fuse chart INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 50 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-41

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 0 CONTROL UNITNKS004D0

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1 INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-41

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 0 CONTROL UNITNKS004D0

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1](/img/42/57023/w960_57023-49.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-41

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

DTC 0 CONTROL UNITNKS004D0

1. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

1. Perform self-diagnosis.

2. Check if any item other than “CONTROL UNIT [C1A00]” (DTC 0) is indicated on self-diagnosis display.

Is any indicated?

YES >> 1. Repair or replace applicable item. Refer to ACS-39, "Diagnostic Trouble Code (DTC) Chart" .

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

DTC 1 POWER SUPPLY CIR, DTC 2 POWER SUPPLY CIR 2NKS004D1

1. CHECK CONNECTOR ICC SENSOR INTEGRATED UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC sensor integrated unit connector, and connect it securely again.

3. Erase DTC and perform ICC running test. Then perform self-diagnosis of ICC system again.

4. Check if “POWER SUPPLY CIR [C1A01]” (DTC 1) or “ POWER SUPPLY CIR 2 [C1A02]” (DTC 2) is indi-

cated in self-diagnosis item in the display.

Is malfunction indicated?

YES >> GO TO 2.

NO >> Poor connector connection

1. Check connector. (Check connector housing for disconnected, loose, bent, and collapsed ter-

minals. If any malfunction is detected, repair applicable part.)

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

2. CHECK POWER SUPPLY CIRCUIT FOR ICC SENSOR INTEGRATED UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC sensor integrated unit connector.

3. Turn ignition switch ON.

4. Check voltage between ICC sensor integrated unit harness con-

nector and ground.

OK or NG

OK >> GO TO 3.

NG >> 1. Repair or replace ICC sensor integrated unit power

supply harness or fuse.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Te r m i n a l s

Voltage

(Approx.) (+)

(–)

ICC sensor integrated

unit connectorTe r m i n a l

E61 1 Ground Battery voltage

PKIB8375E

Page 970 of 5621

POWER DOOR LOCK SYSTEM

BL-31

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Terminals and Reference Value of BCMNIS001WV

Work FlowNIS001WW

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-25, "

System Description" .

3. According to the trouble diagnosis chart by symptom, repair or replace the cause of the malfunction.

Refer to BL-34, "

Trouble Diagnosis Chart by Symptom" .

4. Does power door lock system operate normally?

YES: GO TO 5.

NO: GO TO 3.

5. INSPECTION END

Termi-

nalWire

colorItem ConditionVoltage [V]

(Approx.)

11 V Ignition switch (ACC) Ignition switch is in ACC position Battery voltage

22 G Power window serial link Ignition switch ON

38 W Ignition switch (ON)Ignition switch is in ON or START posi-

tionBattery voltage

39 L CAN H — —

40 P CAN L — —

42 P Battery source (Fuse) — Battery voltage

44 GRDriver door lock actuator

(unlock) signalDoor lock / unlock switch

(Free

Unlock)0 Battery voltage 0

50 V Door lock actuator (lock) signalDoor lock / unlock switch

(Free

Lock)0 Battery voltage 0

51 GRear doors lock actuator and

fuel lid lock actuator (unlock) sig-

nalDoor lock / unlock switch

(Free

Unlock)0 Battery voltage 0

52 B Ground — 0

55 W Power source (Fusible link) — Battery voltage

70 GFront door lock actuator (pas-

senger side) lock signalDoor lock / unlock switch

(Free

Unlock)0 Battery voltage 0

PIIA2344J

Page 1217 of 5621

BL-278

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect multifunction switch (security indicator) connector.

3. Check voltage between multifunction switch (security indicator)

connector and ground.

OK or NG

OK >> Check the following.

Harness for open or short between BCM and multifunction switch (security indicator)

Security indicator lamp condition

NG >> Check the following.

15A fuse [No.37, located in fuse block (J/B)]

Harness for open or short between multifunction switch (security indicator) and fuse

DTC P1612 CHAIN of ECM-IMMUNIS0020S

Self-diagnostic results:

“CHAIN OF ECM-IMMU” displayed on CONSULT-II screen

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, then perform the trouble diagno-

sis of malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-15, "

CAN Com-

munication Inspection Using CONSULT-II (Self-Diagnosis)" .

1. CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “CHAIN OF ECM-IMMU”

displayed on CONSULT-II screen.

NOTE:

In rare case, “CHAIN OF ECM-IMMU” might be stored during key

registration procedure, even if the system is not malfunctioning.

Is CONSULT-II screen displayed as shown in figure?

Yes >> GO TO 2.

No >> GO TO BL-271, "

“NATS V5.0” SELF-DIAGNOSTIC

RESULTS ITEM CHART" .

Te r m i n a l s

Voltage (V)

(Approx.) (+)

(–) multifunction switch

(security indicator)

connectorTerminal

M69 1 Ground Battery voltage

PIIB6218E

PIIA1260E

Page 1529 of 5621

DI-96

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

SYMPTOM CHART

Power Supply and Ground Circuit InspectionNKS003VO

1. CHECK FUSE

Check for blown LDW camera unit fuse.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3, "

POWER

SUPPLY ROUTING CIRCUIT" .

2. CHECK POWER SUPPLY CIRCUIT

Check voltage between LDW camera unit and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between LDW camera unit and fuse.

Symptom Diagnosis/Service procedure

LDW system is not activated.

(LDW system ON indicator turns ON/OFF.)Perform the following inspections.

1.DI-98, "

LDW Chime Circuit Inspection"

2.DI-102, "LDW Indicator Lamp Circuit Inspection"

Replace LDW camera unit, found normal function in the above inspections.

LDW system does not turn ON/OFF.

(LDW system ON indicator does not turn ON/OFF.)Perform DI-99, "

LDW Switch Circuit Inspection" .

Replace LDW camera unit, found normal function in the above inspection.

Warning functions are untimely.

(Example)

Warning does not function when driving on lane mark-

ers.

Warning functions when driving in a lane.

Differs position from actual condition functions.Perform DI-81, "

Camera Aiming Adjustment" .

Functions when changing the course to the turn signal

direction.Perform DI-103, "

Turn Signal Input Inspection" .

Replace LDW camera unit, found normal function in the above inspection.

LDW indicator lamp does not illuminate with ignition

switch ON.Perform DI-102, "

LDW Indicator Lamp Circuit Inspection" .

Replace LDW camera unit, found normal function in the above inspection.

Unit Power source Fuse No.

LDW camera unit Ignition switch ON or START 12

Terminals Ignition switch position

(+)

(–) OFF ON

LDW camera

unit connectorTerminal

M182 1 Ground 0 V Battery voltage

PKIC0246E

Page 1531 of 5621

![INFINITI M35 2006 Factory Service Manual DI-98

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

DTC [U1000] CAN COMM CIRCUITNKS003VT

1. CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “LDW” with CONS INFINITI M35 2006 Factory Service Manual DI-98

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

DTC [U1000] CAN COMM CIRCUITNKS003VT

1. CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “LDW” with CONS](/img/42/57023/w960_57023-1530.png)

DI-98

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

DTC [U1000] CAN COMM CIRCUITNKS003VT

1. CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “LDW” with CONSULT-II.

2. Print out CONSULT-II screen.

>> Go to “LAN SYSTEM”. Refer to LAN-7, "

Precautions When Using CONSULT-II" .

DTC [U1010] CONTROL UNIT (CAN)NKS003VU

Replace LDW camera unit, when “[U1010] CONTROL UNIT (CAN)” is displayed on self-diagnosis display.

LDW Chime Circuit InspectionNKS003VV

1. CHECK OPERATION OF LDW CHIME

Check LDW chime operation “BUZZER DRIVE” in “ACTIVE TEST”

mode with CONSULT-II.

OK or NG

OK >> LDW chime is OK. Return to DI-96, "SYMPTOM

CHART" .

NG >> GO TO 2.

2. CHECK LDW CHIME POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW chime connector.

3. Turn ignition switch ON.

4. Check voltage between LDW chime harness connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between fuse and LDW chime.

3. CHECK LDW CHIME GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between LDW chime harness connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.“BUZZER DRIVE”

Touch “ON” : LDW chime is activated.

Touch “OFF” : LDW chime is not activated.

SKIB1787E

Terminals

Voltage (Approx.) (+)

(–)

LDW chime connector Terminal

M58 1 Ground Battery voltage

PKIC0248E

LDW chime connector Terminal

GroundContinuity

M58 3 Yes

PKIC0249E

Page 3482 of 5621

HOW TO USE THIS MANUAL

GI-19

C

D

E

F

G

H

I

J

K

L

MB

GI

Revision: 2006 January2006 M35/M45

14 Wire color

This shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light GreenBR = Brown

OR or O = Orange

P = Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe color as shown

below:

Example: L/W = Blue with White Stripe

15 Option description

This shows a description of the option abbreviation used on the page.

16 Switch

This shows that continuity exists between terminals 1 and 2 when the switch is in the A posi-

tion. Continuity exists between terminals 1 and 3 when the switch is in the B position.

17 Assembly parts

Connector terminal in component shows that it is a harness incorporated assembly.

18 Cell code

This identifies each page of the wiring diagram by section, system and wiring diagram page

number.

19 Current flow arrow

Arrow indicates electric current flow, especially where the direction of standard flow (vertically

downward or horizontally from left to right) is difficult to follow.

A double arrow “ ” shows that current can flow in either direction depending on cir-

cuit operation.

20 System branch

This shows that the system branches to another system identified by cell code (section and

system).

21 Page crossing

This arrow shows that the circuit continues to another page identified by cell code.

The C will match with the C on another page within the system other than the next or preced-

ing pages.

22 Shielded line

The line enclosed by broken line circle shows shield wire.

23Component box in

wave line

This shows that another part of the component is also shown on another page (indicated by

wave line) within the system.

24 Component name

This shows the name of a component.

25 Connector number

This shows the connector number.

The letter shows which harness the connector is located in.

Example: M : main harness. For detail and to locate the connector, refer to PG section "Main

Harness", “Harness Layout”. A coordinate grid is included for complex harnesses to aid in

locating connectors.

26 Ground (GND)

The line spliced and grounded under wire color shows that ground line is spliced at the

grounded connector.

27 Ground (GND)

This shows the ground connection. For detailed ground distribution information, refer to

"Ground Distribution" in PG section.

28 Connector views

This area shows the connector faces of the components in the wiring diagram on the page.

29 Common component

Connectors enclosed in broken line show that these connectors belong to the same compo-

nent.

30 Connector color

This shows a code for the color of the connector. For code meaning, refer to wire color codes,

Number 14 of this chart.

31Fusible link and fuse

box

This shows the arrangement of fusible link(s) and fuse(s), used for connector views of

"POWER SUPPLY ROUTING" in PG section.

The open square shows current flow in, and the shaded square shows current flow out.

32 Reference area

This shows that more information on the Super Multiple Junction (SMJ) and Joint Connectors

(J/C) exists on the PG section. Refer to "Reference Area" for details. Num-

berItem Description

Page 3645 of 5621

IDX-4

ALPHABETICAL INDEX

Electronic ignition (EI) system ............. EC-33, EC-743

Engine control module (ECM) .......... EC-496, EC-1215

Engine control system diagram ........... EC-30, EC-740

Engine coolant temperature sensor (ECTS) ... EC-226,

EC-238

, EC-948, EC-961

Engine coolant(VK45DE) .................................. CO-40

Engine coolant(VQ35DE) ................................. CO-11

Engine oil filter replacement ............................. MA-26

Engine oil filter replacement(VQ35DE) ............. MA-19

Engine oil precautions .......................................... GI-8

Engine oil replacement(VQ35DE) ..................... MA-18

Engine oil(VK45DE) ........................................... LU-26

Engine oil(VQ35DE) ............................................ LU-7

Engine removal(VK45DE) ............................... EM-244

Engine removal(VQ35DE) .............................. EM-113

Engine room cover ............................................ EM-14

Engine room cover(VK45DE) ......................... EM-173

ETC1 - Wiring diagram .................... EC-614, EC-1345

ETC2 - Wiring diagram .................... EC-609, EC-1340

ETC3 - Wiring diagram .................... EC-620, EC-1352

EVAP canister ...................................... EC-42, EC-752

EVAP canister purge volume control solenoid valve ....

EC-412

, EC-420, EC-1132, EC-1140

EVAP canister vent control valve ...... EC-427, EC-434,

EC-1147

, EC-1154

EVAP control system (small leak) diagnosis .. EC-403,

EC-466

, EC-1124, EC-1185

EVAP control system pressure sensor ........... EC-440,

EC-443

, EC-450, EC-1160, EC-1163, EC-1170

EVAP control system purge flow monitoring diagnosis

EC-398

, EC-1119

EVAP vapor lines inspection ................. MA-21, MA-28

Evaporative emission (EVAP) system . EC-39, EC-749

Evaporator ..................................................... ATC-168

Exhaust manifold(VK45DE) ............................ EM-183

Exhaust system ................................................... EX-3

Exhaust system inspection ..................... EX-3, MA-29

Expansion valve ............................................. ATC-169

F

F/FOG - Wiring diagram ................................... LT-197

F/PUMP - Wiring diagram ................ EC-686, EC-1428

Final drive pre-inspection .................. FFD-16, RFD-19

Final drive removal and installation .. FFD-13, RFD-16

Floor trim ............................................................. EI-50

Flow charts ......................................................... GI-28

Fluid temperature sensor (A/T) ........................ AT-135

Fluorescent leak detector .............................. ATC-170

FPCM - Wiring diagram ................... EC-527, EC-1253

Freeze frame data ............................... EC-59, EC-770

Front brake solenoid valve ................. AT-151, AT-153

Front bumper ...................................................... EI-11

Front combination lamp removal and installation LT-76

Front door ............................. BL-190, BL-196, GW-63

Front passenger air bag .................................. SRS-42

Front seat belt .................................................... SB-30

Front seat belt pre-tensioner ..... SB-2, SRS-3, SRS-47

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-136

FTTS - Wiring diagram .... EC-345, EC-350, EC-1068,

EC-1073

Fuel cut control (at no load high engine speed) EC-34,

EC-744

Fuel filter replacement ......................................... FL-4

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injection system (Bank 2) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injector ................................................... EC-1420

Fuel injector and fuel tube(VK45DE) .............. EM-193

Fuel injector and fuel tube(VQ35DE) ................ EM-45

Fuel level sensor EC-475, EC-477, EC-479, EC-1194,

EC-1196

, EC-1198

Fuel line inspection .................................. FL-3, MA-25

Fuel line inspection(VQ35DE) .......................... MA-18

Fuel precautions ................................................... GI-6

Fuel pressure check ........................... EC-98, EC-809

Fuel pressure release ......................... EC-98, EC-809

Fuel pump ....................................... EC-685, EC-1427

Fuel pump and gauge .......................................... FL-4

Fuel pump control module .............. EC-525, EC-1251

Fuel pump dropping resistor ........... EC-525, EC-1251

Fuel system ......................................................... FL-3

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor .......... EC-343, EC-349,

EC-1066

, EC-1072

Fuel tank vacuum relief valve ............. EC-42, EC-752

FUELB1 - Wiring diagram EC-323, EC-334, EC-1046,

EC-1057

FUELB2 - Wiring diagram EC-325, EC-336, EC-1048,

EC-1059

Fuse .................................................................. PG-17

Fuse and fusible link box ................................ PG-112

Fusible link ........................................................ PG-17

G

Gauges ................................................................. DI-5

Generator ........................................................... SC-23

Generator - See Alternator ................................ SC-23

Glass ........................ GW-11, GW-61, GW-63, GW-67

Grille - See Exterior ............................................ EI-16

Ground distribution ........................................... PG-46

H

H/LAMP - Wiring diagram ....................... LT-13

, LT-48

Harness connector .......................................... PG-102

Harness layout .................................................. PG-63

Hazard warning lamp ....................................... LT-211

Headlamp removal and installation .................... LT-76

Headlining - See Roof trim .................................. EI-52

Heated oxygen sensor 2 (bank 1) .... EC-286, EC-297,

EC-310

, EC-1009, EC-1020, EC-1033

Heated oxygen sensor 2 (bank 2) .... EC-286, EC-297,

Page 4466 of 5621

HEADLAMP (FOR USA) - CONVENTIONAL TYPE -

LT-39

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aiming.

Use the aiming chart shown in the figure.

Basic illumination area for adjustment should be within the range shown on the aiming chart.

Adjust headlamp accordingly.

Bulb ReplacementNKS003OH

HEADLAMP (INNER) HIGH BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

4. Remove washer tank inlet when replacing bulb RH. Refer to WW-47, "

Removal and Installation of Washer

Ta n k" .

5. Turn plastic cap counterclockwise and unlock it.

6. Turn bulb socket counterclockwise and unlock it.

7. Disconnect connector, and remove bulb.

SKIB4153E

Headlamp (inner) high beam : 12V - 60W (HB3)

Page 4502 of 5621

HEADLAMP (FOR USA) - XENON TYPE -

LT-75

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

ADJUSTMENT USING AN ADJUSTMENT SCREEN (LIGHT/DARK BORDERLINE)

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aiming.

Use the aiming chart shown in the figure.

Basic illumination area for adjustment should be within the range shown on the aiming chart.

Adjust headlamp accordingly.

Bulb ReplacementNKS003P6

HEADLAMP (INNER) HIGH BEAM

1. Turn lighting switch OFF.

2. Disconnect negative battery cable or remove circuit fuse.

3. Remove air cleaner case when replacing bulb LH. Refer to EM-17, "

Removal and Installation" (VQ35) or

EM-177, "

Removal and Installation" (VK45).

4. Remove washer tank inlet when replacing bulb RH. Refer to WW-47, "

Removal and Installation of Washer

Ta n k" .

5. Turn plastic cap counterclockwise and unlock it.

6. Turn bulb socket counterclockwise and unlock it.

7. Disconnect connector, and remove bulb.

SKIB4153E

Headlamp (inner) high beam : 12V - 60W (HB3)

Page 4828 of 5621

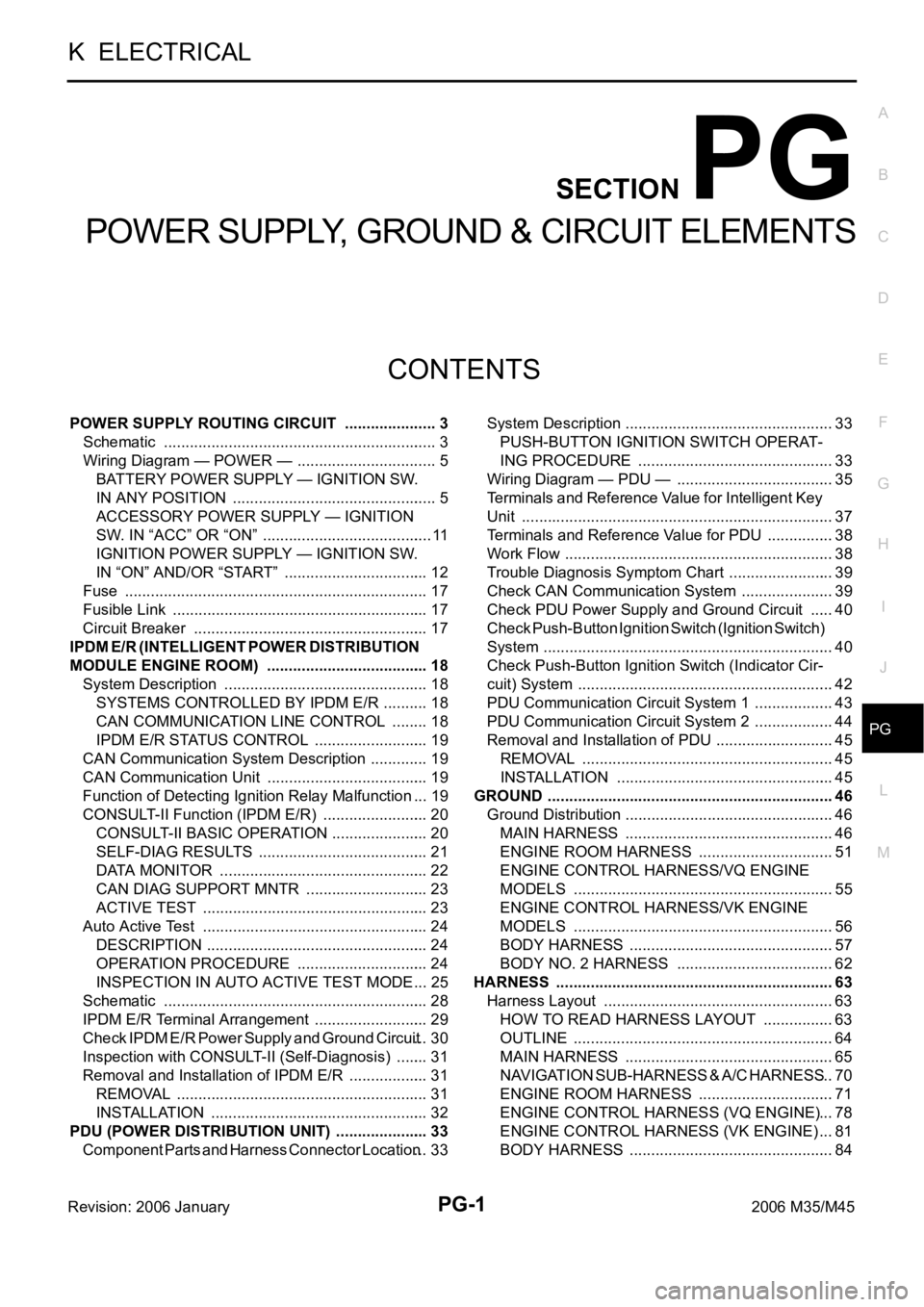

PG-1

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION PG

A

B

PG

Revision: 2006 January2006 M35/M45

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

POWER SUPPLY ROUTING CIRCUIT ...................... 3

Schematic ................................................................ 3

Wiring Diagram — POWER — ................................. 5

BATTERY POWER SUPPLY — IGNITION SW.

IN ANY POSITION ................................................ 5

ACCESSORY POWER SUPPLY — IGNITION

SW. IN “ACC” OR “ON” ........................................ 11

IGNITION POWER SUPPLY — IGNITION SW.

IN “ON” AND/OR “START” .................................. 12

Fuse ....................................................................... 17

Fusible Link ............................................................ 17

Circuit Breaker ....................................................... 17

IPDM E/R (INTELLIGENT POWER DISTRIBUTION

MODULE ENGINE ROOM) ...................................... 18

System Description ................................................ 18

SYSTEMS CONTROLLED BY IPDM E/R ........... 18

CAN COMMUNICATION LINE CONTROL ......... 18

IPDM E/R STATUS CONTROL ........................... 19

CAN Communication System Description .............. 19

CAN Communication Unit ...................................... 19

Function of Detecting Ignition Relay Malfunction ... 19

CONSULT-II Function (IPDM E/R) ......................... 20

CONSULT-II BASIC OPERATION ....................... 20

SELF-DIAG RESULTS ........................................ 21

DATA MONITOR ................................................. 22

CAN DIAG SUPPORT MNTR ............................. 23

ACTIVE TEST ..................................................... 23

Auto Active Test ..................................................... 24

DESCRIPTION .................................................... 24

OPERATION PROCEDURE ............................... 24

INSPECTION IN AUTO ACTIVE TEST MODE ... 25

Schematic .............................................................. 28

IPDM E/R Terminal Arrangement ........................... 29

Check IPDM E/R Power Supply and Ground Circuit ... 30

Inspection with CONSULT-II (Self-Diagnosis) ........ 31

Removal and Installation of IPDM E/R ................... 31

REMOVAL ........................................................

... 31

INSTALLATION ................................................... 32

PDU (POWER DISTRIBUTION UNIT) ...................... 33

Component Parts and Harness Connector Location ... 33System Description ................................................. 33

PUSH-BUTTON IGNITION SWITCH OPERAT-

ING PROCEDURE .............................................. 33

Wiring Diagram — PDU — ..................................... 35

Terminals and Reference Value for Intelligent Key

Unit ......................................................................... 37

Terminals and Reference Value for PDU ................ 38

Work Flow ............................................................... 38

Trouble Diagnosis Symptom Chart ......................... 39

Check CAN Communication System ...................... 39

Check PDU Power Supply and Ground Circuit ...... 40

Check Push-Button Ignition Switch (Ignition Switch)

System .................................................................... 40

Check Push-Button Ignition Switch (Indicator Cir-

cuit) System ............................................................ 42

PDU Communication Circuit System 1 ................... 43

PDU Communication Circuit System 2 ................... 44

Removal and Installation of PDU ............................ 45

REMOVAL ........................................................

... 45

INSTALLATION ................................................... 45

GROUND ................................................................... 46

Ground Distribution ................................................. 46

MAIN HARNESS ................................................. 46

ENGINE ROOM HARNESS ................................ 51

ENGINE CONTROL HARNESS/VQ ENGINE

MODELS ............................................................. 55

ENGINE CONTROL HARNESS/VK ENGINE

MODELS ............................................................. 56

BODY HARNESS ................................................ 57

BODY NO. 2 HARNESS ..................................... 62

HARNESS ................................................................. 63

Harness Layout ...................................................... 63

HOW TO READ HARNESS LAYOUT ................. 63

OUTLINE ............................................................. 64

MAIN HARNESS ................................................. 65

NAVIGATION SUB-HARNESS & A/C HARNESS ... 70

ENGINE ROOM HARNESS ................................ 71

ENGINE CONTROL HARNESS (VQ ENGINE) ... 78

ENGINE CONTROL HARNESS (VK ENGINE) ... 81

BODY HARNESS ................................................ 84