check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1364 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-53

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

2. CHECK PARKING BRAKE SWITCH HARNESS

1. Disconnect ABS actuator and electric unit (control unit) c INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-53

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

2. CHECK PARKING BRAKE SWITCH HARNESS

1. Disconnect ABS actuator and electric unit (control unit) c](/img/42/57023/w960_57023-1363.png)

TROUBLE DIAGNOSIS

BRC-53

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

2. CHECK PARKING BRAKE SWITCH HARNESS

1. Disconnect ABS actuator and electric unit (control unit) connector E30.

2. Check continuity between parking brake switch connector E110

and ABS actuator and electric unit (control unit) connector E30.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace malfunctioning components.

Inspection 19: Warning Lamp and Indicator Lamp CircuitNFS000R3

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSIS RESULTS

Perform ABS actuator and electric unit (control unit) self-diagnosis.

OK or NG

OK >> GO TO 2.

NG >> Check items displayed by self-diagnosis. Refer to BRC-24, "

DISPLAY ITEM LIST" .

2. CHECK COMBINATION METER

Check the indication and operation of combination meter are normal. Refer to DI-17, "

Self-Diagnosis Mode of

Combination Meter" .

OK or NG

OK >> INSPECTION END

NG >> Combination meter is malfunctioning. Repair or replace combination meter. Refer to DI-5, "

COM-

BINATION METERS" .

Symptom 1 Excessive ABS Function Operation FrequencyNFS000R4

1. CHECK START

Check front and rear brake force distribution using a brake tester. Refer to BR-35, "

SERVICE DATA AND

SPECIFICATIONS (SDS)" .

OK or NG

OK >> GO TO 2.

NG >> Check brake system.

SFIA3048E

ABS actuator and electric unit (control unit) Parking brake switch Continuity

361Yes

Ground No

Page 1365 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-54

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FAX-5, &# INFINITI M35 2006 Factory Service Manual BRC-54

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FAX-5, &#](/img/42/57023/w960_57023-1364.png)

BRC-54

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

2. CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear axles. Refer to front: FAX-5, "

WHEEL BEAR-

ING INSPECTION" , Rear: RAX-5, "WHEEL BEARING INSPECTION" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace malfunctioning components.

3. CHECK WHEEL SENSOR AND SENSOR ROTOR

Check the following.

Wheel sensor installation for damage.

Sensor rotor installation for damage.

Wheel sensor connector connection.

Wheel sensor harness inspection.

OK or NG

OK >> GO TO 4.

NG >>

Replace wheel sensor or sensor rotor.

Repair harness.

4. CHECK ABS WARNING LAMP DISPLAY

Make sure that the ABS warning lamp is turned off after the ignition switch is turned ON or when driving.

OK or NG

OK >> Normal

NG >> Perform self-diagnosis. Refer to BRC-23, "

Self-Diagnosis" .

Symptom 2 Unexpected Pedal ReactionNFS000R5

1. CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to BR-6, "

Inspection and Adjustment" .

Is the stroke too big?

YES >>Bleed air from brake tube and hose. Refer to BR-11, "Bleeding Brake System" .

Check brake pedal, brake booster, and master cylinder for mount play, looseness, brake sys-

tem fluid leakage, etc. Refer to brake pedal: BR-7, "

COMPONENTS" , brake booster and mas-

ter cylinder: BR-19, "

COMPONENTS" .

NO >> GO TO 2.

2. CHECK FUNCTION

Disconnect ABS actuator and electric unit (control unit) connector to deactivate ABS. Check if braking force is

normal in this condition.Connect connector after inspection.

OK or NG

OK >> GO TO procedure 3 “CHECK WHEEL SENSOR AND SENSOR ROTOR” of symptom 1. Refer to

BRC-53, "

Symptom 1 Excessive ABS Function Operation Frequency" .

NG >> Check brake system.

Page 1366 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-55

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Symptom 3 The Braking Distance Is LongNFS000R6

CAUTION:

The stopping distance on slippery road INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-55

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Symptom 3 The Braking Distance Is LongNFS000R6

CAUTION:

The stopping distance on slippery road](/img/42/57023/w960_57023-1365.png)

TROUBLE DIAGNOSIS

BRC-55

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Symptom 3 The Braking Distance Is LongNFS000R6

CAUTION:

The stopping distance on slippery road surfaces might be longer with the ABS operating than when

the ABS is not operating.

1. CHECK FUNCTION

Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector to deactivate

ABS. In this condition, check stopping distance. After inspection, connect connector.

OK or NG

OK >> GO TO procedure 3 “CHECK WHEEL SENSOR AND SENSOR ROTOR” of symptom 1. Refer to

BRC-53, "

Symptom 1 Excessive ABS Function Operation Frequency" .

NG >> Check brake system.

Symptom 4 ABS Function Does Not OperateNFS000R7

CAUTION:

ABS does not operate when speed is 10 km/h (6 MPH) or lower.

1. CHECK ABS WARNING LAMP DISPLAY

Make sure that the ABS warning lamp turns OFF after ignition switch is turned on or when driving.

OK or NG

OK >> GO TO procedure 3 “CHECK WHEEL SENSOR AND SENSOR ROTOR” of symptom 1. Refer to

BRC-53, "

Symptom 1 Excessive ABS Function Operation Frequency" .

NG >> Perform self-diagnosis. Refer to BRC-23, "

Self-Diagnosis" .

Symptom 5 Pedal Vibration or ABS Operation Sound OccursNFS000R8

CAUTION:

Under the following conditions, ABS is activated and vibration is felt when brake pedal is lightly

depressed (just place a foot on it).However, this is normal.

When shifting gears

When driving on slippery road

During cornering at high speed

When passing over bumps or grooves [at approximately 50 mm (1.97 in) or more]

When pulling away just after starting engine [at approximately 10 km/h (6 MPH) or higher]

1. SYMPTOM CHECK 1

Check if there is pedal vibration or operation sound when the engine is started.

Do symptoms occur?

YES >> GO TO 2.

NO >> Perform self -diagnosis. Refer to BRC-23, "

Self-Diagnosis" .

2. SYMPTOM CHECK 2

Check symptoms when electrical component (headlamps, etc.) switches are operated.

Do symptoms occur?

YES >> Check if there is a radio, antenna, antenna lead wire, or wiring close to the control unit. If there is,

move it farther away.

NO >> GO TO procedure 3 “CHECK WHEEL SENSOR AND SENSOR ROTOR” of symptom 1. Refer to

BRC-53, "

Symptom 1 Excessive ABS Function Operation Frequency" .

Page 1367 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-56

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Symptom 6 Vehicle Jerks During VDC/TCS/ABS ControlNFS000R9

1. SYMPTOM CHECK

Check if the vehicle jerks during VDC/TCS/ABS cont INFINITI M35 2006 Factory Service Manual BRC-56

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Symptom 6 Vehicle Jerks During VDC/TCS/ABS ControlNFS000R9

1. SYMPTOM CHECK

Check if the vehicle jerks during VDC/TCS/ABS cont](/img/42/57023/w960_57023-1366.png)

BRC-56

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Symptom 6 Vehicle Jerks During VDC/TCS/ABS ControlNFS000R9

1. SYMPTOM CHECK

Check if the vehicle jerks during VDC/TCS/ABS control.

OK or NG

OK >> Normal.

NG >> GO TO 2.

2. CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnostic of ABS actuator and electric unit (control unit).

Are self-diagnosis results indicated?

YES >> Check corresponding items, make repairs, and perform ABS actuator and electric unit (control

unit) self-diagnosis.

NO >> GO TO 3.

3. CHECK CONNECTOR

Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector and check

terminal for deformation, disconnection, looseness, etc.

Securely connect connectors and perform ABS actuator and electric unit (control unit) self-diagnosis.

Are self-diagnosis results indicated?

YES >> If poor contact, damage, open or short circuit of connector terminal is found, repair or replace.

NO >> GO TO 4.

4. CHECK ECM AND A/T SELF-DIAGNOSIS RESULTS

Perform ECM and A/T self-diagnosis.

Are self-diagnosis results indicated?

YES >> Check the corresponding items.

ECM: Refer to EC-100, "TROUBLE DIAGNOSIS" (VQ35DE), EC-811, "TROUBLE DIAGNO-

SIS" (VK45DE).

A/T: Refer to AT-44, "TROUBLE DIAGNOSIS" .

NO >> Replace ABS actuator and electric unit (control unit).

Page 1376 of 5621

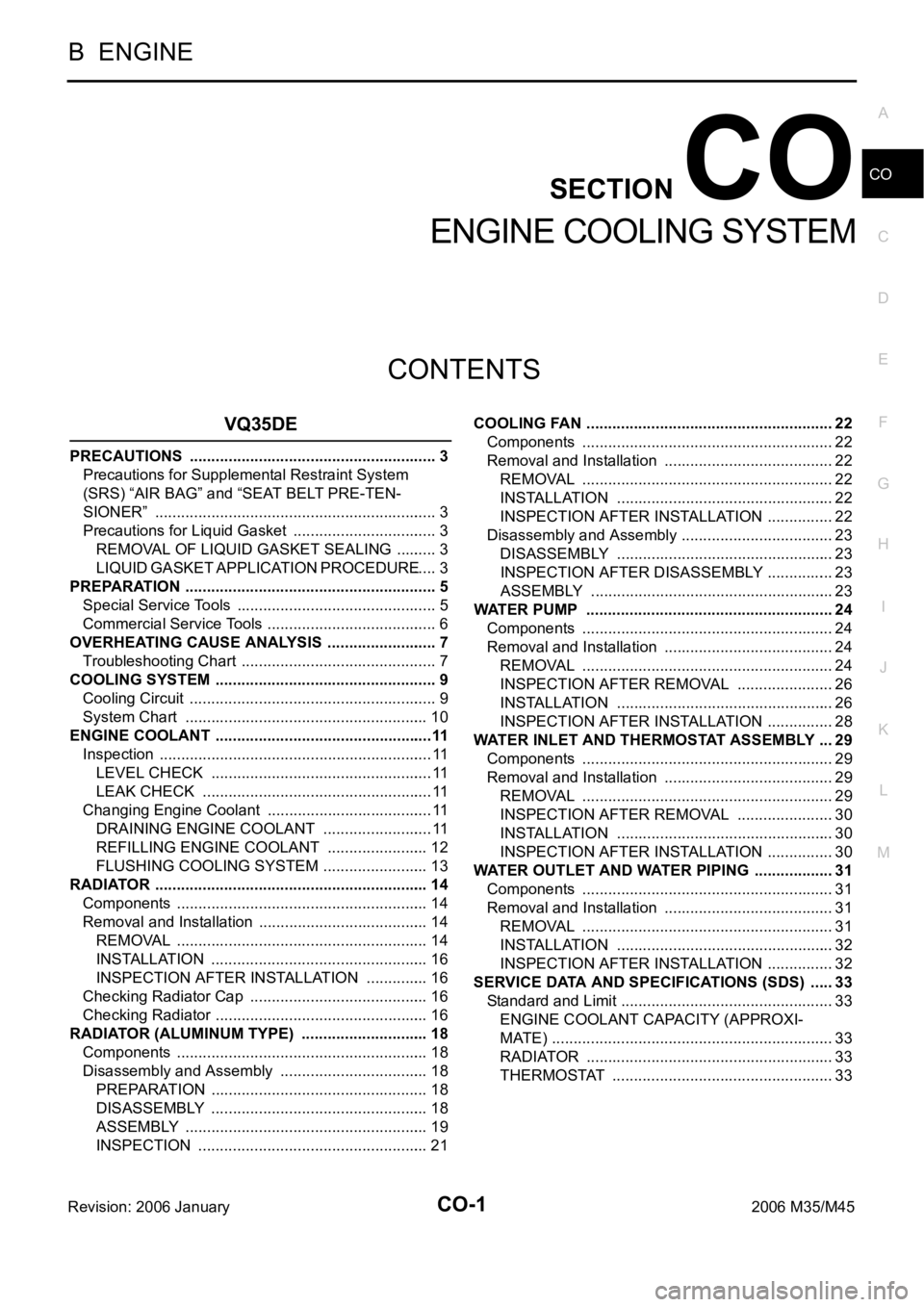

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION CO

A

CO

Revision: 2006 January2006 M35/M45

ENGINE COOLING SYSTEM

VQ35DE

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Liquid Gasket .................................. 3

REMOVAL OF LIQUID GASKET SEALING .......... 3

LIQUID GASKET APPLICATION PROCEDURE ..... 3

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 6

OVERHEATING CAUSE ANALYSIS .......................... 7

Troubleshooting Chart .............................................. 7

COOLING SYSTEM .................................................... 9

Cooling Circuit .......................................................... 9

System Chart ......................................................... 10

ENGINE COOLANT ...................................................11

Inspection ................................................................ 11

LEVEL CHECK .................................................... 11

LEAK CHECK ...................................................... 11

Changing Engine Coolant ....................................... 11

DRAINING ENGINE COOLANT .......................... 11

REFILLING ENGINE COOLANT ........................ 12

FLUSHING COOLING SYSTEM ......................... 13

RADIATOR ................................................................ 14

Components ........................................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSTALLATION ................................................... 16

INSPECTION AFTER INSTALLATION ............... 16

Checking Radiator Cap .......................................... 16

Checking Radiator .................................................. 16

RADIATOR (ALUMINUM TYPE) .............................. 18

Components ........................................................... 18

Disassembly and Assembly ................................... 18

PREPARATION ................................................... 18

DISASSEMBLY ................................................... 18

ASSEMBLY ......................................................... 19

INSPECTION ...................................................... 21COOLING FAN .......................................................... 22

Components ........................................................... 22

Removal and Installation ........................................ 22

REMOVAL ........................................................

... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 22

Disassembly and Assembly .................................... 23

DISASSEMBLY ................................................... 23

INSPECTION AFTER DISASSEMBLY ................ 23

ASSEMBLY ......................................................... 23

WATER PUMP .......................................................... 24

Components ........................................................... 24

Removal and Installation ........................................ 24

REMOVAL ........................................................

... 24

INSPECTION AFTER REMOVAL ....................... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 28

WATER INLET AND THERMOSTAT ASSEMBLY .... 29

Components ........................................................... 29

Removal and Installation ........................................ 29

REMOVAL ........................................................

... 29

INSPECTION AFTER REMOVAL ....................... 30

INSTALLATION ................................................... 30

INSPECTION AFTER INSTALLATION ................ 30

WATER OUTLET AND WATER PIPING ................... 31

Components ........................................................... 31

Removal and Installation ........................................ 31

REMOVAL ........................................................

... 31

INSTALLATION ................................................... 32

INSPECTION AFTER INSTALLATION ................ 32

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 33

Standard and Limit .................................................. 33

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 33

RADIATOR .......................................................

... 33

THERMOSTAT .................................................... 33

Page 1377 of 5621

CO-2Revision: 2006 January2006 M35/M45

VK45DE

PRECAUTIONS ......................................................... 34

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................. 34

PREPARATION ......................................................... 35

Special Service Tools ............................................. 35

Commercial Service Tools ...................................... 35

OVERHEATING CAUSE ANALYSIS ........................ 36

Troubleshooting Chart ............................................ 36

COOLING SYSTEM .................................................. 38

Cooling Circuit ........................................................ 38

System Chart .......................................................... 39

ENGINE COOLANT .................................................. 40

Inspection ............................................................... 40

LEVEL CHECK .................................................... 40

LEAK CHECK ...................................................... 40

Changing Engine Coolant ....................................... 40

DRAINING ENGINE COOLANT .......................... 40

REFILLING ENGINE COOLANT ......................... 41

FLUSHING COOLING SYSTEM ......................... 42

RADIATOR ................................................................ 43

Components ........................................................... 43

Removal and Installation ........................................ 43

REMOVAL ........................................................

... 43

INSTALLATION .................................................... 45

INSPECTION AFTER INSTALLATION ................ 45

Checking Radiator Cap .......................................... 45

Checking Radiator .................................................. 45

RADIATOR (ALUMINUM TYPE) ............................... 47

Components ........................................................... 47

Disassembly and Assembly .................................... 47

PREPARATION ................................................... 47

DISASSEMBLY ................................................... 47

ASSEMBLY ......................................................... 48

INSPECTION ....................................................... 50COOLING FAN .......................................................... 51

Components ............................................................ 51

Removal and Installation ......................................... 51

REMOVAL ............................................................ 51

INSTALLATION .................................................... 51

INSPECTION AFTER INSTALLATION ................ 51

Disassembly and Assembly .................................... 52

DISASSEMBLY .................................................... 52

INSPECTION AFTER DISASSEMBLY ................ 52

ASSEMBLY .......................................................... 52

WATER PUMP ........................................................... 53

Components ............................................................ 53

Removal and Installation ......................................... 53

REMOVAL ............................................................ 53

INSPECTION AFTER REMOVAL ........................ 54

INSTALLATION .................................................... 54

INSPECTION AFTER INSTALLATION ................ 54

THERMOSTAT AND WATER CONTROL VALVE ..... 55

Components ............................................................ 55

Removal and Installation ......................................... 55

REMOVAL ............................................................ 55

INSPECTION AFTER REMOVAL ........................ 56

INSTALLATION .................................................... 56

INSPECTION AFTER INSTALLATION ................ 57

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 58

Standard and Limit .................................................. 58

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 58

RADIATOR ........................................................... 58

THERMOSTAT ..................................................... 58

WATER CONTROL VALVE .................................. 58

Page 1381 of 5621

![INFINITI M35 2006 Factory Service Manual CO-6

[VQ35DE]

PREPARATION

Revision: 2006 January2006 M35/M45

Commercial Service ToolsNBS004QM

Tool nameDescription

Power toolLoosening nuts and bolts

Radiator cap tester Checking radiator and radiator INFINITI M35 2006 Factory Service Manual CO-6

[VQ35DE]

PREPARATION

Revision: 2006 January2006 M35/M45

Commercial Service ToolsNBS004QM

Tool nameDescription

Power toolLoosening nuts and bolts

Radiator cap tester Checking radiator and radiator](/img/42/57023/w960_57023-1380.png)

CO-6

[VQ35DE]

PREPARATION

Revision: 2006 January2006 M35/M45

Commercial Service ToolsNBS004QM

Tool nameDescription

Power toolLoosening nuts and bolts

Radiator cap tester Checking radiator and radiator cap

PBIC0190E

PBIC1982E

Page 1382 of 5621

![INFINITI M35 2006 Factory Service Manual OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartNBS004QN

Symptom Check items

Cooling sys- INFINITI M35 2006 Factory Service Manual OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartNBS004QN

Symptom Check items

Cooling sys-](/img/42/57023/w960_57023-1381.png)

OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartNBS004QN

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

Fan assembly — High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio

———

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 1383 of 5621

![INFINITI M35 2006 Factory Service Manual CO-8

[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Revision: 2006 January2006 M35/M45

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in l INFINITI M35 2006 Factory Service Manual CO-8

[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Revision: 2006 January2006 M35/M45

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in l](/img/42/57023/w960_57023-1382.png)

CO-8

[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Revision: 2006 January2006 M35/M45

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 1386 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE COOLANT

CO-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

ENGINE COOLANTPFP:KQ100

InspectionNBS004QQ

LEVEL CHECK

Check if the reservoir tank engine coolant leve INFINITI M35 2006 Factory Service Manual ENGINE COOLANT

CO-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

ENGINE COOLANTPFP:KQ100

InspectionNBS004QQ

LEVEL CHECK

Check if the reservoir tank engine coolant leve](/img/42/57023/w960_57023-1385.png)

ENGINE COOLANT

CO-11

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

ENGINE COOLANTPFP:KQ100

InspectionNBS004QQ

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the

“MIN” to “MAX” when the engine is cool.

Adjust the engine coolant level as necessary.

LEAK CHECK

To check for leaks, apply pressure to the cooling system with the

radiator cap tester (commercial service tool) and radiator cap

tester adapter (SST).

WAR NING :

Do not remove radiator cap when engine is hot. Serious

burns could occur from high-pressure engine coolant

escaping from radiator.

CAUTION:

Higher test pressure than specified may cause radiator

damage.

NOTE:

In a case that engine coolant decreases, replenish radiator with engine coolant.

If anything is found, repair or replace damaged parts.

Changing Engine CoolantNBS004QR

WAR NING :

To avoid being scalded, do not change engine coolant when the engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

DRAINING ENGINE COOLANT

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove air duct (inlet). Refer to EM-17, "

AIR CLEANER AND AIR DUCT" .

3. Open radiator drain plug at the bottom of radiator, and then remove radiator cap.

When draining all of engine coolant in the system, open water drain plugs on cylinder block. Refer

to EM-124, "

DISASSEMBLY" .

SMA412B

Testing pressure

: 157 kPa (1.6 kg/cm

2 , 23 psi)

SLC756A

1 : Radiator drain plug hole

2 : Front engine under cover

: Engine front

PBIC3395E