belt INFINITI M35 2006 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1466 of 5621

UNIFIED METER AND A/C AMP

DI-33

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

DATA MONITOR

Operation Procedure

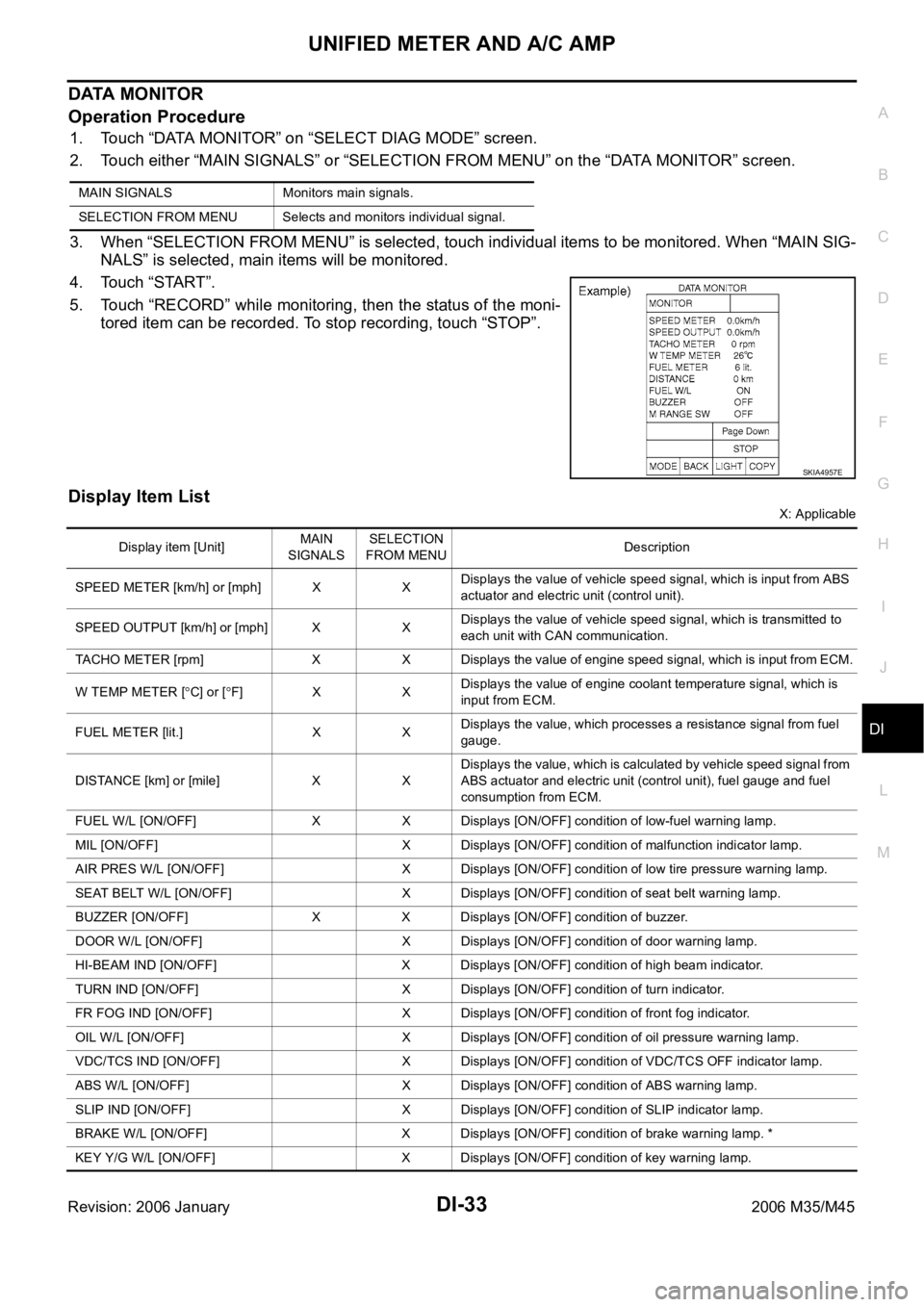

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch either “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. When “MAIN SIG-

NALS” is selected, main items will be monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring, then the status of the moni-

tored item can be recorded. To stop recording, touch “STOP”.

Display Item List

X: Applicable MAIN SIGNALS Monitors main signals.

SELECTION FROM MENU Selects and monitors individual signal.

SKIA4957E

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUDescription

SPEED METER [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is input from ABS

actuator and electric unit (control unit).

SPEED OUTPUT [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is transmitted to

each unit with CAN communication.

TACHO METER [rpm] X X Displays the value of engine speed signal, which is input from ECM.

W TEMP METER [

C] or [F] X XDisplays the value of engine coolant temperature signal, which is

input from ECM.

FUEL METER [lit.] X XDisplays the value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] or [mile] X XDisplays the value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and fuel

consumption from ECM.

FUEL W/L [ON/OFF] X X Displays [ON/OFF] condition of low-fuel warning lamp.

MIL [ON/OFF] X Displays [ON/OFF] condition of malfunction indicator lamp.

AIR PRES W/L [ON/OFF] X Displays [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L [ON/OFF] X Displays [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Displays [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Displays [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Displays [ON/OFF] condition of high beam indicator.

TURN IND [ON/OFF] X Displays [ON/OFF] condition of turn indicator.

FR FOG IND [ON/OFF] X Displays [ON/OFF] condition of front fog indicator.

OIL W/L [ON/OFF] X Displays [ON/OFF] condition of oil pressure warning lamp.

VDC/TCS IND [ON/OFF] X Displays [ON/OFF] condition of VDC/TCS OFF indicator lamp.

ABS W/L [ON/OFF] X Displays [ON/OFF] condition of ABS warning lamp.

SLIP IND [ON/OFF] X Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Displays [ON/OFF] condition of brake warning lamp. *

KEY Y/G W/L [ON/OFF] X Displays [ON/OFF] condition of key warning lamp.

Page 1494 of 5621

WARNING CHIME

DI-61

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

IGNITION KEY WARNING CHIME (WITH INTELLIGENT KEY)

Refer to BL-55, "WARNING FUNCTION" in intelligent key system.

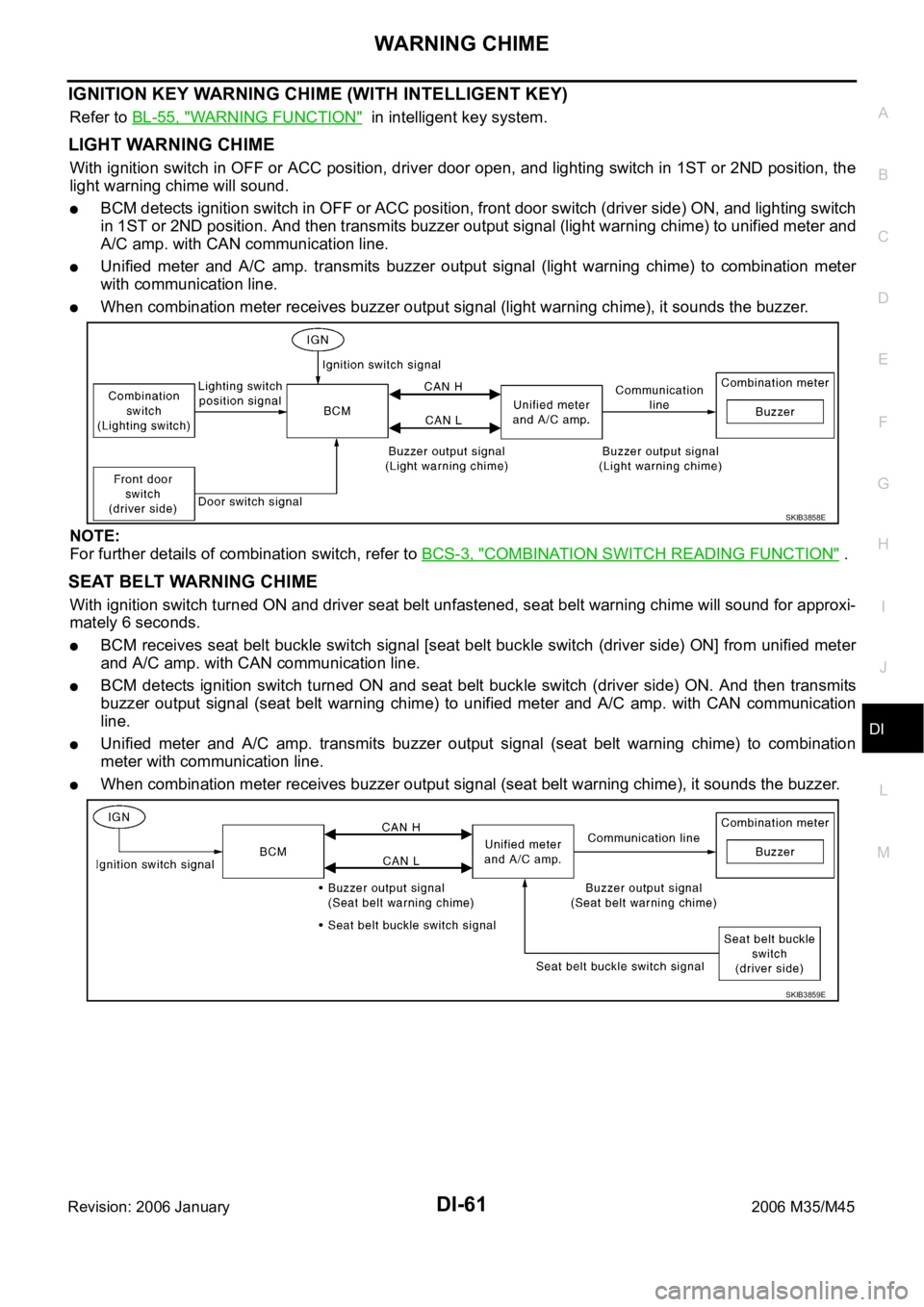

LIGHT WARNING CHIME

With ignition switch in OFF or ACC position, driver door open, and lighting switch in 1ST or 2ND position, the

light warning chime will sound.

BCM detects ignition switch in OFF or ACC position, front door switch (driver side) ON, and lighting switch

in 1ST or 2ND position. And then transmits buzzer output signal (light warning chime) to unified meter and

A/C amp. with CAN communication line.

Unified meter and A/C amp. transmits buzzer output signal (light warning chime) to combination meter

with communication line.

When combination meter receives buzzer output signal (light warning chime), it sounds the buzzer.

NOTE:

For further details of combination switch, refer to BCS-3, "

COMBINATION SWITCH READING FUNCTION" .

SEAT BELT WARNING CHIME

With ignition switch turned ON and driver seat belt unfastened, seat belt warning chime will sound for approxi-

mately 6 seconds.

BCM receives seat belt buckle switch signal [seat belt buckle switch (driver side) ON] from unified meter

and A/C amp. with CAN communication line.

BCM detects ignition switch turned ON and seat belt buckle switch (driver side) ON. And then transmits

buzzer output signal (seat belt warning chime) to unified meter and A/C amp. with CAN communication

line.

Unified meter and A/C amp. transmits buzzer output signal (seat belt warning chime) to combination

meter with communication line.

When combination meter receives buzzer output signal (seat belt warning chime), it sounds the buzzer.

SKIB3858E

SKIB3859E

Page 1500 of 5621

WARNING CHIME

DI-67

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

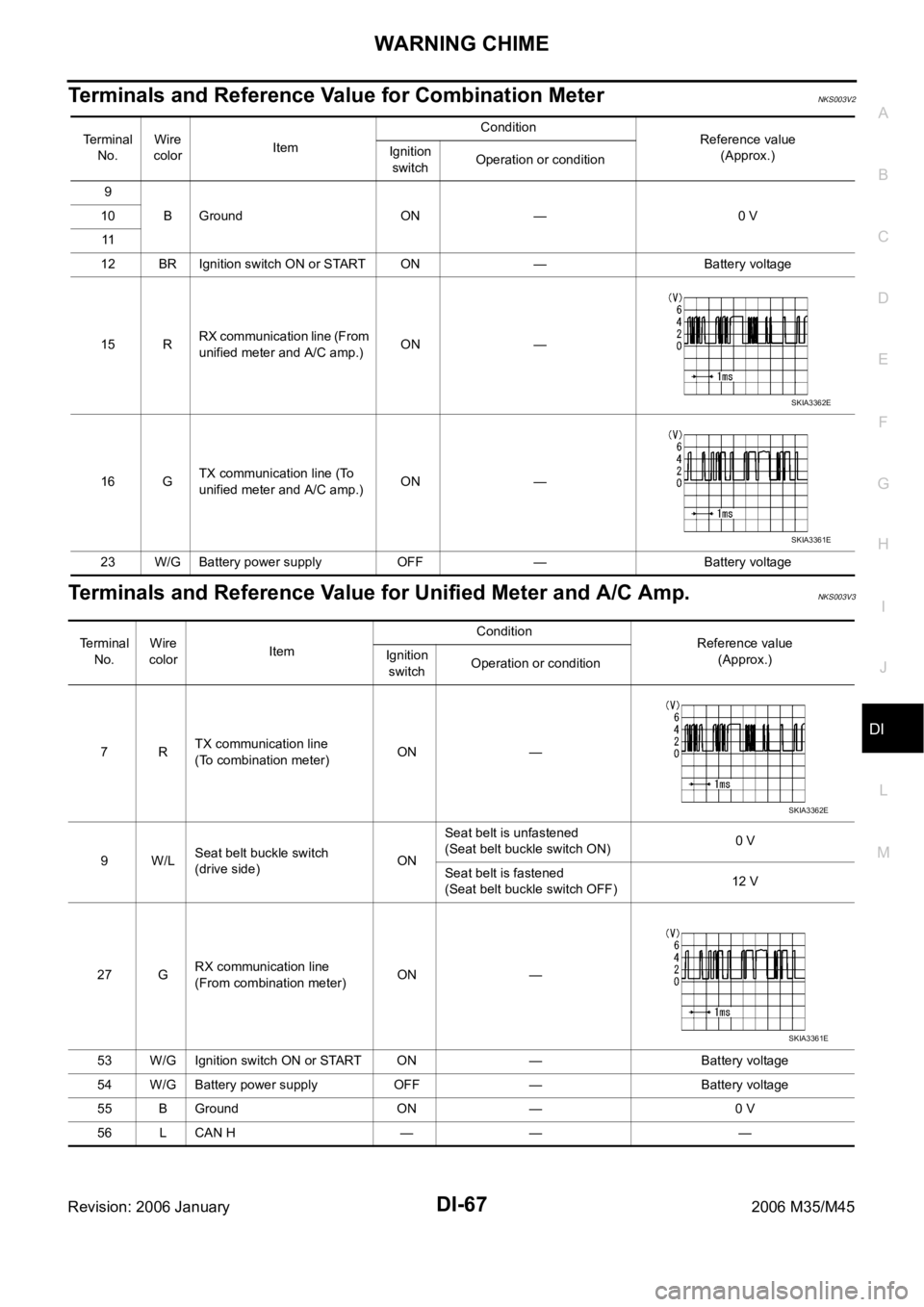

Terminals and Reference Value for Combination MeterNKS003V2

Terminals and Reference Value for Unified Meter and A/C Amp.NKS003V3

Te r m i n a l

No.Wire

colorItemCondition

Reference value

(Approx.) Ignition

switchOperation or condition

9

B Ground ON — 0 V 10

11

12 BR Ignition switch ON or START ON — Battery voltage

15 RRX communication line (From

unified meter and A/C amp.)ON —

16 GTX communication line (To

unified meter and A/C amp.)ON —

23 W/G Battery power supply OFF — Battery voltage

SKIA3362E

SKIA3361E

Terminal

No.Wire

colorItemCondition

Reference value

(Approx.) Ignition

switchOperation or condition

7RTX communication line

(To combination meter)ON —

9W/LSeat belt buckle switch

(drive side)ONSeat belt is unfastened

(Seat belt buckle switch ON)0 V

Seat belt is fastened

(Seat belt buckle switch OFF)12 V

27 GRX communication line

(From combination meter)ON —

53 W/G Ignition switch ON or START ON — Battery voltage

54 W/G Battery power supply OFF — Battery voltage

55 B Ground ON — 0 V

56 L CAN H — — —

SKIA3362E

SKIA3361E

Page 1503 of 5621

DI-70

WARNING CHIME

Revision: 2006 January2006 M35/M45

4. Touch “BUZZER” or “BCM”.

5. Select “DATA MONITOR”, “ACTIVE TEST” or “SELF-DIAG

RESULTS”.

DATA MONITOR

Operation Procedure

1. Touch “BUZZER” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch “ALL SIGNALS” or “SELECTION FROM MENU” on “DATA MONITOR” screen.

4. If “SELECTION FROM MENU” is selected, touch the desired monitor item. If “ALL SIGNALS” is selected,

all items required to control are monitored.

5. Touch “START”.

6. During monitoring, touching “RECORD” can start recording the monitored item status.

Display Item List

: Applicable

PKIB4914E

BCIA0031E

ALL SIGNALS Monitors main items.

SELECTION FROM MENU Selects and monitors items.

Display item [Unit] ALL SIGNALSSELECTION

FROM MENUDescription

IGN ON SW [ON/OFF] X X Displays [ON/OFF] condition of ignition switch.

KEY ON SW [ON/OFF] X X Displays [ON/OFF] condition of key switch.

DOOR SW-DR [ON/OFF] X X Displays [ON/OFF] condition of front door switch (driver side).

TAIL LAMP SW [ON/OFF] X X Displays [ON/OFF] condition of lighting switch.

FR FOG SW [ON/OFF] X X Displays [ON/OFF] condition of front fog lamp switch.

BUCKLE SW [ON/OFF] X X Displays [ON/OFF] condition of seat belt buckle switch (driver side).

Page 1504 of 5621

WARNING CHIME

DI-71

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

ACTIVE TEST

Operation Procedure

1. Touch “BUZZER” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch the item to be tested, and check the operation.

4. During the operation check, touching “OFF” deactivates the operation.

Display Item List

SELF-DIAG RESULTS

Operation Procedure

1. Touch “BCM” on “SELECT TEST ITEM” screen.

2. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

3. Self-diagnosis results are displayed.

Display Item List

NOTE:

If “CAN communication [U1000]” is indicated, after printing the monitor item, go to “LAN system”. Refer to

LAN-7, "

Precautions When Using CONSULT-II" .

CONSULT-II Function (METER A/C AMP)NKS003V6

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

NOTE:

For the further details, refer to DI-71, "

CONSULT-II Function (METER A/C AMP)" .

Trouble DiagnosisNKS003V7

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Confirm the symptom and customer complaint.

2. Understand the outline of system. Refer to DI-60, "

System Description" .

3. Perform the preliminary inspection. Refer to DI-71, "

PRELIMINARY INSPECTION" .

4. Referring to trouble diagnosis chart, make sure the cause of the malfunction and repair or replace applica-

ble parts. Refer to DI-72, "

SYMPTOM CHART" .

5. Does warning chime system operate normally? If yes, GO TO 6. If no, GO TO 3.

6. INSPECTION END

PRELIMINARY INSPECTION

1. CHECK BCM (CONSULT-II)

Perform self-diagnosis of BCM. Refer to BCS-13, "

CONSULT-II Function (BCM)" .

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

Display item Description

LIGHT WARN ALM This test is able to check light warning chime operation.

IGN KEY WARN ALM This test is able to check key warning chime operation.

SEAT BELT WARN TEST This test is able to check seat belt warning chime operation.

Display item [Code] Malfunction is detected when...

CAN communication [U1000] Malfunction is detected in CAN communication.

System Diagnosis mode DescriptionReference

page

METER A/C

AMPSELF-DIAG RESULTSUnified meter and A/C amp. checks the conditions and displays

memorized error.DI-32

DATA MONITOR Displays unified meter and A/C amp. input data in real time.DI-33

Page 1505 of 5621

DI-72

WARNING CHIME

Revision: 2006 January2006 M35/M45

2. CHECK UNIFIED METER AND A/C AMP. (CONSULT-II)

Perform self-diagnosis of unified meter and A/C amp. Refer to DI-71, "

CONSULT-II Function (METER A/C

AMP)" .

Self

-diagnostic results content

No malfunction detected>> INSPECTION END

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

SYMPTOM CHART

Meter Buzzer Circuit InspectionNKS003V8

1. CHECK OPERATION OF METER BUZZER

1. Select “BUZZER” of “BCM” on CONSULT-II.

2. Perform “LIGHT WARN ALM”, “IGN KEY WARN ALM” or “SEAT

BELT WARN TEST” of “ACTIVE TEST”.

Does meter buzzer beep?

YES >> GO TO 3.

NO >> GO TO 2.

2. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Select “METER A/C AMP” on CONSULT-II.

2. With “DATA MONITOR”, confirm “BUZZER” under the condition

of buzzer input. (Seat belt warning chime, turn signal lamp oper-

ate, etc.)

OK or NG

OK >> Replace combination meter.

NG >> Replace BCM. Refer to BCS-17, "

Removal and Installa-

tion of BCM" .

3. CHECK BATTERY POWER SUPPLY OF COMBINATION METER

Check battery power supply of combination meter. Refer to DI-19, "

Power Supply and Ground Circuit Inspec-

tion" in combination meter.

OK or NG

OK >> GO TO 4.

NG >> Repair battery power supply circuit of combination meter.

Symptom Diagnosis/Service procedure

All warning chime systems do not activate. Perform DI-72, "

Meter Buzzer Circuit Inspection" .

Light warning chime does not activate.Perform the following inspections.

1.DI-73, "

Lighting Switch Signal Inspection"

2.DI-73, "Front Door Switch (Driver Side) Signal Inspection"

Replace BCM, found normal function in the above inspections.

Seat belt warning chime does not activate.Perform DI-74, "

Seat Belt Buckle Switch Signal Inspection" .

Replace BCM, found normal function in the above inspection.

SKIA6331E

“BUZZER”

Under the condition of buzzer input : ON

Except above : OFF

PKIA2063E

Page 1507 of 5621

DI-74

WARNING CHIME

Revision: 2006 January2006 M35/M45

2. CHECK FRONT DOOR SWITCH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch (driver side)

connector.

3. Check continuity between BCM harness connector (A) and front

door switch (driver side) harness connector (B).

4. Check continuity between BCM harness connector (A) and

ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK FRONT DOOR SWITCH (DRIVER SIDE)

Check front door switch (driver side). Refer to DI-76, "

FRONT DOOR SWITCH (DRIVER SIDE)" .

OK or NG

OK >> Replace BCM. Refer to BCS-17, "Removal and Installation of BCM" .

NG >> Replace front door switch (driver side).

Seat Belt Buckle Switch Signal InspectionNKS003VB

1. CHECK BCM INPUT SIGNAL

1. Select “BCM” on CONSULT-II.

2. With “DATA MONITOR” of “BUZZER”, confirm “BUCKLE SW”

when the seat belt is fastened/unfastened.

OK or NG

OK >> Seat belt buckle switch signal is OK. Return to DI-72,

"SYMPTOM CHART" .

NG >> GO TO 2.

AB

Continuity

Connector Terminal Connector Terminal

M3 62 B11 2 Yes

A

GroundContinuity

Connector Terminal

M3 62 No

PKIB7663E

“BUCKLE SW”

When seat belt is fastened : OFF

When seat belt is unfastened : ON

SKIA8674E

Page 1508 of 5621

WARNING CHIME

DI-75

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

2. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between unified meter and A/C amp. harness

connector and ground.

OK or NG

OK >> Replace unified meter and A/C amp.

NG >> GO TO 3.

3. CHECK SEAT BELT BUCKLE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector and seat belt

buckle switch (driver side) connector.

3. Check continuity between unified meter and A/C amp. harness

connector (A) and seat belt buckle switch (driver side) harness

connector (B).

4. Check harness continuity between unified meter and A/C amp.

harness connector (A) and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check seat belt buckle switch (driver side). Refer to DI-76, "

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)" .

OK or NG

OK >> Check seat belt buckle switch (driver side) ground circuit.

NG >> Replace seat belt buckle switch (driver side).

Terminals

Condition

Voltage

(Approx.) (+)

(–)

Unified meter and

A/C amp. connectorTerminalSeat belt

(driver side):

M64 9 GroundFasten 12 V

Unfasten 0 V

PKIB7664E

AB

Continuity

Connector Terminal Connector Terminal

M64 9 B203 1 Yes

A

GroundContinuity

Connector Terminal

M64 9 No

PKIB7666E

Page 1509 of 5621

DI-76

WARNING CHIME

Revision: 2006 January2006 M35/M45

Electrical Component InspectionNKS003VC

FRONT DOOR SWITCH (DRIVER SIDE)

Check continuity between terminal 2 and door switch case ground.

SEAT BELT BUCKLE SWITCH (DRIVER SIDE)

Check continuity between terminals 1 and 2.

Terminal Condition Continuity

2Door switch

case groundWhen door switch is released. Yes

When door switch is pushed. No

PKIC0245E

Terminal Condition Continuity

12When seat belt is unfastened. Yes

When seat belt is fastened. No

PKIB7665E

Page 1544 of 5621

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

Revision: 2006 January2006 M35/M45

ENGINE CONTROL SYSTEM

VQ35DE

INDEX FOR DTC ...................................................... 16

DTC No. Index ....................................................... 16

Alphabetical Index .................................................. 20

PRECAUTIONS ........................................................ 24

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 24

Precautions for Procedures without Cowl Top Cover ... 24

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 24

Precaution .............................................................. 25

PREPARATION ......................................................... 28

Special Service Tools ............................................. 28

Commercial Service Tools ...................................... 29

ENGINE CONTROL SYSTEM .................................. 30

System Diagram ..................................................... 30

Multiport Fuel Injection (MFI) System .................... 31

Electronic Ignition (EI) System ............................... 33

Fuel Cut Control (At No Load and High Engine

Speed) .................................................................... 34

AIR CONDITIONING CUT CONTROL ..................... 35

Input/Output Signal Chart ....................................... 35

System Description ................................................ 35

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ... 36

System Description ................................................ 36

Component Description .......................................... 37

CAN COMMUNICATION .......................................... 38

System Description ................................................ 38

EVAPORATIVE EMISSION SYSTEM ....................... 39

Description ............................................................. 39

Component Inspection ........................................... 42

Removal and Installation ........................................ 43

How to Detect Fuel Vapor Leakage ....................... 43

ON BOARD REFUELING VAPOR RECOVERY

(ORVR) ...................................................................... 46

System Description ................................................ 46

Diagnostic Procedure ............................................. 47

Component Inspection ........................................... 49POSITIVE CRANKCASE VENTILATION ................. 51

Description .............................................................. 51

Component Inspection ............................................ 51

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS) ........................................................................ 53

Description .............................................................. 53

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 54

Introduction ..................................................

........... 54

Two Trip Detection Logic ........................................ 54

Emission-Related Diagnostic Information ............... 55

Malfunction Indicator Lamp (MIL) ........................... 69

OBD System Operation Chart ................................ 72

BASIC SERVICE PROCEDURE ............................... 77

Basic Inspection ..................................................... 77

Idle Speed and Ignition Timing Check .................... 82

Idle Mixture Ratio Adjustment ................................. 84

VIN Registration ..................................................... 95

Accelerator Pedal Released Position Learning ...... 95

Throttle Valve Closed Position Learning ................. 95

Idle Air Volume Learning ........................................ 96

Fuel Pressure Check .............................................. 98

TROUBLE DIAGNOSIS ..........................................100

Trouble Diagnosis Introduction .............................100

DTC Inspection Priority Chart ...............................106

Fail-Safe Chart .....................................................108

Symptom Matrix Chart ..........................................109

Engine Control Component Parts Location ..........113

Vacuum Hose Drawing .........................................121

Circuit Diagram .....................................................122

ECM Harness Connector Terminal Layout ...........124

ECM Terminals and Reference Value ...................124

CONSULT-II Function (ENGINE) ..........................133

Generic Scan Tool (GST) Function .......................146

CONSULT-II Reference Value in Data Monitor .....149

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................153

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .155

Description ............................................................155

Testing Condition ..................................................155