center console INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 302 of 5621

SHIFT CONTROL SYSTEM

AT-223

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

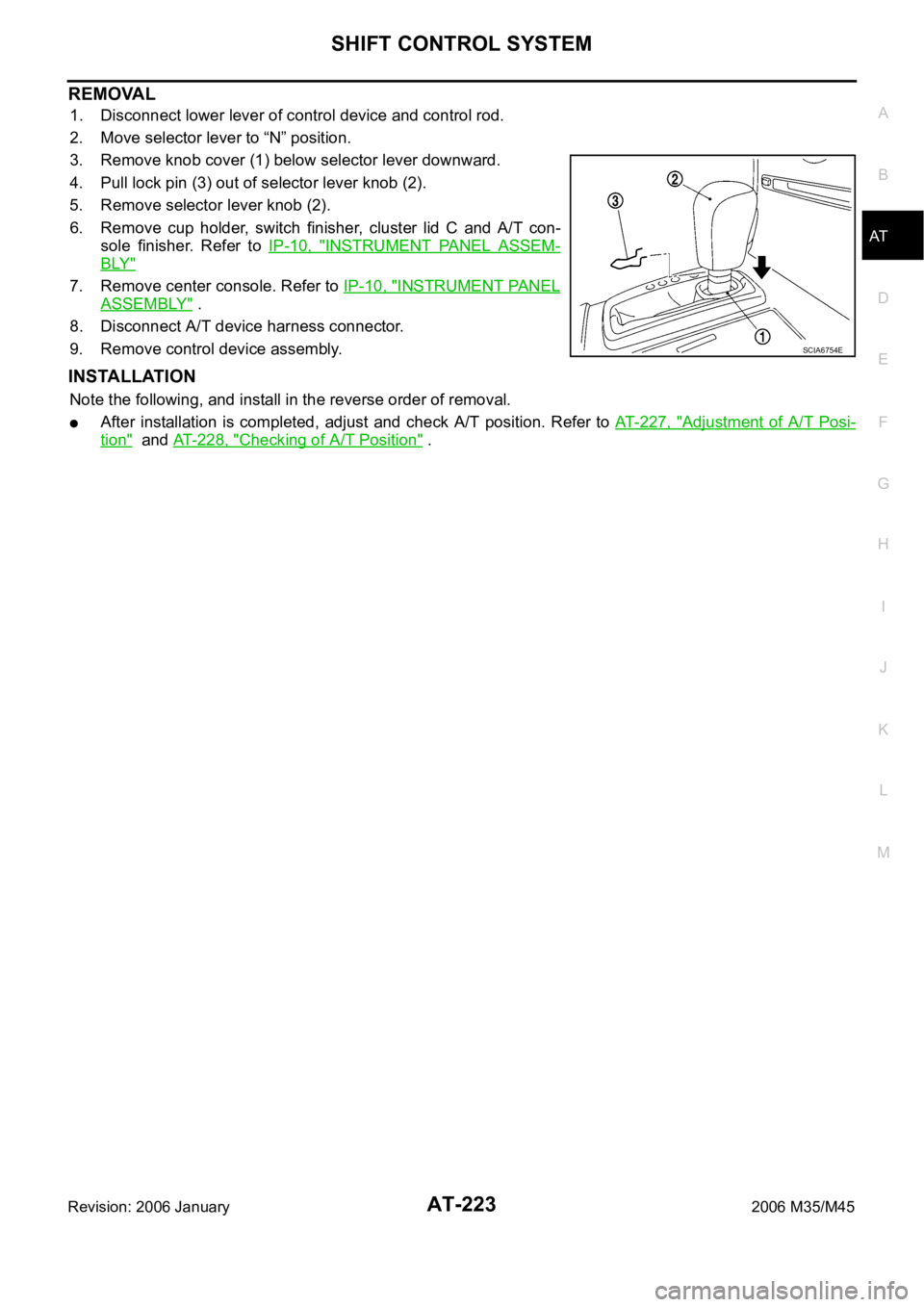

REMOVAL

1. Disconnect lower lever of control device and control rod.

2. Move selector lever to “N” position.

3. Remove knob cover (1) below selector lever downward.

4. Pull lock pin (3) out of selector lever knob (2).

5. Remove selector lever knob (2).

6. Remove cup holder, switch finisher, cluster lid C and A/T con-

sole finisher. Refer to IP-10, "

INSTRUMENT PANEL ASSEM-

BLY"

7. Remove center console. Refer to IP-10, "INSTRUMENT PANEL

ASSEMBLY" .

8. Disconnect A/T device harness connector.

9. Remove control device assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

After installation is completed, adjust and check A/T position. Refer to AT- 2 2 7 , "Adjustment of A/T Posi-

tion" and AT-228, "Checking of A/T Position" .

SCIA6754E

Page 304 of 5621

SHIFT CONTROL SYSTEM

AT-225

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

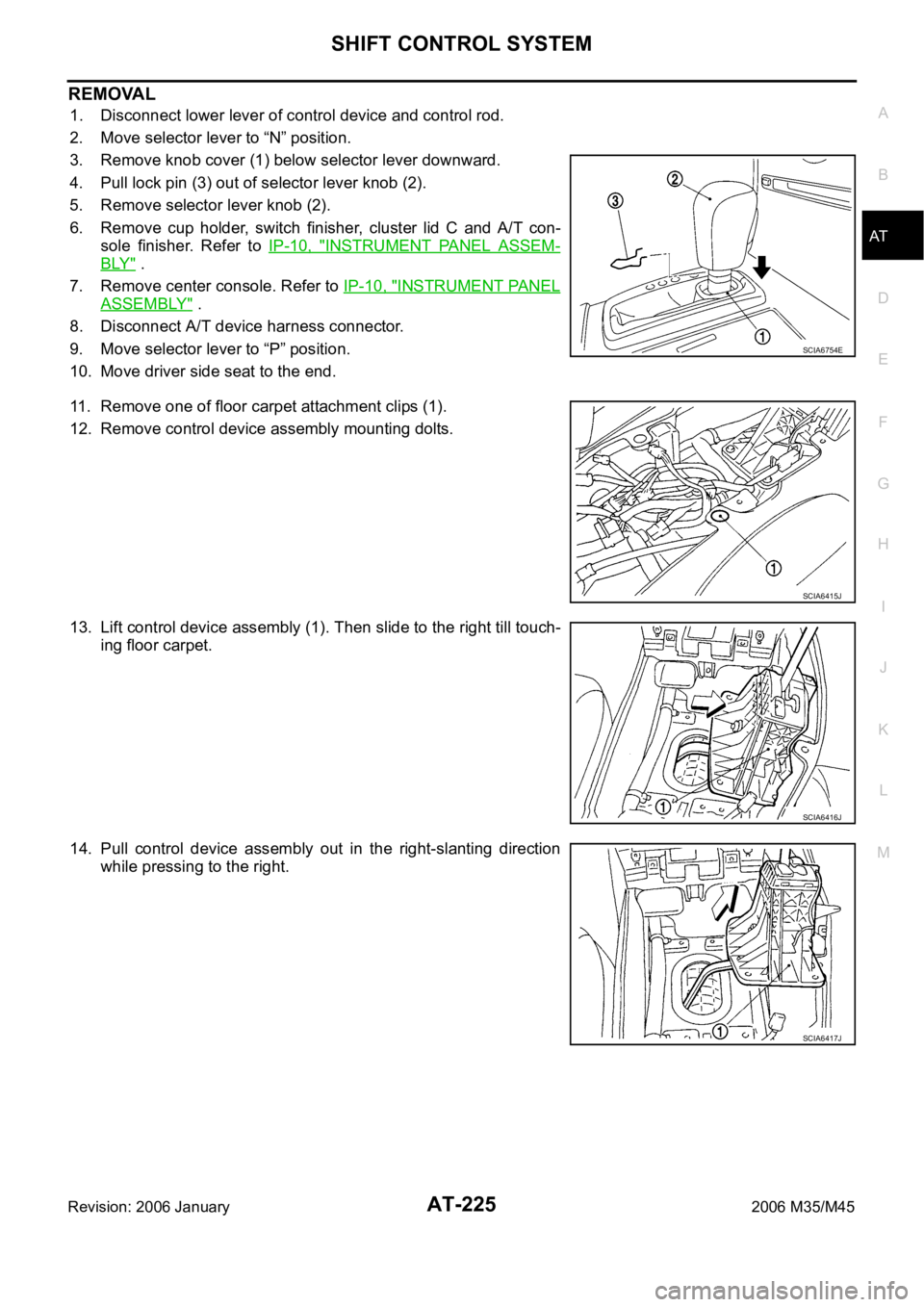

REMOVAL

1. Disconnect lower lever of control device and control rod.

2. Move selector lever to “N” position.

3. Remove knob cover (1) below selector lever downward.

4. Pull lock pin (3) out of selector lever knob (2).

5. Remove selector lever knob (2).

6. Remove cup holder, switch finisher, cluster lid C and A/T con-

sole finisher. Refer to IP-10, "

INSTRUMENT PANEL ASSEM-

BLY" .

7. Remove center console. Refer to IP-10, "

INSTRUMENT PANEL

ASSEMBLY" .

8. Disconnect A/T device harness connector.

9. Move selector lever to “P” position.

10. Move driver side seat to the end.

11. Remove one of floor carpet attachment clips (1).

12. Remove control device assembly mounting dolts.

13. Lift control device assembly (1). Then slide to the right till touch-

ing floor carpet.

14. Pull control device assembly out in the right-slanting direction

while pressing to the right.

SCIA6754E

SCIA6415J

SCIA6416J

SCIA6417J

Page 595 of 5621

ATC-148

DUCTS AND GRILLES

Revision: 2006 January2006 M35/M45

Removal of Rear Ventilator Grille

1. Remove console rear finisher. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove mounting clips, and then remove rear ventilator grille.

Removal of Rear Ventilator Ducts

1. Remove center console. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove mounting clip, and then remove rear ventilator duct 2.

3. Remove mounting clips, and then remove rear ventilator ducts

1.

4. Remove mounting screws, and then remove rear ventilator duct

3.

RJIA4139E

RJIA4140E

RJIA4141E

RJIA4142E

Page 597 of 5621

ATC-150

DUCTS AND GRILLES

Revision: 2006 January2006 M35/M45

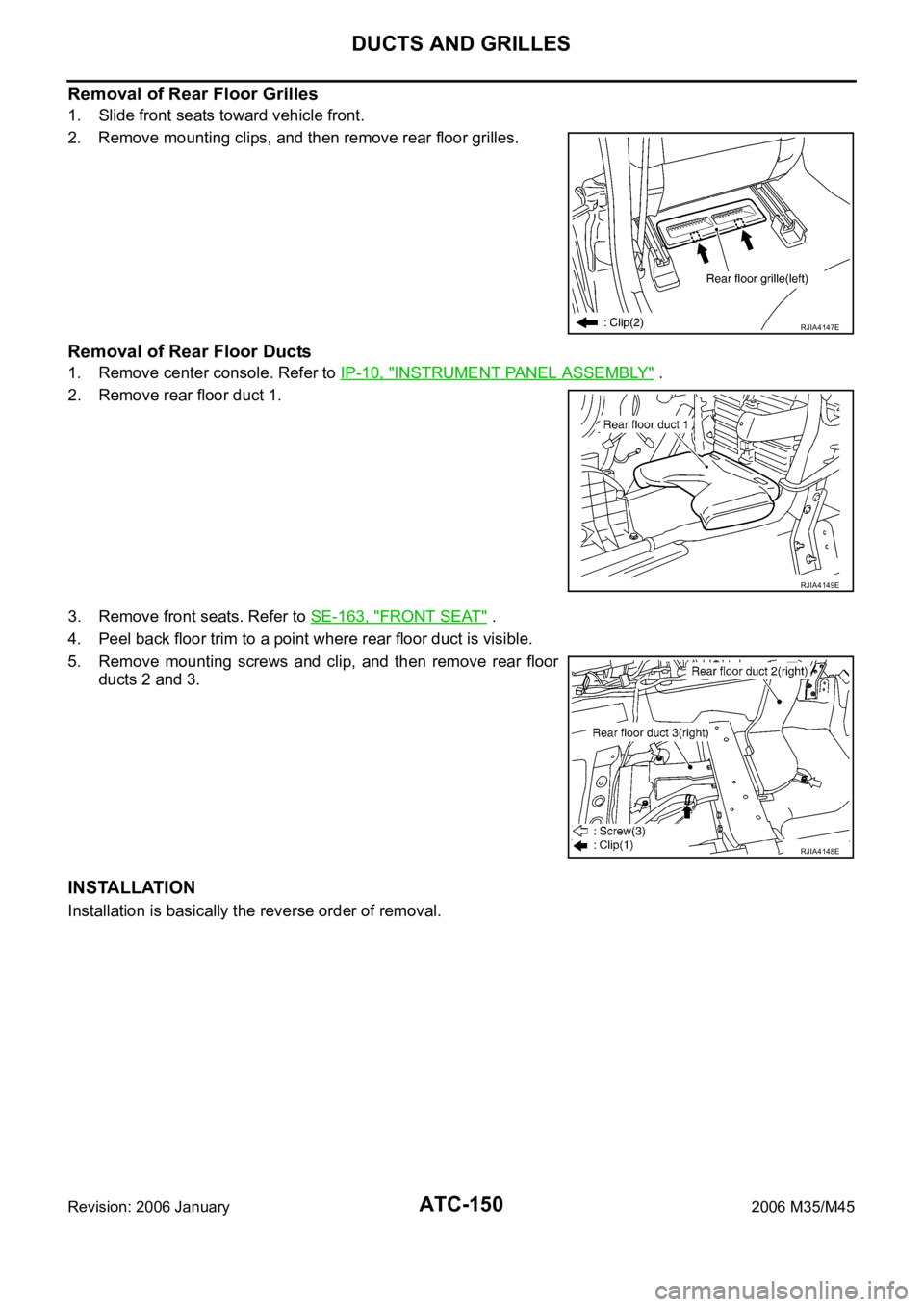

Removal of Rear Floor Grilles

1. Slide front seats toward vehicle front.

2. Remove mounting clips, and then remove rear floor grilles.

Removal of Rear Floor Ducts

1. Remove center console. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove rear floor duct 1.

3. Remove front seats. Refer to SE-163, "

FRONT SEAT" .

4. Peel back floor trim to a point where rear floor duct is visible.

5. Remove mounting screws and clip, and then remove rear floor

ducts 2 and 3.

INSTALLATION

Installation is basically the reverse order of removal.

RJIA4147E

RJIA4149E

RJIA4148E

Page 761 of 5621

![INFINITI M35 2006 Factory Service Manual AV-140

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

Auxiliary Input JacksNKS004A1

REMOVAL

1. Remove center console rear finisher. Refer to IP-10, & INFINITI M35 2006 Factory Service Manual AV-140

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

Auxiliary Input JacksNKS004A1

REMOVAL

1. Remove center console rear finisher. Refer to IP-10, &](/img/42/57023/w960_57023-760.png)

AV-140

[WITHOUT MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

Auxiliary Input JacksNKS004A1

REMOVAL

1. Remove center console rear finisher. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove screws (A) and disconnect connector. Remove auxil-

iary input jacks (1) from center console rear finisher.

INSTALLATION

Installation is the reverse order of removal.

MicrophoneNKS004A2

REMOVAL

1. Remove front pillar garnish. Refer to EI-37, "BODY SIDE TRIM" .

2. Remove sun-visor and sun-visor holder. Refer to EI-52, "

HEADLINING" .

3. Remove dual-sunvisor. Refer to EI-52, "

HEADLINING" .

4. Remove assistance grip (front). Refer to EI-52, "

HEADLINING" .

5. Bear down headlining assembly (front) to obtain work space between headlining assembly and vehicle.

6. Disengage tabs (A) and connector to separate microphone unit

(1).

INSTALLATION

Installation is the reverse order of removal.

GPS AntennaNKS004A3

REMOVAL

1. Remove NAVI control unit. Refer to AV-135, "AV (NAVI) Control Unit" .

2. Remove upper ventilator grille. Refer toIP-10, "

INSTRUMENT PANEL ASSEMBLY" .

SKIB4351E

SKIB4302E

Page 917 of 5621

![INFINITI M35 2006 Factory Service Manual AV-296

[WITH MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

Auxiliary Input JacksNKS004C4

REMOVAL

1. Remove center console rear finisher. Refer to IP-10, " INFINITI M35 2006 Factory Service Manual AV-296

[WITH MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

Auxiliary Input JacksNKS004C4

REMOVAL

1. Remove center console rear finisher. Refer to IP-10, "](/img/42/57023/w960_57023-916.png)

AV-296

[WITH MOBILE ENTERTAINMENT SYSTEM]

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

Auxiliary Input JacksNKS004C4

REMOVAL

1. Remove center console rear finisher. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove screws (A) and disconnect connector. Remove auxil-

iary input jacks (1) from center console rear finisher.

INSTALLATION

Installation is the reverse order of removal.

Headphone AmpNKS004C5

: Vehicle front

REMOVAL

1. Remove rear display cover. Refer to IP-19, "Disassembly and Assembly" .

2. Remove nuts (A) and disconnect connector. Remove head-

phone amp (1).

INSTALLATION

Installation is the reverse order of removal.

MicrophoneNKS004C6

REMOVAL

1. Remove front pillar garnish. Refer to EI-37, "BODY SIDE TRIM" .

2. Remove sun-visor and sun-visor holder. Refer to EI-52, "

HEADLINING" .

3. Remove dual-sunvisor. Refer to EI-52, "

HEADLINING" .

4. Remove assistance grip (front). Refer to EI-52, "

HEADLINING" .

5. Bear down headlining assembly (front) to obtain work space between headlining assembly and vehicle.

6. Disengage tabs (A) and connector to separate microphone unit

(1).

SKIB4351E

SKIB4353E

SKIB4302E

Page 940 of 5621

BL-1

BODY, LOCK & SECURITY SYSTEM

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

Revision: 2006 January2006 M35/M45

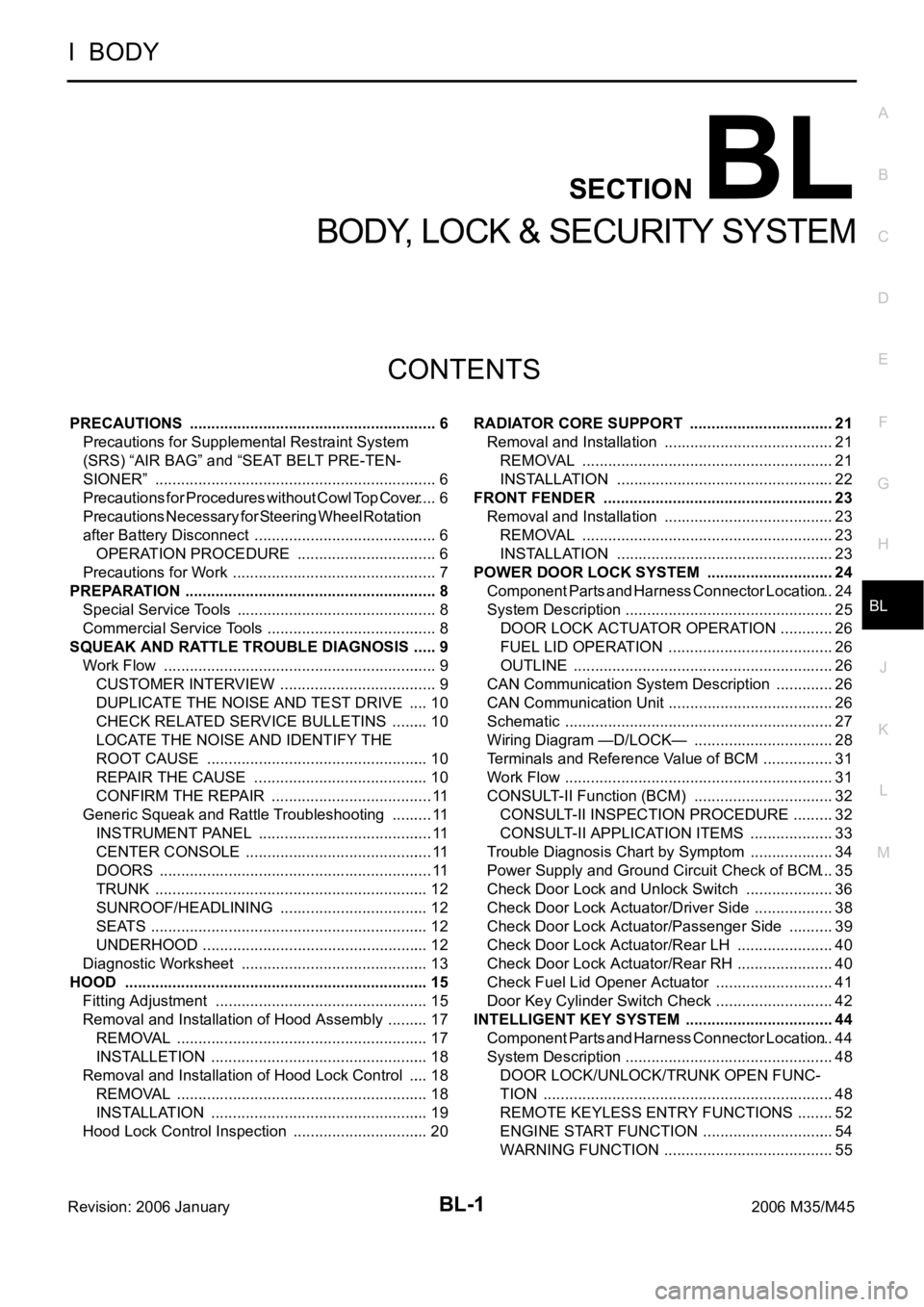

BODY, LOCK & SECURITY SYSTEM

PRECAUTIONS .......................................................... 6

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 6

Precautions for Procedures without Cowl Top Cover ..... 6

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 6

OPERATION PROCEDURE ................................. 6

Precautions for Work ...........................................

..... 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ........................................ 8

SQUEAK AND RATTLE TROUBLE DIAGNOSIS ...... 9

Work Flow ................................................................ 9

CUSTOMER INTERVIEW ..................................... 9

DUPLICATE THE NOISE AND TEST DRIVE ..... 10

CHECK RELATED SERVICE BULLETINS ......... 10

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE .................................................... 10

REPAIR THE CAUSE ......................................... 10

CONFIRM THE REPAIR ...................................... 11

Generic Squeak and Rattle Troubleshooting .......... 11

INSTRUMENT PANEL ......................................... 11

CENTER CONSOLE ............................................ 11

DOORS ................................................................ 11

TRUNK ................................................................ 12

SUNROOF/HEADLINING ................................... 12

SEATS ................................................................. 12

UNDERHOOD ..................................................... 12

Diagnostic Worksheet ............................................ 13

HOOD ....................................................................... 15

Fitting Adjustment .................................................. 15

Removal and Installation of Hood Assembly .......... 17

REMOVAL ........................................................

... 17

INSTALLETION ................................................... 18

Removal and Installation of Hood Lock Control ..... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 19

Hood Lock Control Inspection ................................ 20RADIATOR CORE SUPPORT .................................. 21

Removal and Installation ........................................ 21

REMOVAL ........................................................

... 21

INSTALLATION ................................................... 22

FRONT FENDER ................................................... ... 23

Removal and Installation ........................................ 23

REMOVAL ........................................................

... 23

INSTALLATION ................................................... 23

POWER DOOR LOCK SYSTEM .............................. 24

Component Parts and Harness Connector Location ... 24

System Description ................................................. 25

DOOR LOCK ACTUATOR OPERATION ............. 26

FUEL LID OPERATION ....................................... 26

OUTLINE ............................................................. 26

CAN Communication System Description .............. 26

CAN Communication Unit ....................................... 26

Schematic ............................................................... 27

Wiring Diagram —D/LOCK— ................................. 28

Terminals and Reference Value of BCM ................. 31

Work Flow ............................................................... 31

CONSULT-II Function (BCM) ................................. 32

CONSULT-II INSPECTION PROCEDURE .......... 32

CONSULT-II APPLICATION ITEMS .................... 33

Trouble Diagnosis Chart by Symptom .................... 34

Power Supply and Ground Circuit Check of BCM ... 35

Check Door Lock and Unlock Switch ..................... 36

Check Door Lock Actuator/Driver Side ................... 38

Check Door Lock Actuator/Passenger Side ........... 39

Check Door Lock Actuator/Rear LH ....................... 40

Check Door Lock Actuator/Rear RH ....................... 40

Check Fuel Lid Opener Actuator ............................ 41

Door Key Cylinder Switch Check ............................ 42

INTELLIGENT KEY SYSTEM ................................... 44

Component Parts and Harness Connector Location ... 44

System Description ................................................. 48

DOOR LOCK/UNLOCK/TRUNK OPEN FUNC-

TION .................................................................... 48

REMOTE KEYLESS ENTRY FUNCTIONS ......... 52

ENGINE START FUNCTION ............................... 54

WARNING FUNCTION ........................................ 55

Page 950 of 5621

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

BL-11

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30

50 mm (1.181.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15

25 mm (0.590.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingNIS001WH

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

Page 986 of 5621

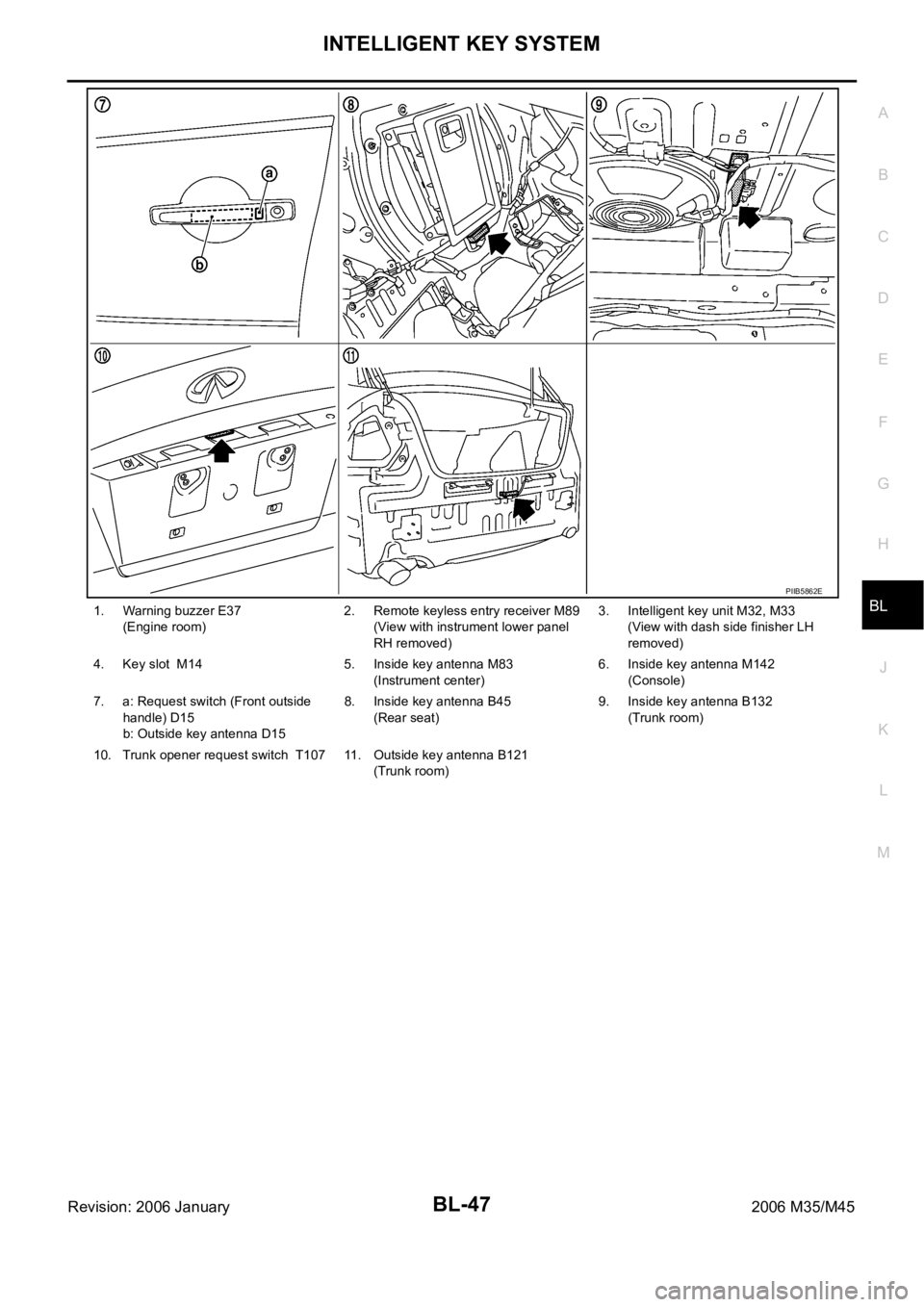

INTELLIGENT KEY SYSTEM

BL-47

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M451. Warning buzzer E37

(Engine room) 2. Remote keyless entry receiver M89

(View with instrument lower panel

RH removed) 3. Intelligent key unit M32, M33

(View with dash side finisher LH

removed)

4. Key slot M14 5. Inside key antenna M83

(Instrument center) 6. Inside key antenna M142

(Console)

7. a: Request switch (Front outside

handle) D15

b: Outside key antenna D158. Inside key antenna B45

(Rear seat) 9. Inside key antenna B132

(Trunk room)

10. Trunk opener request switch T107 11. Outside key antenna B121

(Trunk room)

PIIB5862E

Page 1023 of 5621

BL-84

INTELLIGENT KEY SYSTEM

Revision: 2006 January2006 M35/M45

ACTIVE TEST

PANIC ALARM DELAYPanic alarm button's pressing time on Intelligent Key remote control button can be selected from

the following with this mode. The operation mode will be changed when “CHANGE SETT” on

CONSULT-II screen is touched.0.5 sec

1.5 sec

OFF: Non-operation

TRUNK/GLASS HATCH OPENBuzzer reminder function mode by trunk opener request switch can be changed to operate (ON)

or not operate (OFF) with this mode. The operation mode will be changed when “CHANGE

SETT” on CONSULT-II screen is touched.

TRUNK OPEN DELAYTrunk button's pressing time on Intelligent Key button can be selected from the following with this

mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-II screen is

touched.

0.5 sec

1.5 sec

OFF: Non-operation

P/W DOWN DELAYUnlock button's pressing time on Intelligent Key button can be selected from the following with

this mode. The operation mode will be changed when “CHANGE SETT” on CONSULT-II screen

is touched.

3 sec

5 sec

OFF: Non-operation

ENGINE START BY I-KEYEngine start function mode can be changed to operate (ON) or not operate (OFF) with this mode.

The operation mode will be changed when “CHANGE SETT” on CONSULT-II screen is touched.

LOCK/UNLOCK BY I-KEYDoor lock/unlock function by door request switch (driver side, passenger side and trunk) mode

can be changed to operate (ON) or not operate (OFF) with this mode. The operation mode will be

changed when “CHANGE SETT” on CONSULT-II screen is touched. Monitor item Description

Test item Description

DOOR LOCK/UNLOCKThis test is able to check door lock/unlock operation.

The all door lock actuators are locked when “LOCK” on CONSULT-II screen is touched.

The all door lock actuators are unlocked when “ALL UNLK” on CONSULT-II screen is touched.

The door lock actuator (driver side) is unlocked when “DR UNLK” on CONSULT-II screen is

touched.

The door lock actuator (passenger side) is unlocked when “AS UNLK” on CONSULT- II screen

is touched.

The trunk lid opener actuator is open when “TRUNK OPEN” on CONSULT- II screen is

touched.

ANTENNAThis test is able to check Intelligent Key antenna operation.

When the following conditions are met, hazard warning lamps flash.

Inside key antenna (Instrument center) detects Intelligent Key, when “ROOM ANT1” on CON-

SULT-II screen is touched.

Inside key antenna (Center console) detects Intelligent Key, when “ROOM ANT2” on CON-

SULT-II screen is touched.

Inside key antenna (rear seat) detects Intelligent Key, when “ROOM ANT3” on CONSULT-II

screen is touched.

Inside key antenna (Trunk room) detects Intelligent Key, when “LAG ANT1” on CONSULT-II

screen is touched.

Outside key antenna (Driver side) detects Intelligent Key, when “DRIVER ANT” on CONSULT-II

screen is touched.

Outside key antenna (Passenger side) detects Intelligent Key, when “ASSIST ANT” on CON-

SULT-II screen is touched.

Outside key antenna (Trunk room) detects Intelligent Key, when “BD/TR ANT” on CONSULT-II

screen is touched.