ground INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 263 of 5621

AT-184

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

Revision: 2006 January2006 M35/M45

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

PFP:18002

CONSULT-II Reference ValueNCS001PR

Diagnostic ProcedureNCS001PS

1. CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "Diagnostic Pro-

cedure without CONSULT-II" .

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 1 0 5 , "DTC U1000 CAN COMMUNICATION LINE" .

NO >> GO TO 2.

2. CHECK THROTTLE POSITION SIGNAL CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Depress accelerator pedal and read out the value of “CLSD THL

POS” and “W/O THL POS”.

OK or NG

OK >>INSPECTION END

NG >> Check the following. If NG, repair or replace damaged parts.

Perform the self-diagnosis for “ENGINE” with CONSULT-II. Refer to EC-137, "SELF-DIAG

RESULTS MODE" (for VQ35DE engine), EC-850, "SELF-DIAG RESULTS MODE" (for

VK45DE engine).

Open circuit or short to ground or short to power in harness or connectors.

Pin terminals for damage or loose connection with harness connector.

Item name Condition Display value

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POSFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

Accelerator Pedal OperationMonitor Item

CLSD THL POS W/O THL POS

Released ON OFF

Fully depressed OFF ON

PCIA0070E

Page 269 of 5621

AT-190

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

TCM terminals and data are reference value. Measured between each terminal and ground.

A/T CHECK Indicator Lamp Does Not Come OnNCS001PZ

SYMPTOM:

A/T CHECK indicator lamp does not come on for about 2 seconds when turning ignition switch to ON.

DIAGNOSTIC PROCEDURE

1. CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)" .

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 1 0 5 , "DTC U1000 CAN COMMUNICATION LINE" .

NO >> GO TO 2.

2. CHECK A/T CHECK INDICATOR LAMP CIRCUIT

Check combination meters. Refer to DI-5, "

COMBINATION METERS" .

OK or NG

OK >> GO TO 3

NG >> Repair or replace damaged parts.

3. CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT- 1 8 0 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT" .

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in “P” or “N” PositionNCS001Q0

SYMPTOM:

Engine cannot be started with selector lever in “P” or “N” position.

Engine can be started with selector lever in “D”or “R” position.

DIAGNOSTIC PROCEDURE

1. CHECK PNP SWITCH CIRCUIT

Perform self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "TCM SELF-DIAG-

NOSTIC PROCEDURE (NO TOOLS)" .

Do the self-diagnostic results indicate PNP switch?

YES >> Check malfunctioning system. Refer to AT- 11 3 , "DTC P0705 PARK/NEUTRAL POSITION

SWITCH" .

NO >> GO TO 2.

Terminal Item Condition Data (Approx.)

3CAN-H – –

4K-line (CONSULT-II

signal)The terminal is connected to the data link connector for CONSULT- I I. –

7 Back-up lamp relaySelector lever in “R” position. 0V

Selector lever in other positions. Battery voltage

8CAN-L – –

Page 311 of 5621

AT-232

A/T SHIFT LOCK SYSTEM

Revision: 2006 January2006 M35/M45

Diagnostic ProcedureNCS001QS

SYMPTOM:

Selector lever cannot be moved from “P” position with key in ON position and brake pedal

applied.

Selector lever can be moved from “P” position with key in ON position and brake pedal released.

1. CHECK SELECTOR LEVER POSITION

Check the selector lever position for damage. Refer to AT- 2 2 8 , "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust control linkage. Refer to AT-227, "

Adjustment of A/T Position" .

2. CHECK POWER SOURCE

1. Turn ignition switch OFF.

2. Disconnect shift lock relay.

3. Check voltage between shift lock relay E35 terminal 2 and

ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.Vo l ta g e

Brake pedal depressed: Battery voltage

Brake pedal released: 0V

SCIA6866E

Page 312 of 5621

A/T SHIFT LOCK SYSTEM

AT-233

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

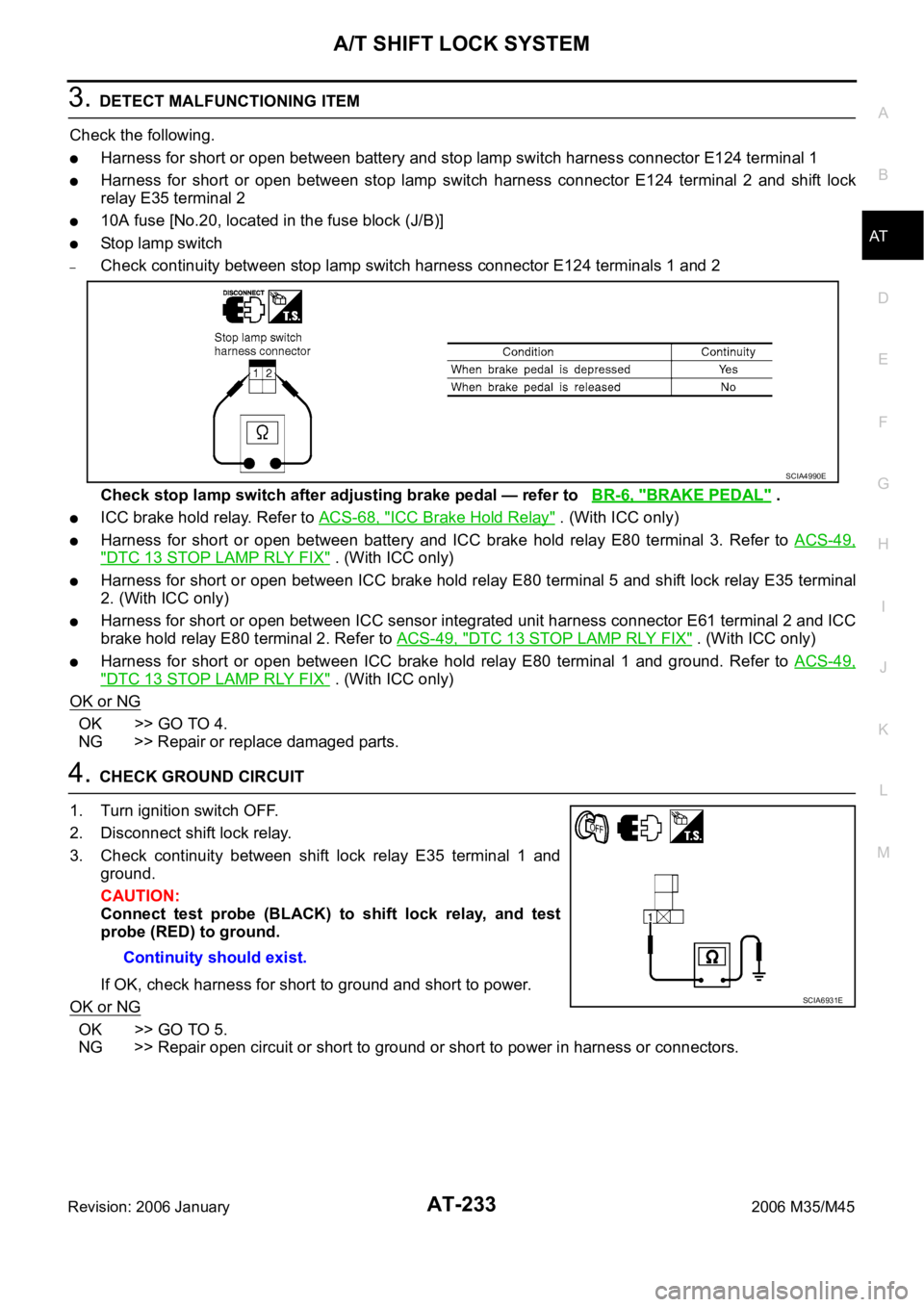

3. DETECT MALFUNCTIONING ITEM

Check the following.

Harness for short or open between battery and stop lamp switch harness connector E124 terminal 1

Harness for short or open between stop lamp switch harness connector E124 terminal 2 and shift lock

relay E35 terminal 2

10A fuse [No.20, located in the fuse block (J/B)]

Stop lamp switch

–Check continuity between stop lamp switch harness connector E124 terminals 1 and 2

Check stop lamp switch after adjusting brake pedal — refer to BR-6, "

BRAKE PEDAL" .

ICC brake hold relay. Refer to ACS-68, "ICC Brake Hold Relay" . (With ICC only)

Harness for short or open between battery and ICC brake hold relay E80 terminal 3. Refer to ACS-49,

"DTC 13 STOP LAMP RLY FIX" . (With ICC only)

Harness for short or open between ICC brake hold relay E80 terminal 5 and shift lock relay E35 terminal

2. (With ICC only)

Harness for short or open between ICC sensor integrated unit harness connector E61 terminal 2 and ICC

brake hold relay E80 terminal 2. Refer to ACS-49, "

DTC 13 STOP LAMP RLY FIX" . (With ICC only)

Harness for short or open between ICC brake hold relay E80 terminal 1 and ground. Refer to ACS-49,

"DTC 13 STOP LAMP RLY FIX" . (With ICC only)

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect shift lock relay.

3. Check continuity between shift lock relay E35 terminal 1 and

ground.

CAUTION:

Connect test probe (BLACK) to shift lock relay, and test

probe (RED) to ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

SCIA4990E

Continuity should exist.

SCIA6931E

Page 313 of 5621

AT-234

A/T SHIFT LOCK SYSTEM

Revision: 2006 January2006 M35/M45

5. CHECK INPUT SIGNAL A/T DEVICE

1. Turn ignition switch OFF.

2. Disconnect A/T device harness connector.

3. Turn ignition switch ON. (Do not start engine.)

4. Check voltage between A/T device harness connector M133 ter-

minal 7 and ground.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6. DETECT MALFUNCTIONING ITEM

Check the following.

Harness for short or open between push-button ignition switch and shift lock relay E35 terminal 5

Harness for short or open between shift lock relay E35 terminal 3 and A/T device harness connector

M133 terminal 7

10A fuse [No.12, located in the fuse block (J/B)]

Push-button ignition switch (Refer to PG-3, "POWER SUPPLY ROUTING CIRCUIT" .)

Shift lock relay

–Check continuity between shift lock relay E35 terminal 3 and 5

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness connector M133

terminal 8 and ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors. Vo l ta g e

Brake pedal depressed: Battery voltage

Brake pedal released: 0V

SCIA6867E

Condition Continuity

12V direct current supply between terminal 1 and 2 Yes

OFF No

SCIA1245E

Continuity should exist.

SCIA6868E

Page 449 of 5621

ATC-2Revision: 2006 January2006 M35/M45 AUTO SWITCH ................................................... 34

DEFROSTER (DEF) SWITCH ............................. 34

UPPER VENT SWITCH ...................................... 34

A/C SWITCH ....................................................... 35

FAN SWITCHES .................................................. 35

OFF SWITCH ...................................................... 35

REAR WINDOW DEFOGGER SWITCH ............. 35

INTAKE SWITCH ................................................. 35

DUAL SWITCH .................................................... 35

Control Operation (Rear Control Switch) ................ 35

AUTO SWITCH ................................................... 35

FAN SWITCH ...................................................... 35

REAR TEMPERATURE CONTROL SWITCH ..... 35

Fail-Safe Function .................................................. 36

Discharge Air Flow ................................................. 37

System Description ................................................. 38

SWITCHES AND THEIR CONTROL FUNCTION ... 38

CAN Communication System Description .............. 39

TROUBLE DIAGNOSIS ............................................ 40

CONSULT-II Function (ECM) .................................. 40

CONSULT-II BASIC OPERATION ....................... 40

DATA MONITOR .................................................. 40

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 40

WORK FLOW ...................................................... 40

SYMPTOM TABLE .............................................. 41

Component Parts and Harness Connector Location ... 42

ENGINE COMPARTMENT .................................. 42

PASSENGER COMPARTMENT .......................... 43

Schematic ............................................................... 44

Wiring Diagram —A/C— ......................................... 46

Auto Amp. Terminals and Reference Value ............ 53

PIN CONNECTOR TERMINAL LAYOUT ............ 53

TERMINALS AND REFERENCE VALUE FOR

UNIFIED METER AND A/C AMP. ........................ 53

Self-diagnosis Function .......................................... 55

DESCRIPTION .................................................... 55

FUNCTION CONFIRMATION PROCEDURE ...... 56

AUXILIARY MECHANISM: TEMPERATURE

SETTING TRIMMER ........................................... 62

AUXILIARY MECHANISM: FOOT POSITION

SETTING TRIMMER ........................................... 63

AUXILIARY MECHANISM: INLET PORT MEM-

ORY FUNCTION ................................................. 63

Operational Check .................................................. 64

CHECKING MEMORY FUNCTION ..................... 64

CHECKING BLOWER ......................................... 64

CHECKING DISCHARGE AIR (MODE SWITCH

AND DEF SWITCH) ............................................ 64

CHECKING DISCHARGE AIR (UPPER VENT

SWITCH) ............................................................. 65

CHECKING INTAKE AIR ..................................... 65

CHECKING TEMPERATURE DECREASE ......... 65

CHECKING TEMPERATURE INCREASE .......... 65

CHECKING A/C SWITCH ................................... 65

CHECKING AUTO MODE ................................... 65

Power Supply and Ground Circuit for Auto Amp. ... 66

INSPECTION FLOW ........................................... 66

COMPONENT DESCRIPTION ............................ 67DIAGNOSIS PROCEDURE FOR A/C SYSTEM ... 67

Rear Control Switch Circuit ..................................... 69

DIAGNOSIS PROCEDURE FOR REAR CON-

TROL SWITCH .................................................... 69

LAN System Circuit ................................................. 70

DIAGNOSIS PROCEDURE FOR LAN CIRCUIT ... 70

Mode Door Motor Circuit ......................................... 75

INSPECTION FLOW ............................................ 76

SYSTEM DESCRIPTION ..................................... 78

COMPONENT DESCRIPTION ............................ 79

DIAGNOSIS PROCEDURE FOR MODE DOOR

MOTOR ................................................................ 79

Upper Ventilator Door Motor Circuit ........................ 80

INSPECTION FLOW ............................................ 80

SYSTEM DESCRIPTION ..................................... 81

COMPONENT DESCRIPTION ............................ 82

DIAGNOSIS PROCEDURE FOR UPPER VEN-

TILATOR DOOR MOTOR .................................... 82

Air Mix Door Motor Circuit ....................................... 83

INSPECTION FLOW ............................................ 83

SYSTEM DESCRIPTION ..................................... 84

COMPONENT DESCRIPTION ............................ 85

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR

MOTOR ................................................................ 85

Air Mix Door Motor PBR Circuit .............................. 85

DIAGNOSIS PROCEDURE FOR AIR MIX DOOR

MOTOR PBR ....................................................... 85

Intake Door Motor Circuit ........................................ 86

INSPECTION FLOW ............................................ 86

SYSTEM DESCRIPTION ..................................... 87

COMPONENT DESCRIPTION ............................ 88

DIAGNOSIS PROCEDURE FOR INTAKE DOOR

MOTOR ................................................................ 88

Blower Motor Circuit ................................................ 89

INSPECTION FLOW ............................................ 89

SYSTEM DESCRIPTION ..................................... 90

COMPONENT DESCRIPTION ............................ 91

DIAGNOSIS PROCEDURE FOR BLOWER

MOTOR ................................................................ 91

COMPONENT INSPECTION ............................... 93

Magnet Clutch Circuit .............................................. 94

INSPECTION FLOW ............................................ 94

SYSTEM DESCRIPTION ..................................... 95

DIAGNOSIS PROCEDURE FOR MAGNET

CLUTCH .............................................................. 95

COMPONENT INSPECTION ............................... 98

Insufficient Cooling .................................................. 99

INSPECTION FLOW ............................................ 99

PERFORMANCE TEST DIAGNOSIS ................101

PERFORMANCE CHART ..................................103

TROUBLE DIAGNOSIS FOR UNUSUAL PRES-

SURE .................................................................105

DIAGNOSIS PROCEDURE FOR INSUFFI-

CIENT COOLING ...............................................107

Insufficient Heating ...............................................109

INSPECTION FLOW ..........................................109

Noise .....................................................................110

INSPECTION FLOW ..........................................110

Self-Diagnosis ....................................................... 111

Page 476 of 5621

AIR CONDITIONER CONTROL

ATC-29

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

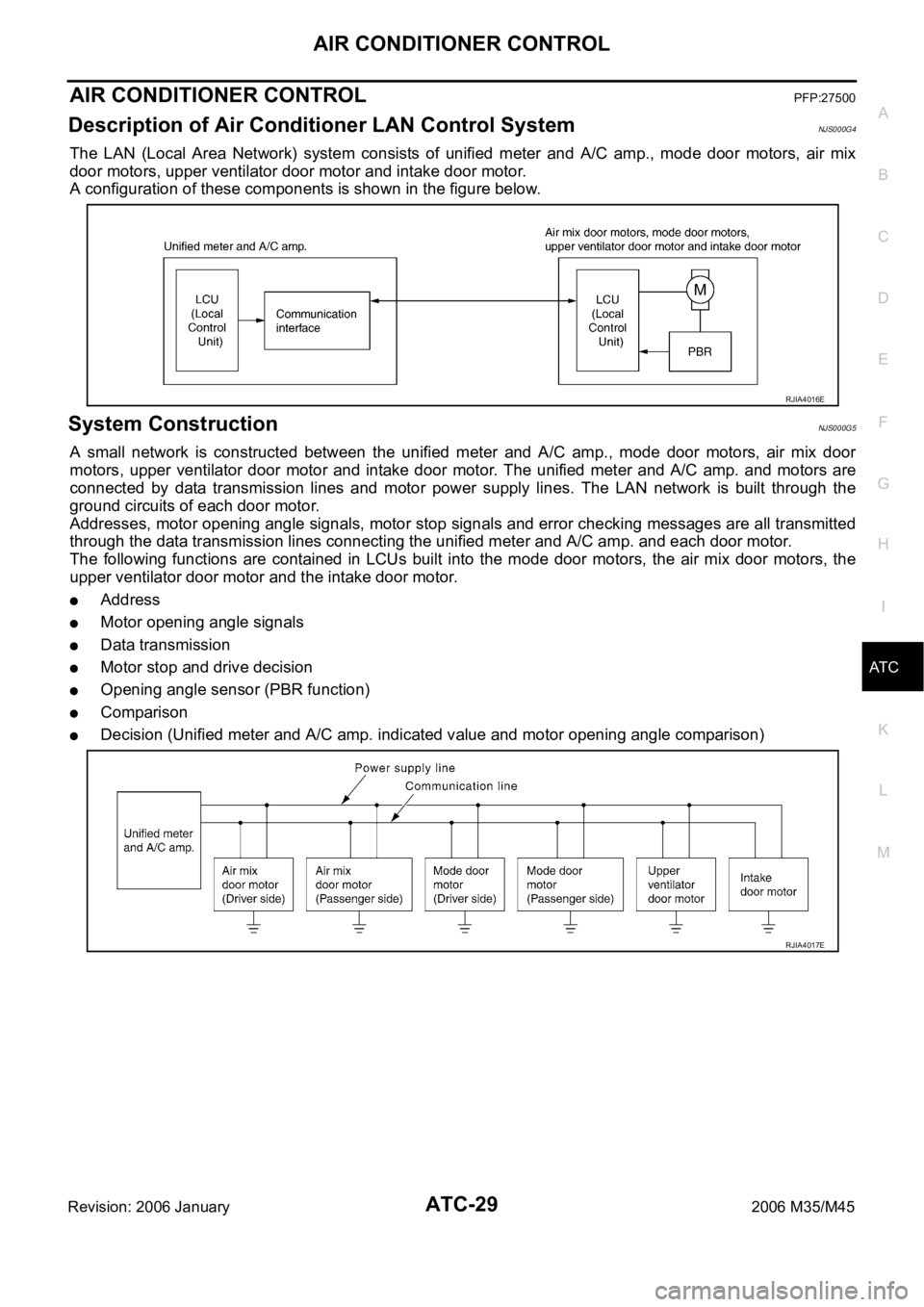

AIR CONDITIONER CONTROLPFP:27500

Description of Air Conditioner LAN Control SystemNJS000G4

The LAN (Local Area Network) system consists of unified meter and A/C amp., mode door motors, air mix

door motors, upper ventilator door motor and intake door motor.

A configuration of these components is shown in the figure below.

System ConstructionNJS000G5

A small network is constructed between the unified meter and A/C amp., mode door motors, air mix door

motors, upper ventilator door motor and intake door motor. The unified meter and A/C amp. and motors are

connected by data transmission lines and motor power supply lines. The LAN network is built through the

ground circuits of each door motor.

Addresses, motor opening angle signals, motor stop signals and error checking messages are all transmitted

through the data transmission lines connecting the unified meter and A/C amp. and each door motor.

The following functions are contained in LCUs built into the mode door motors, the air mix door motors, the

upper ventilator door motor and the intake door motor.

Address

Motor opening angle signals

Data transmission

Motor stop and drive decision

Opening angle sensor (PBR function)

Comparison

Decision (Unified meter and A/C amp. indicated value and motor opening angle comparison)

RJIA4016E

RJIA4017E

Page 488 of 5621

TROUBLE DIAGNOSIS

ATC-41

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

SYMPTOM TABLE

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System.ATC-66, "

Power

Supply and Ground

Circuit for Auto

Amp."

A/C system cannot be controlled. Go to Multifunction Switch System.AV-108, "

Multifunc-

tion Switch Cannot

Be Operated" (With-

out mobile enter-

tainment system) or

AV-253, "

Multifunc-

tion Switch Cannot

Be Operated" ( Wi t h

mobile entertain-

ment system)

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor. (LAN)ATC-75, "

Mode

Door Motor Circuit"Mode door motor does not operate normally.

Upper ventilator outlet does not change.

Go to Trouble Diagnosis Procedure for Upper Ventilator Door

Motor. (LAN)ATC-80, "

Upper

Ventilator Door

Motor Circuit"Upper ventilator door motor does not oper-

ate normally.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor.

(LAN)AT C - 8 3 , "

Air Mix

Door Motor Circuit"Air mix door motor does not operate nor-

mally.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor. (LAN)AT C - 8 6 , "

Intake

Door Motor Circuit"Intake door motor does not operate nor-

mally.

Blower motor operation is malfunctioning. Go to Trouble Diagnosis Procedure for Blower Motor.ATC-89, "

Blower

Motor Circuit"

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.AT C - 9 4 , "Magnet

Clutch Circuit"

Insufficient coolingGo to Trouble Diagnosis Procedure for Insufficient Cooling.ATC-99, "

Insufficient

Cooling"

Go to Diagnosis Procedure for Insufficient Cooling.ATC-107, "

DIAG-

NOSIS PROCE-

DURE FOR

INSUFFICIENT

COOLING"

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating.ATC-109, "Insuffi-

cient Heating"

Noise Go to Trouble Diagnosis Procedure for Noise.AT C - 11 0 , "Noise"

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis.AT C - 111 , "Self-

Diagnosis"

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.AT C - 11 2 , "Memory

Function"

Rear control switch does not operate. Go to Trouble Diagnosis Procedure for Rear Control Switch.AT C - 6 9 , "Rear Con-

trol Switch Circuit"

Page 500 of 5621

TROUBLE DIAGNOSIS

ATC-53

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

Auto Amp. Terminals and Reference ValueNJS000GI

Measure voltage between each terminal and ground by referring ter-

minals and reference value for unified meter and A/C amp.

PIN CONNECTOR TERMINAL LAYOUT

TERMINALS AND REFERENCE VALUE FOR UNIFIED METER AND A/C AMP.

RJIA4032E

RJIA4033E

Terminal

No.Wire

colorItemIgnition

switchConditionVoltage

(V)

38 L/Y Blower motor control signal ON Blower speed: 1st step

41 V Power supply from ACC ACC — Battery voltage

43 R Intake sensor — — —

44 GR In-vehicle sensor — — —

45 W/V Ambient sensor — — —

46 BR/Y Sunload sensor — — —

53 W/G Power supply from IGN ON — Battery voltage

54 W/G Power supply from BATT OFF — Battery voltage

55 B Ground ON — Approx. 0

56 L CAN-H — — —

59 O/B Intake sensor ground ON — Approx. 0

60 P In-vehicle sensor ground ON — Approx. 0

61 LG/R Ambient sensor ground ON — Approx. 0

62 V/R Sunload sensor ground ON — Approx. 0

SJIA1454J

Page 501 of 5621

ATC-54

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

65 OECV (Electric Control Valve)

signalONSelf-diagnosis. STEP-4

(Code No. 45)

69 R A/C LAN signal ON —

70 WPower supply for each door

motorON — Battery voltage

71 B Ground (Power) ON — Approx. 0

72 P CAN-L — — — Te r m i n a l

No.Wire

colorItemIgnition

switchConditionVoltag e

(V)

SJIA1458J

SJIA1453J