SFU INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 169 of 5621

AT-90

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

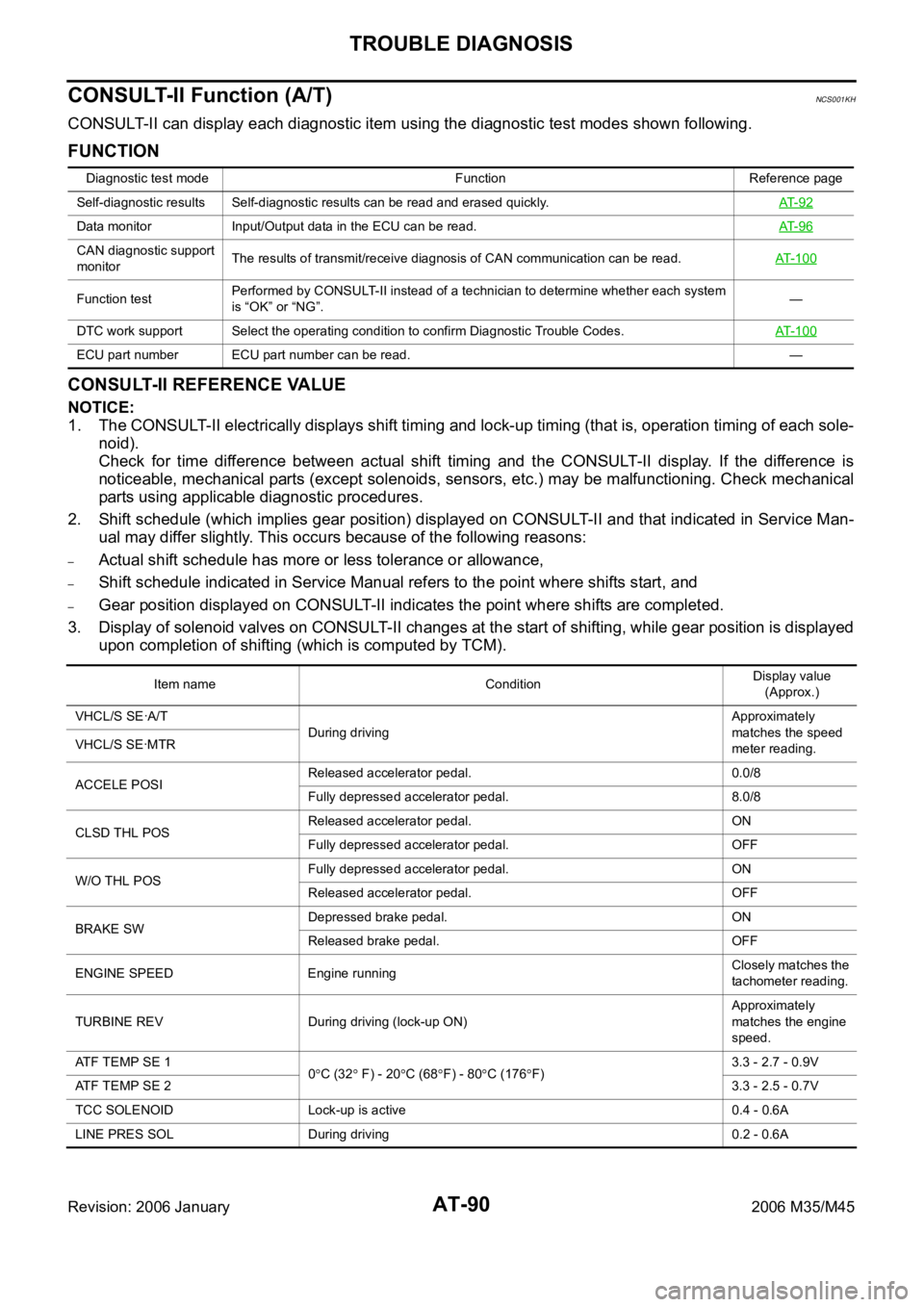

CONSULT-II Function (A/T)NCS001KH

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

FUNCTION

CONSULT-II REFERENCE VALUE

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

–Actual shift schedule has more or less tolerance or allowance,

–Shift schedule indicated in Service Manual refers to the point where shifts start, and

–Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Display of solenoid valves on CONSULT-II changes at the start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

Diagnostic test mode Function Reference page

Self-diagnostic results Self-diagnostic results can be read and erased quickly.AT- 9 2

Data monitor Input/Output data in the ECU can be read.AT- 9 6

CAN diagnostic support

monitorThe results of transmit/receive diagnosis of CAN communication can be read.AT- 1 0 0

Function testPerformed by CONSULT-II instead of a technician to determine whether each system

is “OK” or “NG”.—

DTC work support Select the operating condition to confirm Diagnostic Trouble Codes.AT- 1 0 0

ECU part number ECU part number can be read. —

Item name Condition Display value

(Approx.)

VHCL/S SEꞏA/T

During drivingApproximately

matches the speed

meter reading. VHCL/S SEꞏMTR

ACCELE POSIReleased accelerator pedal. 0.0/8

Fully depressed accelerator pedal. 8.0/8

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POSFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

ENGINE SPEED Engine runningClosely matches the

tachometer reading.

TURBINE REV During driving (lock-up ON)Approximately

matches the engine

speed.

ATF TEMP SE 1

0

C (32 F) - 20C (68F) - 80C (176F)3.3 - 2.7 - 0.9V

ATF TEMP SE 23.3 - 2.5 - 0.7V

TCC SOLENOID Lock-up is active 0.4 - 0.6A

LINE PRES SOL During driving 0.2 - 0.6A

Page 263 of 5621

AT-184

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

Revision: 2006 January2006 M35/M45

CLOSED THROTTLE POSITION AND WIDE OPEN THROTTLE POSITION CIR-

CUIT

PFP:18002

CONSULT-II Reference ValueNCS001PR

Diagnostic ProcedureNCS001PS

1. CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to AT- 9 2 , "

SELF-DIAGNOSTIC RESULT MODE" , AT- 1 0 3 , "Diagnostic Pro-

cedure without CONSULT-II" .

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to AT- 1 0 5 , "DTC U1000 CAN COMMUNICATION LINE" .

NO >> GO TO 2.

2. CHECK THROTTLE POSITION SIGNAL CIRCUIT

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Depress accelerator pedal and read out the value of “CLSD THL

POS” and “W/O THL POS”.

OK or NG

OK >>INSPECTION END

NG >> Check the following. If NG, repair or replace damaged parts.

Perform the self-diagnosis for “ENGINE” with CONSULT-II. Refer to EC-137, "SELF-DIAG

RESULTS MODE" (for VQ35DE engine), EC-850, "SELF-DIAG RESULTS MODE" (for

VK45DE engine).

Open circuit or short to ground or short to power in harness or connectors.

Pin terminals for damage or loose connection with harness connector.

Item name Condition Display value

CLSD THL POSReleased accelerator pedal. ON

Fully depressed accelerator pedal. OFF

W/O THL POSFully depressed accelerator pedal. ON

Released accelerator pedal. OFF

Accelerator Pedal OperationMonitor Item

CLSD THL POS W/O THL POS

Released ON OFF

Fully depressed OFF ON

PCIA0070E

Page 1067 of 5621

BL-128

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Revision: 2006 January2006 M35/M45

System DescriptionNIS001Y8

The engine start function of Intelligent Key system is a system that makes it possible to start and stop the

engine without removing the key. It verifies the electronic ID using two-way communications when press-

ing the push-button ignition switch while carrying the Intelligent Key, which operates based on the results

of electronic ID verification for Intelligent Key using two-way communications between the Intelligent Key

and the vehicle (Intelligent Key unit).

NOTE:

The driver should always carry the intelligent key at all times.

Intelligent Key has 2 IDs (for Intelligent Key and for immobilizer). It can perform the door lock/unlock oper-

ation and the push-button ignition switch operation when carrying the registered Intelligent Key.

When the Intelligent Key battery is discharged, it can be used as emergency by inserting the Intelligent

Key to the key slot. At that time, perform the immobilizer ID verification. If it is used when carrying the

Intelligent Key, perform the Intelligent Key ID verification.

If the ID is successfully verified, and when push-button ignition switch is pressed, steering lock will be

released and initiating the engine will be possible.

If the door lock/unlock operation is performed when the Intelligent Key battery is discharged, all doors

lock/unlock can be performed by operating the driver door key cylinder using the mechanical key set into

the Intelligent Key.

Intelligent Key can be registered up to 4 keys (Including the standard Intelligent Key) on request from the

owner.

NOTE:

Refer to BL-44, "INTELLIGENT KEY SYSTEM" for any functions other than engine start function of

Intelligent Key system.

10. Unified meter and A/C amp M64,

M6511. Combination meter M52 12. Security indicator

(Multifunction switch) M69

13. Steering lock unit M35

(Steering column)14. Remote keyless entry receiver

(View with instrument lower panel

RH removed) M89 15. Key slot M14

PIIB5896E

Page 1068 of 5621

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

BL-129

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

PRECAUTIONS FOR INTELLIGENT KEY SYSTEM

In the Intelligent Key system of model Y50, the transponder (the chip for immobilizer ID verifica-

tion) is integrated into the Intelligent Key. (For the conventional models, it is integrated into the

mechanical key.) Therefore, the mechanical key cannot perform the ID verification, and thus it can-

not start the engine. Instead of it, the immobilizer ID verification can be performed by inserting the

Intelligent Key into the key slot, and then it can start the engine.

When registering the Intelligent Key, 2 registration procedures (immobilizer ID registration and

Intelligent Key ID registration) should be performed. The immobilizer ID registration is the proce-

dure that registers the ID stored into the transponder (integrated into Intelligent Key) to the BCM.

The Intelligent Key ID registration is the procedure that registers the ID to the Intelligent Key unit.

Each registration is a different procedure.

When performing the Intelligent Key ID registration only, the engine cannot be started by inserting

the key into the key slot. When performing the engine immobilizer ID registration only, the engine

cannot be started by the operation when carrying the key. The registrations of both systems

should be performed.

Operation DescriptionNIS001Y9

SYSTEM DIAGRAM

OPERATION WHEN INTELLIGENT KEY IS CARRIED

Description

1. When the push-button switch is pressed, the Intelligent Key unit signals the inside key antenna and sends

the request signal to the Intelligent Key.

2. The Intelligent Key receives the request signal and sends the Intelligent Key ID signal to the Intelligent

Key unit via the remote keyless entry receiver.

3. The Intelligent Key receives the Intelligent Key ID signal and verifies it with the registered ID.

4. If the ID is successfully verified, the Intelligent Key unit sends the steering unlock signal to the steering

lock unit. Then, it sends each power supply request signal to PDU (Power Distribution Unit) after unlock-

ing the steering lock.

5. If the Intelligent Key unit judges that the engine start condition is satisfied, it sends the starter request sig-

nal via CAN communication to IPDM E/R and turns the starter motor relay ON.

6. The steering lock unit unlocks the steering lock when receiving the signal. PDU starts the power supply

distribution according to the push-button ignition switch operation when receiving the signal. If it enters the

engine start permission mode, the power supply is supplied from PDU to the starter motor relay and the

cranking is started.

CAUTION:

If a malfunction is detected in the Intelligent Key system, the “KEY” warning lamp in the combina-

tion meter illuminates for 15 seconds. At that time, the engine cannot be started.

7. When Intelligent Key unit received feedback signal from ECM acknowledging the engine has been initi-

ated, the Intelligent Key unit sends a stop signal to IPDM E/R and stops the cranking by turning OFF the

PIIB6272E

Page 1612 of 5621

![INFINITI M35 2006 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-69

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

–Te s t v a l u e s

Actual work procedures are explained using a DTC as an example. Be INFINITI M35 2006 Factory Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-69

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

–Te s t v a l u e s

Actual work procedures are explained using a DTC as an example. Be](/img/42/57023/w960_57023-1611.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-69

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

–Te s t v a l u e s

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)NBS004SO

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-40, "

WARNING LAMPS" ,

or see EC-722, "

MIL AND DATA LINK CONNECTOR" .

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

SEF217U

Diagnostic Test

ModeKEY and ENG.

StatusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MIL bulb for damage (blown,

open circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When a malfunction is

detected twice in two consecutive driving cycles (two trip

detection logic), the MIL will light up to inform the driver

that a malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

Misfire (Possible three way catalyst damage)

One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Page 1622 of 5621

![INFINITI M35 2006 Factory Service Manual BASIC SERVICE PROCEDURE

EC-79

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

6. PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-96, "

Idle Air Volume Learning" .

Is Idle Ai INFINITI M35 2006 Factory Service Manual BASIC SERVICE PROCEDURE

EC-79

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

6. PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-96, "

Idle Air Volume Learning" .

Is Idle Ai](/img/42/57023/w960_57023-1621.png)

BASIC SERVICE PROCEDURE

EC-79

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

6. PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Ye s > > G O T O 7 .

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

7. CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-82, "

IDLE SPEED" .

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-82, "

IDLE SPEED" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8. DETECT MALFUNCTIONING PART

Check the Following.

Check camshaft position sensor (PHASE) and circuit. Refer to EC-383, "DTC P0340, P0345 CMP SEN-

SOR (PHASE)" .

Check crankshaft position sensor (POS) and circuit. Refer to EC-376, "DTC P0335 CKP SENSOR (POS)"

.

OK or NG

OK >> GO TO 9.

NG >> 1. Repair or replace.

2. GO TO 4.

9. CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

BL-252, "

ECM Re-Communicating Function" .

>> GO TO 4. 650

50 rpm (in P or N position)

650

50 rpm (in P or N position)

SEF174Y

Page 1623 of 5621

![INFINITI M35 2006 Factory Service Manual EC-80

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

10. CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-82, "

IGNITION INFINITI M35 2006 Factory Service Manual EC-80

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

10. CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-82, "

IGNITION](/img/42/57023/w960_57023-1622.png)

EC-80

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

10. CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-82, "

IGNITION TIMING" .

OK or NG

OK >> GO TO 19.

NG >> GO TO 11.

11 . PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-95, "

Accelerator Pedal Released Position Learning" .

>> GO TO 12.

12. PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-95, "

Throttle Valve Closed Position Learning" .

>> GO TO 13.

13. PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Yes >> GO TO 14.

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

14. CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-82, "

IDLE SPEED" .

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-82, "

IDLE SPEED" .

OK or NG

OK >> GO TO 15.

NG >> GO TO 17.15

5 BTDC (in P or N position)

PBIB1602E

650 50 rpm (in P or N position)

650

50 rpm (in P or N position)

SEF174Y

Page 1631 of 5621

![INFINITI M35 2006 Factory Service Manual EC-88

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

6. PERFORM IDLE AIR VOLUME LEARNING

Perform EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried o INFINITI M35 2006 Factory Service Manual EC-88

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

6. PERFORM IDLE AIR VOLUME LEARNING

Perform EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried o](/img/42/57023/w960_57023-1630.png)

EC-88

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

6. PERFORM IDLE AIR VOLUME LEARNING

Perform EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Yes >> GO TO 7.

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

7. CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-82, "

IDLE SPEED" .

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-82, "

IDLE SPEED" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 8.

8. DETECT MALFUNCTIONING PART

Check the following.

Check camshaft position sensor (PHASE) and circuit. Refer to EC-383, "DTC P0340, P0345 CMP SEN-

SOR (PHASE)" .

Check crankshaft position sensor (POS) and circuit. Refer to EC-376, "DTC P0335 CKP SENSOR (POS)"

.

OK or NG

OK >> GO TO 9.

NG >> 1. Repair or replace.

2. GO TO 4.

9. CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

BL-252, "

ECM Re-Communicating Function" .

>> GO TO 4. 650

50 rpm (in P or N position)

650

50 rpm (in P or N position)

Page 1632 of 5621

![INFINITI M35 2006 Factory Service Manual BASIC SERVICE PROCEDURE

EC-89

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

10. CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer INFINITI M35 2006 Factory Service Manual BASIC SERVICE PROCEDURE

EC-89

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

10. CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer](/img/42/57023/w960_57023-1631.png)

BASIC SERVICE PROCEDURE

EC-89

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

10. CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

Refer to EC-82, "

IGNITION TIMING" .

OK or NG

OK (With CONSULT-II)>>GO TO 19.

OK (With GST)>>GO TO 20.

NG >> GO TO 11.

11 . PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-95, "

Accelerator Pedal Released Position Learning" .

>> GO TO 12.

12. PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-95, "

Throttle Valve Closed Position Learning" .

>> GO TO 13.

13. PERFORM IDLE AIR VOLUME LEARNING

Perform EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Ye s > > G O T O 1 4 .

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

14. CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-82, "

IDLE SPEED" .

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

Refer to EC-82, "

IDLE SPEED" .

OK or NG

OK >> GO TO 15.

NG >> GO TO 17.15

5 BTDC (in P or N position)

PBIB1602E

650 50 rpm (in P or N position)

650

50 rpm (in P or N position)

Page 1635 of 5621

![INFINITI M35 2006 Factory Service Manual EC-92

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

21. CHECK AIR FUEL RATIO (A/F) SENSOR 1 HARNESS

1. Turn ignition switch OFF and disconnect battery ground cable.

2. Disconnect INFINITI M35 2006 Factory Service Manual EC-92

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

21. CHECK AIR FUEL RATIO (A/F) SENSOR 1 HARNESS

1. Turn ignition switch OFF and disconnect battery ground cable.

2. Disconnect](/img/42/57023/w960_57023-1634.png)

EC-92

[VQ35DE]

BASIC SERVICE PROCEDURE

Revision: 2006 January2006 M35/M45

21. CHECK AIR FUEL RATIO (A/F) SENSOR 1 HARNESS

1. Turn ignition switch OFF and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect A/F sensor 1 harness connector.

4. Check harness continuity between the following terminals.

Refer to EC-249, "

Wiring Diagram" .

5. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 22.

NG >> 1. Repair open circuit or short to ground or short to power in harness or connectors.

2. GO TO 4.

22. PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Reconnect ECM harness connector.

2. Perform EC-95, "

Accelerator Pedal Released Position Learning" .

>> GO TO 23.

23. PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-95, "

Throttle Valve Closed Position Learning" .

>> GO TO 24.

24. PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-96, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Yes (With CONSULT-II)>>GO TO 25.

Yes (Without CONSULT-II)>>GO TO 26.

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

A/F sensor 1 terminal ECM terminal

Bank1116

275

42

535

656

Bank 2176

277

424

557

658

Continuity should exist.