instrument panel INFINITI M35 2006 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3668 of 5621

INSTRUMENT PANEL ASSEMBLY

IP-19

C

D

E

F

G

H

J

K

L

MA

B

IP

Revision: 2006 January2006 M35/M45

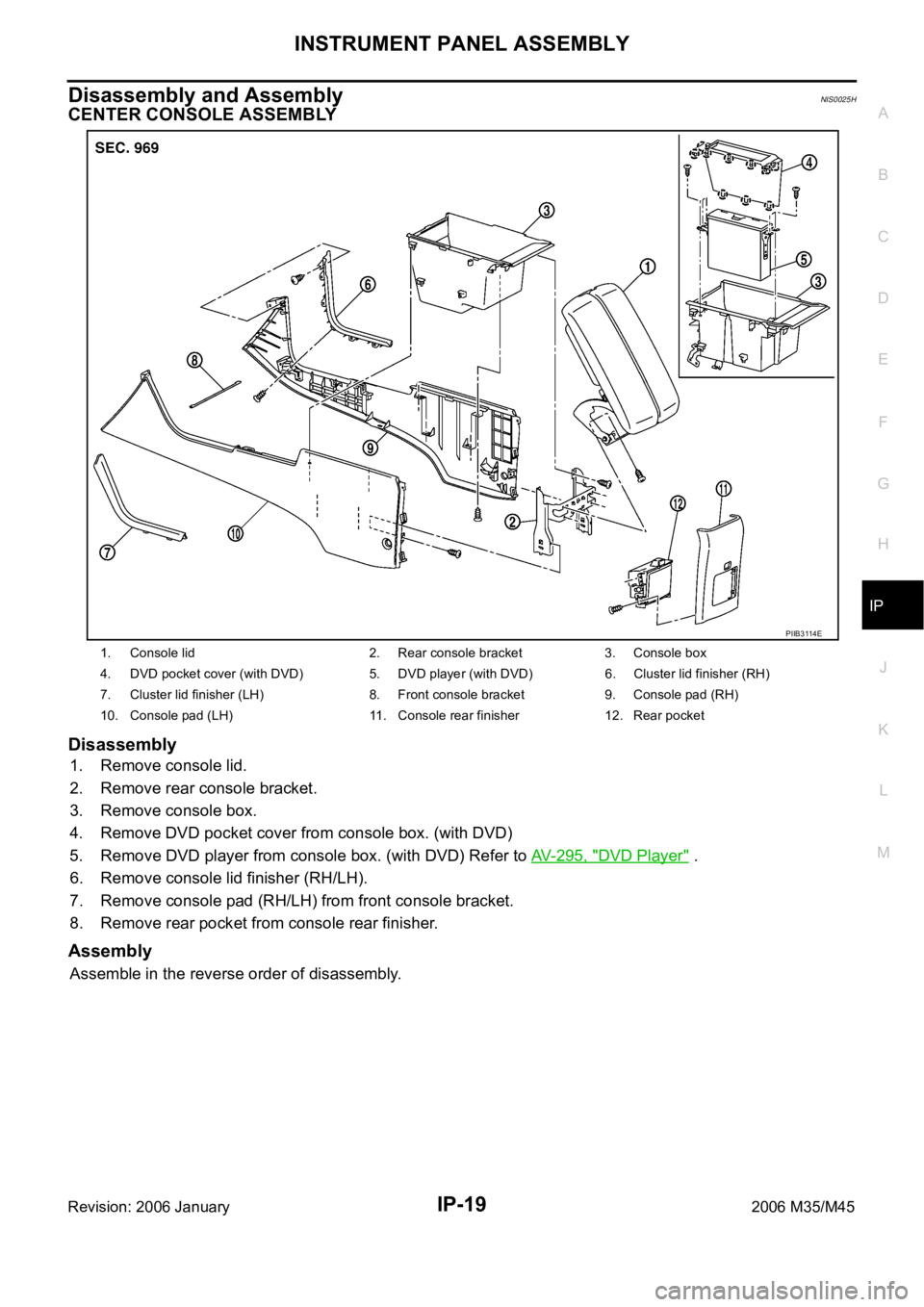

Disassembly and AssemblyNIS0025H

CENTER CONSOLE ASSEMBLY

Disassembly

1. Remove console lid.

2. Remove rear console bracket.

3. Remove console box.

4. Remove DVD pocket cover from console box. (with DVD)

5. Remove DVD player from console box. (with DVD) Refer to AV- 2 9 5 , "

DVD Player" .

6. Remove console lid finisher (RH/LH).

7. Remove console pad (RH/LH) from front console bracket.

8. Remove rear pocket from console rear finisher.

Assembly

Assemble in the reverse order of disassembly.

1. Console lid 2. Rear console bracket 3. Console box

4. DVD pocket cover (with DVD) 5. DVD player (with DVD) 6. Cluster lid finisher (RH)

7. Cluster lid finisher (LH) 8. Front console bracket 9. Console pad (RH)

10. Console pad (LH) 11. Console rear finisher 12. Rear pocket

PIIB3114E

Page 3669 of 5621

IP-20

INSTRUMENT PANEL ASSEMBLY

Revision: 2006 January2006 M35/M45

Page 4618 of 5621

ACTIVE AFS

LT-191

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Removal and Installation of AFS Control UnitNKS003QZ

REMOVAL

1. Remove dash side finisher RH. Refer to EI-37, "BODY SIDE TRIM" in EI section.

2. Remove screw (A).

3. Disconnect AFS control unit connector.

4. Remove AFS control unit (1).

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of AFS SwitchNKS003R0

REMOVAL

1. Remove instrument lower driver panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" in IP section.

2. Press AFS switch fixing pawls (A) and remove unit (1) from

instrument lower driver panel.

INSTALLATION

Installation is the reverse order of removal.

SKIB4766E

SKIB4768E

Page 4657 of 5621

LT-230

LIGHTING AND TURN SIGNAL SWITCH

Revision: 2006 January2006 M35/M45

LIGHTING AND TURN SIGNAL SWITCHPFP:25540

Removal and InstallationNKS003S2

REMOVAL

1. Remove steering column lower cover. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. While pressing pawls (A) in direction as shown in the figure, pull

lighting and turn signal switch (1) toward driver door and discon-

nect from the base.

INSTALLATION

Installation is the reverse order of removal.

Switch Circuit InspectionNKS003S3

Refer to LT- 2 4 0 , "Combination Switch Inspection" .

SKIB4186E

Page 4740 of 5621

ILLUMINATION

LT-313

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

Glove Box LampNKS003TM

BULB REPLACEMENT, REMOVAL AND INSTALLATION

Removal

1. Remove glove box cover. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Turn globe box lamp bulb socket (1) counterclockwise and

unlock it.

3. Remove bulb (2).

Installation

Installation is the reverse order of removal.

Cigarette Lighter IlluminationNKS003TN

BULB REPLACEMENT, REMOVAL AND INSTALLATION

Removal

1. Remove A/T console finisher. Refer to IP-11, "Removal and Installation of Instrument Panel & Pad" .

2. Remove screws (A).

3. Use a screwdriver to undo hooks, remove bulb sockets (1).

4. Remove bulb (2).

Installation

Installation is the reverse order of removal.Glove box lamp : 12V - 1.4W

SKIB4206E

SKIB4207E

Front ashtray and cigarette lighter

illumination: 12V - 1.4W

SKIB4209E

Page 4823 of 5621

PB-4

PARKING BRAKE CONTROL

Revision: 2006 January2006 M35/M45

Removal and InstallationNFS000PT

REMOVAL

1. Remove rear tires from vehicle with power tool.

2. Remove instrument driver lower panel. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

3. Disconnect parking brake switch connector.

4. Remove adjusting nut and loosen front cable.

5. Remove device assembly mounting nuts and remove device assembly from vehicle.

6. Remove center console. Refer to IP-19, "

CENTER CONSOLE ASSEMBLY" .

7. Separate rear cable from front cable, remove front cable from vehicle.

8. Remove heat insulator of the exhaust center tube from vehicle.

9. Remove parking brake shoe, and remove rear cable from toggle lever. Refer to PB-6, "

Removal and

Installation" .

10. Remove rear cable mounting bolts and nuts, pull out rear cable from vehicle.

INSTALLATION

1. Install in the reverse order of the removal. Refer to PB-3, "Components" for tightening torque.

CAUTION:

Do not reuse adjusting nut.

2. Adjust parking brake. Refer to PB-2, "

ADJUSTMENT" .

Page 4892 of 5621

HARNESS

PG-65

C

D

E

F

G

H

I

J

L

MA

B

PG

Revision: 2006 January2006 M35/M45

MAIN HARNESS

Instrument Panel

TKIT0442E

Page 4968 of 5621

STEERING COLUMN

PS-15

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

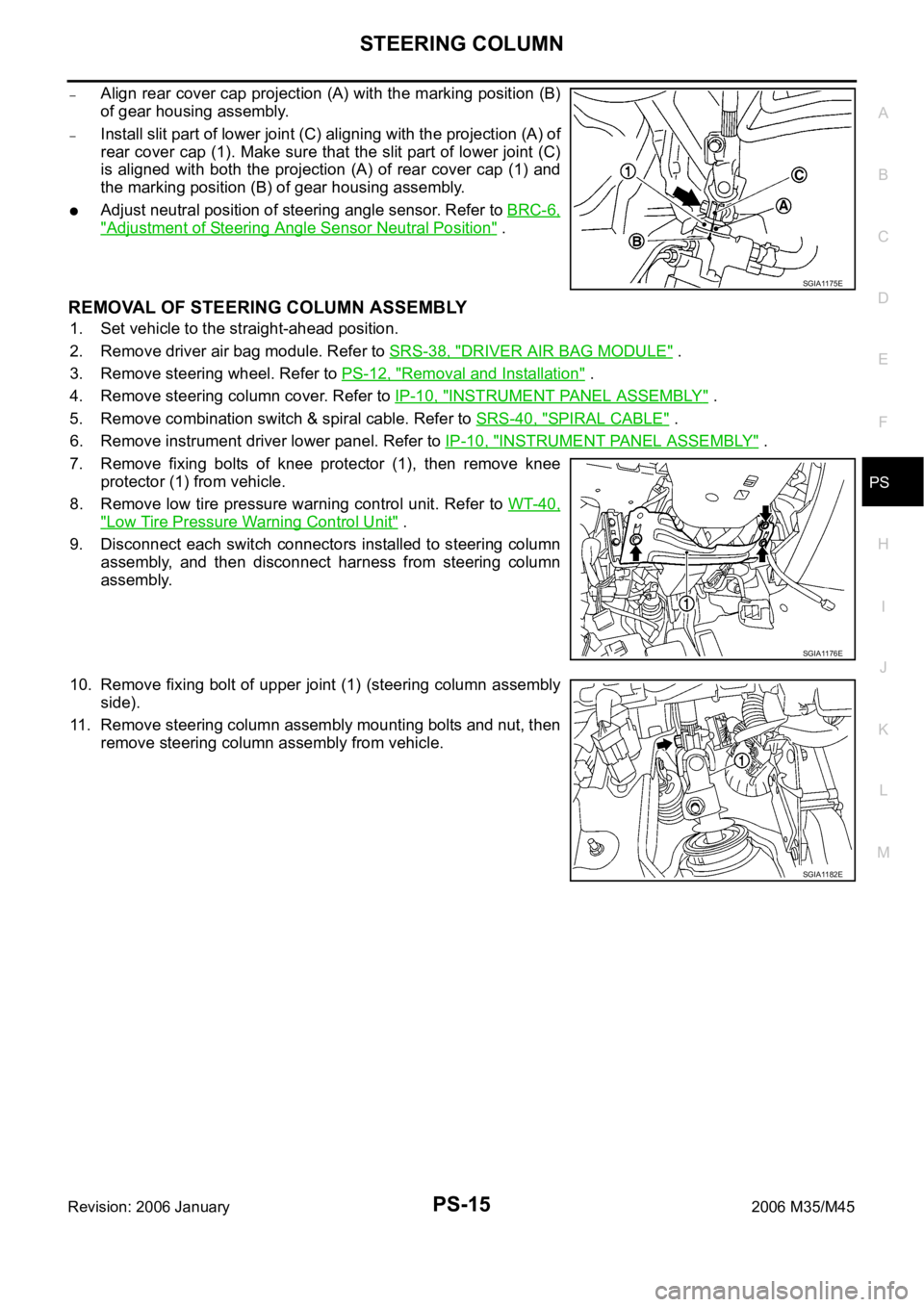

–Align rear cover cap projection (A) with the marking position (B)

of gear housing assembly.

–Install slit part of lower joint (C) aligning with the projection (A) of

rear cover cap (1). Make sure that the slit part of lower joint (C)

is aligned with both the projection (A) of rear cover cap (1) and

the marking position (B) of gear housing assembly.

Adjust neutral position of steering angle sensor. Refer to BRC-6,

"Adjustment of Steering Angle Sensor Neutral Position" .

REMOVAL OF STEERING COLUMN ASSEMBLY

1. Set vehicle to the straight-ahead position.

2. Remove driver air bag module. Refer to SRS-38, "

DRIVER AIR BAG MODULE" .

3. Remove steering wheel. Refer to PS-12, "

Removal and Installation" .

4. Remove steering column cover. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

5. Remove combination switch & spiral cable. Refer to SRS-40, "

SPIRAL CABLE" .

6. Remove instrument driver lower panel. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

7. Remove fixing bolts of knee protector (1), then remove knee

protector (1) from vehicle.

8. Remove low tire pressure warning control unit. Refer to WT-40,

"Low Tire Pressure Warning Control Unit" .

9. Disconnect each switch connectors installed to steering column

assembly, and then disconnect harness from steering column

assembly.

10. Remove fixing bolt of upper joint (1) (steering column assembly

side).

11. Remove steering column assembly mounting bolts and nut, then

remove steering column assembly from vehicle.

SGIA1175E

SGIA1176E

SGIA1182E

Page 5014 of 5621

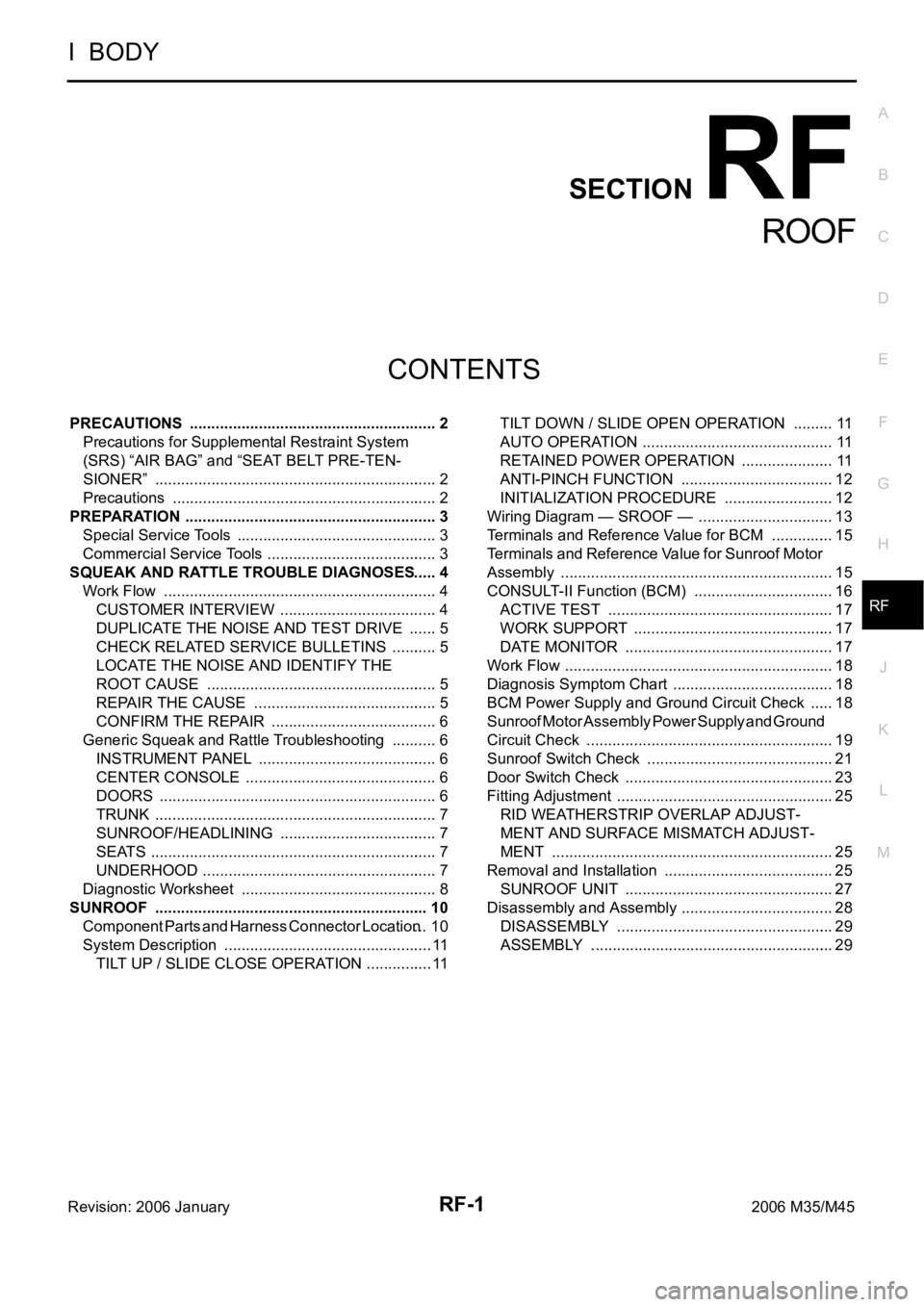

RF-1

ROOF

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION RF

A

B

RF

Revision: 2006 January2006 M35/M45

ROOF

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet .............................................. 8

SUNROOF ................................................................ 10

Component Parts and Harness Connector Location ... 10

System Description ................................................. 11

TILT UP / SLIDE CLOSE OPERATION ................ 11TILT DOWN / SLIDE OPEN OPERATION .......... 11

AUTO OPERATION ............................................. 11

RETAINED POWER OPERATION ...................... 11

ANTI-PINCH FUNCTION .................................... 12

INITIALIZATION PROCEDURE .......................... 12

Wiring Diagram — SROOF — ................................ 13

Terminals and Reference Value for BCM ............... 15

Terminals and Reference Value for Sunroof Motor

Assembly ................................................................ 15

CONSULT-II Function (BCM) ................................. 16

ACTIVE TEST ..................................................... 17

WORK SUPPORT ............................................... 17

DATE MONITOR ................................................. 17

Work Flow ............................................................... 18

Diagnosis Symptom Chart ...................................... 18

BCM Power Supply and Ground Circuit Check ...... 18

Sunroof Motor Assembly Power Supply and Ground

Circuit Check .......................................................... 19

Sunroof Switch Check .........................................

... 21

Door Switch Check ..............................................

... 23

Fitting Adjustment ................................................... 25

RID WEATHERSTRIP OVERLAP ADJUST-

MENT AND SURFACE MISMATCH ADJUST-

MENT .................................................................. 25

Removal and Installation ........................................ 25

SUNROOF UNIT ................................................. 27

Disassembly and Assembly .................................... 28

DISASSEMBLY ................................................... 29

ASSEMBLY ......................................................... 29

Page 5019 of 5621

RF-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30

50 mm (1.181.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15

25 mm (0.590.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingNIS0023O

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.