differential INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5 of 5621

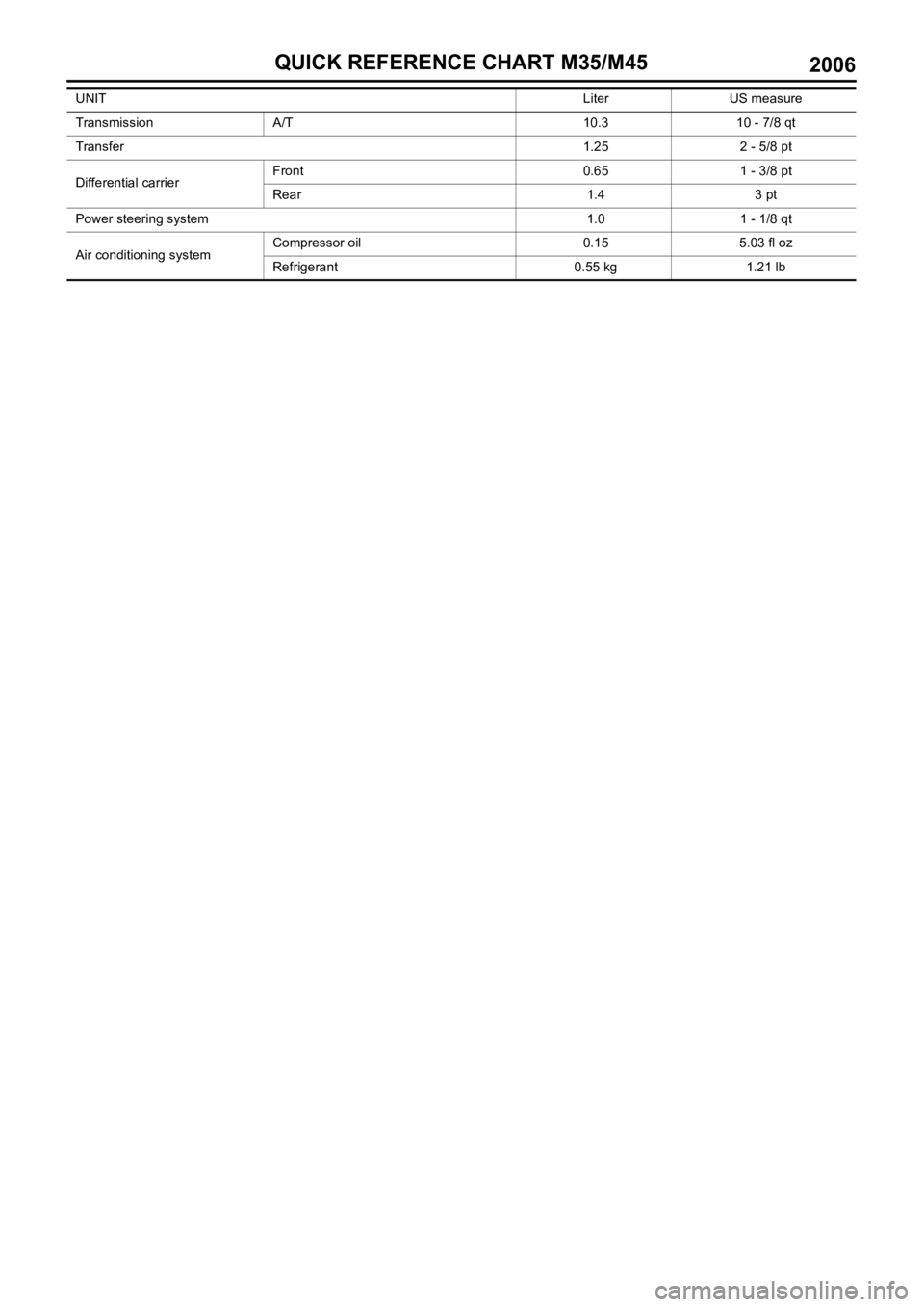

QUICK REFERENCE CHART M35/M45

Transmission A/T 10.3 10 - 7/8 qt

Transfer1.25 2 - 5/8 pt

Differential carrierFront 0.65 1 - 3/8 pt

Rear 1.4 3 pt

Power steering system 1.0 1 - 1/8 qt

Air conditioning systemCompressor oil 0.15 5.03 fl oz

Refrigerant 0.55 kg 1.21 lb UNITLiter US measure

2006

Page 1225 of 5621

BL-286

BODY REPAIR

Revision: 2006 January2006 M35/M45

1. Front strut housing

2. Upper front hoodledge

3. Upper rear hoodledge

4. Hoodledge reinforcement

5. Upper dash assembly

6. Upper dash crossmember assembly

7. Harness clamp bracket

8. Cowl top

9. Lower center dash crossmember reinforcement

10. Lower dash crossmember reinforcement

11. Lower dash crossmember assembly (LH)

12. Lower dash crossmember (RH)

13. Front crossmember center

14. Steering column mounting reinforcement

15. Lower dash

16. Front floor center

17. Front floor

18. Inner sill

19. Rear seat crossmember reinforcement assembly

20. Front carpet bracket

21. Rear floor front

22. Rear floor seat belt anchor reinforcement

23. Rear seat reclining device bracket

24. Rear floor rear

25. Differential mounting bracket assembly

26. Rear floor side assembly

27. Rear bumper side stay

28. Front side member assembly

29. Front side member front extension

30. Front side member closing plate assembly

31. Front side member front closing plate

32. Front side member center closing plate

33. Front suspension mounting bracket

34. Front side member rear extension

35. Front side member rear reinforcement

36. Front side member outrigger assembly

37. Rear seat crossmember

38. 2ND rear crossmember

39. Rear crossmember

40. Rear side member assembly

41. Rear side member extension

Page 1273 of 5621

BL-334

BODY REPAIR

Revision: 2006 January2006 M35/M45

Change parts

Rear floor rearDifferential mounting bracket assembly

Page 1280 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

BR-5

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNFS000OR

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: Applicable Reference page

BR-23

, BR-29

BR-23

, BR-29

BR-23

, BR-29

—

—

BR-28

, BR-34

—

—

—

BR-28

, BR-34

—

NVH in PR section

NHV in RFD section

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in PS section

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKENoiseShake

Shimmy, Judder

Page 3213 of 5621

![INFINITI M35 2006 Factory Service Manual EM-150

[VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

Standard and LimitNBS004O4

GENERAL SPECIFICATIONS

Cylinder arran INFINITI M35 2006 Factory Service Manual EM-150

[VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

Standard and LimitNBS004O4

GENERAL SPECIFICATIONS

Cylinder arran](/img/42/57023/w960_57023-3212.png)

EM-150

[VQ35DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

Standard and LimitNBS004O4

GENERAL SPECIFICATIONS

Cylinder arrangementV-6

Displacement cm

3 (cu in)3,498 (213.45)

Bore and stroke mm (in)95.5 x 81.4 (3.76 x 3.205)

Valve arrangementDOHC

Firing order1-2-3-4-5-6

Number of piston ringsCompression 2

Oil 1

Number of main bearings4

Compression ratio10.3

Compression pressure

kPa (kg/cm

2 , psi)/300 rpmStandard 1,275 (13.0, 185)

Minimum 981 (10.0, 142)

Differential limit between cylinders 98 (1.0, 14)

Cylinder number

Va l v e t i m i n g

(Intake valve timing control - “OFF”)

Unit: degree

abcde f

240 238

664 8 52

SEM713A

PBIC0187E

Page 3339 of 5621

![INFINITI M35 2006 Factory Service Manual EM-276

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004PQ

GENERAL SPECIFICATIONS

DRIVE BELTS

IN INFINITI M35 2006 Factory Service Manual EM-276

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004PQ

GENERAL SPECIFICATIONS

DRIVE BELTS

IN](/img/42/57023/w960_57023-3338.png)

EM-276

[VK45DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Standard and LimitNBS004PQ

GENERAL SPECIFICATIONS

DRIVE BELTS

INTAKE MANIFOLD AND EXHAUST MANIFOLD

Unit: mm (in) Cylinder arrangementV-8

Displacement cm

3 (cu in)4,494 (274.22)

Bore and stroke mm (in)93 x 82.7 (3.66 x 3.256)

Valve arrangementDOHC

Firing order1-8-7-3-6-5-4-2

Number of piston ringsCompression 2

Oil 1

Number of main bearings5

Compression ratio10.5

Compression pressure

kPa (kg/cm

2 , psi)/300 rpmStandard 1,320 (13.5, 191)

Minimum 1,130 (11.5, 164)

Differential limit

between cylinders98 (1.0, 14)

Cylinder number

Va l v e t i m i n g

Unit: degree

abcde f

228 240 -2 62 4 44

SEM957C

PBIC0187E

Tension of drive belts Auto adjustment by auto tensioner

Items Limit

Surface distortionIntake manifold (upper) 0.1 (0.004)

Intake manifold (lower) 0.1 (0.004)

Exhaust manifold 0.3 (0.012)

Page 3378 of 5621

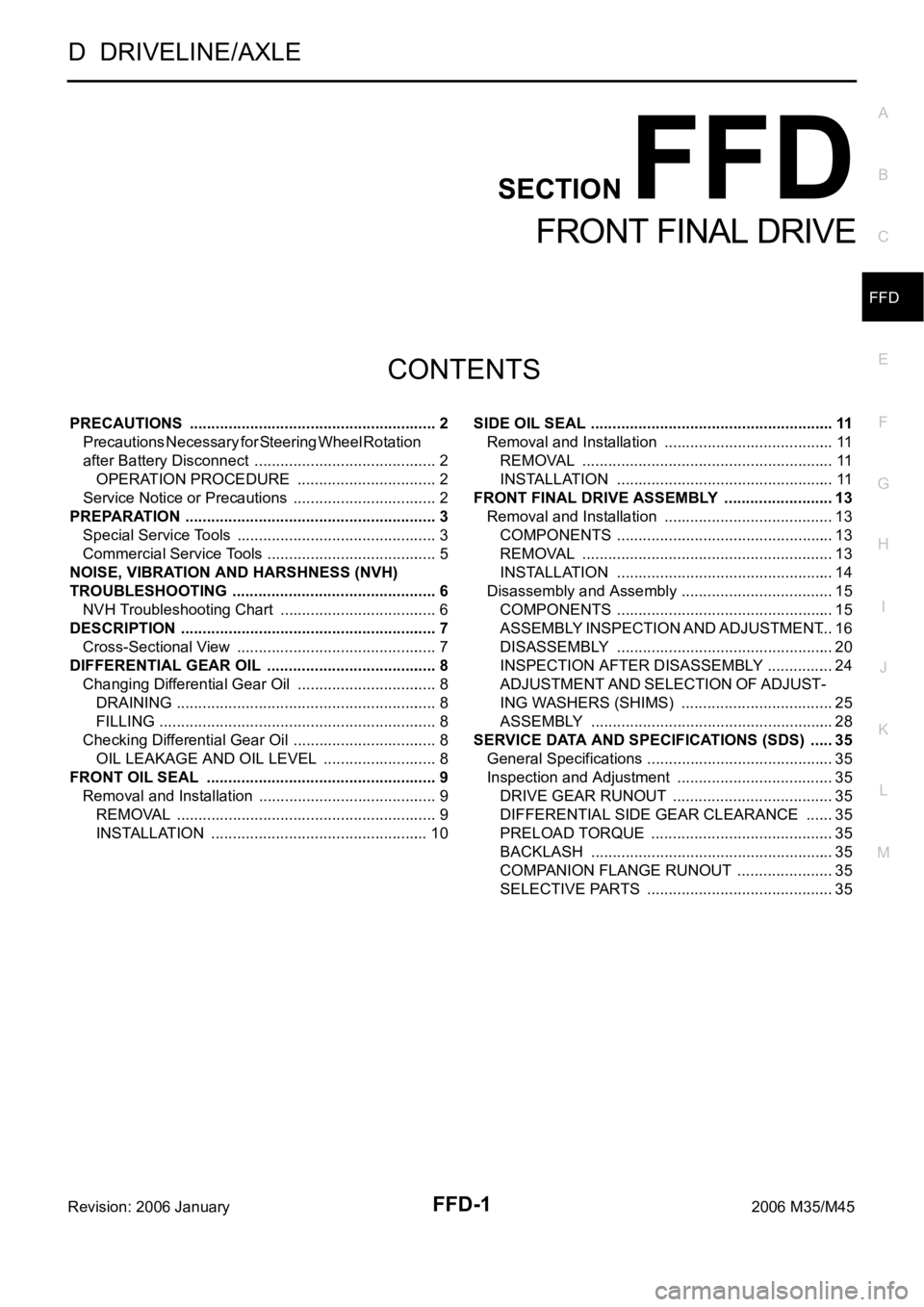

FFD-1

FRONT FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION FFD

A

B

FFD

Revision: 2006 January2006 M35/M45

FRONT FINAL DRIVE

PRECAUTIONS .......................................................... 2

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 2

OPERATION PROCEDURE ................................. 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ............................................................ 7

Cross-Sectional View ............................................... 7

DIFFERENTIAL GEAR OIL ........................................ 8

Changing Differential Gear Oil ................................. 8

DRAINING ............................................................. 8

FILLING ................................................................. 8

Checking Differential Gear Oil .................................. 8

OIL LEAKAGE AND OIL LEVEL ........................... 8

FRONT OIL SEAL .................................................

..... 9

Removal and Installation .......................................... 9

REMOVAL ........................................................

..... 9

INSTALLATION ................................................... 10SIDE OIL SEAL ......................................................... 11

Removal and Installation ........................................ 11

REMOVAL ........................................................

... 11

INSTALLATION ................................................... 11

FRONT FINAL DRIVE ASSEMBLY .......................... 13

Removal and Installation ........................................ 13

COMPONENTS ................................................... 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 14

Disassembly and Assembly .................................... 15

COMPONENTS ................................................... 15

ASSEMBLY INSPECTION AND ADJUSTMENT ... 16

DISASSEMBLY ................................................... 20

INSPECTION AFTER DISASSEMBLY ................ 24

ADJUSTMENT AND SELECTION OF ADJUST-

ING WASHERS (SHIMS) .................................... 25

ASSEMBLY ......................................................... 28

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

General Specifications ......................................... ... 35

Inspection and Adjustment ..................................... 35

DRIVE GEAR RUNOUT ...................................... 35

DIFFERENTIAL SIDE GEAR CLEARANCE ....... 35

PRELOAD TORQUE ........................................... 35

BACKLASH ......................................................... 35

COMPANION FLANGE RUNOUT ....................... 35

SELECTIVE PARTS ............................................ 35

Page 3381 of 5621

FFD-4

PREPARATION

Revision: 2006 January2006 M35/M45

KV10111100

(J-37228)

Seal cutterRemoving carrier cover

ST3306S001

(J-22888-D)

Differential side bearing puller set

1: ST33051001

(J-22888-20)

Puller

2: ST33061000

(J-8107-2)

Base

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.Removing and installing side bearing inner

race

ST30031000

(J-22912-01)

ReplacerRemoving pinion rear bearing inner race

KV31103000

(J-38982)

Drift

a: 49 mm (1.93 in) dia.

b: 70 mm (2.76 in) dia.Installing side bearing outer race

ST30611000

(J-25742-1)

Drift barInstalling side bearing outer race (Use with

KV31103000)

ST37820000

(—)

Drift

a: 39 mm (1.54 in) dia.

b: 72 mm (2.83 in) dia.Installing pinion front and rear bearing outer

race

ST33230000

(J-25805-01)

Drift

a: 51 mm (2.01 in) dia.

b: 41 mm (1.61 in) dia.

c: 28.5 mm (1.122 in) dia.Installing side bearing inner race Tool number

(Kent-Moore No.)

Tool nameDescription

S-NT046

NT072

ZZA0700D

ZZA1113D

S-NT090

ZZA0836D

ZZA1046D

Page 3383 of 5621

FFD-6

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000EO

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

Refer to FFD-24, "

INSPECTION AFTER DISASSEMBLY

" .

Refer to FFD-17, "

Tooth Contact

" .

Refer to FFD-24, "

INSPECTION AFTER DISASSEMBLY

" .

Refer to FFD-19, "

Backlash

" .

Refer to FFD-19, "

Companion Flange Runout

" .

Refer to FFD-8, "

Checking Differential Gear Oil

" .

NVH in PR section.

NVH in FAX, RAX, FSU and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in FAX and RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise

Page 3384 of 5621

DESCRIPTION

FFD-7

C

E

F

G

H

I

J

K

L

MA

B

FFD

Revision: 2006 January2006 M35/M45

DESCRIPTIONPFP:00000

Cross-Sectional ViewNDS000EP

1. Side retainer 2. Side bearing 3. Differential case

4. Drive gear 5. Pinion mate shaft 6. Pinion mate gear

7. Side gear 8. Side shaft 9. Gear carrier

10. Drive pinion 11. Companion flange 12. Pinion front bearing

13. Pinion rear bearing 14. Extension tube retainer 15. Engine assembly

PDIA0647E