checking oil INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3310 of 5621

![INFINITI M35 2006 Factory Repair Manual ENGINE ASSEMBLY

EM-247

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Separation Work

1. Install engine slingers into front of cylinder head (left bank) and

rear of cylinder h INFINITI M35 2006 Factory Repair Manual ENGINE ASSEMBLY

EM-247

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Separation Work

1. Install engine slingers into front of cylinder head (left bank) and

rear of cylinder h](/img/42/57023/w960_57023-3309.png)

ENGINE ASSEMBLY

EM-247

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Separation Work

1. Install engine slingers into front of cylinder head (left bank) and

rear of cylinder head (right bank).

2. Remove engine mounting insulators (RH and LH) under side nut with power tool.

3. Lift with hoist and separate engine and transmission assembly from front suspension member.

CAUTION:

Avoid damage to and oil/grease smearing or spills onto engine mounting insulator.

4. Remove alternator. Refer to SC-23, "

CHARGING SYSTEM" .

5. Remove starter motor. Refer to SC-10, "

STARTING SYSTEM" .

6. Separate engine from transmission assembly. Refer to AT-271, "

TRANSMISSION ASSEMBLY" .

7. Remove engine mounting insulators (RH and LH) and brackets (RH and LH) from engine with power tool.

8. Remove rear engine mounting member and engine mounting insulator (rear) from transmission.

INSTALLATION

Note the following, and install in the reverse order of removal.

Do not allow engine mounting insulator to be damage and careful no engine oil gets on it.

For a location with a positioning pin, insert it securely into hole of mating part.

For a part with a specified installation orientation, refer to component figure in EM-244, "Components" .

When installing engine mounting brackets (RH and LH) on cylin-

der block, tighten two upper bolts (shown as “A” in the figure)

first. Then tighten two lower bolts (shown as “B” in the figure).

NOTE:

Figure shows LH bank.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedure for checking fluids leak, lubricates leak and exhaust gases leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

Use procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.Slinger bolts:

:33.4 Nꞏm (3.4 kg-m, 25 ft-lb)

PBIC2447E

PBIC3305E

Page 3378 of 5621

FFD-1

FRONT FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION FFD

A

B

FFD

Revision: 2006 January2006 M35/M45

FRONT FINAL DRIVE

PRECAUTIONS .......................................................... 2

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 2

OPERATION PROCEDURE ................................. 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Sectional View ............................................... 7

DIFFERENTIAL GEAR OIL ........................................ 8

Changing Differential Gear Oil ................................. 8

DRAINING ............................................................. 8

FILLING ................................................................. 8

Checking Differential Gear Oil .................................. 8

OIL LEAKAGE AND OIL LEVEL ........................... 8

FRONT OIL SEAL .................................................

..... 9

Removal and Installation .......................................... 9

REMOVAL ........................................................

..... 9

INSTALLATION ................................................... 10SIDE OIL SEAL ......................................................... 11

Removal and Installation ........................................ 11

REMOVAL ........................................................

... 11

INSTALLATION ................................................... 11

FRONT FINAL DRIVE ASSEMBLY .......................... 13

Removal and Installation ........................................ 13

COMPONENTS ................................................... 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 14

Disassembly and Assembly .................................... 15

COMPONENTS ................................................... 15

ASSEMBLY INSPECTION AND ADJUSTMENT ... 16

DISASSEMBLY ................................................... 20

INSPECTION AFTER DISASSEMBLY ................ 24

ADJUSTMENT AND SELECTION OF ADJUST-

ING WASHERS (SHIMS) .................................... 25

ASSEMBLY ......................................................... 28

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

General Specifications ......................................... ... 35

Inspection and Adjustment ..................................... 35

DRIVE GEAR RUNOUT ...................................... 35

DIFFERENTIAL SIDE GEAR CLEARANCE ....... 35

PRELOAD TORQUE ........................................... 35

BACKLASH ......................................................... 35

COMPANION FLANGE RUNOUT ....................... 35

SELECTIVE PARTS ............................................ 35

Page 3383 of 5621

FFD-6

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000EO

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

Refer to FFD-24, "

INSPECTION AFTER DISASSEMBLY

" .

Refer to FFD-17, "

Tooth Contact

" .

Refer to FFD-24, "

INSPECTION AFTER DISASSEMBLY

" .

Refer to FFD-19, "

Backlash

" .

Refer to FFD-19, "

Companion Flange Runout

" .

Refer to FFD-8, "

Checking Differential Gear Oil

" .

NVH in PR section.

NVH in FAX, RAX, FSU and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in FAX and RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise

Page 3385 of 5621

FFD-8

DIFFERENTIAL GEAR OIL

Revision: 2006 January2006 M35/M45

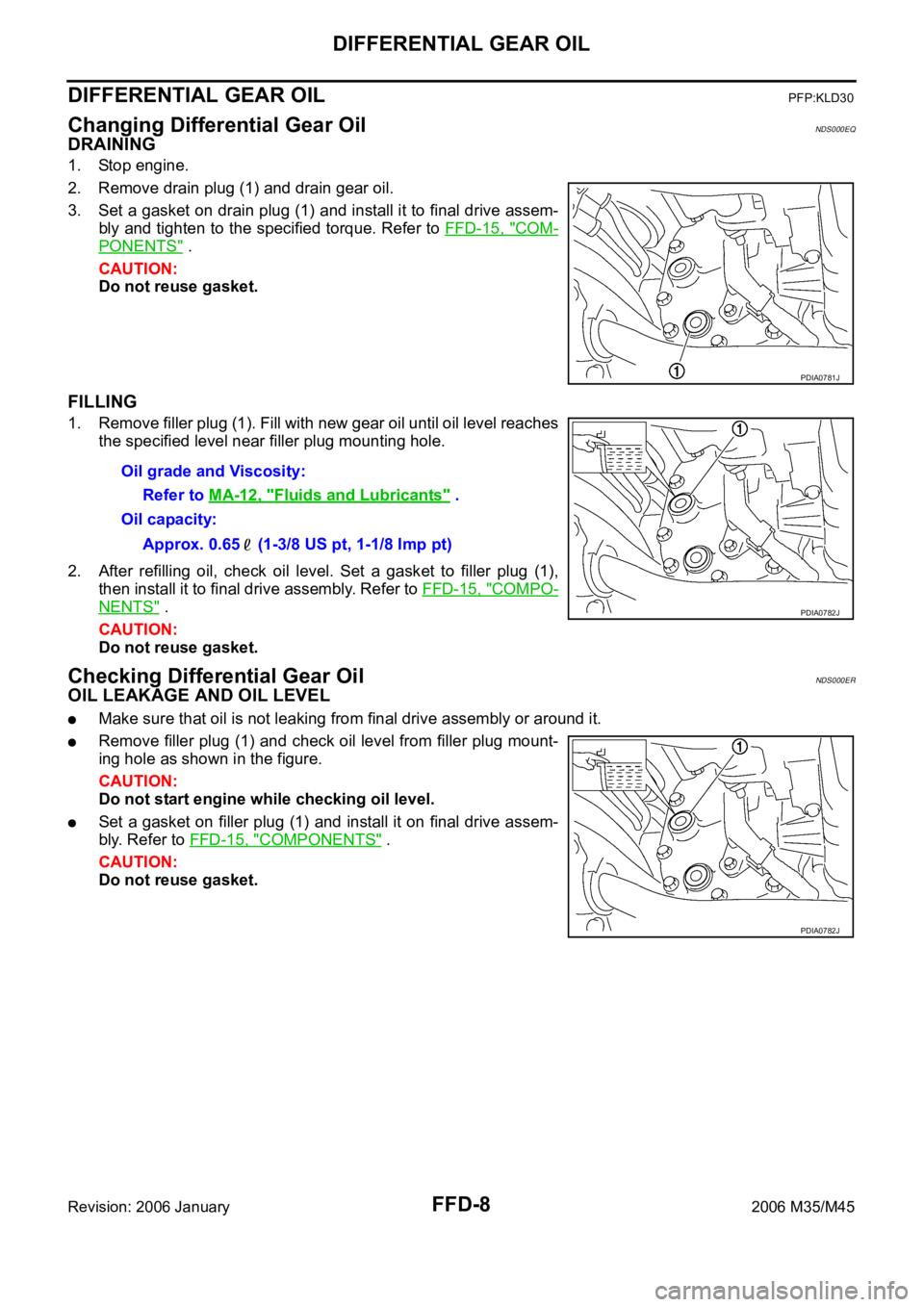

DIFFERENTIAL GEAR OILPFP:KLD30

Changing Differential Gear OilNDS000EQ

DRAINING

1. Stop engine.

2. Remove drain plug (1) and drain gear oil.

3. Set a gasket on drain plug (1) and install it to final drive assem-

bly and tighten to the specified torque. Refer to FFD-15, "

COM-

PONENTS" .

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new gear oil until oil level reaches

the specified level near filler plug mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug (1),

then install it to final drive assembly. Refer to FFD-15, "

COMPO-

NENTS" .

CAUTION:

Do not reuse gasket.

Checking Differential Gear OilNDS000ER

OIL LEAKAGE AND OIL LEVEL

Make sure that oil is not leaking from final drive assembly or around it.

Remove filler plug (1) and check oil level from filler plug mount-

ing hole as shown in the figure.

CAUTION:

Do not start engine while checking oil level.

Set a gasket on filler plug (1) and install it on final drive assem-

bly. Refer to FFD-15, "

COMPONENTS" .

CAUTION:

Do not reuse gasket.

PDIA0781J

Oil grade and Viscosity:

Refer to MA-12, "

Fluids and Lubricants" .

Oil capacity:

Approx. 0.65 (1-3/8 US pt, 1-1/8 Imp pt)

PDIA0782J

PDIA0782J

Page 3388 of 5621

SIDE OIL SEAL

FFD-11

C

E

F

G

H

I

J

K

L

MA

B

FFD

Revision: 2006 January2006 M35/M45

SIDE OIL SEALPFP:33142

Removal and InstallationNDS000ET

NOTE:

Left side oil seal is attached to engine assembly. Replace it after removing front final drive assembly

from vehicle.

REMOVAL

Right Side:

1. Remove the front drive shaft. Refer to FAX-11, "Removal and Installation" .

2. Remove the side oil seal using a puller.

CAUTION:

Be careful not to damage gear carrier.

Left Side:

1. Remove the front final drive assembly from vehicle with power tool. Refer to FFD-13, "Removal and Instal-

lation" .

2. Remove the side oil seal using a flat-bladed screwdriver.

CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

Right Side:

1. Apply multi-purpose grease to sealing lips of side oil seal.

2. Using the drift, press-fit side oil seal so that its surface comes

face to face with the end surface of the side retainer.

CAUTION:

Do not reuse oil seal.

When installing, do not incline oil seal.

3. Install the front drive shaft. Refer to FAX-11, "

Removal and

Installation" .

4. When oil leaks while removing, check oil level after the installa-

tion. Refer to FFD-8, "

Checking Differential Gear Oil" .

Left Side:

1. Apply multi-purpose grease to sealing lips of side oil seal.

2. Using the drift, press-fit side oil seal so that its surface comes

face to face with the end surface of the gear carrier.

CAUTION:

Do not reuse oil seal.

When installing, do not incline oil seal.

3. Install the front final drive assembly on vehicle. Refer toFFD-13,

"Removal and Installation" .

4. Install the front drive shaft. Refer to FAX-11, "

Removal and

Installation" . Tool number A: KV381054S0 (J-34286)

PDIA0838J

Tool number A: ST33400001 (J-26082)

PDIA0787J

Tool number A: KV38102100 (J-25803-01)

PDIA0788J

Page 3389 of 5621

FFD-12

SIDE OIL SEAL

Revision: 2006 January2006 M35/M45

5. When oil leaks while removing, check oil level after the installation. Refer to FFD-8, "Checking Differential

Gear Oil" .

Page 3391 of 5621

FFD-14

FRONT FINAL DRIVE ASSEMBLY

Revision: 2006 January2006 M35/M45

INSTALLATION

Note the following, and installation is in the reverse order of removal.

Refer to FFD-13, "COMPONENTS" about each tightening torque.

When installing the side shaft, apply multi-purpose grease to contact surface of side shaft and side shaft

oil seal.

Tighten mounting bolts in the order as described below when

installing front final drive assembly: side of gear carrier (1),

upper side of gear carrier (2), part of carrier cover (3), lower part

of gear carrier (4).

CAUTION:

Align the mating faces of gear carrier and oil pan for instal-

lation.

When installing breather hoses (1) and tube (2), refer to the fig-

ure.

CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when install-

ing it.

–Make sure the paint mark facing up ( ).

–Securely install the hose until it seats the rounded portion of the

tube ( ).

–Install breather connector as shown in the figure.

–Seat the breather tube bracket end (A) to the machined face (B)

of gear carrier boss.

When oil leaks while removing final drive assembly, check oil

level after the installation. Refer to FFD-8, "

Checking Differential

Gear Oil" .

PDIA0839J

PDIA0790J

Angle “A”: 0 - 30

PDIA0841J

PDIA0842E

Page 3438 of 5621

![INFINITI M35 2006 Factory Repair Manual COIL SPRING AND SHOCK ABSORBER

FSU-11

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

COIL SPRING AND SHOCK ABSORBERPFP:55302

Removal and InstallationNES000IE

REMOVAL

1. Remove tir INFINITI M35 2006 Factory Repair Manual COIL SPRING AND SHOCK ABSORBER

FSU-11

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

COIL SPRING AND SHOCK ABSORBERPFP:55302

Removal and InstallationNES000IE

REMOVAL

1. Remove tir](/img/42/57023/w960_57023-3437.png)

COIL SPRING AND SHOCK ABSORBER

FSU-11

[2WD]

C

D

F

G

H

I

J

K

L

MA

B

FSU

Revision: 2006 January2006 M35/M45

COIL SPRING AND SHOCK ABSORBERPFP:55302

Removal and InstallationNES000IE

REMOVAL

1. Remove tires from vehicle with a power tool.

2. Remove harness of wheel sensor from shock absorber. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

4. Remove the mounting nut on the upper side of stabilizer connecting rod with a power tool, and then

remove stabilizer connecting rod from transverse link.

5. Remove mounting nut and bolt on the lower side of shock absorber with a power tool, and then remove

shock absorber from transverse link.

6. Remove cotter pin of transverse link and steering knuckle, and then loosen nut.

7. Remove transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover (suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

8. Remove the mounting nuts of shock absorber mounting bracket, then remove shock absorber from vehi-

cle.

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer to FSU-8, "Components" .

Perform final tightening of bolt and nut at the shock absorber lower side (rubber bushing), under unladen

conditions with tires on level ground. Check wheel alignment. Refer to FSU-6, "

Wheel Alignment Inspec-

tion" .

Adjust neutral position of steering angle sensor after checking wheel alignment. Refer to BRC-6, "Adjust-

ment of Steering Angle Sensor Neutral Position" .

Check wheel sensor harness for proper connection. Refer to BRC-57, "WHEEL SENSOR" .

Disassembly and AssemblyNES000IF

DISASSEMBLY

CAUTION:

Do not damage shock absorber piston rod when removing components from shock absorber.

1. Install strut attachment [SST] to shock absorber and secure it in

a vise.

CAUTION:

When installing the strut attachment to shock absorber,

wrap a shop cloth around strut to protect it from damage.

SEIA0296E

Page 3455 of 5621

![INFINITI M35 2006 Factory Repair Manual FSU-28

[AWD]

COIL SPRING AND SHOCK ABSORBER

Revision: 2006 January2006 M35/M45

COIL SPRING AND SHOCK ABSORBERPFP:55302

Removal and InstallationNES000IU

REMOVAL

1. Remove tires from vehicle with a powe INFINITI M35 2006 Factory Repair Manual FSU-28

[AWD]

COIL SPRING AND SHOCK ABSORBER

Revision: 2006 January2006 M35/M45

COIL SPRING AND SHOCK ABSORBERPFP:55302

Removal and InstallationNES000IU

REMOVAL

1. Remove tires from vehicle with a powe](/img/42/57023/w960_57023-3454.png)

FSU-28

[AWD]

COIL SPRING AND SHOCK ABSORBER

Revision: 2006 January2006 M35/M45

COIL SPRING AND SHOCK ABSORBERPFP:55302

Removal and InstallationNES000IU

REMOVAL

1. Remove tires from vehicle with a power tool.

2. Remove harness of wheel sensor from shock absorber. Refer to BRC-57, "

WHEEL SENSOR" .

CAUTION:

Do not pull on wheel sensor harness.

3. Remove brake hose bracket. Refer to BR-12, "

BRAKE TUBE AND HOSE" .

4. Remove the mounting nut on the upper side of stabilizer connecting rod with a power tool, and then

remove stabilizer connecting rod from transverse link.

5. Remove mounting nut and bolt on the lower side of shock absorber arm with a power tool, and then

remove shock absorber arm from transverse link.

6. Remove cotter pin of transverse link and steering knuckle, and then loosen nut.

7. Remove transverse link from steering knuckle so as not to damage ball joint boot using the ball joint

remover (suitable tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from suddenly coming off.

8. Remove the mounting bolt on the upper side of shock absorber arm with a power tool, and then remove

shock absorber arm from shock absorber.

9. Remove the mounting nuts of shock absorber mounting bracket, then remove shock absorber from vehi-

cle.

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer to FSU-25, "Components" .

Perform final tightening of bolt and nut at the shock absorber arm lower side (rubber bushing) under

unladen conditions with tires on level ground. Check wheel alignment. Refer to FSU-23, "

Wheel Align-

ment Inspection" .

Adjust neutral position of steering angle sensor after checking wheel alignment. Refer to BRC-6, "Adjust-

ment of Steering Angle Sensor Neutral Position" .

Check wheel sensor harness for proper connection. Refer to BRC-57, "WHEEL SENSOR" .

Disassembly and AssemblyNES000IV

DISASSEMBLY

CAUTION:

Do not damage shock absorber piston rod when removing components from shock absorber.

1. Install strut attachment [SST] to shock absorber and secure it in

a vise.

CAUTION:

When installing the strut attachment to shock absorber,

wrap a shop cloth around strut to protect it from damage.

SEIA0296E

Page 3464 of 5621

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

Revision: 2006 January2006 M35/M45

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS) (If

Equipped) ................................................................. 3

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 4

OPERATION PROCEDURE ................................. 4

Precautions for Procedures without Cowl Top Cover ..... 4

General Precautions ................................................ 4

Precautions for Three Way Catalyst ......................... 6

Precautions for Fuel (Unleaded Premium Gasoline

Recommended) ...................................................

..... 6

Precautions for Fuel (Unleaded Premium Gasoline

Required) ................................................................. 6

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 7

Precautions for Hoses .............................................. 7

HOSE REMOVAL AND INSTALLATION ............... 7

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 8

HEALTH PROTECTION PRECAUTIONS ............. 8

Precautions for Air Conditioning ............................... 8

HOW TO USE THIS MANUAL ................................... 9

Description ............................................................... 9

Terms ....................................................................... 9

Units ......................................................................... 9

Contents ................................................................... 9

Relation between Illustrations and Descriptions .... 10

Components ............................................................ 11

SYMBOLS ........................................................

.... 11

How to Follow Trouble Diagnoses .......................... 12

DESCRIPTION .................................................... 12

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 12

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ....................................... 13KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 14

How to Read Wiring Diagrams ............................... 16

CONNECTOR SYMBOLS ................................... 16

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 17

DESCRIPTION .................................................... 18

Abbreviations .......................................................... 24

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 25

How to Check Terminal ........................................... 25

CONNECTOR AND TERMINAL PIN KIT ............ 25

HOW TO PROBE CONNECTORS ...................... 25

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 28

WORK FLOW ...................................................... 28

INCIDENT SIMULATION TESTS ........................ 28

CIRCUIT INSPECTION ....................................

... 31

Control Units and Electrical Parts ........................... 36

PRECAUTIONS .................................................. 36

CONSULT-II CHECKING SYSTEM .......................... 38

Description .............................................................. 38

Function and System Application ........................... 38

Nickel Metal Hydride Battery Replacement ............ 39

Checking Equipment .............................................. 39

CONSULT-II Start Procedure .................................. 39

CONSULT-II Data Link Connector (DLC) Circuit .... 40

INSPECTION PROCEDURE .............................. 40

CIRCUIT DIAGRAM ............................................ 41

LIFTING POINT ......................................................... 42

Special Service Tools ............................................. 42

Garage Jack and Safety Stand and 2-Pole Lift ....... 42

Board-On Lift .......................................................... 43

TOW TRUCK TOWING ............................................. 44

Tow Truck Towing ................................................... 44

2WD MODELS .................................................... 44

AWD MODELS .................................................... 45

Vehicle Recovery (Freeing a Stuck Vehicle) ........... 45

FRONT ................................................................ 45

REAR .................................................................. 45

AUTOMATIC TRANSMISSION ........................... 46