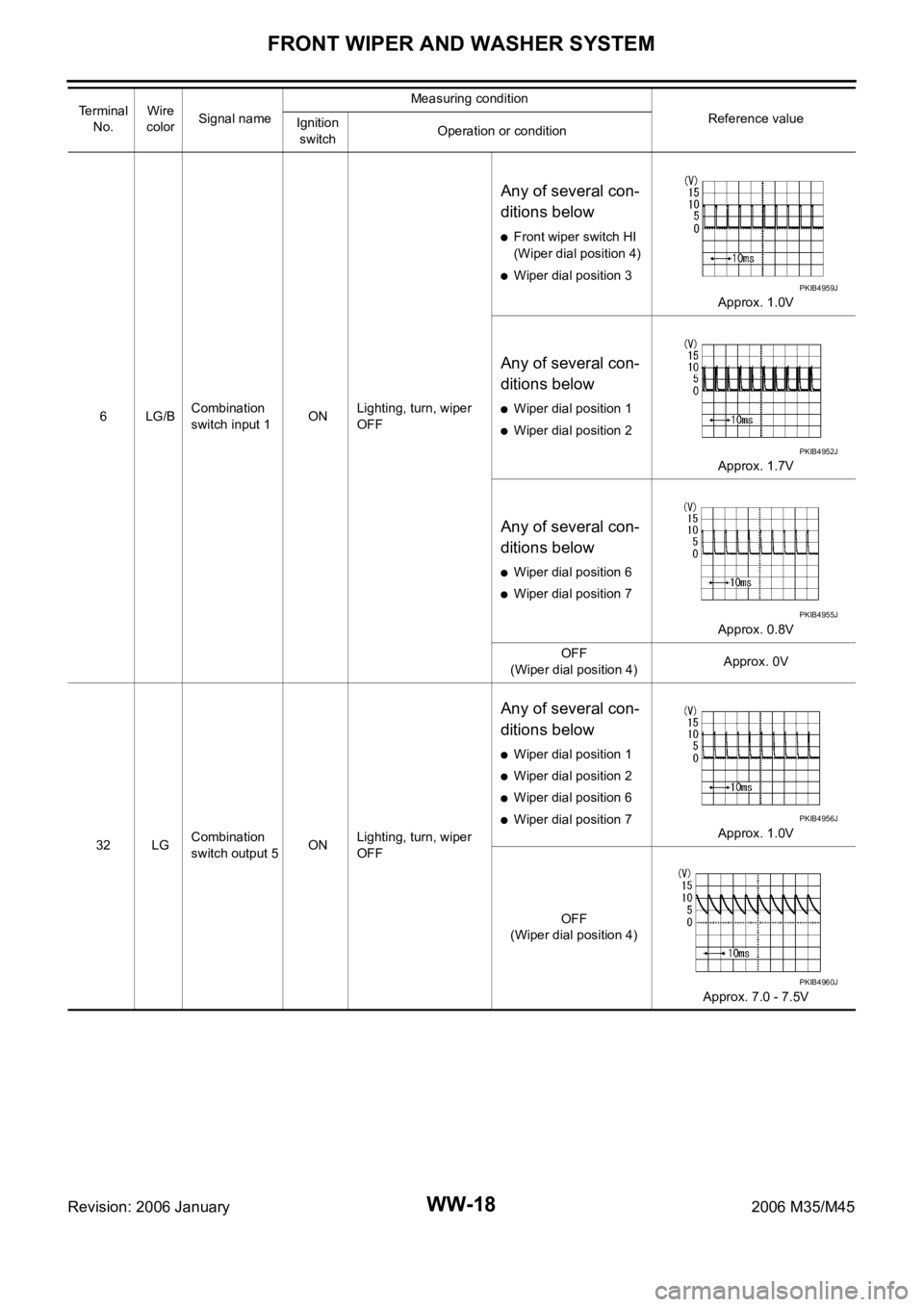

6LG/BCombination

switch input 1ONLighting, turn, wiper

OFF

Any of several con-

ditions below

Front wiper switch HI

(Wiper dial position 4)

Wiper dial position 3

Approx. 1.0V

Any of several con-

ditions below

Wiper dial position 1

Wiper dial position 2

Approx. 1.7V

Any of several con-

ditions below

Wiper dial position 6

Wiper dial position 7

Approx. 0.8V

OFF

(Wiper dial position 4)Approx. 0V

32 LGCombination

switch output 5ONLighting, turn, wiper

OFF

Any of several con-

ditions below

Wiper dial position 1

Wiper dial position 2

Wiper dial position 6

Wiper dial position 7

Approx. 1.0V

OFF

(Wiper dial position 4)

Approx. 7.0 - 7.5V Te r m i n a l

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

PKIB4959J

PKIB4952J

PKIB4955J

PKIB4956J

PKIB4960J