ground INFINITI M35 2006 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 249 of 5621

AT-170

DTC P1815 MANUAL MODE SWITCH

Revision: 2006 January2006 M35/M45

TCM terminals and data are reference value. Measured between each terminal and ground.

Diagnostic ProcedureNCS001OZ

1. CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" .

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 1 0 5 , "DTC U1000 CAN COMMUNICATION LINE" .

NO >> GO TO 2.

2. CHECK MANUAL MODE SWITCH CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out ON/OFF switching action of “MANU MODE SW”,

“NON M-MODE SW”, “UP SW LEVER”, “DOWN SW LEVER”.

Without CONSULT-II

Drive vehicle in the manual mode, and confirm that the actual gear position and the meter's indication of the

position mutually coincide when the selector lever is shifted to the “+ (up)” or “- (down)” side (1st

5th gear).

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3. DETECT MALFUNCTIONING ITEM

Check the following.

Manual mode switch. Refer to AT-171, "Component Inspection" .

Pin terminals for damage or loose connection with harness connector.

Open circuit or short to ground or short to power in harness or connector for A/T device (manual mode

switch).

Unified meter and A/C amp. Refer to DI-5, "COMBINATION METERS" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

Terminal Item Condition Data (Approx.)

3CAN-H – –

8CAN-L – –

9 Starter relaySelector lever in “N”, “P” positions. Battery voltage

Selector lever in “R”, “D” positions. 0V

Item name Condition Display Value

MANU MODE SWManual shift gate position (neutral) ON

Other than the above OFF

NON M-MODE SWManual shift gate position OFF

Other than the above ON

UP SW LEVERSelector lever: +side ON

Other than the above OFF

DOWN SW LEVERSelector lever: -side ON

Other than the above OFF

SCIA4988E

Page 250 of 5621

DTC P1815 MANUAL MODE SWITCH

AT-171

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

4. CHECK DTC

Perform “DTC Confirmation Procedure”. Refer to AT- 1 6 7 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 5.

5. CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-180, "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6. DETECT MALFUNCTIONING ITEM

Check the following.

The A/T assembly harness connector pin terminals for damage or loose connection with harness connec-

tor.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT- 2 3 6 , "Control Valve With TCM and A/T Fluid

Temperature Sensor 2" .

NG >> Repair or replace damaged parts.

Component InspectionNCS001P0

MANUAL MODE SWITCH

Check continuity between terminals.

Item Position Connector Terminal Continuity

Manual mode

select switchAuto

M1334 - 5

Ye s Manual 1 - 4

Manual mode

position select

switchUP 3 - 4

DOWN 2 - 4

SCIA6860E

Page 252 of 5621

DTC P1841 ATF PRESSURE SWITCH 1

AT-173

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Diagnostic ProcedureNCS001P6

1. CHECK INPUT SIGNAL

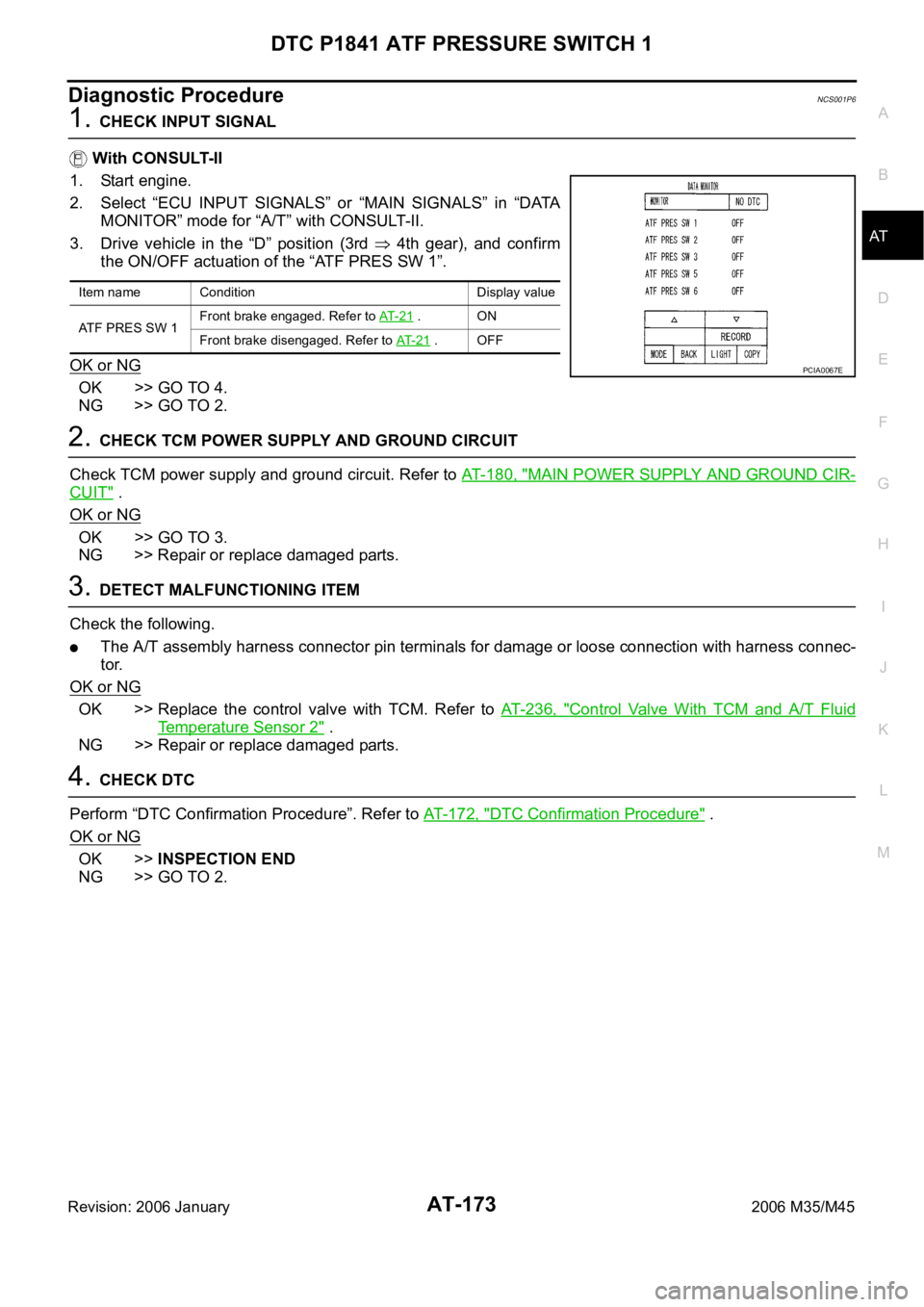

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Drive vehicle in the “D” position (3rd

4th gear), and confirm

the ON/OFF actuation of the “ATF PRES SW 1”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2. CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-180, "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3. DETECT MALFUNCTIONING ITEM

Check the following.

The A/T assembly harness connector pin terminals for damage or loose connection with harness connec-

tor.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT- 2 3 6 , "Control Valve With TCM and A/T Fluid

Temperature Sensor 2" .

NG >> Repair or replace damaged parts.

4. CHECK DTC

Perform “DTC Confirmation Procedure”. Refer to AT- 1 7 2 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item name Condition Display value

ATF PRES SW 1Front brake engaged. Refer to AT- 2 1

. ON

Front brake disengaged. Refer to AT- 2 1

. OFF

PCIA0067E

Page 254 of 5621

DTC P1843 ATF PRESSURE SWITCH 3

AT-175

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Diagnostic ProcedureNCS001PC

1. CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Drive vehicle in the “D” position (3rd

4th gear), and confirm

the ON/OFF actuation of the “ATF PRES SW 3”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2. CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-180, "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3. DETECT MALFUNCTIONING ITEM

Check the following.

The A/T assembly harness connector pin terminals for damage or loose connection with harness connec-

tor.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT- 2 3 6 , "Control Valve With TCM and A/T Fluid

Temperature Sensor 2" .

NG >> Repair or replace damaged parts.

4. CHECK DTC

Perform “DTC Confirmation Procedure”. Refer to AT- 1 7 4 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item name Condition Display value

ATF PRES SW 3Input clutch engaged. Refer to AT- 2 1

. ON

Input clutch disengaged. Refer to AT- 2 1

. OFF

PCIA0067E

Page 256 of 5621

DTC P1845 ATF PRESSURE SWITCH 5

AT-177

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Diagnostic ProcedureNCS001PI

1. CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Drive vehicle in the “D” position (1st

2nd gear), and confirm

the ON/OFF actuation of the “ATF PRES SW 5”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2. CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-180, "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3. DETECT MALFUNCTIONING ITEM

Check the following.

The A/T assembly harness connector pin terminals for damage or loose connection with harness connec-

tor.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT- 2 3 6 , "Control Valve With TCM and A/T Fluid

Temperature Sensor 2" .

NG >> Repair or replace damaged parts.

4. CHECK DTC

Perform “DTC Confirmation Procedure”. Refer to AT- 1 7 6 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item name Condition Display value

ATF PRES SW 5Direct clutch engaged. Refer to AT- 2 1

. ON

Direct clutch disengaged. Refer to AT- 2 1

. OFF

PCIA0067E

Page 258 of 5621

DTC P1846 ATF PRESSURE SWITCH 6

AT-179

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Diagnostic ProcedureNCS001PO

1. CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Drive vehicle in the “D” position (2nd

3rd gear), and confirm

the ON/OFF actuation of the “ATF PRES SW 6”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2. CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-180, "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT" .

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3. DETECT MALFUNCTIONING ITEM

Check the following.

The A/T assembly harness connector pin terminals for damage or loose connection with harness connec-

tor.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT- 2 3 6 , "Control Valve With TCM and A/T Fluid

Temperature Sensor 2" .

NG >> Repair or replace damaged parts.

4. CHECK DTC

Perform “DTC Confirmation Procedure”. Refer to AT- 1 7 8 , "

DTC Confirmation Procedure" .

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item name Condition Display value

ATF PRES SW 6High and low reverse clutch engaged.

Refer to AT- 2 1

.ON

High and low reverse clutch disengaged

Refer to AT- 2 1

.OFFPCIA0067E

Page 259 of 5621

AT-180

MAIN POWER SUPPLY AND GROUND CIRCUIT

Revision: 2006 January2006 M35/M45

MAIN POWER SUPPLY AND GROUND CIRCUITPFP:00100

Wiring Diagram — AT — MAINNCS001PP

TCWT0349E

Page 260 of 5621

MAIN POWER SUPPLY AND GROUND CIRCUIT

AT-181

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

TCM terminals and data are reference value. Measured between each terminal and ground.

Diagnostic ProcedureNCS001PQ

1. CHECK TCM POWER SOURCE STEP 1

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector.

3. Check voltage between A/T assembly harness connector termi-

nals and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2. CHECK TCM POWER SOURCE STEP 2

1. Disconnect A/T assembly harness connector.

2. Turn ignition switch ON. (Do not start engine.)

3. Check voltage between A/T assembly harness connector termi-

nals and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Terminal Item Condition Data (Approx.)

1Power supply

(Memory back-up)Always Battery voltage

2Power supply

(Memory back-up)Always Battery voltage

5 Ground Always 0V

6 Power supply– Battery voltage

–0V

10 Ground Always 0V

Item Connector Terminal Voltage

TCM F421 - Ground

Battery voltage

2 - Ground

6 - Ground 0V

SCIA2104E

Item Connector Terminal Voltage

TCM F421 - Ground

Battery voltage 2 - Ground

6 - Ground

SCIA2105E

Page 261 of 5621

AT-182

MAIN POWER SUPPLY AND GROUND CIRCUIT

Revision: 2006 January2006 M35/M45

3. DETECT MALFUNCTIONING ITEM

Check the following.

Harness for short or open between battery and A/T assembly harness connector terminals 1, 2

Harness for short or open between push-button ignition switch and A/T assembly harness connector ter-

minal 6

10A fuse (No. 34, located in the fuse and fusible link block) and 10A fuse (No. 83, located in the IPDM E/

R)

Push-button ignition switch (Refer to PG-3, "POWER SUPPLY ROUTING CIRCUIT" )

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector.

3. Check continuity between A/T assembly harness connector ter-

minals and ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

5. DETECT MALFUNCTIONING ITEM

Check the following.

The A/T assembly harness connector terminals for damage or loose connection with harness connector.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6. PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" .

OK or NG

OK >>INSPECTION END

NG-1 >> Self-diagnosis does not activate: GO TO 7.

NG-2 >> DTC is displayed: Check the malfunctioning system. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC

RESULT MODE" . Continuity should exist.

SCIA2106E

Page 262 of 5621

MAIN POWER SUPPLY AND GROUND CIRCUIT

AT-183

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

7. CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer to AT-236, "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2" .

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter-

minals and TCM connector terminals.

4. Check continuity between A/T assembly harness connector ter-

minals and TCM connector terminals.

5. If OK, check harness for short to ground and short to power.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT- 2 3 6 , "Control Valve With TCM and A/T Fluid

Temperature Sensor 2" .

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

Item Connector Terminal Continuity

A/T assembly harness con-

nectorF42 1

Ye s

TCM connector F502 9

A/T assembly harness con-

nectorF42 2

Ye s

TCM connector F502 10

A/T assembly harness con-

nectorF42 6

Ye s

TCM connector F502 4

SCIA5464E

Item Connector Terminal Continuity

A/T assembly harness con-

nectorF42 5

Ye s

TCM connector F504 21

A/T assembly harness con-

nectorF42 10

Ye s

TCM connector F504 22

SCIA5465E