lights INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4453 of 5621

LT-26

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

Revision: 2006 January2006 M35/M45

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECTION DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitors the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item nameCONSULT-II

screen displayDisplay

or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM

MENU

Position lights request TAIL&CLR REQ ON/OFF

Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF

Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF

Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF

Signal status input from BCM

Test itemCONSULT-II

screen displayDescription

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON,

LO ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows fog lamp relay to operate by switching operation ON-OFF at your option.

Page 4488 of 5621

HEADLAMP (FOR USA) - XENON TYPE -

LT-61

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECTION DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item nameCONSULT-II

screen displayDisplay

or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Position lights request TAIL&CLR REQ ON/OFF

Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF

Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF

Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF

Signal status input from BCM

Test itemCONSULT-II

screen displayDescription

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON, LO

ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows fog lamp relay to operate by switching operation ON-OFF at your option.

Page 4500 of 5621

HEADLAMP (FOR USA) - XENON TYPE -

LT-73

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

General Information for Xenon Headlamp Trouble DiagnosisNKS003P2

In most cases, malfunction of xenon headlamp - "does not illuminate", "flickers" or "dark" - is caused by a mal-

functioning xenon bulb. A HID control unit or lamp housing, however, may be a cause of malfunction. Be sure

to perform trouble diagnosis following the steps described below.

Caution:NKS003P3

Installation or removal of connector must be done with lighting switch OFF.

Disconnect the battery cable from the negative terminal or remove power fuse.

When the lamp is illuminated (when lighting switch is ON), never touch harness, HID control unit, inside of

lamp, or lamp metal parts.

To check illumination, temporarily install lamp in vehicle. Be sure to connect power at vehicle side connec-

tor.

If error can be traced directly to electrical system, first check for items such as blown fuses and fusible

links, broken wires or loose connectors, dislocated terminals, and improper connections.

Never work with wet hands.

Using a tester for HID control unit circuit trouble diagnosis is prohibited.

Disassembling HID control unit or harnesses (bulb socket harness, ECM harness) is prohibited.

Immediately after illumination, light intensity and color will fluctuate, but there is nothing wrong.

When bulb has come to end of its life, brightness will drop significantly, it will flash repeatedly, or light color

will turn reddish.

Xenon Headlamp Trouble DiagnosisNKS003P4

1. CHECK 1: XENON HEADLAMP LIGHTING

Install normal xenon bulb to corresponding xenon bulb headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon bulb.

NG >> GO TO 2.

2. CHECK 2: XENON HEADLAMP LIGHTING

Install normal HID control unit to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace HID control unit.

NG >> GO TO 3.

3. CHECK 3: XENON HEADLAMP LIGHTING

Install normal xenon lamp housing assembly to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon headlamp housing assembly. [Malfunction in starter (boosting circuit) in xenon

headlamp housing]

NG >> INSPECTION END

Page 4509 of 5621

LT-82

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

DAYTIME LIGHT OPERATION

With the engine running, the lighting switch in the OFF or AUTO position (headlamp is not illuminate) and

parking brake released, the IPDM E/R receives input request signal from BCM to turn on daytime light. This

input is communicated across the CAN communication lines. The CPU of the IPDM E/R controls the daytime

light relay coil. When energized, this relay directs power

through daytime light relay terminals 5 and 3

through front combination lamp RH terminal 2

through front combination lamp RH terminal 6

through IPDM E/R terminal 27

through 10A fuse (No. 72, located in IPDM E/R)

through 10A fuse (No. 74, located in IPDM E/R)

through IPDM E/R terminal 28

to front combination lamp LH terminal 6.

Ground is supplied

to combination lamp LH terminal 2

through grounds E22 and E43.

With power and grounds supplied, the daytime lights illuminate. The high beam headlamps are now wired in

series and illuminate at a reduced intensity.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "COMBINATION SWITCH READING FUNCTION" .

AUTO LIGHT OPERATION

For auto light operation, refer to LT- 11 6 , "System Description" .

CAN Communication System DescriptionNKS003PB

Refer to LAN-34, "CAN COMMUNICATION" .

Page 4520 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-93

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

INSPECTION FOR PARKING BRAKE SWITCH CIRCUIT

1. CHECK BRAKE INDICATOR

1. Turn ignition switch ON.

2. When parking brake is switched ON/OFF, it checks whether the brake indicator lamp of combination meter

lights up / puts out the light.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2. CHECK PARKING BRAKE SWITCH SIGNAL

1. Turn ignition switch OFF.

2. Disconnect parking brake switch connector.

3. Turn ignition switch ON.

4. Check voltage between parking brake switch harness connector

E110 terminal 1 and ground.

OK or NG

OK >> Replace parking brake switch.

NG >> GO TO 3.

3. CHECK PARKING BRAKE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter harness connector

(A) M52 terminal 5 and parking brake switch harness connector

(B) E110 terminal 1.

OK or NG

OK >> Replace combination meter.

NG >> Repair harness or connector.1 – Ground : Battery voltage

SKIB4868E

5 – 1 : Continuity should exist.

SKIB4869E

Page 4525 of 5621

LT-98

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

Revision: 2006 January2006 M35/M45

4. Select the desired part to be diagnosed on the “SELECT DIAG

MODE” screen.

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECTION DIAG MODE ” screen.

2. Touch “ALL SIGNALS”, “MAIN SIGNALS” or “SELECTION FROM MENU” on the “SELECT MONITOR

ITEM” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. In “ALL SIG-

NALS”, all items are monitored. In “MAIN SIGNALS”, predetermined items are monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring to record the status of the item being monitored. To stop recording,

touch “STOP”.

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the display may not be correct.

ACTIVE TEST

Operation Procedure

1. Touch “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Touch item to be tested, and check operation.

3. Touch “START”.

4. Touch “STOP” while testing to stop the operation.

BCIA0031E

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item nameCONSULT-II

screen displayDisplay

or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Position lights request TAIL&CLR REQ ON/OFF

Signal status input from BCM

Headlamp low beam request HL LO REQ ON/OFF

Signal status input from BCM

Headlamp high beam request HL HI REQ ON/OFF

Signal status input from BCM

Front fog lights request FR FOG REQ ON/OFF

Signal status input from BCM

Daytime running light request DTRL REQ ON/OFF

–Signal status input from BCM

Test itemCONSULT-II

screen displayDescription

Tail lamp relay output TAIL LAMP Allows tail lamp relay to operate by switching operation ON-OFF at your option.

Headlamp relay (HI, LO) output

LAMPSAllows headlamp relay (HI, LO) to operate by switching operation (OFF, HI ON, LO

ON) at your option (Headlamp high beam repeats ON-OFF every 1 second).

Front fog lamp relay output Allows fog lamp relay to operate by switching operation ON-OFF at your option.

Page 4542 of 5621

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-115

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

General Information for Xenon Headlamp Trouble DiagnosisNKS003PR

In most cases, malfunction of xenon headlamp - "does not illuminate", "flickers" or "dark" - is caused by a mal-

functioning xenon bulb. A HID control unit or lamp housing, however, may be a cause of malfunction. Be sure

to perform trouble diagnosis following the steps described below.

CAUTION:NKS003PS

Installation or removal of connector must be done with lighting switch OFF.

When lamp is illuminated (when lighting switch is ON), do not touch harness, HID control unit, inside of

lamp, or lamp metal parts.

To check illumination, temporarily install lamp in the vehicle. Be sure to connect power at the vehicle-side

connector.

If the error can be traced directly to the electrical system, first check for items such as burned-out fuses

and fusible links, broken wires or loose connectors, pulled-out terminals, and improper connections.

Do not work with wet hands.

Using a tester for HID control unit circuit trouble diagnosis is prohibited.

Disassembling the HID control unit or harnesses (bulb socket harness, ECM harness) is prohibited.

Immediately after illumination, the light intensity and color will fluctuate, but there is nothing wrong.

When the bulb has reached the end of its lifetime, the brightness may drop significantly, it may flash

repeatedly, or the light may turn a reddish color.

Xenon Headlamp Trouble DiagnosisNKS003PT

1. CHECK 1: XENON HEADLAMP LIGHTING

Install normal xenon bulb to corresponding xenon bulb headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon bulb.

NG >> GO TO 2.

2. CHECK 2: XENON HEADLAMP LIGHTING

Install normal HID control unit to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace HID control unit.

NG >> GO TO 3.

3. CHECK 3: XENON HEADLAMP LIGHTING

Install normal xenon lamp housing assembly to corresponding xenon headlamp, and check if lamp lights up.

OK or NG

OK >> Replace xenon headlamp housing assembly. [Malfunction in starter (boosting circuit) in xenon

headlamp housing]

NG >> INSPECTION END

Aiming AdjustmentNKS003PU

Refer to LT- 7 4 , "Aiming Adjustment" .

Bulb ReplacementNKS003PV

Refer to LT- 7 5 , "Bulb Replacement" .

Removal and InstallationNKS003PW

Refer to LT- 4 1 , "Removal and Installation" .

Disassembly and AssemblyNKS003PX

Refer to LT- 7 7 , "Disassembly and Assembly" .

Page 4544 of 5621

AUTO LIGHT SYSTEM

LT-117

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

to optical sensor terminal 1.

Optical sensor, ground is supplied

to optical sensor terminal 3

through BCM terminal 18.

When ignition switch is turn to ON position, and

When outside brightness is darker than prescribed level, input is supplied

from optical sensor terminal 2

to BCM terminal 14.

The headlamps will then illuminate. For a description of headlamp operation, Refer to LT- 11 6 , "

System

Description" .

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "COMBINATION SWITCH READING FUNCTION" .

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 2ND position (or if auto light system is activated), and

the ignition switch is turned from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the headlamps remain illuminated for 5 minutes, then the headlamps are turned off.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

DELAY TIMER FUNCTION

Delay timer function carries out a function that BCM activates the timer and controls lights out of headlamps by

door switch signal and lightning switch signal when turning the Ignition switch OFF while it is ON and head-

lamps are ON by the auto light function.

Timer types are a 5 minutes timer and a 45 seconds timer

When opening any door (door switch is ON), the 5 minutes timer starts and then headlamps go out five

minutes later

When all the doors are closed (from door switch ON to OFF), the 45 second timer starts and then head-

lamps go out 45 seconds later. If any door is opened (door switch ON) while the 45 seconds timer is in

operation, the 5 minutes timer starts again

The timer stops when turning on the ignition switch or turning off the auto light switch under the above

conditions.

Delay timer control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionNKS003Q0

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing the high rate of information transmission with less wir-

ing. Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitNKS003Q1

Refer to LAN-34, "CAN Communication Unit" .

Major Components and FunctionsNKS003Q2

Components Functions

BCM

Turns on/off circuits of tail light and headlamp according to signals from optical sensor, lighting switch

(AUTO), driver door switch, passenger door switch, rear door switch, and ignition switch (ON, OFF).

Optical sensor

Converts outside brightness (lux) to voltage, and sends it to BCM. (Detects brightness of 50 to 1,300 lux)

Page 5393 of 5621

SRS-32

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

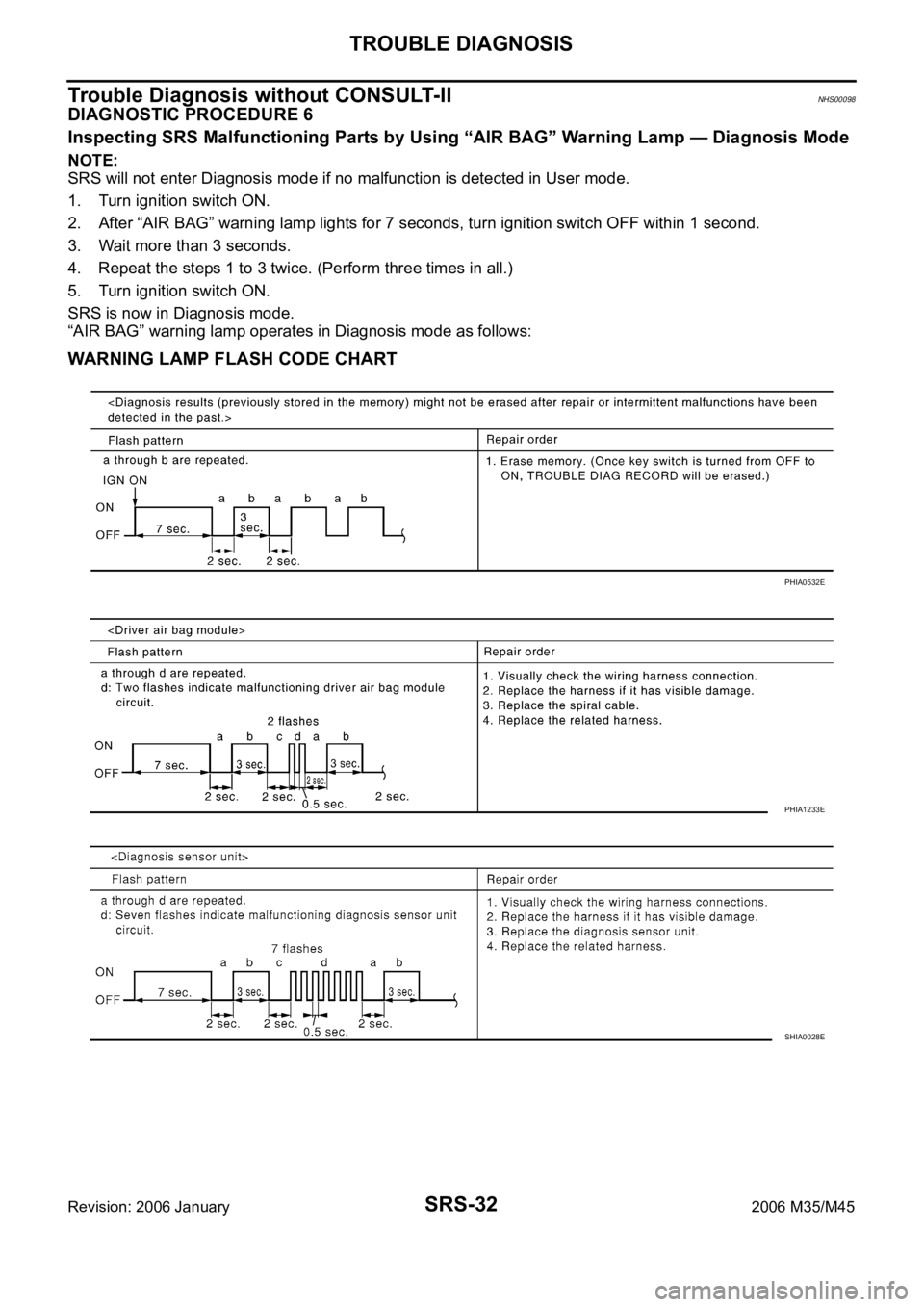

Trouble Diagnosis without CONSULT-IINHS00098

DIAGNOSTIC PROCEDURE 6

Inspecting SRS Malfunctioning Parts by Using “AIR BAG” Warning Lamp — Diagnosis Mode

NOTE:

SRS will not enter Diagnosis mode if no malfunction is detected in User mode.

1. Turn ignition switch ON.

2. After “AIR BAG” warning lamp lights for 7 seconds, turn ignition switch OFF within 1 second.

3. Wait more than 3 seconds.

4. Repeat the steps 1 to 3 twice. (Perform three times in all.)

5. Turn ignition switch ON.

SRS is now in Diagnosis mode.

“AIR BAG” warning lamp operates in Diagnosis mode as follows:

WARNING LAMP FLASH CODE CHART

PHIA0532E

PHIA1233E

SHIA0028E