water pump INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1376 of 5621

CO-1

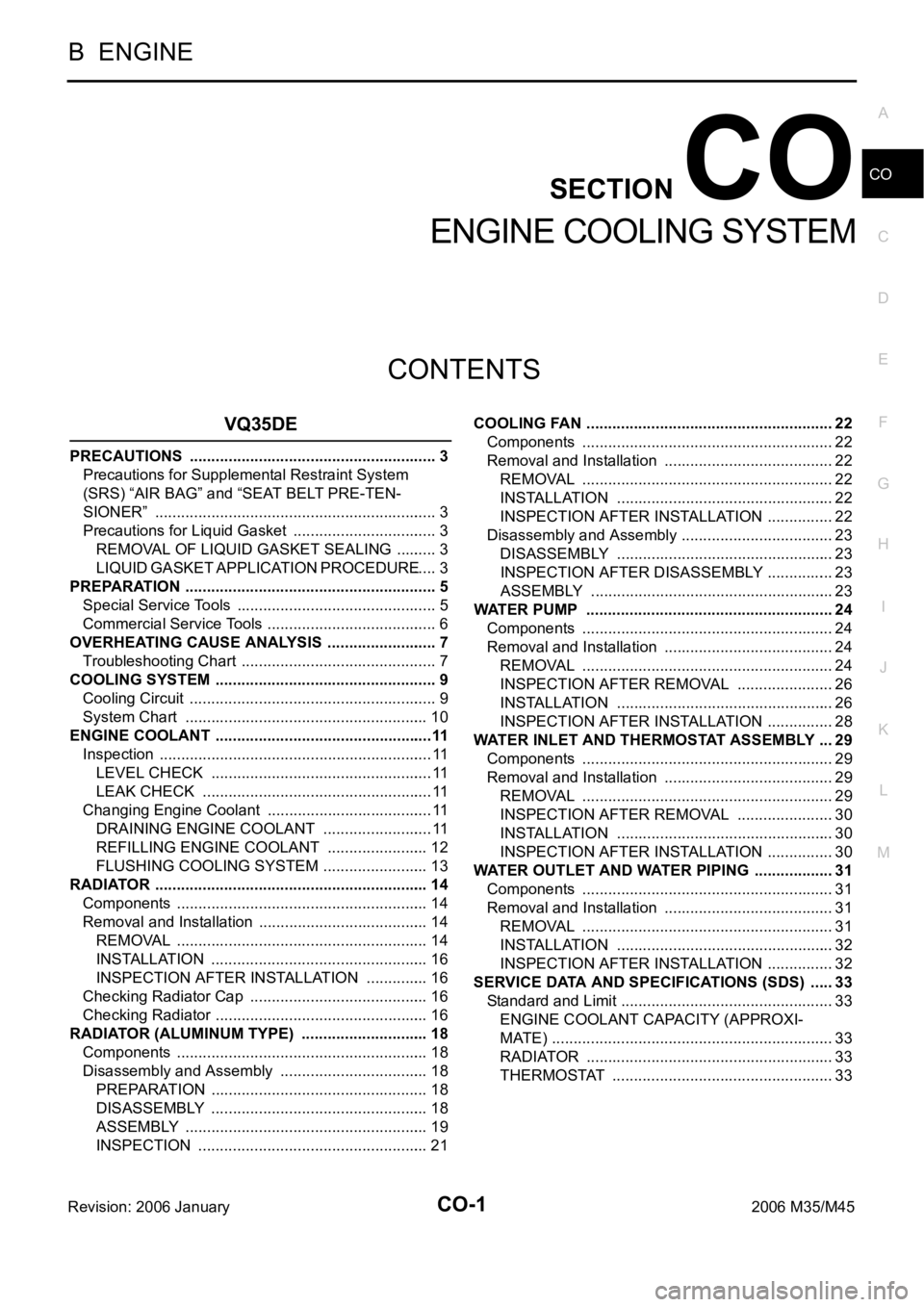

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION CO

A

CO

Revision: 2006 January2006 M35/M45

ENGINE COOLING SYSTEM

VQ35DE

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Liquid Gasket .................................. 3

REMOVAL OF LIQUID GASKET SEALING .......... 3

LIQUID GASKET APPLICATION PROCEDURE ..... 3

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 6

OVERHEATING CAUSE ANALYSIS .......................... 7

Troubleshooting Chart .............................................. 7

COOLING SYSTEM .................................................... 9

Cooling Circuit .......................................................... 9

System Chart ......................................................... 10

ENGINE COOLANT ...................................................11

Inspection ................................................................ 11

LEVEL CHECK .................................................... 11

LEAK CHECK ...................................................... 11

Changing Engine Coolant ....................................... 11

DRAINING ENGINE COOLANT .......................... 11

REFILLING ENGINE COOLANT ........................ 12

FLUSHING COOLING SYSTEM ......................... 13

RADIATOR ................................................................ 14

Components ........................................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSTALLATION ................................................... 16

INSPECTION AFTER INSTALLATION ............... 16

Checking Radiator Cap .......................................... 16

Checking Radiator .................................................. 16

RADIATOR (ALUMINUM TYPE) .............................. 18

Components ........................................................... 18

Disassembly and Assembly ................................... 18

PREPARATION ................................................... 18

DISASSEMBLY ................................................... 18

ASSEMBLY ......................................................... 19

INSPECTION ...................................................... 21COOLING FAN .......................................................... 22

Components ........................................................... 22

Removal and Installation ........................................ 22

REMOVAL ........................................................

... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 22

Disassembly and Assembly .................................... 23

DISASSEMBLY ................................................... 23

INSPECTION AFTER DISASSEMBLY ................ 23

ASSEMBLY ......................................................... 23

WATER PUMP .......................................................... 24

Components ........................................................... 24

Removal and Installation ........................................ 24

REMOVAL ........................................................

... 24

INSPECTION AFTER REMOVAL ....................... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 28

WATER INLET AND THERMOSTAT ASSEMBLY .... 29

Components ........................................................... 29

Removal and Installation ........................................ 29

REMOVAL ........................................................

... 29

INSPECTION AFTER REMOVAL ....................... 30

INSTALLATION ................................................... 30

INSPECTION AFTER INSTALLATION ................ 30

WATER OUTLET AND WATER PIPING ................... 31

Components ........................................................... 31

Removal and Installation ........................................ 31

REMOVAL ........................................................

... 31

INSTALLATION ................................................... 32

INSPECTION AFTER INSTALLATION ................ 32

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 33

Standard and Limit .................................................. 33

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 33

RADIATOR .......................................................

... 33

THERMOSTAT .................................................... 33

Page 1377 of 5621

CO-2Revision: 2006 January2006 M35/M45

VK45DE

PRECAUTIONS ......................................................... 34

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................. 34

PREPARATION ......................................................... 35

Special Service Tools ............................................. 35

Commercial Service Tools ...................................... 35

OVERHEATING CAUSE ANALYSIS ........................ 36

Troubleshooting Chart ............................................ 36

COOLING SYSTEM .................................................. 38

Cooling Circuit ........................................................ 38

System Chart .......................................................... 39

ENGINE COOLANT .................................................. 40

Inspection ............................................................... 40

LEVEL CHECK .................................................... 40

LEAK CHECK ...................................................... 40

Changing Engine Coolant ....................................... 40

DRAINING ENGINE COOLANT .......................... 40

REFILLING ENGINE COOLANT ......................... 41

FLUSHING COOLING SYSTEM ......................... 42

RADIATOR ................................................................ 43

Components ........................................................... 43

Removal and Installation ........................................ 43

REMOVAL ........................................................

... 43

INSTALLATION .................................................... 45

INSPECTION AFTER INSTALLATION ................ 45

Checking Radiator Cap .......................................... 45

Checking Radiator .................................................. 45

RADIATOR (ALUMINUM TYPE) ............................... 47

Components ........................................................... 47

Disassembly and Assembly .................................... 47

PREPARATION ................................................... 47

DISASSEMBLY ................................................... 47

ASSEMBLY ......................................................... 48

INSPECTION ....................................................... 50COOLING FAN .......................................................... 51

Components ............................................................ 51

Removal and Installation ......................................... 51

REMOVAL ............................................................ 51

INSTALLATION .................................................... 51

INSPECTION AFTER INSTALLATION ................ 51

Disassembly and Assembly .................................... 52

DISASSEMBLY .................................................... 52

INSPECTION AFTER DISASSEMBLY ................ 52

ASSEMBLY .......................................................... 52

WATER PUMP ........................................................... 53

Components ............................................................ 53

Removal and Installation ......................................... 53

REMOVAL ............................................................ 53

INSPECTION AFTER REMOVAL ........................ 54

INSTALLATION .................................................... 54

INSPECTION AFTER INSTALLATION ................ 54

THERMOSTAT AND WATER CONTROL VALVE ..... 55

Components ............................................................ 55

Removal and Installation ......................................... 55

REMOVAL ............................................................ 55

INSPECTION AFTER REMOVAL ........................ 56

INSTALLATION .................................................... 56

INSPECTION AFTER INSTALLATION ................ 57

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 58

Standard and Limit .................................................. 58

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 58

RADIATOR ........................................................... 58

THERMOSTAT ..................................................... 58

WATER CONTROL VALVE .................................. 58

Page 1380 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

CO-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNBS004QL

The actual shapes of Kent-Moore tools may differ from those of INFINITI M35 2006 Factory Service Manual PREPARATION

CO-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNBS004QL

The actual shapes of Kent-Moore tools may differ from those of](/img/42/57023/w960_57023-1379.png)

PREPARATION

CO-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service ToolsNBS004QL

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

To o l n u m b e r

(Kent-Moore No.)

To o l n a m eDescription

EG17650301

(J33984-A)

Radiator cap tester adapterAdapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

(—)

Radiator plate pliers AInstalling radiator upper and lower tanks

KV99103520

(—)

Radiator plate pliers BRemoving radiator upper and lower tanks

KV10111100

(J37228)

Seal cutterRemoving chain tensioner cover and water

pump cover

WS39930000

(—)

Tube presserPressing the tube of liquid gasket

S-NT564

S-NT224

S-NT225

NT046

S-NT052

Page 1382 of 5621

![INFINITI M35 2006 Factory Service Manual OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartNBS004QN

Symptom Check items

Cooling sys- INFINITI M35 2006 Factory Service Manual OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartNBS004QN

Symptom Check items

Cooling sys-](/img/42/57023/w960_57023-1381.png)

OVERHEATING CAUSE ANALYSIS

CO-7

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

OVERHEATING CAUSE ANALYSISPFP:00012

Troubleshooting ChartNBS004QN

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

— Thermostat stuck closed —

Damaged finsDust contamination or

paper clogging

Physical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

Fan assembly — High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio

———

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolantEngine coolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

Page 1399 of 5621

![INFINITI M35 2006 Factory Service Manual CO-24

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

WATE R PU M PPFP:21020

ComponentsNBS004R1

Removal and InstallationNBS004R2

CAUTION:

When removing water pump assembly, be careful not to g INFINITI M35 2006 Factory Service Manual CO-24

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

WATE R PU M PPFP:21020

ComponentsNBS004R1

Removal and InstallationNBS004R2

CAUTION:

When removing water pump assembly, be careful not to g](/img/42/57023/w960_57023-1398.png)

CO-24

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

WATE R PU M PPFP:21020

ComponentsNBS004R1

Removal and InstallationNBS004R2

CAUTION:

When removing water pump assembly, be careful not to get engine coolant on drive belts.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, connect hose and clamp securely, then check for leaks using the radi-

ator cap tester (commercial service tool) and the radiator cap tester adapter [SST: EG17650301

(J33984-A)].

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove air duct (inlet) and air cleaner case assembly. Refer to EM-17, "

AIR CLEANER AND AIR DUCT"

.

3. Remove front engine undercover with power tool.

4. Remove drive belts. Refer to EM-15, "

DRIVE BELTS" .

5. Drain engine coolant from radiator. Refer to CO-11, "

Changing Engine Coolant" .

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

6. Remove water drain plug (front) on water pump side of cylinder

block to drain engine coolant from engine inside.

7. Remove chain tensioner cover and water pump cover from front timing chain case.

1. Timing chain tensioner (primary) 2. Chain tensioner cover 3. Water pump cover

4. Water pump 5. O-rings 6. Water drain plug (front)

SBIA0482E

PBIC2662E

Page 1400 of 5621

![INFINITI M35 2006 Factory Service Manual WATER PUMP

CO-25

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

U s e t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ( J 3 7 2 2 8 )] to cut liquid gasket for r INFINITI M35 2006 Factory Service Manual WATER PUMP

CO-25

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

U s e t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ( J 3 7 2 2 8 )] to cut liquid gasket for r](/img/42/57023/w960_57023-1399.png)

WATER PUMP

CO-25

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

U s e t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 ( J 3 7 2 2 8 )] to cut liquid gasket for removal.

8. Remove timing chain tensioner (primary) as follows:

a. Remove lower mounting bolt.

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

b. Loosen upper mounting bolt slowly, and then turn chain ten-

sioner (primary) on the mounting bolt so that plunger is fully

expanded.

NOTE:

Even if plunger is fully expanded, it is not dropped from the body

of timing chain tensioner (primary).

c. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

d. Remove upper mounting bolt, and then remove timing chain ten-

sioner (primary).

CAUTION:

Be careful not to drop mounting bolt inside timing chain

case.

9. Remove water pump as follows:

a. Remove three water pump mounting bolts. Secure a gap

between water pump gear and timing chain, by turning crank-

shaft pulley counterclockwise until timing chain looseness on

water pump sprocket becomes maximum.

PBIC3575E

PBIC1805E

PBIC3576E

PBIC1193E

Page 1401 of 5621

![INFINITI M35 2006 Factory Service Manual CO-26

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

b. Screw M8 bolts [pitch: 1.25 mm (0.049 in) length: approx. 50

mm (1.97 in)] into water pumps upper and lower mounting b INFINITI M35 2006 Factory Service Manual CO-26

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

b. Screw M8 bolts [pitch: 1.25 mm (0.049 in) length: approx. 50

mm (1.97 in)] into water pumps upper and lower mounting b](/img/42/57023/w960_57023-1400.png)

CO-26

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

b. Screw M8 bolts [pitch: 1.25 mm (0.049 in) length: approx. 50

mm (1.97 in)] into water pumps upper and lower mounting bolt

holes until they reach timing chain case. Then, alternately

tighten each bolt for a half turn, and pull out water pump.

CAUTION:

Pull straight out while preventing vane from contacting

socket in installation area.

Remove water pump without causing sprocket to contact

timing chain.

c. Remove M8 bolts and O-rings from water pump.

CAUTION:

Do not disassemble water pump.

INSPECTION AFTER REMOVAL

Check for badly rusted or corroded water pump body assembly.

Check for rough operation due to excessive end play.

If anything is found, replace water pump.

INSTALLATION

1. Install new O-rings to water pump.

Apply engine oil and engine coolant to O-rings as shown in

the figure.

Locate O-ring with white paint mark to engine front side.

2. Install water pump.

CAUTION:

Do not allow cylinder block to nip O-rings when installing

water pump.

Make sure timing chain and water pump sprocket are

engaged.

Insert water pump by tightening mounting bolts alternately

and evenly.

3. Install timing chain tensioner (primary) as follows:

JLC357B

SLC943A

PBIC1397E

PBIC1058E

Page 1402 of 5621

![INFINITI M35 2006 Factory Service Manual WATER PUMP

CO-27

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose. INFINITI M35 2006 Factory Service Manual WATER PUMP

CO-27

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.](/img/42/57023/w960_57023-1401.png)

WATER PUMP

CO-27

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

a. Turn crankshaft pulley clockwise so that timing chain on the tim-

ing chain tensioner (primary) side is loose.

b. Pull plunger stopper tab up (or turn lever downward) so as to

remove plunger stopper tab from the ratchet of plunger.

NOTE:

Plunger stopper tab and lever are synchronized.

c. Push plunger into the inside of tensioner body.

d. Hold plunger in the fully compressed position by engaging

plunger stopper tab with the tip of ratchet.

e. To secure lever, insert stopper pin through hole of lever into ten-

sioner body hole.

The lever parts and the tab are synchronized. Therefore, the

plunger will be secured under this condition.

NOTE:

Figure shows the example of 1.2 mm (0.047 in) diameter thin screwdriver being used as the stopper pin.

f. Install timing chain tensioner (primary).

Remove dust and foreign material completely from backside of timing chain tensioner (primary) and

from installation area of rear timing chain case.

g. Remove stopper pin.

h. Make sure again that timing chain and water pump sprocket are engaged.

4. Install chain tensioner cover and water pump cover as follows:

a. Before installing, remove all traces of old liquid gasket from mat-

ing surface of water pump cover and chain tensioner cover

using scraper. Also remove traces of old liquid gasket from the

mating surface of front timing chain case.

PBIC1805E

PBIC3568E

PBIC3577E

SLC446B

Page 1403 of 5621

![INFINITI M35 2006 Factory Service Manual CO-28

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with tube presser [SST:

WS39930000 ( — )] to mating surface of chain tensioner

cover a INFINITI M35 2006 Factory Service Manual CO-28

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with tube presser [SST:

WS39930000 ( — )] to mating surface of chain tensioner

cover a](/img/42/57023/w960_57023-1402.png)

CO-28

[VQ35DE]

WATER PUMP

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with tube presser [SST:

WS39930000 ( — )] to mating surface of chain tensioner

cover and water pump cover.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

CAUTION:

Attaching should be done within 5 minutes after coating.

c. Tighten mounting bolts.

5. Install water drain plug (front) on water pump side of cylinder block.

Apply liquid gasket to the thread of water drain plug (front).

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-48, "

RECOMMENDED CHEMICAL

PRODUCTS AND SEALANTS" .

6. Install in the reverse order of removal for remaining parts.

After starting engine, let idle for three minutes, then rev engine up to 3,000 rpm under no load to

purge air from the high-pressure chamber of chain tensioner. Engine may produce a rattling

noise. This indicates that air still remains in the chamber and is not a matter of concern.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant using the radiator cap tester adapter [SST: EG17650301 (J33984-A)]

and the radiator cap tester (commercial service tool). Refer to CO-11, "

LEAK CHECK" .

Start and warm up the engine. Visually make sure that there is no leaks of engine coolant.

PBIC2663E

Page 1404 of 5621

![INFINITI M35 2006 Factory Service Manual WATER INLET AND THERMOSTAT ASSEMBLY

CO-29

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER INLET AND THERMOSTAT ASSEMBLYPFP:21200

ComponentsNBS004R3

Removal and Installation INFINITI M35 2006 Factory Service Manual WATER INLET AND THERMOSTAT ASSEMBLY

CO-29

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER INLET AND THERMOSTAT ASSEMBLYPFP:21200

ComponentsNBS004R3

Removal and Installation](/img/42/57023/w960_57023-1403.png)

WATER INLET AND THERMOSTAT ASSEMBLY

CO-29

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

Revision: 2006 January2006 M35/M45

WATER INLET AND THERMOSTAT ASSEMBLYPFP:21200

ComponentsNBS004R3

Removal and InstallationNBS004R4

REMOVAL

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove air duct (inlet). Refer to EM-17, "

AIR CLEANER AND AIR DUCT" .

3. Remove front engine undercover using power tool.

4. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-11, "

Changing Engine Coolant" and CO-24, "WATER PUMP" .

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

5. Disconnect radiator hose (lower) and oil cooler water hose from water inlet and thermostat assembly.

6. Remove water inlet and thermostat assembly.

CAUTION:

Do not disassemble water inlet and thermostat assembly.

Replace them as a unit, if necessary.

1. Water inlet and thermostat assembly 2. Gasket

SBIA0483E

SLC962AB