width INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 178 of 5621

TROUBLE DIAGNOSIS

AT-99

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

ATF WARN LAMP (ON/OFF) — — Not mounted but displayed.

BACK-UP LAMP (ON/OFF) — —

STARTER RELAY (ON/OFF) — —

PNP SW3 MON (ON/OFF) — —

C/V CLB ID1 — —

C/V CLB ID2 — —

C/V CLB ID3 — —

UNIT CLB ID1 — —

UNIT CLB ID2 — —

UNIT CLB ID3 — —

TRGT GR RATIO — —

TRGT PRES TCC (kPa) — —

TRGT PRES L/P (kPa) — —

TRGT PRES I/C (kPa) — —

TRGT PRE FR/B (kPa) — —

TRGT PRES D/C (kPa) — —

TRG PRE HLR/C (kPa) — —

SHIFT PATTERN — —

DRV CST JUDGE — —

START RLY MON — —

NEXT GR POSI — —

SHIFT MODE — —

MANU GR POSI — —

VEHICLE SPEED (km/h) — X Vehicle speed recognized by the TCM.

Voltage (V) — —Displays the value measured by the voltage

probe.

Frequency (Hz) — —

The value measured by the pulse probe is dis-

played. DUTY-HI (high) (%) — —

DUTY-LOW (low) (%) — —

PLS WIDTH-HI (ms) — —

PLS WIDTH-LOW (ms) — —Monitored item (Unit)Monitor Item Selection

Remarks ECU

INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

Page 1310 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-35

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

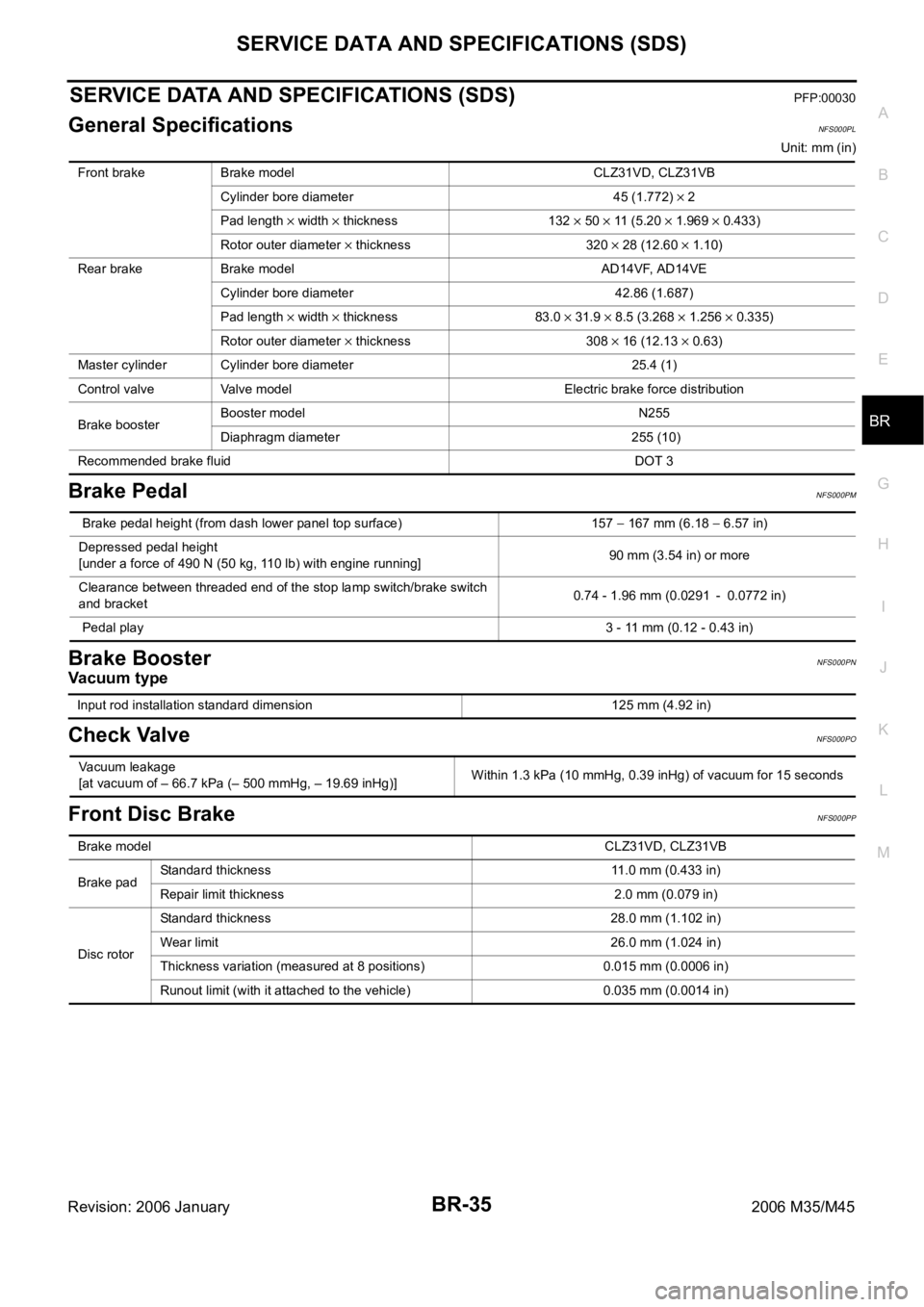

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsNFS000PL

Unit: mm (in)

Brake PedalNFS000PM

Brake BoosterNFS000PN

Va c u u m t y p e

Check ValveNFS000PO

Front Disc BrakeNFS000PP

Front brake Brake model CLZ31VD, CLZ31VB

Cylinder bore diameter 45 (1.772)

2

Pad length

width thickness 132 50 11 (5.20 1.969 0.433)

Rotor outer diameter

thickness 320 28 (12.60 1.10)

Rear brake Brake model AD14VF, AD14VE

Cylinder bore diameter 42.86 (1.687)

Pad length

width thickness 83.0 31.9 8.5 (3.268 1.256 0.335)

Rotor outer diameter

thickness 308 16 (12.13 0.63)

Master cylinder Cylinder bore diameter 25.4 (1)

Control valve Valve model Electric brake force distribution

Brake boosterBooster model N255

Diaphragm diameter 255 (10)

Recommended brake fluid DOT 3

Brake pedal height (from dash lower panel top surface) 157 167 mm (6.18 6.57 in)

Depressed pedal height

[under a force of 490 N (50 kg, 110 lb) with engine running]90 mm (3.54 in) or more

Clearance between threaded end of the stop lamp switch/brake switch

and bracket 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Pedal play3 - 11 mm (0.12 - 0.43 in)

Input rod installation standard dimension 125 mm (4.92 in)

Vacuum leakage

[at vacuum of – 66.7 kPa (– 500 mmHg, – 19.69 inHg)]Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

Brake modelCLZ31VD, CLZ31VB

Brake padStandard thickness 11.0 mm (0.433 in)

Repair limit thickness 2.0 mm (0.079 in)

Disc rotorStandard thickness 28.0 mm (1.102 in)

Wear limit 26.0 mm (1.024 in)

Thickness variation (measured at 8 positions) 0.015 mm (0.0006 in)

Runout limit (with it attached to the vehicle) 0.035 mm (0.0014 in)

Page 1511 of 5621

DI-78

LANE DEPARTURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

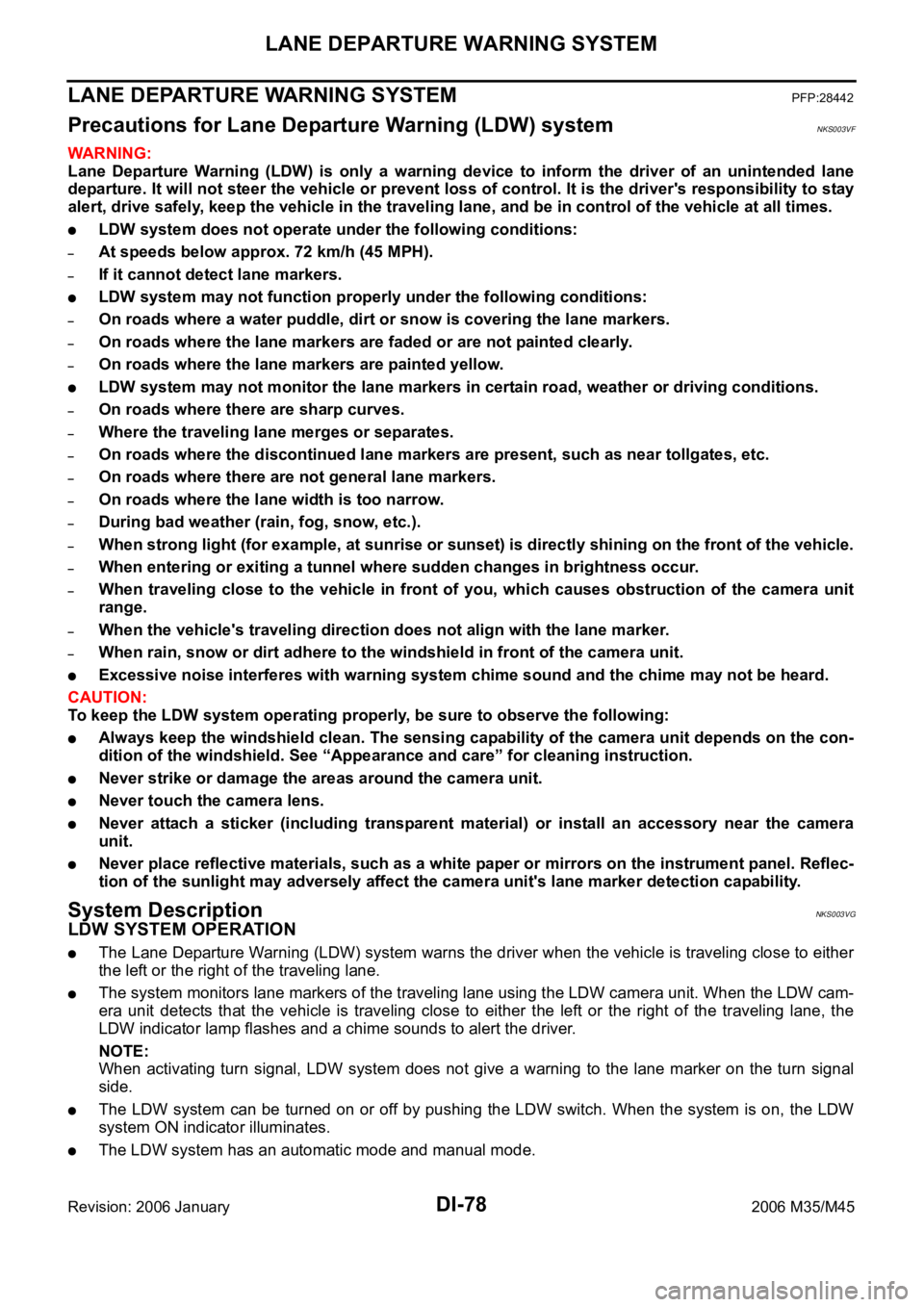

LANE DEPARTURE WARNING SYSTEM PFP:28442

Precautions for Lane Departure Warning (LDW) systemNKS003VF

WAR NING :

Lane Departure Warning (LDW) is only a warning device to inform the driver of an unintended lane

departure. It will not steer the vehicle or prevent loss of control. It is the driver's responsibility to stay

alert, drive safely, keep the vehicle in the traveling lane, and be in control of the vehicle at all times.

LDW system does not operate under the following conditions:

–At speeds below approx. 72 km/h (45 MPH).

–If it cannot detect lane markers.

LDW system may not function properly under the following conditions:

–On roads where a water puddle, dirt or snow is covering the lane markers.

–On roads where the lane markers are faded or are not painted clearly.

–On roads where the lane markers are painted yellow.

LDW system may not monitor the lane markers in certain road, weather or driving conditions.

–On roads where there are sharp curves.

–Where the traveling lane merges or separates.

–On roads where the discontinued lane markers are present, such as near tollgates, etc.

–On roads where there are not general lane markers.

–On roads where the lane width is too narrow.

–During bad weather (rain, fog, snow, etc.).

–When strong light (for example, at sunrise or sunset) is directly shining on the front of the vehicle.

–When entering or exiting a tunnel where sudden changes in brightness occur.

–When traveling close to the vehicle in front of you, which causes obstruction of the camera unit

range.

–When the vehicle's traveling direction does not align with the lane marker.

–When rain, snow or dirt adhere to the windshield in front of the camera unit.

Excessive noise interferes with warning system chime sound and the chime may not be heard.

CAUTION:

To keep the LDW system operating properly, be sure to observe the following:

Always keep the windshield clean. The sensing capability of the camera unit depends on the con-

dition of the windshield. See “Appearance and care” for cleaning instruction.

Never strike or damage the areas around the camera unit.

Never touch the camera lens.

Never attach a sticker (including transparent material) or install an accessory near the camera

unit.

Never place reflective materials, such as a white paper or mirrors on the instrument panel. Reflec-

tion of the sunlight may adversely affect the camera unit's lane marker detection capability.

System DescriptionNKS003VG

LDW SYSTEM OPERATION

The Lane Departure Warning (LDW) system warns the driver when the vehicle is traveling close to either

the left or the right of the traveling lane.

The system monitors lane markers of the traveling lane using the LDW camera unit. When the LDW cam-

era unit detects that the vehicle is traveling close to either the left or the right of the traveling lane, the

LDW indicator lamp flashes and a chime sounds to alert the driver.

NOTE:

When activating turn signal, LDW system does not give a warning to the lane marker on the turn signal

side.

The LDW system can be turned on or off by pushing the LDW switch. When the system is on, the LDW

system ON indicator illuminates.

The LDW system has an automatic mode and manual mode.

Page 1575 of 5621

![INFINITI M35 2006 Factory Service Manual EC-32

[VQ35DE]

ENGINE CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio INFINITI M35 2006 Factory Service Manual EC-32

[VQ35DE]

ENGINE CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio](/img/42/57023/w960_57023-1574.png)

EC-32

[VQ35DE]

ENGINE CONTROL SYSTEM

Revision: 2006 January2006 M35/M45

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst 1 can then better reduce CO, HC and NOx emissions. This system uses A/F sensor 1

in the exhaust manifold to monitor whether the engine operation is rich or lean. The ECM adjusts the injection

pulse width according to the sensor voltage signal. For more information about A/F sensor 1, refer to EC-256,

"DTC P0131, P0151 A/F SENSOR 1" . This maintains the mixture ratio within the range of stoichiometric (ideal

air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst 1. Even if the switching characteris-

tics of A/F sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal from heated oxygen sen-

sor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

Deceleration and acceleration

High-load, high-speed operation

Malfunction of A/F sensor 1 or its circuit

Insufficient activation of A/F sensor 1 at low engine coolant temperature

High engine coolant temperature

During warm-up

After shifting from N to D

When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

PBIB2793E

Page 1576 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE CONTROL SYSTEM

EC-33

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel i INFINITI M35 2006 Factory Service Manual ENGINE CONTROL SYSTEM

EC-33

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel i](/img/42/57023/w960_57023-1575.png)

ENGINE CONTROL SYSTEM

EC-33

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all six cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The six injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speeds.

Electronic Ignition (EI) SystemNBS004S4

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 2 - 3 - 4 - 5 - 6

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor (PHASE) sig-

nal. Computing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in

the ECM.

At starting

During warm-up

At idle

At low battery voltage

SEF179U

Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

2

Piston position

Ignition timing

controlPower transistor Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Battery

Battery voltage*

2

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Wheel sensor*

1Vehicle speed

Page 1681 of 5621

![INFINITI M35 2006 Factory Service Manual EC-138

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

*: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

: Applicable VEHICL SPEED

[km/h] INFINITI M35 2006 Factory Service Manual EC-138

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

*: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

: Applicable VEHICL SPEED

[km/h]](/img/42/57023/w960_57023-1680.png)

EC-138

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

*: The items are the same as those of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

: Applicable VEHICL SPEED

[km/h] or [mph]

The vehicle speed at the moment a malfunction is detected is displayed.

ABSOL THꞏP/S [%]

The throttle valve opening angle at the moment a malfunction is detected is displayed.

B/FUEL SCHDL

[msec]

The base fuel schedule at the moment a malfunction is detected is displayed.

INT/A TEMP SE [

C]

or [

F]The intake air temperature at the moment a malfunction is detected is displayed. Freeze frame data

item*Description

Monitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSDescription Remarks

ENG SPEED [rpm]

Indicates the engine speed computed

from the signal of the crankshaft position

sensor (POS) and camshaft position sen-

sor (PHASE).Accuracy becomes poor if engine speed

drops below the idle rpm.

If the signal is interrupted while the

engine is running, an abnormal value may

be indicated.

MAS A/F SE-B1 [V]

The signal voltage of the mass air flow

sensor is displayed.When the engine is stopped, a certain

value is indicated.

B/FUEL SCHDL

[msec]

“Base fuel schedule” indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board cor-

rection.

A/F ALPHA-B1 [%]

The mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated.When the engine is stopped, a certain

value is indicated.

This data also includes the data for the

air-fuel ratio learning control. A/F ALPHA-B2 [%]

COOLAN TEMP/S

[

C] or [F]

The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.

When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine coolant

temperature determined by the ECM is

displayed.

A/F SEN1 (B1) [V]

The A/F signal computed from the input

signal of the air fuel ratio (A/F) sensor 1 is

displayed. A/F SEN1 (B2) [V]

HO2S2 (B1) [V]The signal voltage of the heated oxygen

sensor 2 is displayed.

HO2S2 (B2) [V]

HO2S2 MNTR (B1)

[RICH/LEAN]Display of heated oxygen sensor 2 signal:

RICH: means the amount of oxygen after

three way catalyst is relatively small.

LEAN: means the amount of oxygen after

three way catalyst is relatively large.

When the engine is stopped, a certain

value is indicated.

HO2S2 MNTR (B2)

[RICH/LEAN]

VHCL SPEED SE

[km/h] or [mph]The vehicle speed computed from the

vehicle speed signal sent from combina-

tion meter is displayed.

BATTERY VOLT

[V]

The power supply voltage of ECM is dis-

played.

ACCEL SEN 1 [V]

The accelerator pedal position sensor

signal voltage is displayed.ACCEL SENS2 signal is converted be

ECM internally. Thus, they differs from

ECM terminal voltage signal. ACCEL SEN 2 [V]

Page 1682 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

EC-139

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45THRTL SEN 1 [V]The throttle position sensor signal voltage

is displayed.THRTL SEN 2 signal is converted b INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

EC-139

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45THRTL SEN 1 [V]The throttle position sensor signal voltage

is displayed.THRTL SEN 2 signal is converted b](/img/42/57023/w960_57023-1681.png)

TROUBLE DIAGNOSIS

EC-139

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45THRTL SEN 1 [V]The throttle position sensor signal voltage

is displayed.THRTL SEN 2 signal is converted by

ECM internally. Thus, they differs from

ECM terminal voltage signal. THRTL SEN 2 [V]

FUEL T/TMP SE

[

C] or [F]

The fuel temperature (determined by the

signal voltage of the fuel tank tempera-

ture sensor) is displayed.

INT/A TEMP SE

[

C] or [F]

The intake air temperature (determined

by the signal voltage of the intake air tem-

perature sensor) is indicated.

EVAP SYS PRES

[V]

The signal voltage of EVAP control sys-

tem pressure sensor is displayed.

FPCM DR VOLT

[V]

The voltage between fuel pump and

FPCM is displayed.

FUEL LEVEL SE

[V]

The signal voltage of the fuel level sensor

is displayed.

START SIGNAL

[ON/OFF]

Indicates start signal status [ON/OFF]

computed by the ECM according to the

signals of engine speed and battery volt-

age.

After starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF]

Indicates idle position [ON/OFF] com-

puted by ECM according to the accelera-

tor pedal position sensor signal.

AIR COND SIG

[ON/OFF]

Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]

Indicates [ON/OFF] condition from the

park/neutral position (PNP) switch signal.

PW/ST SIGNAL

[ON/OFF]

[ON/OFF] condition of the power steering

system (determined by the signal voltage

of the power steering pressure sensor

signal) is indicated.

LOAD SIGNAL

[ON/OFF]

Indicates [ON/OFF] condition from the

electrical load signal.

ON: Rear window defogger switch is ON

and/or lighting switch is in 2nd position.

OFF: Both rear window defogger switch

and lighting switch are OFF.

IGNITION SW

[ON/OFF]

Indicates [ON/OFF] condition from igni-

tion switch signal.

HEATER FAN SW

[ON/OFF]

Indicates [ON/OFF] condition from the

heater fan switch signal.

BRAKE SW

[ON/OFF]

Indicates [ON/OFF] condition from the

stop lamp switch signal.

INJ PULSE-B1

[msec]

Indicates the actual fuel injection pulse

width compensated by ECM according to

the input signals.When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

IGN TIMING

[BTDC]

Indicates the ignition timing computed by

ECM according to the input signals.When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE [%]

“Calculated load value” indicates the

value of the current air flow divided by

peak air flow. Monitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSDescription Remarks

Page 1685 of 5621

![INFINITI M35 2006 Factory Service Manual EC-142

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

DATA MONITOR (S INFINITI M35 2006 Factory Service Manual EC-142

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

DATA MONITOR (S](/img/42/57023/w960_57023-1684.png)

EC-142

[VQ35DE]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

DATA MONITOR (SPEC) MODE

Monitored Item

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically. ALT DUTY SIG

The control condition of the power gener-

ation voltage variable control (determined

by ECM according to the input signals) is

indicated.

ON: Power generation voltage variable

control is active.

OFF: Power generation voltage variable

control is inactive.

Voltage [V]

Voltage, frequency, duty cycle or pulse

width measured by the probe.

Only “#” is displayed if item is unable to

be measured.

Figures with “#”s are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured. Frequency [msec],

[Hz] or [%]

DUTY-HI

DUTY-LOW

PLS WIDTH-HI

PLS WIDTH-LOWMonitored item

[Unit]ECM

INPUT

SIG-

NALSMAIN

SIG-

NALSDescription Remarks

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]

Indicates the engine speed computed

from the signal of the crankshaft position

sensor (POS) and camshaft position

sensor (PHASE).

MAS A/F SE-B1 [V]

The signal voltage of the mass air flow

sensor specification is displayed.When engine is running specification

range is indicated.

B/FUEL SCHDL

[msec]

“Base fuel schedule” indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board cor-

rection.

When engine is running specification

range is indicated.

A/F ALPHA-B1 [%]

A/F ALPHA-B2 [%]

The mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated.When engine is running specification

range is indicated.

This data also includes the data for the

air-fuel ratio learning control.

Page 1698 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-155

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSIS - SPECIFICATION VALUEPFP:00031

DescriptionNBS004TB

The specificat INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-155

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSIS - SPECIFICATION VALUEPFP:00031

DescriptionNBS004TB

The specificat](/img/42/57023/w960_57023-1697.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-155

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSIS - SPECIFICATION VALUEPFP:00031

DescriptionNBS004TB

The specification (SP) value indicates the tolerance of the value that is displayed in “DATA MONITOR (SPEC)”

mode of CONSULT-II during normal operation of the Engine Control System. When the value in “DATA MONI-

TOR (SPEC)” mode is within the SP value, the Engine Control System is confirmed OK. When the value in

“DATA MONITOR (SPEC)” mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board cor-

rection)

A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionNBS004TC

Vehicle driven distance: More than 5,000 km (3,107 miles)

Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm2 , 14.25 - 15.12 psi)

Atmospheric temperature: 20 - 30C (68 - 86F)

Engine coolant temperature: 75 - 95C (167 - 203F)

Transmission: Warmed-up*1

Electrical load: Not applied*2

Engine speed: Idle

*1: After the engine is warmed up to normal operating temperature, drive vehicle until “ATF TEMP SE 1” (A/T

fluid temperature sensor signal) indicates more than 60

C (140F).

*2: Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

Inspection ProcedureNBS004TD

NOTE:

Perform “DATA MONITOR (SPEC)” mode in maximum scale display.

1. Perform EC-77, "

Basic Inspection" .

2. Confirm that the testing conditions indicated above are met.

3. Select “B/FUEL SCHDL”, “A/F ALPHA-B1”, “A/F ALPHA-B2”

and “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode with

CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to EC-156, "

Diagnostic Procedure" .

SEF601Z

Page 1740 of 5621

![INFINITI M35 2006 Factory Service Manual DTC P0075, P0081 IVT CONTROL SOLENOID VALVE

EC-197

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0075, P0081 IVT CONTROL SOLENOID VALVEPFP:23796

Component DescriptionNBS00 INFINITI M35 2006 Factory Service Manual DTC P0075, P0081 IVT CONTROL SOLENOID VALVE

EC-197

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0075, P0081 IVT CONTROL SOLENOID VALVEPFP:23796

Component DescriptionNBS00](/img/42/57023/w960_57023-1739.png)

DTC P0075, P0081 IVT CONTROL SOLENOID VALVE

EC-197

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P0075, P0081 IVT CONTROL SOLENOID VALVEPFP:23796

Component DescriptionNBS004UG

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

CONSULT-II Reference Value in Data Monitor ModeNBS004UH

Specification data are reference values.

On Board Diagnosis LogicNBS004UI

DTC Confirmation ProcedureNBS004UJ

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Start engine and let it idle for 5 seconds.

4. If 1st trip DTC is detected, go to EC-202, "

Diagnostic Procedure"

.

WITH GST

Following the procedure “WITH CONSULT-II” above.

PBIB1842E

MONITOR ITEM CONDITION SPECIFICATION

INT/V SOL (B1)

INT/V SOL (B2)

Engine: After warming up

Selector lever: P or N

Air conditioner switch: OFF

No loadIdle 0% - 2%

2,000 rpm Approx. 25% - 50%

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0075

0075

(Bank 1)

Intake valve timing control

solenoid valve circuitAn improper voltage is sent to the ECM

through intake valve timing control solenoid

valve.

Harness or connectors

(Intake valve timing control solenoid valve

circuit is open or shorted.)

Intake valve timing control solenoid valve P0081

0081

(Bank 2)

SEF058Y