immobilizer INFINITI M35 2006 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1217 of 5621

BL-278

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect multifunction switch (security indicator) connector.

3. Check voltage between multifunction switch (security indicator)

connector and ground.

OK or NG

OK >> Check the following.

Harness for open or short between BCM and multifunction switch (security indicator)

Security indicator lamp condition

NG >> Check the following.

15A fuse [No.37, located in fuse block (J/B)]

Harness for open or short between multifunction switch (security indicator) and fuse

DTC P1612 CHAIN of ECM-IMMUNIS0020S

Self-diagnostic results:

“CHAIN OF ECM-IMMU” displayed on CONSULT-II screen

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, then perform the trouble diagno-

sis of malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-15, "

CAN Com-

munication Inspection Using CONSULT-II (Self-Diagnosis)" .

1. CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “CHAIN OF ECM-IMMU”

displayed on CONSULT-II screen.

NOTE:

In rare case, “CHAIN OF ECM-IMMU” might be stored during key

registration procedure, even if the system is not malfunctioning.

Is CONSULT-II screen displayed as shown in figure?

Yes >> GO TO 2.

No >> GO TO BL-271, "

“NATS V5.0” SELF-DIAGNOSTIC

RESULTS ITEM CHART" .

Te r m i n a l s

Voltage (V)

(Approx.) (+)

(–) multifunction switch

(security indicator)

connectorTerminal

M69 1 Ground Battery voltage

PIIB6218E

PIIA1260E

Page 1218 of 5621

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-279

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

2. CHECK POWER SUPPLY CIRCUIT FOR BCM

Check voltage between BCM and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Check the following.

50A fusible link (letter F , located in the fuse and fusible link box)

10A fuse [No.21, located in the fuse block (J/B)]

15A fuse [No. 1, located in the fuse block (J/B)]

Harness for open or short between fusible link and BCM

Harness for open or short between fuse and BCM

3. CHECK GROUND CIRCUIT FOR BCM

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. REPLACE BCM

1. Replace BCM

2. Perform initialization with CONSULT-II.

For initialization, refer to “CONSULT-II Operation Manual NATS-IVIS/NVIS”.

Does the engine start?

Yes >> BCM is malfunctioning.

Replace BCM.

Perform initialization with CONSULT-II

For initialization, refer to “CONSULT-II Operation Manual NATS-IVIS/NVIS”

No >> ECM is malfunctioning.

Replace ECM.

Perform initialization or re-communicating function

For initialization, refer to “CONSULT-II Operation Manual NATS-IVIS/NVIS”

For re-communicating function, refer to BL-252, "ECM Re-Communicating Function"

Terminals

Condition of

ignition switchVoltage (V)

(Approx.) (+)

(–)

BCM connector Terminal

M1 38

GroundON

Battery voltage

M242

OFF

55

PIIB5934E

BCM connector Terminal

GroundContinuity

M2 52 Yes

PIIB5935E

Page 1219 of 5621

BL-280

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

DTC P1611 ID DISCORD, IMM-ECMNIS0020T

Self-diagnostic results:

“ID DISCORD, IMM-ECM” displayed on CONSULT-II screen

1. CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “ID DISCORD, IMM-ECM” displayed on CONSULT-II screen.

NOTE:

“ID DISCORD IMM-ECM”:

Registered ID of BCM is in discord with that of ECM.

Is CONSULT-II screen displayed as shown in figure?

Yes >> GO TO 2.

No >> GO TO BL-271, "

“NATS V5.0” SELF-DIAGNOSTIC

RESULTS ITEM CHART" .

2. PERFORM INITIALIZATION WITH CONSULT-II

Perform initialization with CONSULT-II. Re-register all NATS ignition key IDs.

For initialization, refer to “CONSULT-II Operation Manual NATS-

IVIS/NVIS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-II

shows message on the screen.

Can the system be initialized?

Ye s > >Start engine. (END)

(System initialization had not been completed.)

No >> ECM is malfunctioning.

Replace ECM.

Perform initialization with CONSULT-II

For initialization, refer to “CONSULT-II Operation Manual NATS-IVIS/NVIS”

Removal and Installation of Key SlotNIS0020U

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect key slot connector.

3. Remove key slot mounting screw, and then remove key slot.

INSTALLATION

Installation is in the reverse order of removal.

PIIA1262E

SEL297W

PIIB6284E

Page 1544 of 5621

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

Revision: 2006 January2006 M35/M45

ENGINE CONTROL SYSTEM

VQ35DE

INDEX FOR DTC ...................................................... 16

DTC No. Index ....................................................... 16

Alphabetical Index .................................................. 20

PRECAUTIONS ........................................................ 24

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 24

Precautions for Procedures without Cowl Top Cover ... 24

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 24

Precaution .............................................................. 25

PREPARATION ......................................................... 28

Special Service Tools ............................................. 28

Commercial Service Tools ...................................... 29

ENGINE CONTROL SYSTEM .................................. 30

System Diagram ..................................................... 30

Multiport Fuel Injection (MFI) System .................... 31

Electronic Ignition (EI) System ............................... 33

Fuel Cut Control (At No Load and High Engine

Speed) .................................................................... 34

AIR CONDITIONING CUT CONTROL ..................... 35

Input/Output Signal Chart ....................................... 35

System Description ................................................ 35

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ... 36

System Description ................................................ 36

Component Description .......................................... 37

CAN COMMUNICATION .......................................... 38

System Description ................................................ 38

EVAPORATIVE EMISSION SYSTEM ....................... 39

Description ............................................................. 39

Component Inspection ........................................... 42

Removal and Installation ........................................ 43

How to Detect Fuel Vapor Leakage ....................... 43

ON BOARD REFUELING VAPOR RECOVERY

(ORVR) ...................................................................... 46

System Description ................................................ 46

Diagnostic Procedure ............................................. 47

Component Inspection ........................................... 49POSITIVE CRANKCASE VENTILATION ................. 51

Description .............................................................. 51

Component Inspection ............................................ 51

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS) ........................................................................ 53

Description .............................................................. 53

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 54

Introduction ..................................................

........... 54

Two Trip Detection Logic ........................................ 54

Emission-Related Diagnostic Information ............... 55

Malfunction Indicator Lamp (MIL) ........................... 69

OBD System Operation Chart ................................ 72

BASIC SERVICE PROCEDURE ............................... 77

Basic Inspection ..................................................... 77

Idle Speed and Ignition Timing Check .................... 82

Idle Mixture Ratio Adjustment ................................. 84

VIN Registration ..................................................... 95

Accelerator Pedal Released Position Learning ...... 95

Throttle Valve Closed Position Learning ................. 95

Idle Air Volume Learning ........................................ 96

Fuel Pressure Check .............................................. 98

TROUBLE DIAGNOSIS ..........................................100

Trouble Diagnosis Introduction .............................100

DTC Inspection Priority Chart ...............................106

Fail-Safe Chart .....................................................108

Symptom Matrix Chart ..........................................109

Engine Control Component Parts Location ..........113

Vacuum Hose Drawing .........................................121

Circuit Diagram .....................................................122

ECM Harness Connector Terminal Layout ...........124

ECM Terminals and Reference Value ...................124

CONSULT-II Function (ENGINE) ..........................133

Generic Scan Tool (GST) Function .......................146

CONSULT-II Reference Value in Data Monitor .....149

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................153

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .155

Description ............................................................155

Testing Condition ..................................................155

Page 1551 of 5621

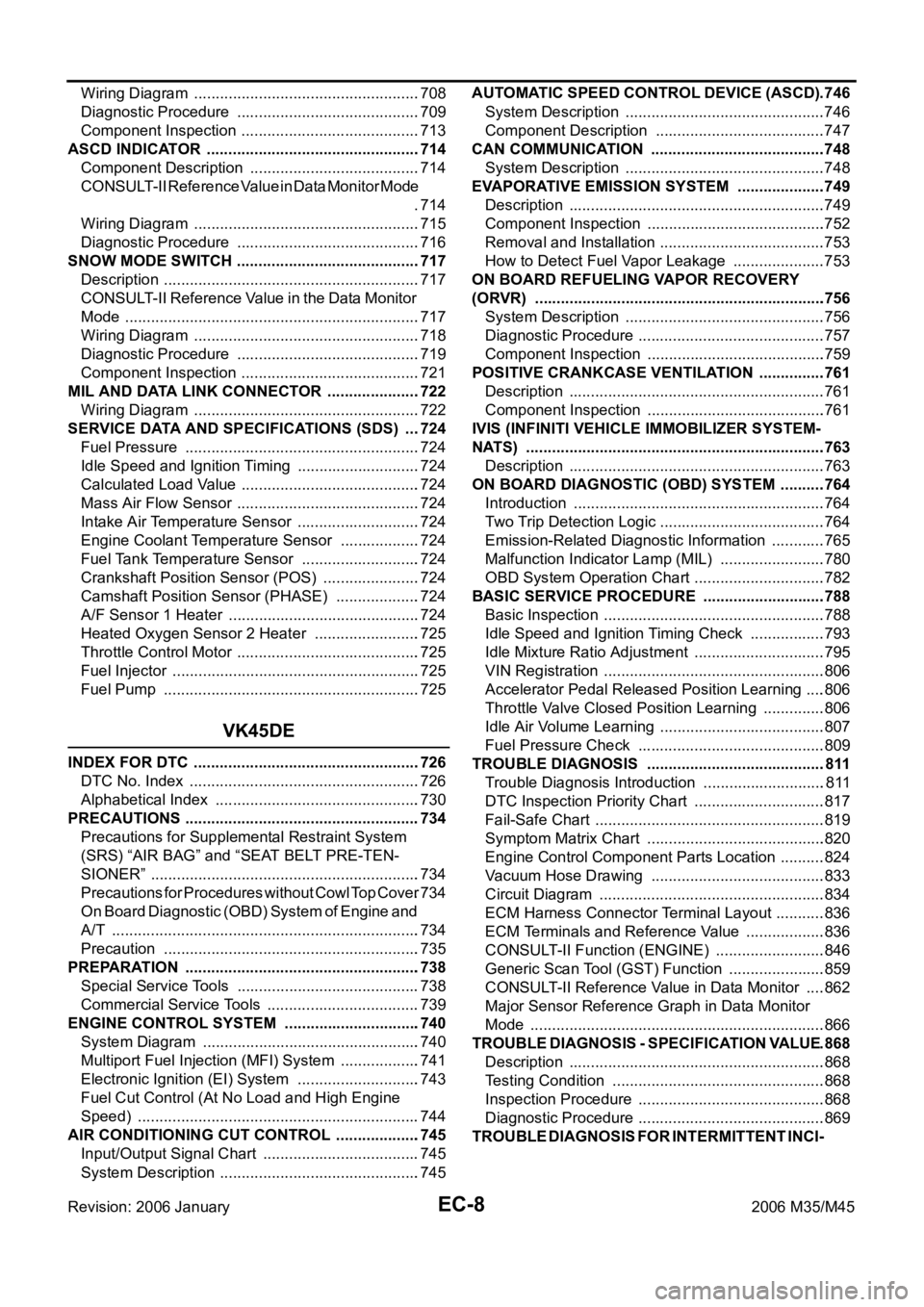

EC-8Revision: 2006 January2006 M35/M45 Wiring Diagram .....................................................708

Diagnostic Procedure ...........................................709

Component Inspection ..........................................713

ASCD INDICATOR .................................................

.714

Component Description ........................................714

CONSULT-II Reference Value in Data Monitor Mode

.714

Wiring Diagram .....................................................715

Diagnostic Procedure ...........................................716

SNOW MODE SWITCH ...........................................717

Description ............................................................717

CONSULT-II Reference Value in the Data Monitor

Mode .....................................................................717

Wiring Diagram .....................................................718

Diagnostic Procedure ...........................................719

Component Inspection ..........................................721

MIL AND DATA LINK CONNECTOR ......................722

Wiring Diagram .....................................................722

SERVICE DATA AND SPECIFICATIONS (SDS) ....724

Fuel Pressure .......................................................724

Idle Speed and Ignition Timing .............................724

Calculated Load Value ..........................................724

Mass Air Flow Sensor ...........................................724

Intake Air Temperature Sensor .............................724

Engine Coolant Temperature Sensor ...................724

Fuel Tank Temperature Sensor ............................724

Crankshaft Position Sensor (POS) .......................724

Camshaft Position Sensor (PHASE) ....................724

A/F Sensor 1 Heater ............................................ .724

Heated Oxygen Sensor 2 Heater .........................725

Throttle Control Motor ...........................................725

Fuel Injector ..........................................................725

Fuel Pump ............................................................725

VK45DE

INDEX FOR DTC .....................................................726

DTC No. Index ......................................................726

Alphabetical Index ................................................730

PRECAUTIONS .......................................................734

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................734

Precautions for Procedures without Cowl Top Cover .734

On Board Diagnostic (OBD) System of Engine and

A/T ........................................................................734

Precaution ............................................................735

PREPARATION .......................................................738

Special Service Tools ...........................................738

Commercial Service Tools ....................................739

ENGINE CONTROL SYSTEM ................................740

System Diagram ...................................................740

Multiport Fuel Injection (MFI) System ...................741

Electronic Ignition (EI) System .............................743

Fuel Cut Control (At No Load and High Engine

Speed) ..................................................................744

AIR CONDITIONING CUT CONTROL ....................745

Input/Output Signal Chart .....................................745

System Description ...............................................745AUTOMATIC SPEED CONTROL DEVICE (ASCD) .746

System Description ...............................................746

Component Description ........................................747

CAN COMMUNICATION .........................................748

System Description ...............................................748

EVAPORATIVE EMISSION SYSTEM .....................749

Description ............................................................749

Component Inspection ..........................................752

Removal and Installation .......................................753

How to Detect Fuel Vapor Leakage ......................753

ON BOARD REFUELING VAPOR RECOVERY

(ORVR) ....................................................................756

System Description ...............................................756

Diagnostic Procedure ............................................757

Component Inspection ..........................................759

POSITIVE CRANKCASE VENTILATION ................761

Description ............................................................761

Component Inspection ..........................................761

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS) ......................................................................763

Description ............................................................763

ON BOARD DIAGNOSTIC (OBD) SYSTEM ...........764

Introduction ..........................................................

.764

Two Trip Detection Logic .......................................764

Emission-Related Diagnostic Information .............765

Malfunction Indicator Lamp (MIL) .........................780

OBD System Operation Chart ...............................782

BASIC SERVICE PROCEDURE .............................788

Basic Inspection ....................................................788

Idle Speed and Ignition Timing Check ..................793

Idle Mixture Ratio Adjustment ...............................795

VIN Registration ....................................................806

Accelerator Pedal Released Position Learning .....806

Throttle Valve Closed Position Learning ...............806

Idle Air Volume Learning .......................................807

Fuel Pressure Check ............................................809

TROUBLE DIAGNOSIS ..........................................811

Trouble Diagnosis Introduction .............................811

DTC Inspection Priority Chart ...............................817

Fail-Safe Chart ......................................................819

Symptom Matrix Chart ..........................................820

Engine Control Component Parts Location ...........824

Vacuum Hose Drawing .........................................833

Circuit Diagram .....................................................834

ECM Harness Connector Terminal Layout ............836

ECM Terminals and Reference Value ...................836

CONSULT-II Function (ENGINE) ..........................846

Generic Scan Tool (GST) Function .......................859

CONSULT-II Reference Value in Data Monitor .....862

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................866

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .868

Description ............................................................868

Testing Condition ..................................................868

Inspection Procedure ...........................................

.868

Diagnostic Procedure ............................................869

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

Page 1596 of 5621

![INFINITI M35 2006 Factory Workshop Manual IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-53

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)PFP:28591

DescriptionNBS004SK INFINITI M35 2006 Factory Workshop Manual IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-53

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)PFP:28591

DescriptionNBS004SK](/img/42/57023/w960_57023-1595.png)

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-53

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)PFP:28591

DescriptionNBS004SK

If the security indicator lights up with the ignition switch in

the ON position or “NATS MALFUNCTION” is displayed on

“SELF-DIAG RESULTS” screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to BL-248, "

IVIS (INFINITI VEHICLE IMMOBILIZER

SYSTEM-NATS)" .

Confirm no self-diagnostic results of IVIS (NATS) is dis-

played before touching “ERASE” in “SELF-DIAG RESULTS”

mode with CONSULT-II.

When replacing ECM, initialization of IVIS (NATS) system

and registration of all IVIS (NATS) ignition key IDs must be

carried out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner. Regarding the procedures of IVIS (NATS)

initialization and all IVIS (NATS) ignition key ID registration, refer to CONSULT-II Operation Manual,

IVIS/NVIS.

SEF543X

Page 1655 of 5621

![INFINITI M35 2006 Factory Workshop Manual EC-112

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-14

,

CO-18

Thermostat INFINITI M35 2006 Factory Workshop Manual EC-112

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-14

,

CO-18

Thermostat](/img/42/57023/w960_57023-1654.png)

EC-112

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-14

,

CO-18

Thermostat 5CO-29

Water pumpCO-24

Water galleryCO-31

Cooling fan

5CO-22

Coolant level (Low)/Contami-

nated coolantCO-11

IVIS (INFINITI Vehicle Immobilizer System —

NATS)11EC-53 or

BL-248

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 2306 of 5621

![INFINITI M35 2006 Factory Workshop Manual IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-763

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)PFP:28591

DescriptionNBS005A INFINITI M35 2006 Factory Workshop Manual IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-763

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)PFP:28591

DescriptionNBS005A](/img/42/57023/w960_57023-2305.png)

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

EC-763

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)PFP:28591

DescriptionNBS005A0

If the security indicator lights up with the ignition switch in

the ON position or “NATS MALFUNCTION” is displayed on

“SELF-DIAG RESULTS” screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to BL-248, "

IVIS (INFINITI VEHICLE IMMOBILIZER

SYSTEM-NATS)" .

Confirm no self-diagnostic results of IVIS (NATS) is dis-

played before touching “ERASE” in “SELF-DIAG RESULTS”

mode with CONSULT-II.

When replacing ECM, initialization of IVIS (NATS) system

and registration of all IVIS (NATS) ignition key IDs must be

carried out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner. Regarding the procedures of IVIS (NATS)

initialization and IVIS (NATS) ignition key ID registration, refer to CONSULT-II operation manual,

IVIS/NVIS.

SEF543X

Page 2366 of 5621

![INFINITI M35 2006 Factory Workshop Manual TROUBLE DIAGNOSIS

EC-823

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45 INFINITI M35 2006 Factory Workshop Manual TROUBLE DIAGNOSIS

EC-823

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45](/img/42/57023/w960_57023-2365.png)

TROUBLE DIAGNOSIS

EC-823

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

1 - 6: The numbers refer to the order of inspection.Cooling

Radiator/Hose/Radiator filler cap

55555 55 45CO-43

,

CO-47

Thermostat 5CO-55

Water pumpCO-53

Water galleryCO-38

Cooling fan

5CO-51

Coolant level (Low)/Contami-

nated coolantCO-40

IVIS (INFINITI Vehicle Immobilizer System —

NATS)11EC-763 or

BL-248

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 3068 of 5621

![INFINITI M35 2006 Factory Workshop Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced INFINITI M35 2006 Factory Workshop Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced](/img/42/57023/w960_57023-3067.png)

PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RR

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004MH

Drain engine coolant and engine oil when the engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004MI

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004MJ

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

PIIB3706J