checking oil INFINITI M35 2006 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4792 of 5621

ENGINE MAINTENANCE (VQ35DE ENGINE)

MA-15

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

ALTERNATOR AND POWER STEERING OIL PUMP BELT

1. Remove front engine undercover with power tool.

2. Loosen idler pulley lock nut (A) and adjust tension by turning

adjusting bolt (B).

For the specified belt tension, refer to EM-15, "Checking Drive

Belts" .

3. Tighten nut (A).

A/C COMPRESSOR BELT

1. Remove front engine undercover with power tool.

2. Loosen idler pulley lock nut (C) and adjust tension by turning adjusting bolt (D).

For the specified belt tension, refer to EM-15, "Checking Drive Belts" .

3. Tighten nut (C).

Changing Engine CoolantNLS0007J

WAR NING :

To avoid being scalded, do not change engine coolant when the engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

Be careful not to allow engine coolant to contact drive belts.

DRAINING ENGINE COOLANT

1. Remove engine room cover (RH and LH). Refer to EM-14, "ENGINE ROOM COVER" .

2. Remove air duct (inlet). Refer to EM-17, "

AIR CLEANER AND AIR DUCT" .

3. Open radiator drain plug at the bottom of radiator, and then remove radiator cap. : 34.8 Nꞏm (3.5 kg-m, 26 ft-lb)

SBIA0532E

: 34.8 Nꞏm (3.5 kg-m, 26 ft-lb)

1 : Radiator drain plug hole

2 : Front engine under cover

: Engine front

PBIC3395E

Page 4795 of 5621

MA-18

ENGINE MAINTENANCE (VQ35DE ENGINE)

Revision: 2006 January2006 M35/M45

Checking Fuel LinesNLS0007K

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterNLS0007L

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-7,

"PERIODIC MAINTENANCE" .

Changing Engine OilNLS0007M

WAR NING :

Be careful not to burn yourself, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct

skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

1. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-7, "

ENGINE

OIL LEAKAGE" .

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove mounting bolts, and then pull down the rear of front

engine under cover (1) and secure it using clip.

5. Remove drain plug (2) and then drain engine oil.

6. Install drain plug with new washer. Refer to EM-29, "

OIL PAN AND OIL STRAINER" .

CAUTION:

Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil.

Engine oil specification and viscosity:

Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

Engine oil capacity (Approximate):

Unit: (US qt, lmp qt)

SMA803A

KBIA3593J

Oil pan drain plug:

: 34.3 Nꞏm (3.5 kg-m, 25 ft-lb)

Drain and refill With oil filter change 4.7 (5, 4-1/8)

Without oil filter change 4.4 (4-5/8, 3-7/8)

Dry engine (Overhaul)5.4 (5-3/4, 4-3/4)

Page 4799 of 5621

MA-22

ENGINE MAINTENANCE (VK45DE ENGINE)

Revision: 2006 January2006 M35/M45

ENGINE MAINTENANCE (VK45DE ENGINE)PFP:10001

Checking Drive BeltsNLS0007Q

WAR NING :

Be sure to perform when the engine is stopped.

Remove air duct (inlet) when inspecting drive belt for alternator, water pump and A/C compressor.

Remove front engine undercover with power tool when inspecting power steering oil pump belt.

Make sure that indicator (single line notch) of each auto tensioner is within the allowable working range

(between three line notches).

NOTE:

Check auto tensioner indication when engine is cold.

When new drive belt is installed, the range should be “A”.

The indicator notch is located on the moving side of the tensioner for alternator, water pump and A/C

compressor belt, while it is found on the fixed side for power steering oil pump belt.

Visually check entire belt for wear, damage or cracks.

If the indicator is out of allowable working range or belt is damaged, replace belt.

Te n s i o n A d j u s t m e n tNLS0007R

Belt tensioning is not necessary, as it is automatically adjusted by auto tensioner.

Changing Engine CoolantNLS0007S

WAR NING :

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

Be careful not to allow engine coolant to contact drive belts.

DRAINING ENGINE COOLANT

1. Remove engine room cover (RH and LH) Refer to EM-173, "ENGINE ROOM COVER" .

2. Remove engine cover with power tool. Refer to EM-179, "

INTAKE MANIFOLD" .

3. Open radiator drain plug at the bottom of radiator, and then remove radiator cap.

PBIC3822E

Page 4802 of 5621

ENGINE MAINTENANCE (VK45DE ENGINE)

MA-25

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to CO-40, "

DRAINING ENGINE COOLANT" .

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Checking Fuel LinesNLS0007T

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

Changing Air Cleaner FilterNLS0007U

VISCOUS PAPER TYPE

The viscous paper type filter does not need cleaning between replacement intervals. Refer to MA-7,

"PERIODIC MAINTENANCE" .

Changing Engine OilNLS0007V

WAR NING :

Be careful not to burn yourself, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct

skin contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand

cleaner as soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-26, "

ENGINE OIL LEAKAGE" .

2. Stop engine and wait for 15 minutes.

3. Loosen oil filler cap.

4. Remove mounting bolts, and then pull down the rear of front engine undercover and secure it using clip.

5. Remove drain plug and then drain engine oil.

6. Install drain plug with new washer. Refer to EM-187, "

OIL PAN AND OIL STRAINER" .

CAUTION:

Be sure to clean drain plug and install with new washer.Air relief plug:

: 1.2 Nꞏm (0.12 kg-m, 11 in-lb)

SMA803A

PBIC0993E

Oil pan drain plug:

: 34.3 Nꞏm (3.5 kg-m, 25 ft-lb)

Page 4809 of 5621

MA-32

CHASSIS AND BODY MAINTENANCE

Revision: 2006 January2006 M35/M45

Changing Transfer FluidNLS00083

CAUTION:

When draining fluid, protect exhaust tube flange with cover.

1. Drain fluid from drain plug and refill with new gear fluid.

(For details, refer to TF-9, "

Replacement" .)

2. Check fluid level.

CAUTION:

Carefully fill the fluid. (Fill up for Approx. 3 minutes.)

Checking Propeller ShaftNLS00084

Check propeller shaft for damage, looseness or grease leakage.

Checking Differential Gear OilNLS00085

Check for oil leakage.

(For details, refer to FFD-8, "

Checking Differential Gear Oil" and

RFD-9, "

Checking Differential Gear Oil" .) Fluid grade:

Genuine NISSAN Matic D ATF (Continental U.S.

and Alaska) or Canada NISSAN Automatic Trans-

mission Fluid

Refer to MA-12, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

Fluid capacity:

: Approx. 1.25 (2-5/8 US pt, 2-1/4 lmp pt)

Drain plug:

: 29.4 Nꞏm (3.0 kg-m, 22 ft-lb)

Filler plug:

: 35 Nꞏm (3.6 kg-m, 26 ft-lb)SDIA2087E

Tightening torque:

Refer to PR-6, "

REAR PROPELLER SHAFT"

SMA118A

SMA012C

Page 4814 of 5621

CHASSIS AND BODY MAINTENANCE

MA-37

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

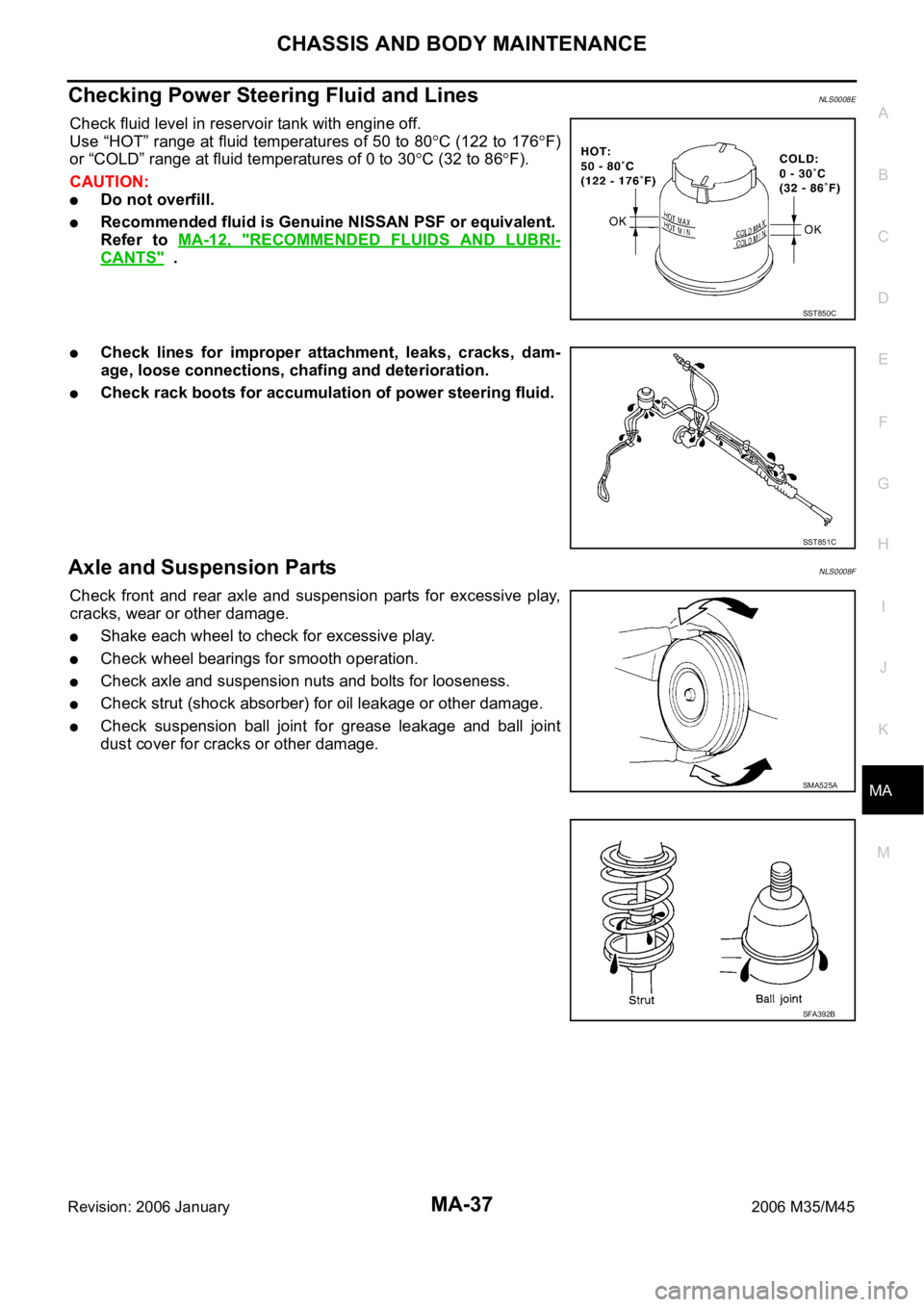

Checking Power Steering Fluid and LinesNLS0008E

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80

C (122 to 176F)

or “COLD” range at fluid temperatures of 0 to 30

C (32 to 86F).

CAUTION:

Do not overfill.

Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS" .

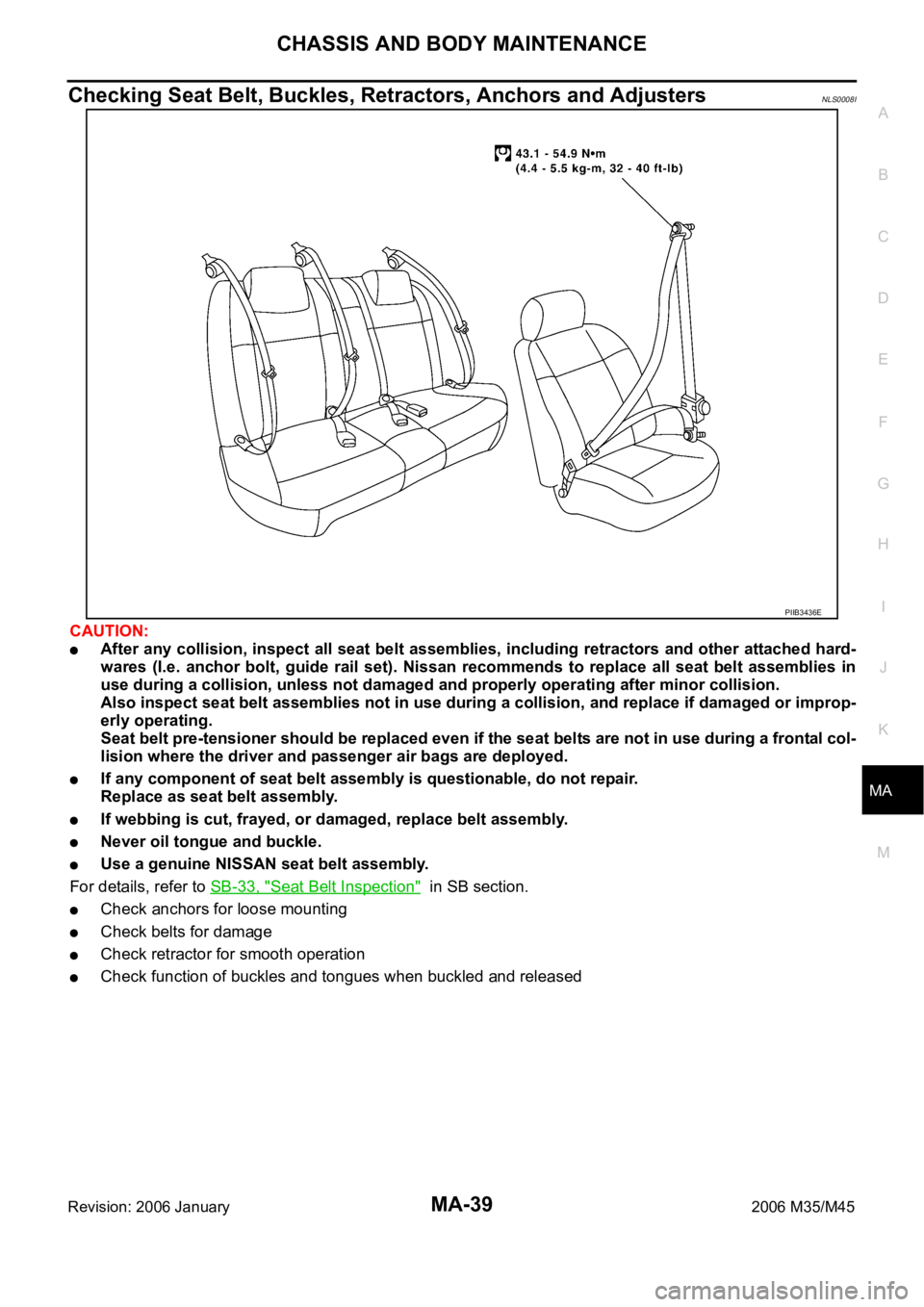

Check lines for improper attachment, leaks, cracks, dam-

age, loose connections, chafing and deterioration.

Check rack boots for accumulation of power steering fluid.

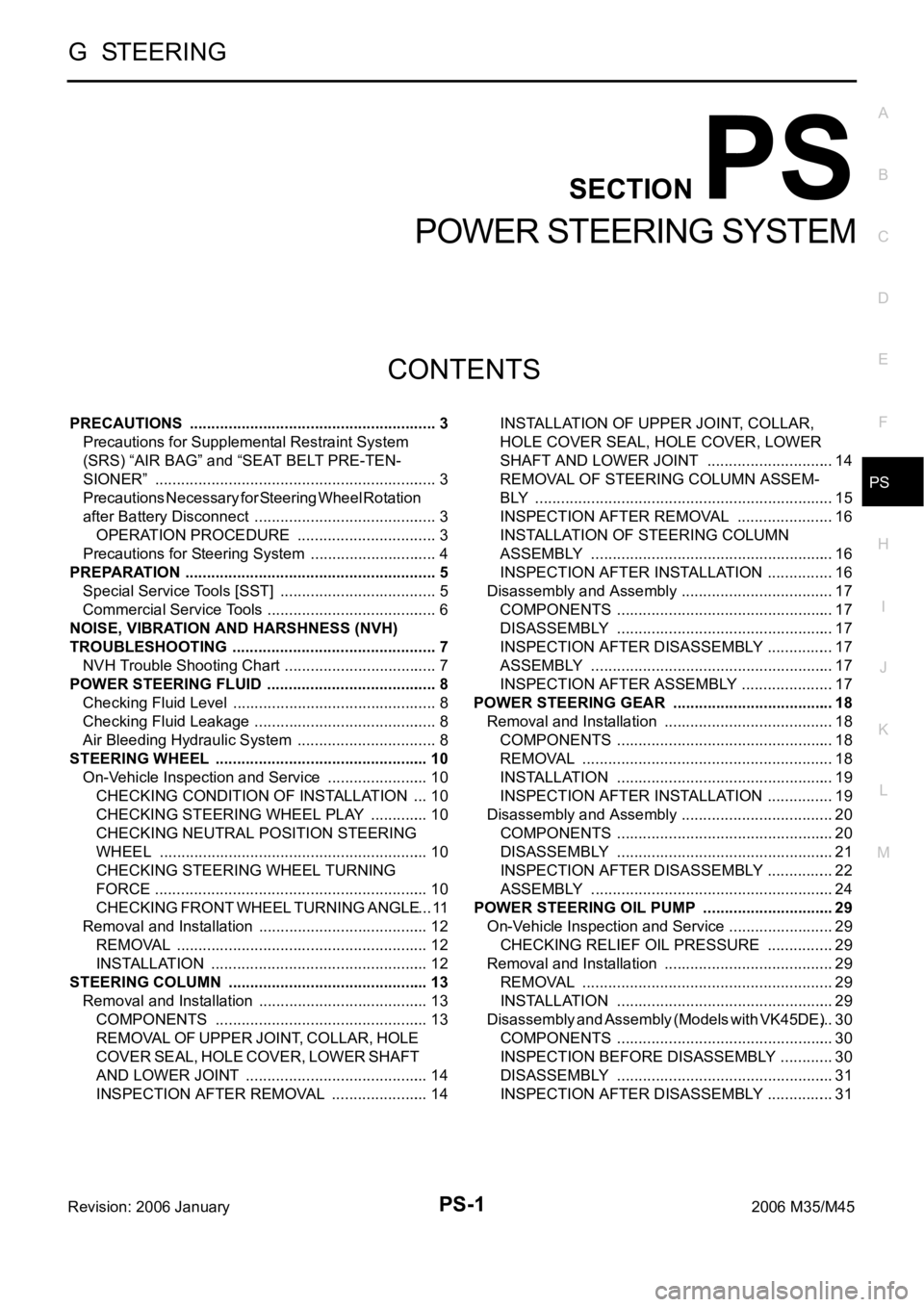

Axle and Suspension PartsNLS0008F

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

Shake each wheel to check for excessive play.

Check wheel bearings for smooth operation.

Check axle and suspension nuts and bolts for looseness.

Check strut (shock absorber) for oil leakage or other damage.

Check suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

SST850C

SST851C

SMA525A

SFA392B

Page 4816 of 5621

CHASSIS AND BODY MAINTENANCE

MA-39

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

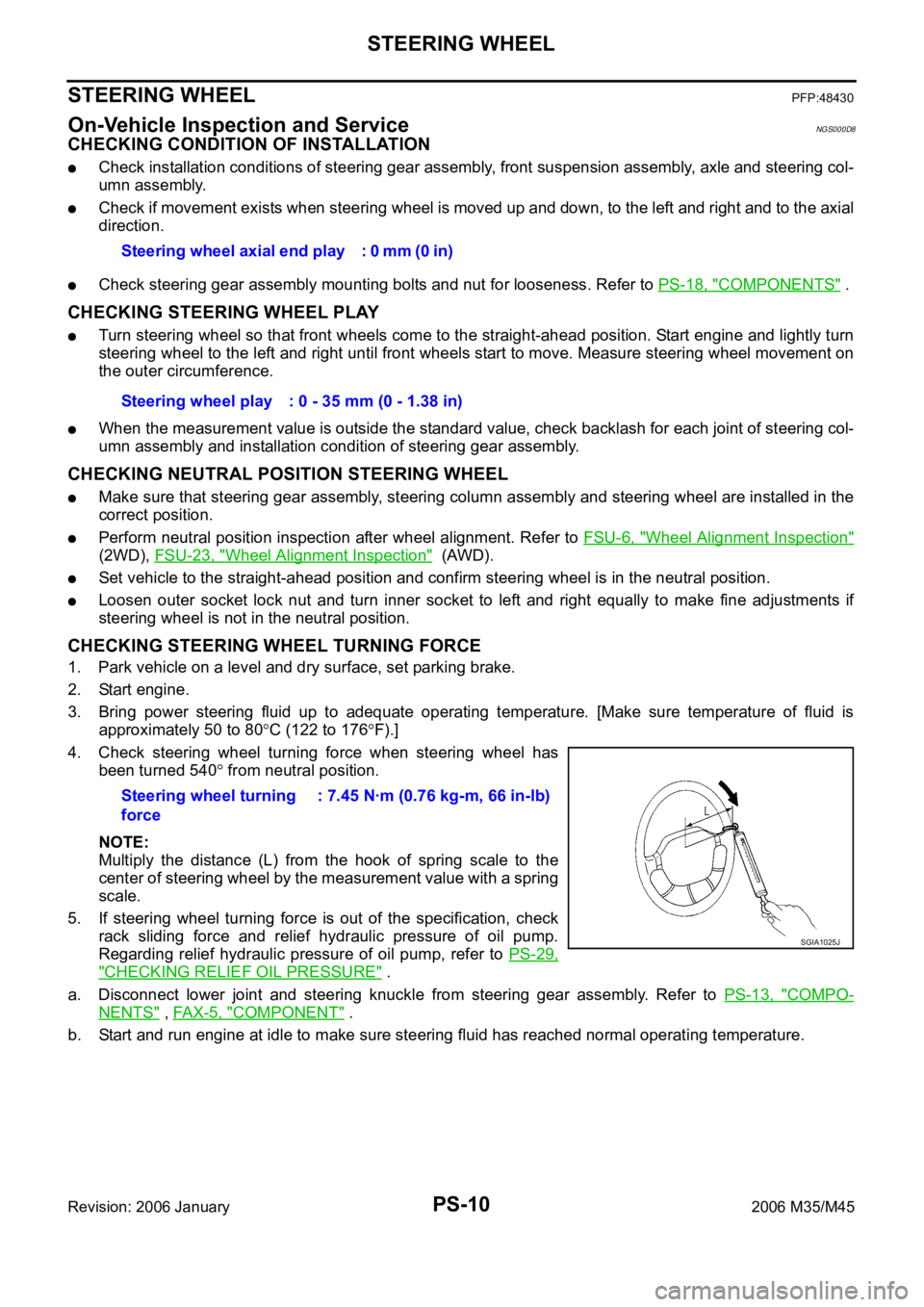

Checking Seat Belt, Buckles, Retractors, Anchors and AdjustersNLS0008I

CAUTION:

After any collision, inspect all seat belt assemblies, including retractors and other attached hard-

wares (I.e. anchor bolt, guide rail set). Nissan recommends to replace all seat belt assemblies in

use during a collision, unless not damaged and properly operating after minor collision.

Also inspect seat belt assemblies not in use during a collision, and replace if damaged or improp-

erly operating.

Seat belt pre-tensioner should be replaced even if the seat belts are not in use during a frontal col-

lision where the driver and passenger air bags are deployed.

If any component of seat belt assembly is questionable, do not repair.

Replace as seat belt assembly.

If webbing is cut, frayed, or damaged, replace belt assembly.

Never oil tongue and buckle.

Use a genuine NISSAN seat belt assembly.

For details, refer to SB-33, "

Seat Belt Inspection" in SB section.

Check anchors for loose mounting

Check belts for damage

Check retractor for smooth operation

Check function of buckles and tongues when buckled and released

PIIB3436E

Page 4954 of 5621

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTION PS

A

B

PS

Revision: 2006 January2006 M35/M45

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 3

OPERATION PROCEDURE ................................. 3

Precautions for Steering System .............................. 4

PREPARATION ........................................................... 5

Special Service Tools [SST] ..................................... 5

Commercial Service Tools ........................................ 6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Trouble Shooting Chart .................................... 7

POWER STEERING FLUID ........................................ 8

Checking Fluid Level ...........................................

..... 8

Checking Fluid Leakage ........................................... 8

Air Bleeding Hydraulic System ................................. 8

STEERING WHEEL .................................................. 10

On-Vehicle Inspection and Service ........................ 10

CHECKING CONDITION OF INSTALLATION .... 10

CHECKING STEERING WHEEL PLAY .............. 10

CHECKING NEUTRAL POSITION STEERING

WHEEL ............................................................... 10

CHECKING STEERING WHEEL TURNING

FORCE ................................................................ 10

CHECKING FRONT WHEEL TURNING ANGLE .... 11

Removal and Installation ........................................ 12

REMOVAL ........................................................

... 12

INSTALLATION ................................................... 12

STEERING COLUMN ............................................... 13

Removal and Installation ........................................ 13

COMPONENTS .................................................. 13

REMOVAL OF UPPER JOINT, COLLAR, HOLE

COVER SEAL, HOLE COVER, LOWER SHAFT

AND LOWER JOINT ........................................... 14

INSPECTION AFTER REMOVAL ....................... 14INSTALLATION OF UPPER JOINT, COLLAR,

HOLE COVER SEAL, HOLE COVER, LOWER

SHAFT AND LOWER JOINT .............................. 14

REMOVAL OF STEERING COLUMN ASSEM-

BLY ...................................................................... 15

INSPECTION AFTER REMOVAL ....................... 16

INSTALLATION OF STEERING COLUMN

ASSEMBLY ......................................................... 16

INSPECTION AFTER INSTALLATION ................ 16

Disassembly and Assembly .................................... 17

COMPONENTS ................................................... 17

DISASSEMBLY ................................................... 17

INSPECTION AFTER DISASSEMBLY ................ 17

ASSEMBLY ......................................................... 17

INSPECTION AFTER ASSEMBLY ...................... 17

POWER STEERING GEAR ...................................... 18

Removal and Installation ........................................ 18

COMPONENTS ................................................... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 19

Disassembly and Assembly .................................

... 20

COMPONENTS ................................................... 20

DISASSEMBLY ................................................... 21

INSPECTION AFTER DISASSEMBLY ................ 22

ASSEMBLY ......................................................... 24

POWER STEERING OIL PUMP ............................... 29

On-Vehicle Inspection and Service ......................... 29

CHECKING RELIEF OIL PRESSURE ................ 29

Removal and Installation ........................................ 29

REMOVAL ........................................................

... 29

INSTALLATION ................................................... 29

Disassembly and Assembly (Models with VK45DE) ... 30

COMPONENTS ................................................... 30

INSPECTION BEFORE DISASSEMBLY ............. 30

DISASSEMBLY ................................................... 31

INSPECTION AFTER DISASSEMBLY ................ 31

Page 4961 of 5621

PS-8

POWER STEERING FLUID

Revision: 2006 January2006 M35/M45

POWER STEERING FLUIDPFP:KLF20

Checking Fluid LevelNGS000D5

Check fluid level with engine stopped.

Make sure that fluid level is between MIN and MAX.

Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive

fluid will cause fluid leakage from the cap.

Do not reuse drained power steering fluid.

Recommended fluid is Genuine Nissan PSF or equiva-

lent.

Checking Fluid LeakageNGS000D6

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80

C (122

to 176

F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to PS-29, "

POWER STEERING OIL

PUMP" .

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

Air Bleeding Hydraulic SystemNGS000D7

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump.

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of

the system.

1. Turn steering wheel several times from full left stop to full right stop with engine off.

CAUTION:

Turn steering wheel while filling reservoir tank with fluid so as not to lower fluid level below the

MIN line.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Do not hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.HOT : Fluid temperature 50 - 80

C (122 - 176F)

COLD : Fluid temperature 0 - 30

C (32 - 86F)

PGIA0007J

SGIA0506E

Page 4963 of 5621

PS-10

STEERING WHEEL

Revision: 2006 January2006 M35/M45

STEERING WHEELPFP:48430

On-Vehicle Inspection and ServiceNGS000D8

CHECKING CONDITION OF INSTALLATION

Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

Check steering gear assembly mounting bolts and nut for looseness. Refer to PS-18, "COMPONENTS" .

CHECKING STEERING WHEEL PLAY

Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

When the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

Perform neutral position inspection after wheel alignment. Refer to FSU-6, "Wheel Alignment Inspection"

(2WD), FSU-23, "Wheel Alignment Inspection" (AWD).

Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if

steering wheel is not in the neutral position.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80

C (122 to 176F).]

4. Check steering wheel turning force when steering wheel has

been turned 540

from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to PS-29,

"CHECKING RELIEF OIL PRESSURE" .

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to PS-13, "

COMPO-

NENTS" , FAX-5, "COMPONENT" .

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature. Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turning

force: 7.45 Nꞏm (0.76 kg-m, 66 in-lb)

SGIA1025J