load capacity INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 470 of 5621

REFRIGERATION SYSTEM

ATC-23

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

Operation

1. Control Valve

–By changing high-pressure valve lift amount, built-in electronic control valve executes the following:

• Controls high-pressure valve discharge amount.

• Changes crankcase pressure in compressor.

• Changes angle of swash plate.

–Amount of high-pressure valve lift is determined by factors below.

• Low-pressure applied to diaphragm

• Spring load of set spring

• Balance of magnetic force generated in magnet coil

–Electronic control valve (ECV) magnet coil receives electric signal (duty control) from unified meter and A/

C amp. Then, magnetic force generated by electric current is changed to control high-pressure valve lift

amount.

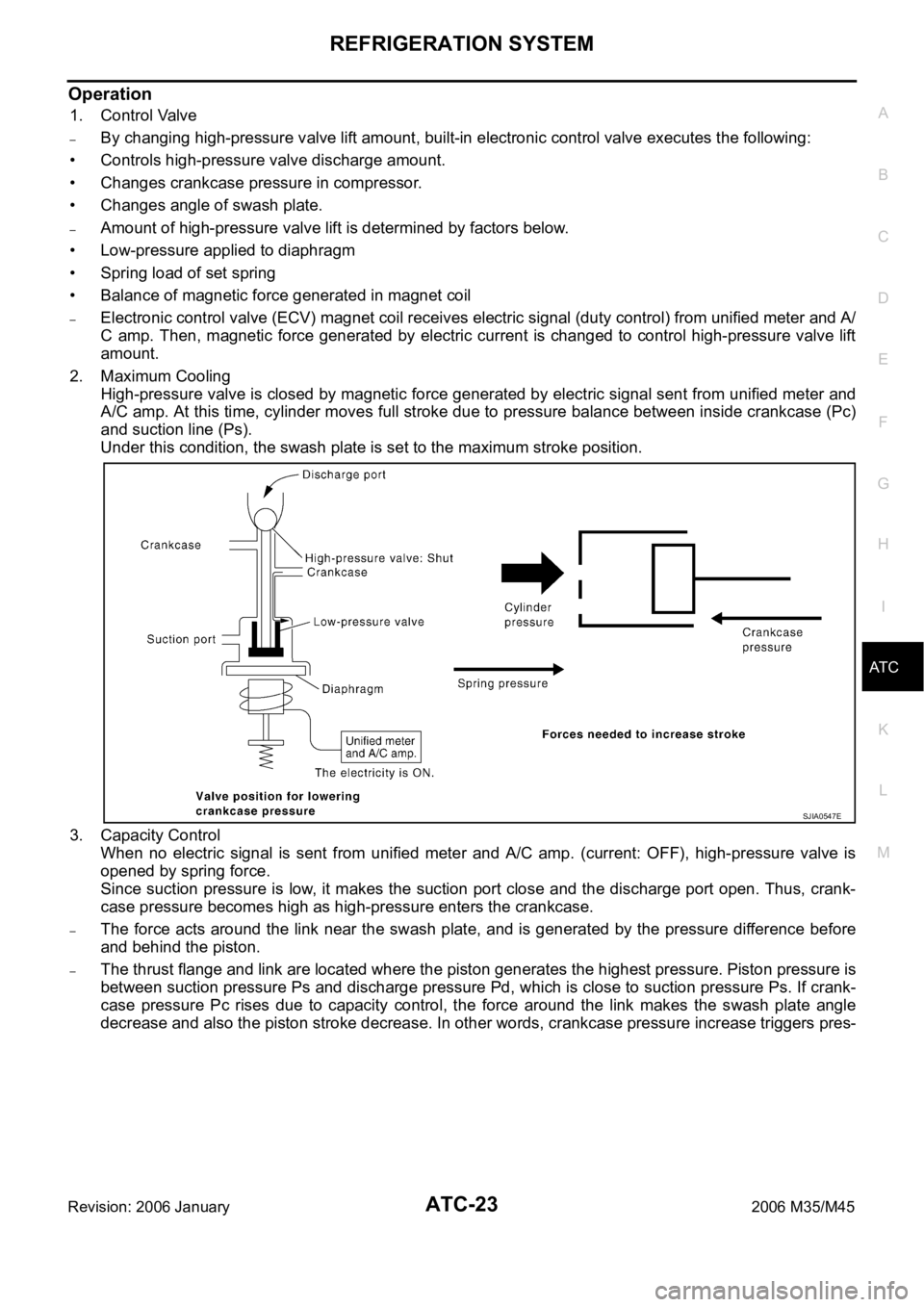

2. Maximum Cooling

High-pressure valve is closed by magnetic force generated by electric signal sent from unified meter and

A/C amp. At this time, cylinder moves full stroke due to pressure balance between inside crankcase (Pc)

and suction line (Ps).

Under this condition, the swash plate is set to the maximum stroke position.

3. Capacity Control

When no electric signal is sent from unified meter and A/C amp. (current: OFF), high-pressure valve is

opened by spring force.

Since suction pressure is low, it makes the suction port close and the discharge port open. Thus, crank-

case pressure becomes high as high-pressure enters the crankcase.

–The force acts around the link near the swash plate, and is generated by the pressure difference before

and behind the piston.

–The thrust flange and link are located where the piston generates the highest pressure. Piston pressure is

between suction pressure Ps and discharge pressure Pd, which is close to suction pressure Ps. If crank-

case pressure Pc rises due to capacity control, the force around the link makes the swash plate angle

decrease and also the piston stroke decrease. In other words, crankcase pressure increase triggers pres-

SJIA0547E

Page 1829 of 5621

![INFINITI M35 2006 Factory Service Manual EC-286

[VQ35DE]

DTC P0137, P0157 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0137, P0157 HO2S2PFP:226A0

Component DescriptionNBS004X1

The heated oxygen sensor 2, after three way catalyst 1, monitors INFINITI M35 2006 Factory Service Manual EC-286

[VQ35DE]

DTC P0137, P0157 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0137, P0157 HO2S2PFP:226A0

Component DescriptionNBS004X1

The heated oxygen sensor 2, after three way catalyst 1, monitors](/img/42/57023/w960_57023-1828.png)

EC-286

[VQ35DE]

DTC P0137, P0157 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0137, P0157 HO2S2PFP:226A0

Component DescriptionNBS004X1

The heated oxygen sensor 2, after three way catalyst 1, monitors the

oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeNBS004X2

Specification data are reference values.

On Board Diagnosis LogicNBS004X3

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst 1 causes the longer

switching time. To judge the malfunctions of heated oxygen sensor

2, ECM monitors whether the maximum voltage of the sensor is suf-

ficiently high during the various driving condition such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

HO2S2 (B2)

Engine: After warming up

After keeping engine speed

between 3,500 and 4,000 rpm for

1 minute and at idle for 1 minute

under no loadRevving engine from idle up to 3,000 rpm

quickly.0 - 0.3V

Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN

RICH

PBIB2030E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0137

0137

(Bank 1)

Heated oxygen sensor

2 circuit low voltageThe maximum voltage from the sensor is not

reached to the specified voltage.

Harness or connectors

(The sensor circuit is open or shorted)

Heated oxygen sensor 2

Fuel pressure

Fuel injector

Intake air leaks P0157

0157

(Bank 2)

Page 1840 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P0138, P0158 HO2S2

EC-297

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0138, P0158 HO2S2PFP:226A0

Component DescriptionNBS004XA

The heated oxygen sensor 2, after thre INFINITI M35 2006 Factory Service Manual DTC P0138, P0158 HO2S2

EC-297

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0138, P0158 HO2S2PFP:226A0

Component DescriptionNBS004XA

The heated oxygen sensor 2, after thre](/img/42/57023/w960_57023-1839.png)

DTC P0138, P0158 HO2S2

EC-297

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0138, P0158 HO2S2PFP:226A0

Component DescriptionNBS004XA

The heated oxygen sensor 2, after three way catalyst 1, monitors the

oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeNBS004XB

Specification data are reference values.

On Board Diagnosis LogicNBS004XC

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capacity of the three way catalyst 1 causes the longer switching time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the voltage is unusually high during the various driving con-

dition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the minimum voltage of sensor is sufficiently low during the

various driving condition such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

HO2S2 (B2)

Engine: After warming up

After keeping engine speed

between 3,500 and 4,000 rpm for

1 minute and at idle for 1 minute

under no loadRevving engine from idle up to 3,000 rpm

quickly.0 - 0.3V

Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN

RICH

PBIB1848E

PBIB2376E

Page 1853 of 5621

![INFINITI M35 2006 Factory Service Manual EC-310

[VQ35DE]

DTC P0139, P0159 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0139, P0159 HO2S2PFP:226A0

Component DescriptionNBS004XJ

The heated oxygen sensor 2, after three way catalyst 1, monitors INFINITI M35 2006 Factory Service Manual EC-310

[VQ35DE]

DTC P0139, P0159 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0139, P0159 HO2S2PFP:226A0

Component DescriptionNBS004XJ

The heated oxygen sensor 2, after three way catalyst 1, monitors](/img/42/57023/w960_57023-1852.png)

EC-310

[VQ35DE]

DTC P0139, P0159 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0139, P0159 HO2S2PFP:226A0

Component DescriptionNBS004XJ

The heated oxygen sensor 2, after three way catalyst 1, monitors the

oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeNBS004XK

Specification data are reference values.

On Board Diagnosis LogicNBS004XL

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst 1 causes the longer

switching time. To judge the malfunctions of heated oxygen sensor

2, ECM monitors whether the switching response of the sensor's

voltage is faster than specified during the various driving condition

such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

HO2S2 (B2)

Engine: After warming up

After keeping engine speed

between 3,500 and 4,000 rpm for

1 minute and at idle for 1 minute

under no loadRevving engine from idle up to 3,000 rpm

quickly.0 - 0.3V

Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN

RICH

SEF302U

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0139

0139

(Bank 1)

Heated oxygen sensor

2 circuit slow responseIt takes more time for the sensor to respond

between rich and lean than the specified time.

Harness or connectors

(The sensor circuit is open or shorted)

Heated oxygen sensor 2

Fuel pressure

Fuel injector

Intake air leaks P0159

0159

(Bank 2)

Page 1935 of 5621

![INFINITI M35 2006 Factory Service Manual EC-392

[VQ35DE]

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

Revision: 2006 January2006 M35/M45

DTC P0420, P0430 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicNBS004ZC

The ECM monitors INFINITI M35 2006 Factory Service Manual EC-392

[VQ35DE]

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

Revision: 2006 January2006 M35/M45

DTC P0420, P0430 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicNBS004ZC

The ECM monitors](/img/42/57023/w960_57023-1934.png)

EC-392

[VQ35DE]

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

Revision: 2006 January2006 M35/M45

DTC P0420, P0430 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicNBS004ZC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F) sensor 1 and heated oxygen sensor 2.

A three way catalyst 1 with high oxygen storage capacity will indicate a low switching frequency of heated oxy-

gen sensor 2. As oxygen storage capacity decreases, the heated oxygen sensor 2 switching frequency will

increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor 2 approaches a specified limit value, the

three way catalyst 1 malfunction is diagnosed.

DTC Confirmation ProcedureNBS004ZD

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

1. Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

2. Start engine and warm it up to the normal operating tempera-

ture.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and

4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70

C

(158

F).

If not, warm up engine and go to next step when “COOLAN

TEMP/S” indication reaches to 70

C (158F).

7. Open engine hood.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420

(Bank 1)

Catalyst system effi-

ciency below threshold

Three way catalyst (manifold) does not oper-

ate properly.

Three way catalyst (manifold) does not have

enough oxygen storage capacity.

Three way catalyst (manifold)

Exhaust tube

Intake air leaks

Fuel injector

Fuel injector leaks

Spark plug

Improper ignition timing P0430

0430

(Bank 2)

PBIB1923E

SEF189Y

Page 2552 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P0137, P0157 HO2S2

EC-1009

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0137, P0157 HO2S2PFP:226A0

Component DescriptionNBS005EI

The heated oxygen sensor 2, afte INFINITI M35 2006 Factory Service Manual DTC P0137, P0157 HO2S2

EC-1009

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0137, P0157 HO2S2PFP:226A0

Component DescriptionNBS005EI

The heated oxygen sensor 2, afte](/img/42/57023/w960_57023-2551.png)

DTC P0137, P0157 HO2S2

EC-1009

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0137, P0157 HO2S2PFP:226A0

Component DescriptionNBS005EI

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeNBS005EJ

Specification data are reference values.

On Board Diagnosis LogicNBS005EK

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the maximum voltage of the sensor

is sufficiently high during the various driving condition such as fuel-

cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

HO2S2 (B2)

Engine: After warming up

After keeping engine speed

between 3,500 and 4,000 rpm for

1 minute and at idle for 1 minute

under no loadRevving engine from idle up to 3,000 rpm

quickly.0 - 0.3V

Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN

RICH

PBIB2030E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0137

0137

(Bank 1)

Heated oxygen sensor

2 circuit low voltageThe maximum voltage from the sensor is not

reached to the specified voltage.

Harness or connectors

(The sensor circuit is open or shorted)

Heated oxygen sensor 2

Fuel pressure

Fuel injector

Intake air leaks P0157

0157

(Bank 2)

Page 2563 of 5621

![INFINITI M35 2006 Factory Service Manual EC-1020

[VK45DE]

DTC P0138, P0158 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0138, P0158 HO2S2PFP:226A0

Component DescriptionNBS005ER

The heated oxygen sensor 2, after three way catalyst ( INFINITI M35 2006 Factory Service Manual EC-1020

[VK45DE]

DTC P0138, P0158 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0138, P0158 HO2S2PFP:226A0

Component DescriptionNBS005ER

The heated oxygen sensor 2, after three way catalyst (](/img/42/57023/w960_57023-2562.png)

EC-1020

[VK45DE]

DTC P0138, P0158 HO2S2

Revision: 2006 January2006 M35/M45

DTC P0138, P0158 HO2S2PFP:226A0

Component DescriptionNBS005ER

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeNBS005ES

Specification data are reference values.

On Board Diagnosis LogicNBS005ET

The heated oxygen sensor 2 has a much longer switching time between rich and lean than the air fuel ratio (A/

F) sensor 1. The oxygen storage capacity of the three way catalyst (manifold) causes the longer switching

time.

MALFUNCTION A

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the voltage is unusually high during the various driving con-

dition such as fuel-cut.

MALFUNCTION B

To judge the malfunctions of heated oxygen sensor 2, ECM monitors

whether the minimum voltage of sensor is sufficiently low during the

various driving condition such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

HO2S2 (B2)

Engine: After warming up

After keeping engine speed

between 3,500 and 4,000 rpm for

1 minute and at idle for 1 minute

under no loadRevving engine from idle up to 3,000 rpm

quickly.0 - 0.3V

Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN

RICH

PBIB1848E

PBIB2376E

Page 2576 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P0139, P0159 HO2S2

EC-1033

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0139, P0159 HO2S2PFP:226A0

Component DescriptionNBS005F0

The heated oxygen sensor 2, afte INFINITI M35 2006 Factory Service Manual DTC P0139, P0159 HO2S2

EC-1033

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0139, P0159 HO2S2PFP:226A0

Component DescriptionNBS005F0

The heated oxygen sensor 2, afte](/img/42/57023/w960_57023-2575.png)

DTC P0139, P0159 HO2S2

EC-1033

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0139, P0159 HO2S2PFP:226A0

Component DescriptionNBS005F0

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the air fuel ratio (A/F) sensor 1

are shifted, the air-fuel ratio is controlled to stoichiometric, by the sig-

nal from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeNBS005F1

Specification data are reference values.

On Board Diagnosis LogicNBS005F2

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the air fuel ratio (A/F) sensor 1. The oxy-

gen storage capacity of the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

HO2S2 (B2)

Engine: After warming up

After keeping engine speed

between 3,500 and 4,000 rpm for

1 minute and at idle for 1 minute

under no loadRevving engine from idle up to 3,000 rpm

quickly.0 - 0.3V

Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN

RICH

SEF302U

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0139

0139

(Bank 1)

Heated oxygen sensor

2 circuit slow responseIt takes more time for the sensor to respond

between rich and lean than the specified time.

Harness or connectors

(The sensor circuit is open or shorted)

Heated oxygen sensor 2

Fuel pressure

Fuel injector

Intake air leaks P0159

0159

(Bank 2)

Page 2656 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-1113

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0420, P0430 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis Logi INFINITI M35 2006 Factory Service Manual DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-1113

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0420, P0430 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis Logi](/img/42/57023/w960_57023-2655.png)

DTC P0420, P0430 THREE WAY CATALYST FUNCTION

EC-1113

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0420, P0430 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicNBS005GS

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC Confirmation ProcedureNBS005GT

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

1. Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

2. Start engine and warm it up to the normal operating tempera-

ture.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and

4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70

C

(158

F).

If not, warm up engine and go to next step when “COOLAN

TEMP/S” indication reaches to 70

C (158F).

7. Open engine hood.

PBIB2055E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420

(Bank 1)

Catalyst system effi-

ciency below threshold

Three way catalyst (manifold) does not oper-

ate properly.

Three way catalyst (manifold) does not have

enough oxygen storage capacity.

Three way catalyst (manifold)

Exhaust tube

Intake air leaks

Fuel injector

Fuel injector leaks

Spark plug

Improper ignition timing P0430

0430

(Bank 2)

SEF189Y

Page 3188 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-125

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CAUTION:

Do not disassemble drive plate.

Never place drive plate with signal plate facing down.

When handlin INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-125

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CAUTION:

Do not disassemble drive plate.

Never place drive plate with signal plate facing down.

When handlin](/img/42/57023/w960_57023-3187.png)

CYLINDER BLOCK

EM-125

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

CAUTION:

Do not disassemble drive plate.

Never place drive plate with signal plate facing down.

When handling signal plate, take care not to damage or

scratch it.

Handle signal plate in a manner that prevents it from

becoming magnetized.

3. Lift the engine with hoist to install it onto the widely use engine stand.

CAUTION:

Use an engine stand that has a load capacity [220 kg (441 lb) or more] large enough for supporting

the engine weight.

If the load capacity of the stand is not adequate, remove the following parts beforehand to reduce the

potential risk of overturning the stand.

–Remove intake manifold collector. Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

–Remove intake manifold. Refer to EM-24, "INTAKE MANIFOLD" .

–Remove fuel injector and fuel tube assembly. Refer to EM-45, "FUEL INJECTOR AND FUEL TUBE" .

–Remove ignition coil. Refer to EM-42, "IGNITION COIL" .

–Remove rocker cover. Refer to EM-51, "ROCKER COVER" .

–Remove exhaust manifold. Refer to EM-26, "EXHAUST MANIFOLD" .

–Other removable brackets.

NOTE:

The figure shows an example of widely use engine stand that

can hold mating surface of transmission with drive plate

removed.

CAUTION:

Before removing the hanging chains, make sure the

engine stand is stable and there is no risk of overturning.

4. Drain engine oil. Refer to LU-9, "

Changing Engine Oil" .

SEM760G

PBIC0085E