check engine INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4465 of 5621

LT-38

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

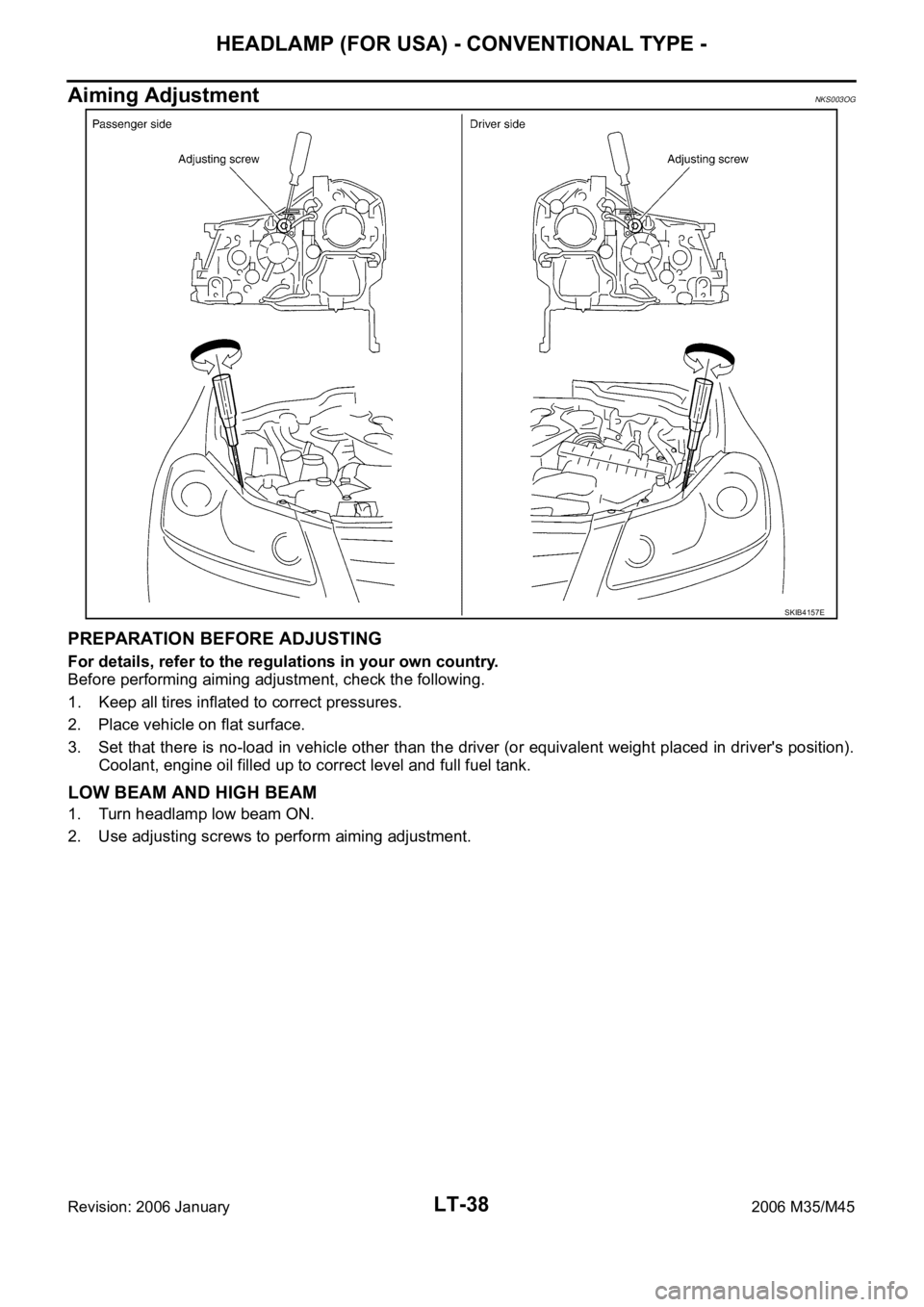

Aiming AdjustmentNKS003OG

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on flat surface.

3. Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

SKIB4157E

Page 4501 of 5621

LT-74

HEADLAMP (FOR USA) - XENON TYPE -

Revision: 2006 January2006 M35/M45

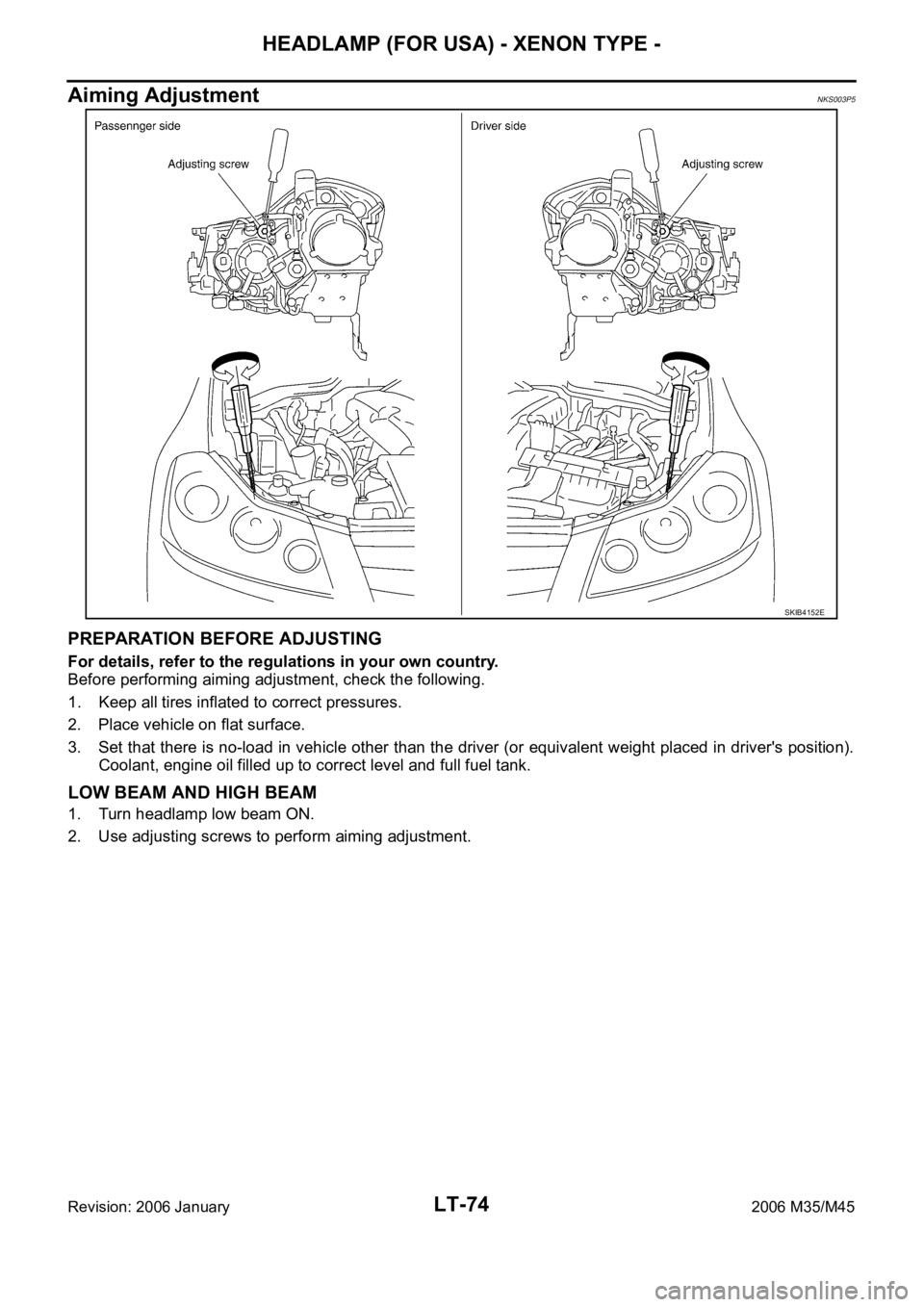

Aiming AdjustmentNKS003P5

PREPARATION BEFORE ADJUSTING

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

1. Keep all tires inflated to correct pressures.

2. Place vehicle on flat surface.

3. Set that there is no-load in vehicle other than the driver (or equivalent weight placed in driver's position).

Coolant, engine oil filled up to correct level and full fuel tank.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam ON.

2. Use adjusting screws to perform aiming adjustment.

SKIB4152E

Page 4518 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-91

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for IPDM E/RNKS003PF

NOTE:

Daytime running light is operating: Lighting switch in OFF position with engine running and parking brake is released.

How to Perform Trouble DiagnosisNKS003PG

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT- 7 9 , "

System Description" .

3. Perform the Preliminary Check. Refer to LT-92, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of malfunction.

5. Does the headlamp operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. INSPECTION END

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

20 R Headlamp low (RH) ON Lighting switch 2ND positionOFF Approx. 0V

ON Battery voltage

27 BR Headlamp high (RH) ONLighting switch HIGH or PASSING

positionOFF Approx. 0V

ON Battery voltage

Daytime running light is operating

NOTEApprox. 6.5V

28 R/Y Headlamp high (LH) ONLighting switch HIGH or PASSING

positionOFF Approx. 0V

ON Battery voltage

Daytime running light is operating

NOTEApprox. 6.5V

30 R/B Headlamp low (LH) ON Lighting switch 2ND positionOFF Approx. 0V

ON Battery voltage

38 B Ground ON — Approx. 0V

49 L CAN

H — — —

50 P CAN

L — — —

51 B Ground ON — Approx. 0V

58 SBDaytime light relay

signalONDaytime running light is operating

NOTEApprox. 0V

Daytime running light is not operating Battery voltage

Page 4523 of 5621

LT-96

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

NOTE:

This item is displayed, but cannot be monitored.

ACTIVE TEST

Operation Procedure

1. Touch “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Touch item to be tested and check operation of the selected item.

4. During the operation check, touching “BACK” deactivates the operation.

Display Item List

DOOR SW - RL “ON/OFF”Displays status of the rear door as judged from the rear door switch (LH) signal. (door is open:

ON/door is closed: OFF)

BACK DOOR SW

NOTE “OFF” —

PKB SW “ON/OFF”Displays status (parking brake released: ON/ parking brake applied: OFF) of parking brake

switch judged from parking brake switch signal.

ENGINE RUN “ON/OFF”Displays status (engine running: ON/ engine stopped: OFF) of engine judged from engine run

signal.

OPTICAL SENSOR “0 - 5V” Displays “outside brightness (close to 5V when light/close to 0V when dark)” judged from opti-

cal sensor signal.

VEHICLE SPEED “km/h” Displays vehicle speed as judged from vehicle speed signal. Monitor item Contents

Test item Description

TAIL LAMP Allows tail lamp relay to operate by switching ON-OFF.

FR FOG LAMP Allows front fog lamp relay to operate by switching ON-OFF.

DAYTIME RUNNING LIGHT Allows daytime relay to operate by switching ON-OFF.

HEAD LAMP (HI, LO) Allows headlamp relay to operate by switching ON-OFF.

Page 4526 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-99

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Daytime Light Control Does Not Operate Properly (Normal Headlamps Operate

Properly)

NKS003PK

1. DAYTIME LIGHT ACTIVE TEST

With CONSULT-II

1. Select “BCM” on CONSULT-II, and select “HEAD LAMP” on

“SELECT TEST ITEM” screen.

2. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

3. Select “DAYTIME RUNNING LIGHT” on “SELECT TEST ITEM”

screen.

4. Touch “ON” screen.

5. Make sure daytime light operation.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2. CHECK INPUT SIGNAL

1. Select “BCM” on CONSULT-II. With “HEAD LAMP” data monitor,

make sure “ENGINE RUN” turns ON-OFF linked with operation

of engine running or stop.

2. Select “BCM” on CONSULT-II. With “HEAD LAMP” data monitor,

make sure “PKB SW” turns ON-OFF linked with operation of

parking brake switch.

OK or NG

OK >> GO TO 3.

NG >> Check BCM CAN communication system. Refer to BCS-15, "

CAN Communication Inspection

Using CONSULT-II (Self-Diagnosis)" .

3. CHECK INPUT SIGNAL

1. Start engine and release parking brake. Headlamp switch OFF.

2. Select “IPDM E/R” on CONSULT-II. With data monitor, make

sure “DTRL REQ” turns ON-OFF linked with operation of park-

ing brake switch.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-31, "Removal and

Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-17, "

Removal and Installa-

tion of BCM" . Daytime light should operate.

PKIC0442E

Engine running : ENGINE RUN ON

Engine stop : ENGINE RUN OFF

Parking brake ON : PKB SW ON

Parking brake OFF : PKB SW OFF

PKIA7591E

Parking brake ON : DTRL REQ ON

Parking brake OFF : DTRL REQ OFF

SKIB4913E

Page 4528 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-101

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

7. CHECK DAYTIME LIGHT RELAY SIGNAL

1. Connect IPDM E/R connector.

2. Install daytime light relay.

3. Turn ignition switch ON.

4. Applied parking brake.

5. Check voltage between IPDM E/R harness connector E9 termi-

nal 58 and ground.

6. Start engine and release parking break. Headlamp switch OFF.

7. Check voltage between IPDM E/R harness connector E9 termi-

nal 58 and ground.

OK or NG

OK >> Check connecting condition daytime relay harness con-

nector.

NG >> GO TO 8.

8. CHECK CAN COMMUNICATIONS

Select “BCM” by CONSULT-II, and perform self-diagnosis for “BCM”.

Displayed self-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-17, "Removal and Installa-

tion of BCM" .

CAN COMM CIRCUIT>>Check BCM CAN communication system.

Refer to BCS-15, "

CAN Communication Inspection

Using CONSULT-II (Self-Diagnosis)" . 58 – Ground : Battery voltage

58 – Ground : Approx. 0V

SKIB4747E

SKIA1039E

Page 4565 of 5621

LT-138

ACTIVE AFS

Revision: 2006 January2006 M35/M45

through front combination lamp RH terminal 21.

Swivel position sensor detects swivel angle during ignition switch ON, and transmits swivel position sensor

signals to the AFS control unit:

When ignition switch is turn to ON position, power is supplied

to front combination lamp RH terminal 15

through AFS control unit terminal 4.

When ignition switch is turn to ON position, swivel position sensor input signal is supplied

to AFS control unit terminal 9

through front combination lamp RH terminal 14.

Ground is supplied

to front combination lamp RH terminal 19

through AFS control unit terminal 2.

The low beam headlamp RH starts to swivel to the right.

The swivel motor driving signals are blocked and the swivel motion stops when the steering angle reaches

approximately more than 80 degrees (predetermined). The low beam headlamp will not swivel any further no

matter how further right. As the steering wheel is turned back to the left, the swivel motor driving signals (both

1-phase and 2-phase) will be reversed, causing low beam headlamp RH to start swiveling to the left. When

steering angle becomes smaller than predetermined value, the low beam headlamp is set in the straight-

ahead position, swivel motor driving signals are blocked and low beam headlamps stop swiveling.

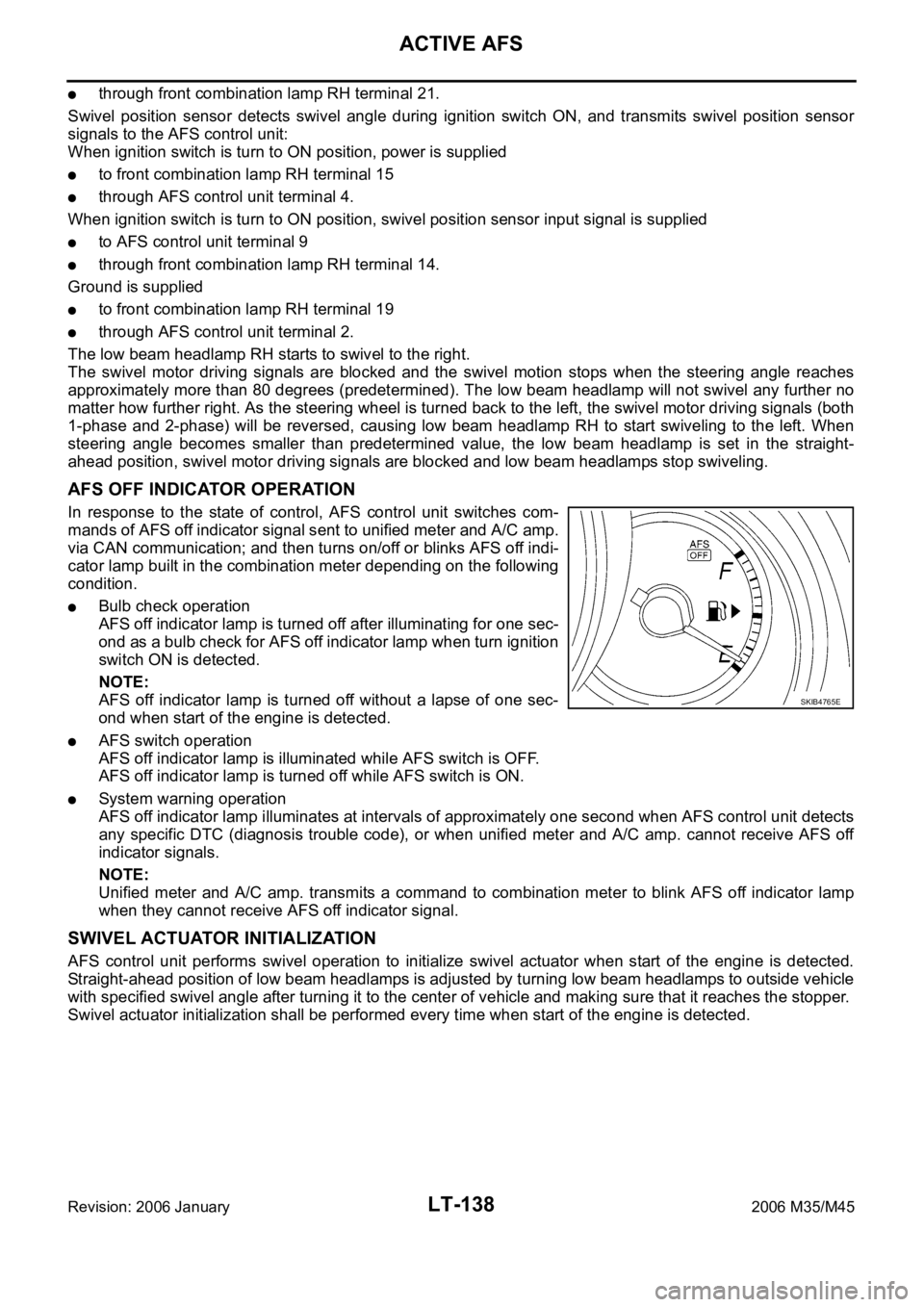

AFS OFF INDICATOR OPERATION

In response to the state of control, AFS control unit switches com-

mands of AFS off indicator signal sent to unified meter and A/C amp.

via CAN communication; and then turns on/off or blinks AFS off indi-

cator lamp built in the combination meter depending on the following

condition.

Bulb check operation

AFS off indicator lamp is turned off after illuminating for one sec-

ond as a bulb check for AFS off indicator lamp when turn ignition

switch ON is detected.

NOTE:

AFS off indicator lamp is turned off without a lapse of one sec-

ond when start of the engine is detected.

AFS switch operation

AFS off indicator lamp is illuminated while AFS switch is OFF.

AFS off indicator lamp is turned off while AFS switch is ON.

System warning operation

AFS off indicator lamp illuminates at intervals of approximately one second when AFS control unit detects

any specific DTC (diagnosis trouble code), or when unified meter and A/C amp. cannot receive AFS off

indicator signals.

NOTE:

Unified meter and A/C amp. transmits a command to combination meter to blink AFS off indicator lamp

when they cannot receive AFS off indicator signal.

SWIVEL ACTUATOR INITIALIZATION

AFS control unit performs swivel operation to initialize swivel actuator when start of the engine is detected.

Straight-ahead position of low beam headlamps is adjusted by turning low beam headlamps to outside vehicle

with specified swivel angle after turning it to the center of vehicle and making sure that it reaches the stopper.

Swivel actuator initialization shall be performed every time when start of the engine is detected.

SKIB4765E

Page 4587 of 5621

LT-160

ACTIVE AFS

Revision: 2006 January2006 M35/M45

ACTIVE TEST

Operation Procedure

1. Start the engine. (Swivel actuator is initialized.)

2. Touch “ADAPTIVE LIGHT” on “SELECT SYSTEM” screen.

3. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Touch “LOW BEAM TEST RIGHT”, “LOW BEAM TEST LEFT”, or “LEVELIZER TEST” on “SELECT TEST

ITEM” screen.

CAUTION:

Can be tested only when swivel actuator initialization is completed. If initialization is not com-

pleted, “RETRY COMMAND” is displayed and cannot be tested.

LOW BEAM TEST RIGHT

Low beam headlamp (right) can be operated to swivel angle

0

by touching “ORIGIN”, and to maximum angle by “PEAK”.

LOW BEAM TEST LEFT

Low beam headlamp (left) can be operated to swivel angle 0

by touching “ORIGIN”, and to maximum angle by “PEAK”.

LEVELIZER TEST

Aiming motor drive signal can be changed to approx. 85%

(ratio to IGN power supply) by touching “ORIGIN”, and to

approx. 15% by “PEAK”. That angles headlamp LO up and

down.

5. During the operation check, touching “BACK” deactivates the operation.

Test Item Swivel Speed Mode

ORIGIN/PEAK - FAST Three times fast as SLOW Normal operation

ORIGIN/PEAK - SLOW — Initialization

SKIB4794E

Test Item Swivel Speed Mode

ORIGIN/PEAK - FAST Three times fast as SLOW Normal operation

ORIGIN/PEAK - SLOW — Initialization

SKIB4795E

Test ItemAiming Motor Drive Signal

Light Axis

(Reference Value) Ratio to IGN

power supplyVoltage

ORIGIN Approx. 85% Approx. 10.6 V 0

PEAK Approx. 15% Approx. 1.9 VApprox. 2.5

(Relatively lower than

that of origin)SKIB4796E

Page 4588 of 5621

ACTIVE AFS

LT-161

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Symptom ChartNKS003QN

CAUTION:

The low beam headlamps performs small movements when AFS control unit detects the engine start.

This is normal with initialization of swivel actuator by AFS control unit.

SymptomAFS OFF

indicatorCausal system Reference

AFS operates, but cannot judge normal/

abnormal.

(AFS function test)NormalCheck swivel operation.LT-181, "AFS

Operation

Check (Func-

tion Test)"

Check steering angle sensor neutral point (straight-ahead

position).

Auto aiming operates, but cannot judge

normal/abnormal.

(Auto aiming function test)NormalCheck auto aiming operation.LT-183, "Auto

Aiming Opera-

tion Check

(Function

Te s t )"

Check height sensor signal value recognized by AFS con-

trol unit at unloaded vehicle position.

Check height sensor signal and aiming motor drive signal.

Neither AFS operates nor auto aiming

operates.BlinkingCheck AFS control unit self-diagnostic results. LT-154,

"SELF-DIAG

RESULTS"

Check AFS control unit power supply and ground circuit.

NOTE:

Check only when “ADAPTIVE LIGHT” is not displayed on

CONSULT-II “SELECT SYSTEM” screen.LT-151, "Pre-

liminary

Check"

AFS does not operate.

(Auto aiming operation is normal.)Blinking Check AFS control unit self-diagnostic results. LT-154,

"SELF-DIAG

RESULTS"

Illuminated Check AFS switch system circuit.LT-185, "

AFS

Switch Does

Not Operate"

Auto aiming does not operate.

(AFS operation is normal.)NormalCheck AFS control unit self-diagnostic results. LT-154,

"SELF-DIAG

RESULTS"

Check aiming motor system circuit.LT-187, "

Auto

Aiming Does

Not Operate

(Check Aiming

Motor System

Circuit)"

Auto aiming operates in the reverse way.

(Lowering vehicle height angles light

axis up.)Normal Replace AFS control unit.LT-191, "Removal and

Installation of

AFS Control

Unit"

AFS OFF indicator does not illuminate.

(AFS operation and auto aiming opera-

tion are normal.)Not

illuminatedCheck circuit between unified meter and A/C amp. and

combination meter.LT-190, "

AFS

OFF Indicator

Does Not

Operate"AFS OFF indicator blinks.

(AFS operation and auto aiming opera-

tion are normal.)BlinkingCheck receive state of AFS off indicator signal from uni-

fied meter and A/C amp.

AFS cannot be cancelled.

(AFS switch does not operate.)Normal Check AFS switch system circuit.LT-185, "AFS

Switch Does

Not Operate"

Page 4608 of 5621

ACTIVE AFS

LT-181

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

AFS Operation Check (Function Test)NKS003QS

1. CHECK SWIVEL ACTUATOR

1. Start engine and turn lighting switch to 2ND position.

2. Select “ADAPTIVE LIGHT” on CONSULT-II. Select “ACTIVE

TEST” on “SELECT DIAG MODE” screen.

3. Select “LOW BEAM TEST RIGHT” or “LOW BEAM TEST LEFT”

on “SELECT TEST ITEM” screen.

4. Touch “ORIGIN–FAST/SLOW” and “PEAK–FAST/SLOW”

screen.

5. Make sure of swivel operation.

OK or NG

OK >> GO TO 2.

NG >>

When interference or poor fitment is found, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, replace headlamp. Refer to LT- 1 9 0 , "Removal and Installation of

Front Combination Lamp" .

When the operation range is irregular, perform aiming adjustment. Refer to LT- 7 4 , "Aiming

Adjustment" . If it is normal, GO TO 3.

2. CHECK STEERING ANGLE SENSOR

Check “STR ANGLE SIG” in “Data Monitor” when driving straight

and steering turn 90

to right or left.

OK or NG

OK >> GO TO 3.

NG >>

When steering is out of range while driving straight, perform steering angle sensor adjustment.

Refer to BRC-6, "

Adjustment of Steering Angle Sensor Neutral Position" in “ON-VEHICLE

SERVICE”.

When the function is normal while driving straight but the displayed value is different from

actual steering position with turning to right or left, replace steering angle sensor. Refer to LT-

190, "Removal and Installation of Steering Angle Sensor" .

SKIB4794E

TEST ITEM ORIGIN PEAKLight axis range at 10 m (394.7 in) off

(Reference value)

LOW BEAM TEST RIGHT Swivel angle 0

Swivel angle 7 to 13Approx. 1.200 to 2.300 mm (48 to 90 in)

LOW BEAM TEST LEFT Swivel angle 0

Swivel angle 17 to 23Approx. 3.000 to 4.200 mm (120 to 167 in)

Steering conditionSTR ANGLE SIG

(Data monitor)

Driving straight

5.0 to + 5.0

Turn 90 to right Approx. + 90

Tu rn 90 to left Approx. 90

SKIB4793E