suspension INFINITI M35 2006 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5088 of 5621

REAR SUSPENSION ASSEMBLY

RSU-7

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

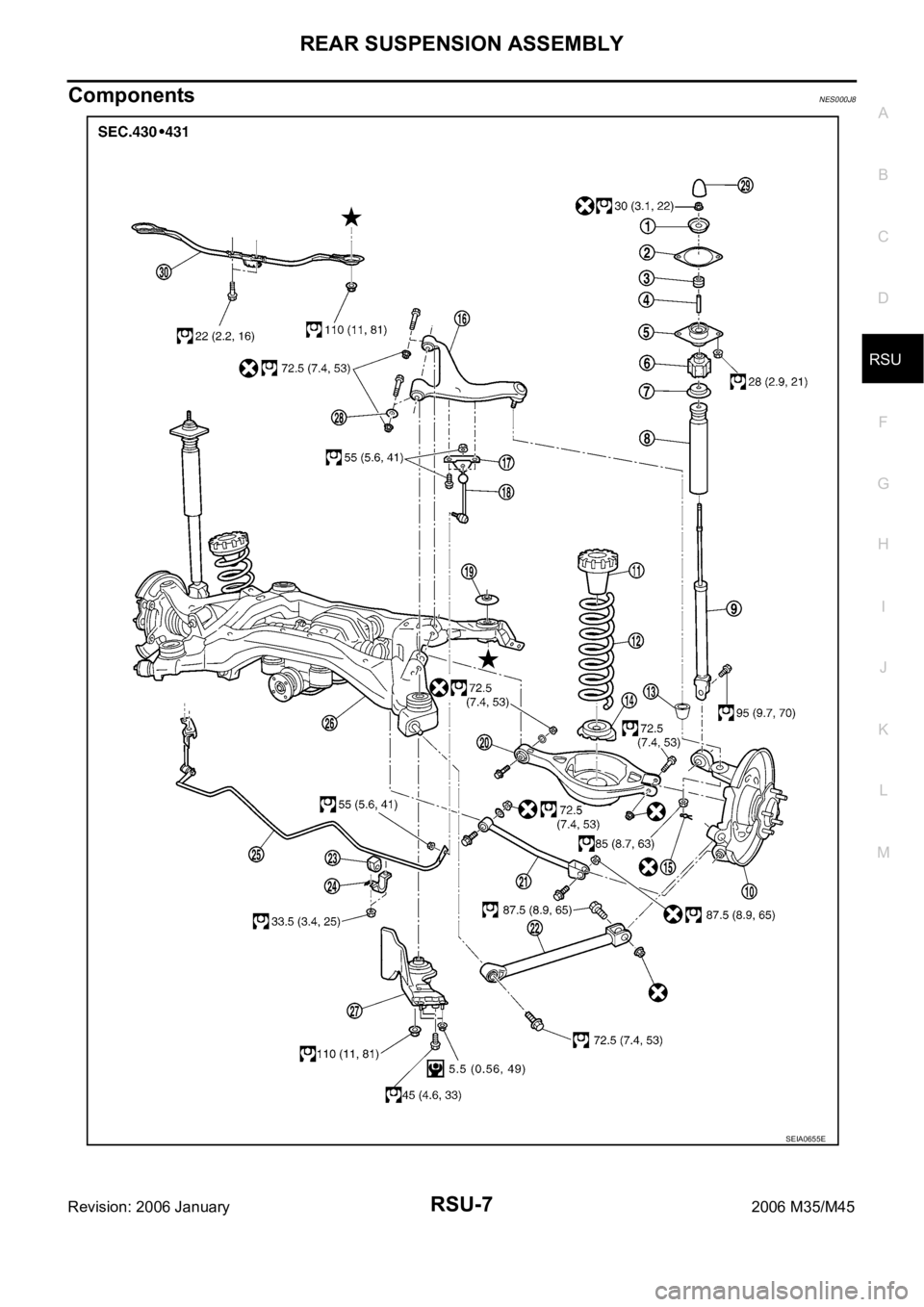

ComponentsNES000J8

SEIA0655E

Page 5089 of 5621

RSU-8

REAR SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and InstallationNES000J9

REMOVAL

1. Remove tire with a power tool.

2. Remove brake caliper with a power tool. Hang it in a place where it will not interfere with work. Refer to

BR-29, "

REAR DISC BRAKE" .

CAUTION:

Do not depressing brake pedal while brake caliper is removed.

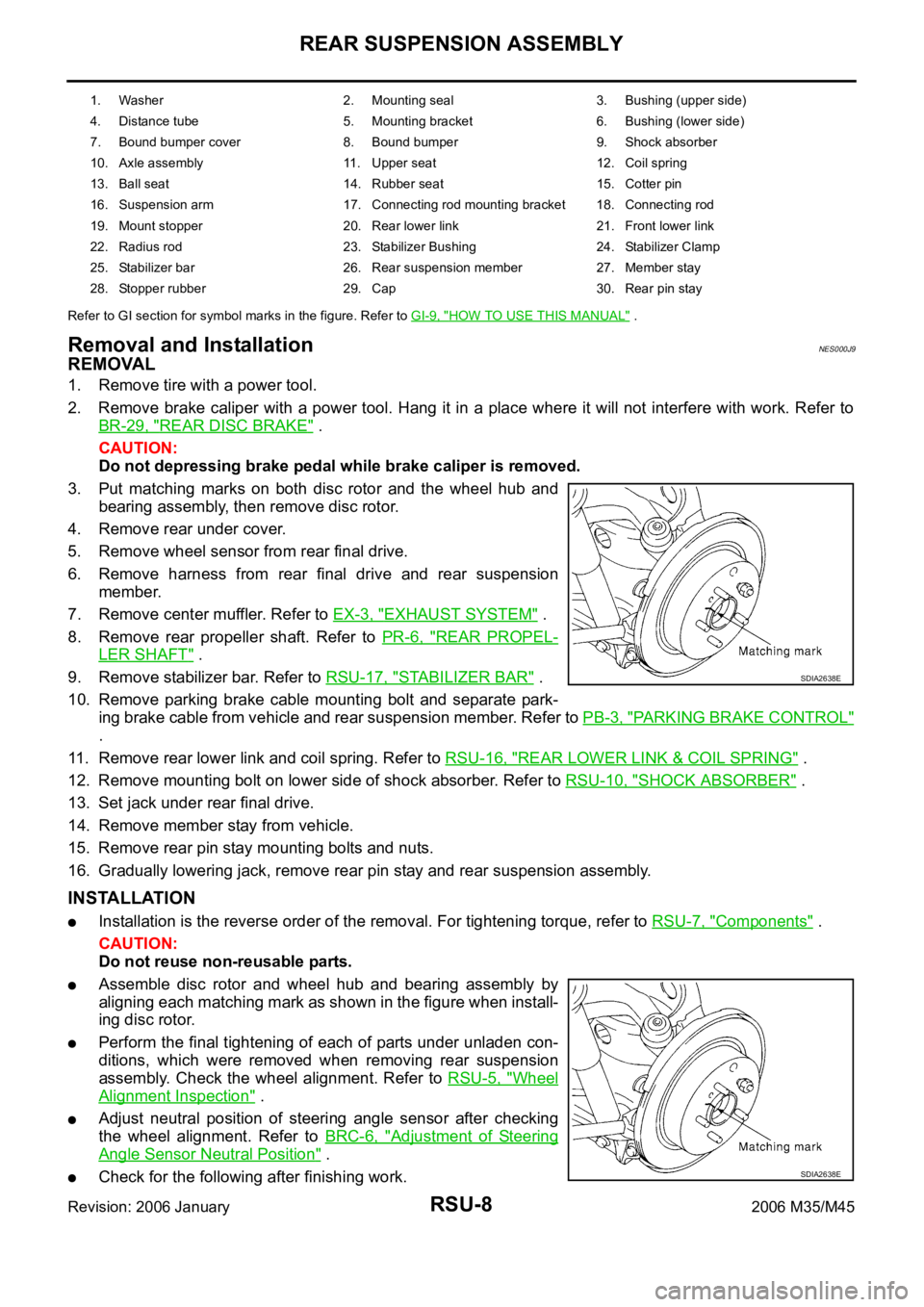

3. Put matching marks on both disc rotor and the wheel hub and

bearing assembly, then remove disc rotor.

4. Remove rear under cover.

5. Remove wheel sensor from rear final drive.

6. Remove harness from rear final drive and rear suspension

member.

7. Remove center muffler. Refer to EX-3, "

EXHAUST SYSTEM" .

8. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPEL-

LER SHAFT" .

9. Remove stabilizer bar. Refer to RSU-17, "

STABILIZER BAR" .

10. Remove parking brake cable mounting bolt and separate park-

ing brake cable from vehicle and rear suspension member. Refer to PB-3, "

PARKING BRAKE CONTROL"

.

11. Remove rear lower link and coil spring. Refer to RSU-16, "

REAR LOWER LINK & COIL SPRING" .

12. Remove mounting bolt on lower side of shock absorber. Refer to RSU-10, "

SHOCK ABSORBER" .

13. Set jack under rear final drive.

14. Remove member stay from vehicle.

15. Remove rear pin stay mounting bolts and nuts.

16. Gradually lowering jack, remove rear pin stay and rear suspension assembly.

INSTALLATION

Installation is the reverse order of the removal. For tightening torque, refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and wheel hub and bearing assembly by

aligning each matching mark as shown in the figure when install-

ing disc rotor.

Perform the final tightening of each of parts under unladen con-

ditions, which were removed when removing rear suspension

assembly. Check the wheel alignment. Refer to RSU-5, "

Wheel

Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

the wheel alignment. Refer to BRC-6, "

Adjustment of Steering

Angle Sensor Neutral Position" .

Check for the following after finishing work.

1. Washer 2. Mounting seal 3. Bushing (upper side)

4. Distance tube 5. Mounting bracket 6. Bushing (lower side)

7. Bound bumper cover 8. Bound bumper 9. Shock absorber

10. Axle assembly 11. Upper seat 12. Coil spring

13. Ball seat 14. Rubber seat 15. Cotter pin

16. Suspension arm 17. Connecting rod mounting bracket 18. Connecting rod

19. Mount stopper 20. Rear lower link 21. Front lower link

22. Radius rod 23. Stabilizer Bushing 24. Stabilizer Clamp

25. Stabilizer bar 26. Rear suspension member 27. Member stay

28. Stopper rubber 29. Cap 30. Rear pin stay

SDIA2638E

SDIA2638E

Page 5090 of 5621

REAR SUSPENSION ASSEMBLY

RSU-9

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

–Parking brake operation (stroke): Refer to PB-2, "PEDAL STROKE" .

–Wheel sensor harness for proper connection: Refer to BRC-57, "WHEEL SENSOR" .

Page 5093 of 5621

RSU-12

SUSPENSION ARM

Revision: 2006 January2006 M35/M45

SUSPENSION ARMPFP:55501

Removal and InstallationNES000JC

REMOVAL

1. Remove tire with a power tool.

2. Set a jack under rear lower link to relieve the coil spring tension.

3. Remove connecting rod mounting bracket from suspension arm with a power tool.

4. Remove mounting nuts and bolts between suspension arm and rear suspension member.

5. Remove cotter pin of suspension arm ball joint, and loosen nut.

6. Use a ball joint remover (suitable tool) to remove suspension arm from axle. Be careful not to damage ball

joint boot.

CAUTION:

Tighten temporarily mounting nut to prevent damage to threads and to prevent ball joint remover

(suitable tool) from coming off.

7. Remove suspension arm and stopper rubber from vehicle.

INSPECTION AFTER REMOVAL

Visual Inspection

Check suspension arm and bushing for deformation, cracks or damage. If any non-standard condition is

found, replace it.

Check boot of ball joint for cracks or damage, and also for grease leakage. If a malfunction is detected,

replace suspension arm.

Ball Joint Inspection

Manually move ball stud at least ten times by hand to check for smooth movement.

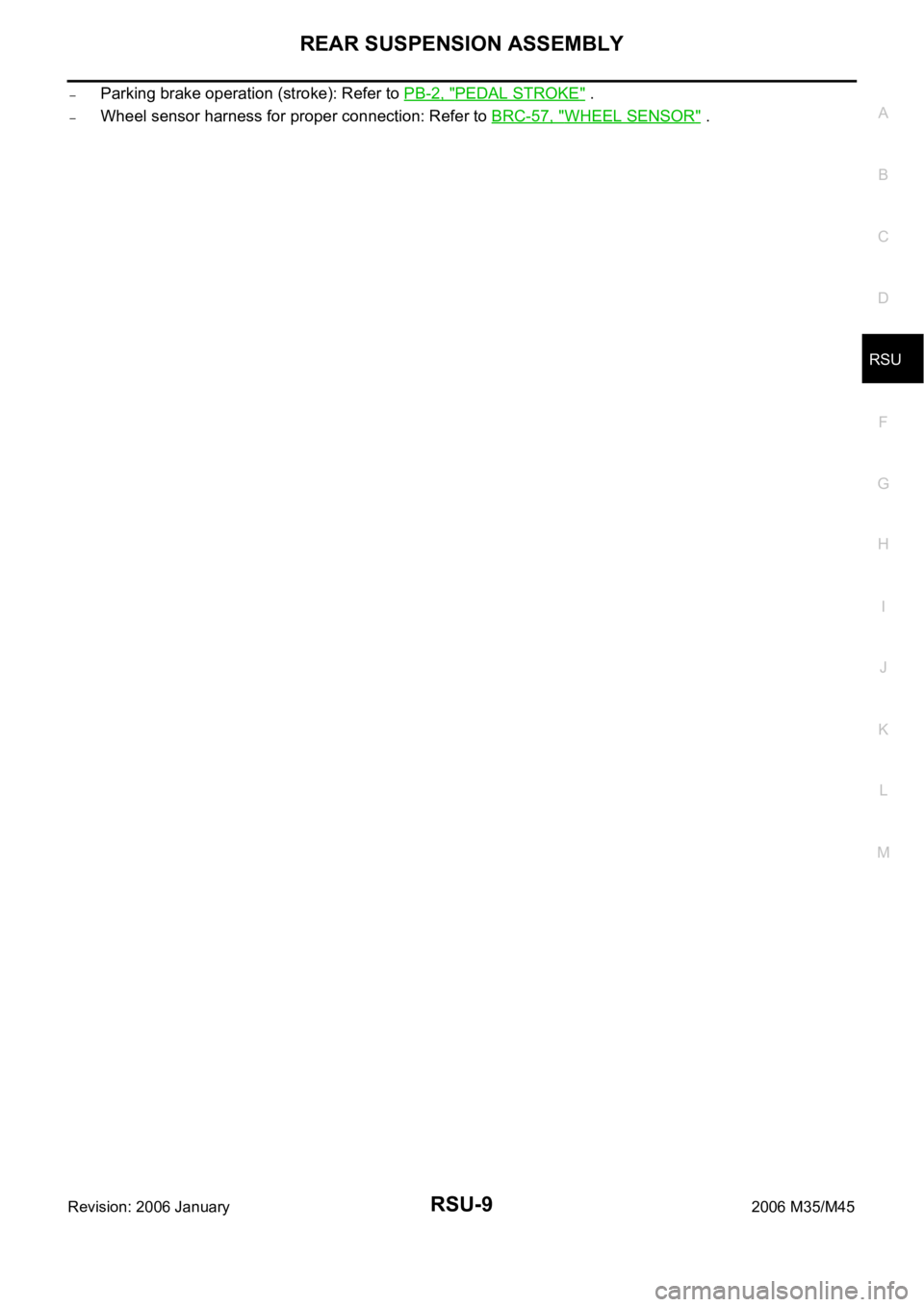

Swing Torque Inspection

Hook spring balance at cotter pin mounting hole. Confirm spring

balance measurement value is within specifications when ball

stud begins moving.

If it is outside the specified range, replace suspension arm

assembly.

Rotating Torque Inspection

Install the mounting nut to ball stud. Make sure that rotating

torque is within the specifications with a preload gauge (SST)

If it is outside the specified range, replace suspension arm

assembly.

Axial End Play Inspection

Move tip of ball stud in axial direction to check for looseness. Standard value

Swing torque:

0.5 - 3.4 Nꞏm (0.06 - 0.34 kg-m, 5 - 30 in-lb)

Measured value of spring balance:

8.1 - 54.8 N (0.83 - 5.5 kg, 1.82 - 12.32 lb)

SEIA0523E

Standard value

Rotating torque:

0.5 - 3.4 Nꞏm (0.06 - 0.34 kg-m, 5 - 30 in-lb)

SDIA1150E

Standard value

Axial end play : 0 mm (0 in)

Page 5094 of 5621

SUSPENSION ARM

RSU-13

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

If it is outside the specified range, replace suspension arm assembly.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Perform the final tightening of rear suspension member installation position (rubber bushing) under

unladen condition with tires on level ground. Refer to RSU-5, "

Wheel Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking the wheel alignment. Refer to BRC-6,

"Adjustment of Steering Angle Sensor Neutral Position" .

Page 5095 of 5621

RSU-14

RADIUS ROD

Revision: 2006 January2006 M35/M45

RADIUS RODPFP:55110

Removal and InstallationNES000JD

REMOVAL

1. Remove tire with a power tool.

2. Remove brake caliper with a power tool. Hang it in a place where it will not interfere with work. Refer to

BR-29, "

REAR DISC BRAKE" .

CAUTION:

Do not depressing brake pedal while brake caliper is removed.

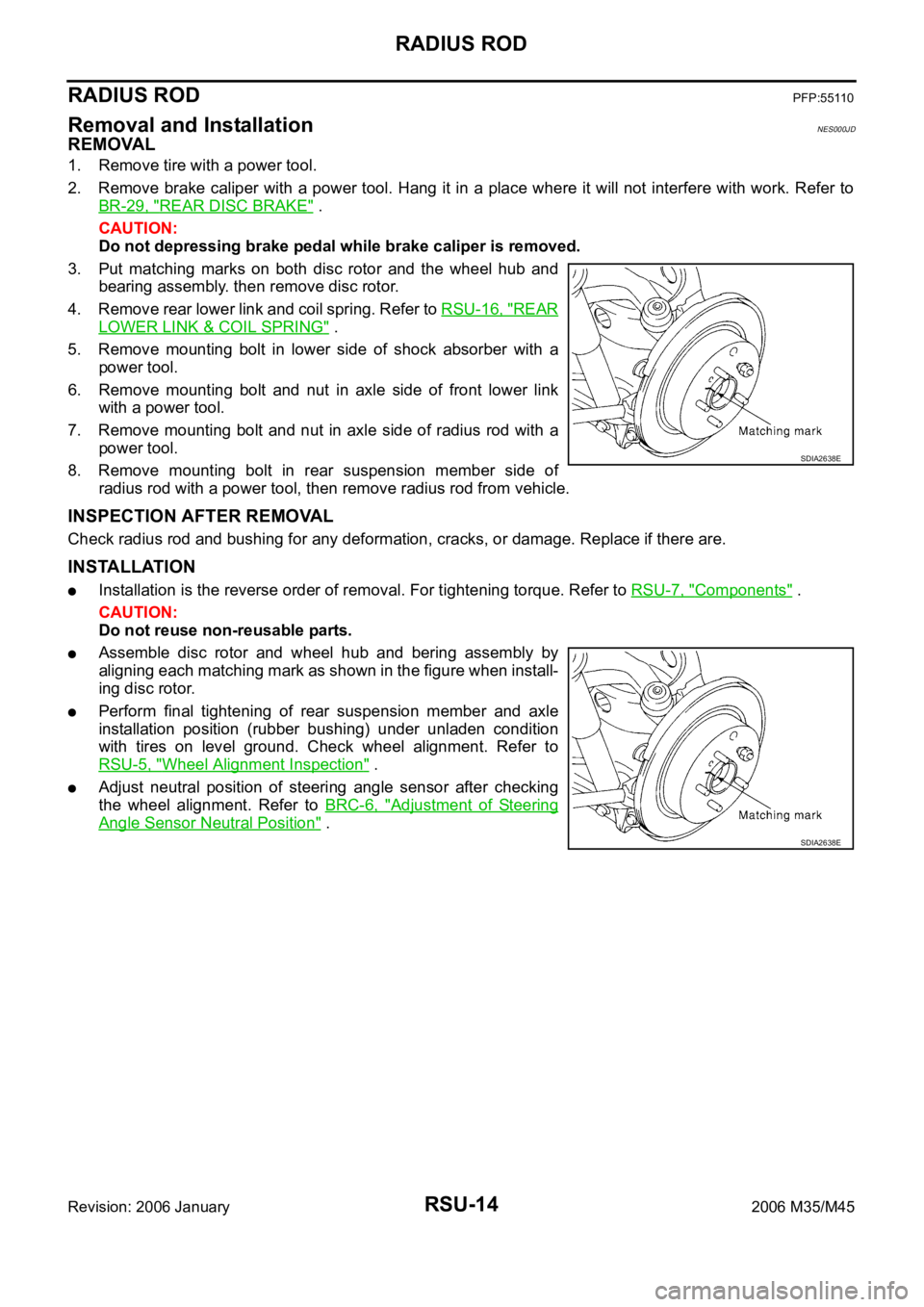

3. Put matching marks on both disc rotor and the wheel hub and

bearing assembly. then remove disc rotor.

4. Remove rear lower link and coil spring. Refer to RSU-16, "

REAR

LOWER LINK & COIL SPRING" .

5. Remove mounting bolt in lower side of shock absorber with a

power tool.

6. Remove mounting bolt and nut in axle side of front lower link

with a power tool.

7. Remove mounting bolt and nut in axle side of radius rod with a

power tool.

8. Remove mounting bolt in rear suspension member side of

radius rod with a power tool, then remove radius rod from vehicle.

INSPECTION AFTER REMOVAL

Check radius rod and bushing for any deformation, cracks, or damage. Replace if there are.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and wheel hub and bering assembly by

aligning each matching mark as shown in the figure when install-

ing disc rotor.

Perform final tightening of rear suspension member and axle

installation position (rubber bushing) under unladen condition

with tires on level ground. Check wheel alignment. Refer to

RSU-5, "

Wheel Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

the wheel alignment. Refer to BRC-6, "

Adjustment of Steering

Angle Sensor Neutral Position" .

SDIA2638E

SDIA2638E

Page 5096 of 5621

FRONT LOWER LINK

RSU-15

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

FRONT LOWER LINKPFP:55110

Removal and InstallationNES000JE

REMOVAL

1. Remove tire with a power tool.

2. Set a jack under rear lower link to relieve the coil spring tension.

3. Remove mounting nut and bolt between front lower link and rear suspension member with a power tool.

4. Remove mounting nut and bolt between front lower link and axle with a power tool.

5. Remove front lower link from vehicle.

INSPECTION AFTER REMOVAL

Check front lower link and bushing for any deformation, cracks, or damage. Replace if there are.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Perform the final tightening of rear suspension member and axle installation position (rubber bushing)

under unladen condition with tires on level ground. Check wheel alignment. Refer to RSU-5, "

Wheel Align-

ment Inspection" .

Adjust neutral position of steering angle sensor after checking the wheel alignment. Refer to Refer to

BRC-6, "

Adjustment of Steering Angle Sensor Neutral Position" .

Page 5097 of 5621

RSU-16

REAR LOWER LINK & COIL SPRING

Revision: 2006 January2006 M35/M45

REAR LOWER LINK & COIL SPRINGPFP:551B0

Removal and InstallationNES000JF

REMOVAL

1. Remove tire with a power tool.

2. Set a jack under rear lower link to relieve the coil spring tension.

3. Loosen mounting bolt and nut of rear lower link inside of suspension member, and then remove mounting

bolt and nut inside of axle with a power tool.

4. Slowly lower jack, then remove upper seat, coil spring and rubber sheet from rear lower link.

5. Remove mounting bolt and nut inside of suspension member to remove rear lower link with a power tool.

INSPECTION AFTER REMOVAL

Check rear lower link, bushing and coil spring for deformation, cracks, and damage. Replace rear lower link

and coil spring if there are.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

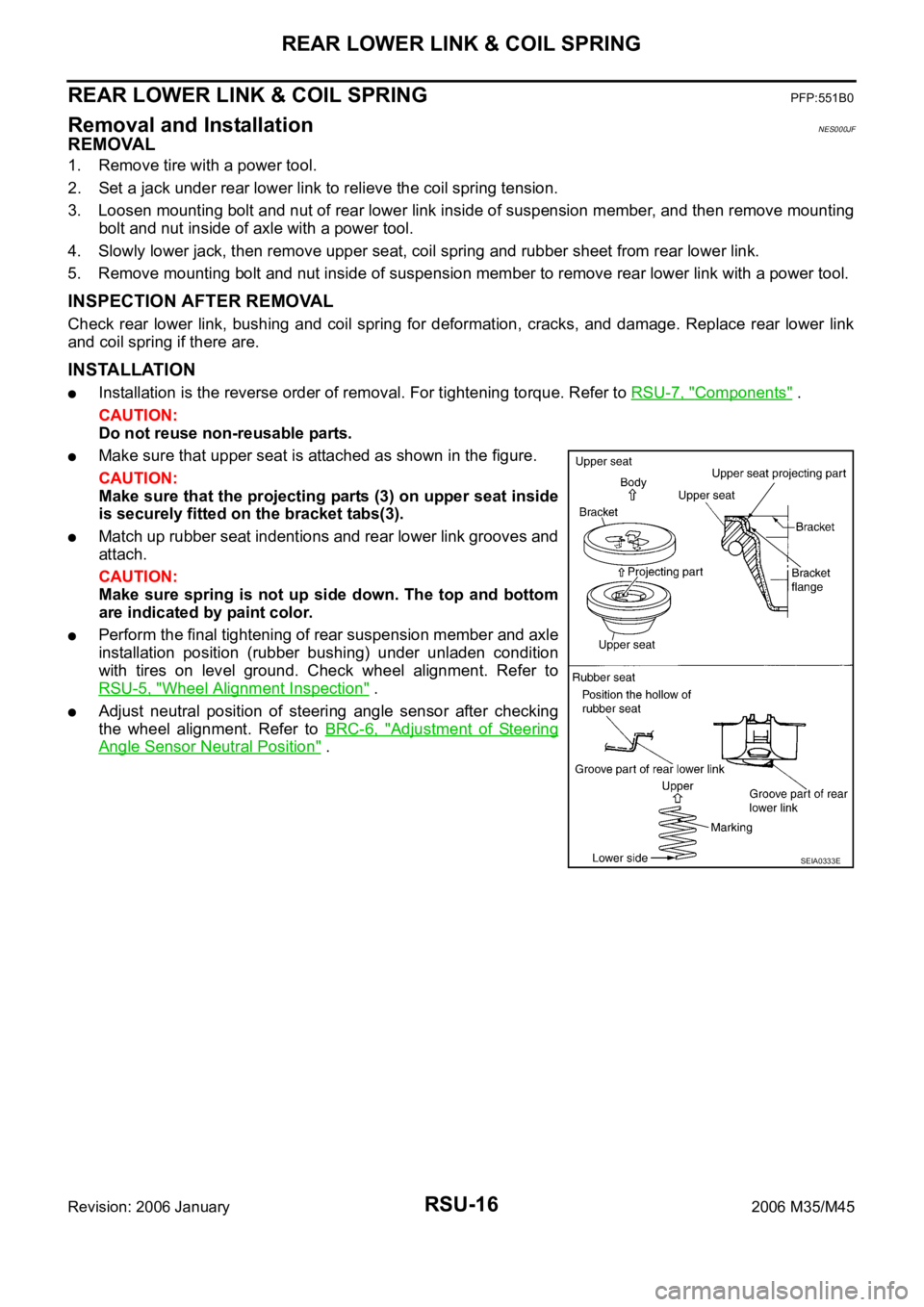

Make sure that upper seat is attached as shown in the figure.

CAUTION:

Make sure that the projecting parts (3) on upper seat inside

is securely fitted on the bracket tabs(3).

Match up rubber seat indentions and rear lower link grooves and

attach.

CAUTION:

Make sure spring is not up side down. The top and bottom

are indicated by paint color.

Perform the final tightening of rear suspension member and axle

installation position (rubber bushing) under unladen condition

with tires on level ground. Check wheel alignment. Refer to

RSU-5, "

Wheel Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

the wheel alignment. Refer to BRC-6, "

Adjustment of Steering

Angle Sensor Neutral Position" .

SEIA0333E

Page 5424 of 5621

![INFINITI M35 2006 Factory Manual PDF TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pr INFINITI M35 2006 Factory Manual PDF TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pr](/img/42/57023/w960_57023-5423.png)

TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pressure and size of tires proper?

Is the specified part used for the steering wheel?

Is control unit a genuine part?

Are there any fluid leakage from steering gear assembly, power steering oil pump, and hydraulic pipes,

etc? Refer to PS-8, "

POWER STEERING FLUID" .

Is the fluid level proper? Refer to PS-8, "POWER STEERING FLUID" .

Is the wheel alignment adjusted properly? Refer to FSU-19, "SERVICE DATA AND SPECIFICATIONS

(SDS)" (2WD), FSU-36, "SERVICE DATA AND SPECIFICATIONS (SDS)" (AWD).

Are there any damage or modification to suspension or body resulting in increased weight or altered

ground clearance?

Check each link installation condition of suspension and axle.

Check each connector connection condition.

Check the following items while driving the vehicle

Check conditions when the malfunction occurred (5W 1H).

Is the engine condition normal?

Basic InspectionNGS000E2

POWER SUPPLY CIRCUIT TERMINAL LOOSENESS AND BATTERY

Check battery terminals for looseness on both positive and negative ones and ground connection. Also make

sure that battery voltage does not drop.

Inspection: Power Steering Control Unit Power Supply Circuit and GroundNGS000E3

1. CHECK POWER STEERING CONTROL UNIT CONNECTOR

Turn ignition switch OFF, disconnect power steering control unit harness connector, and check terminal for

deformation, disconnection, looseness, etc.

OK or NG

OK >> GO TO 2.

NG >> Connector terminal connection is loose, damaged, open, or shorted. Repair or replace the termi-

nal.

2. CHECK POWER STEERING CONTROL UNIT GROUND CIRCUIT

Disconnect power steering control unit harness connector M8, and

then check continuity between power steering control unit harness

connector M8 and ground.

OK or NG

OK >> GO TO 3.

NG >> Ground circuit open or shorted. Repair or replace any

inoperative parts. Terminal 2 – Ground : Continuity exist.

SGIA1231E

Page 5428 of 5621

![INFINITI M35 2006 Factory Manual PDF REAR ACTIVE STEER

STC-13

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

[RAS]REAR ACTIVE STEERPFP:55705

Removal and InstallationNGS000E5

COMPONENTS

REMOVAL

1. Remove coil spring. INFINITI M35 2006 Factory Manual PDF REAR ACTIVE STEER

STC-13

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

[RAS]REAR ACTIVE STEERPFP:55705

Removal and InstallationNGS000E5

COMPONENTS

REMOVAL

1. Remove coil spring.](/img/42/57023/w960_57023-5427.png)

REAR ACTIVE STEER

STC-13

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

[RAS]REAR ACTIVE STEERPFP:55705

Removal and InstallationNGS000E5

COMPONENTS

REMOVAL

1. Remove coil spring. Refer to RSU-16, "REAR LOWER LINK & COIL SPRING" .

2. Disconnect harness connector from RAS actuator assembly and rear suspension member.

3. Remove fixing bolts and nuts of RAS actuator assembly (1), and

then remove RAS actuator assembly (1) from rear suspension

member.

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer to STC-13, "COMPONENTS" .

When installing RAS actuator assembly to rear suspension member, check the mounting surfaces of RAS

actuator assembly and rear suspension member for oil, dirt, sand, or other foreign materials.

To perform the neutral position adjustment. Refer to STC-14, "Neutral Position Adjustment" .

1. Rear lower link 2. Decenter cam 3. RAS actuator assembly

Refer to GI-11, "

Components" , for the symbols in the figure.

SGIA1238E

SGIA1239E