engine coolant INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1993 of 2395

Overheating Cause AnalysisNBLC0029

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, dete-

rioration or improper fit-

ting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deteriora-

tion

Cylinder head gasket

deterioration

ENGINE COOLING SYSTEM

Overheating Cause Analysis

LC-24

Page 1996 of 2395

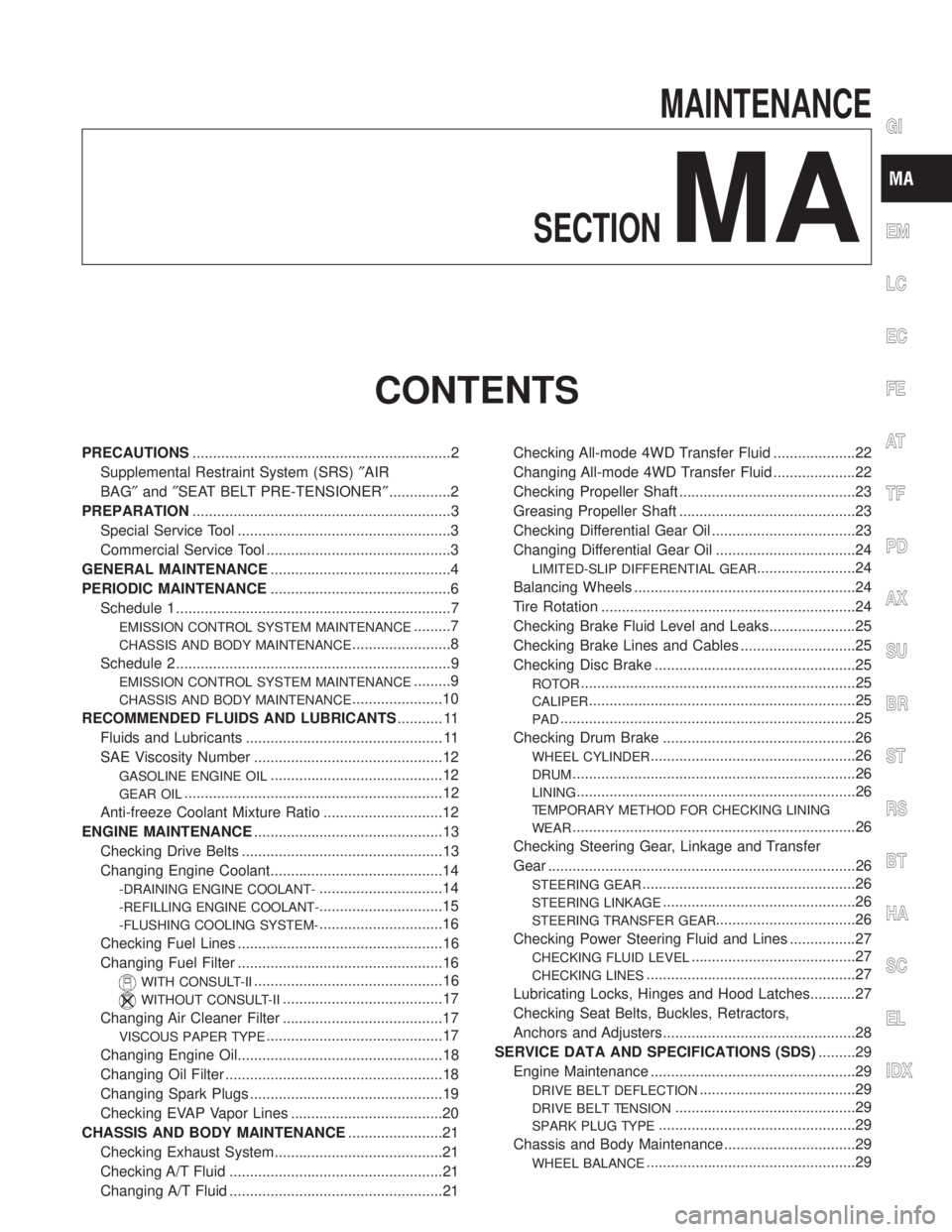

MAINTENANCE

SECTION

MA

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

PREPARATION...............................................................3

Special Service Tool ....................................................3

Commercial Service Tool .............................................3

GENERAL MAINTENANCE............................................4

PERIODIC MAINTENANCE............................................6

Schedule 1 ...................................................................7

EMISSION CONTROL SYSTEM MAINTENANCE.........7

CHASSIS AND BODY MAINTENANCE........................8

Schedule 2 ...................................................................9

EMISSION CONTROL SYSTEM MAINTENANCE.........9

CHASSIS AND BODY MAINTENANCE......................10

RECOMMENDED FLUIDS AND LUBRICANTS........... 11

Fluids and Lubricants ................................................ 11

SAE Viscosity Number ..............................................12

GASOLINE ENGINE OIL..........................................12

GEAR OIL...............................................................12

Anti-freeze Coolant Mixture Ratio .............................12

ENGINE MAINTENANCE..............................................13

Checking Drive Belts .................................................13

Changing Engine Coolant..........................................14

-DRAINING ENGINE COOLANT-..............................14

-REFILLING ENGINE COOLANT-..............................15

-FLUSHING COOLING SYSTEM-..............................16

Checking Fuel Lines ..................................................16

Changing Fuel Filter ..................................................16

WITH CONSULT-II..............................................16

WITHOUT CONSULT-II.......................................17

Changing Air Cleaner Filter .......................................17

VISCOUS PAPER TYPE...........................................17

Changing Engine Oil..................................................18

Changing Oil Filter .....................................................18

Changing Spark Plugs ...............................................19

Checking EVAP Vapor Lines .....................................20

CHASSIS AND BODY MAINTENANCE.......................21

Checking Exhaust System.........................................21

Checking A/T Fluid ....................................................21

Changing A/T Fluid ....................................................21Checking All-mode 4WD Transfer Fluid ....................22

Changing All-mode 4WD Transfer Fluid ....................22

Checking Propeller Shaft ...........................................23

Greasing Propeller Shaft ...........................................23

Checking Differential Gear Oil ...................................23

Changing Differential Gear Oil ..................................24

LIMITED-SLIP DIFFERENTIAL GEAR........................24

Balancing Wheels ......................................................24

Tire Rotation ..............................................................24

Checking Brake Fluid Level and Leaks.....................25

Checking Brake Lines and Cables ............................25

Checking Disc Brake .................................................25

ROTOR...................................................................25

CALIPER.................................................................25

PAD........................................................................25

Checking Drum Brake ...............................................26

WHEEL CYLINDER..................................................26

DRUM.....................................................................26

LINING....................................................................26

TEMPORARY METHOD FOR CHECKING LINING

WEAR

.....................................................................26

Checking Steering Gear, Linkage and Transfer

Gear ...........................................................................26

STEERING GEAR....................................................26

STEERING LINKAGE...............................................26

STEERING TRANSFER GEAR..................................26

Checking Power Steering Fluid and Lines ................27

CHECKING FLUID LEVEL........................................27

CHECKING LINES...................................................27

Lubricating Locks, Hinges and Hood Latches...........27

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................28

SERVICE DATA AND SPECIFICATIONS (SDS).........29

Engine Maintenance ..................................................29

DRIVE BELT DEFLECTION......................................29

DRIVE BELT TENSION............................................29

SPARK PLUG TYPE................................................29

Chassis and Body Maintenance ................................29

WHEEL BALANCE...................................................29

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2000 of 2395

ItemReference page

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper dis-

tance under it when depressed fully. Check the brake booster function. Be

sure to keep floor mats away from the pedal.BR-14, ªBrake Pedal and

Bracketº and BR-19,

ªBrake Boosterº

Parking brakeCheck that the lever has the proper travel and make sure that the vehicle is

held securely on a fairly steep hill when only the parking brake is applied.BR-31, ªParking Brake

Controlº

Automatic transmis-

sion ªParkº mecha-

nismCheck that the lock release button on the selector lever operates properly

and smoothly. On a fairly steep hill check that the vehicle is held securely

with the selector lever in the ªPº position without applying any brakes.Ð

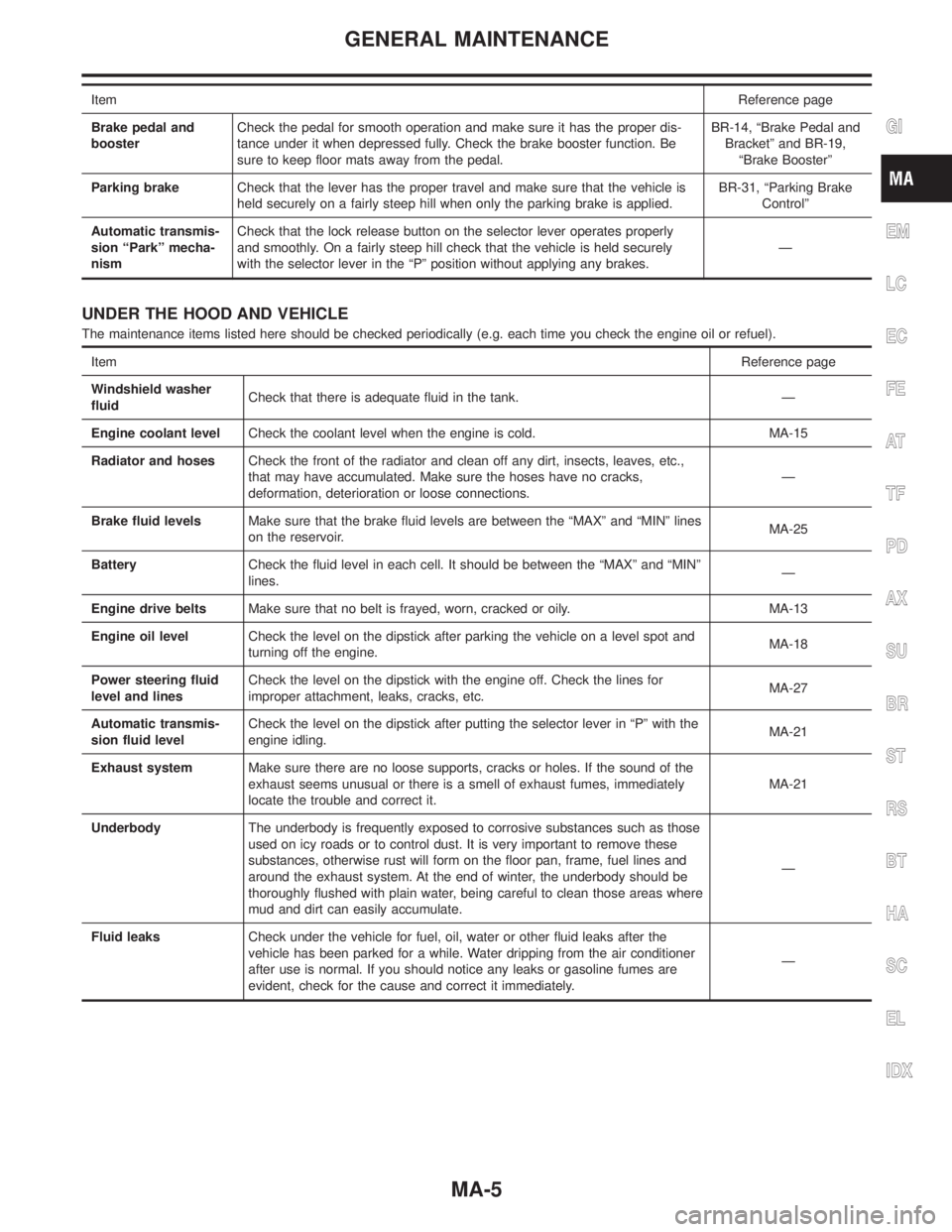

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

ItemReference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-15

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc.,

that may have accumulated. Make sure the hoses have no cracks,

deformation, deterioration or loose connections.Ð

Brake fluid levelsMake sure that the brake fluid levels are between the ªMAXº and ªMINº lines

on the reservoir.MA-25

BatteryCheck the fluid level in each cell. It should be between the ªMAXº and ªMINº

lines.Ð

Engine drive beltsMake sure that no belt is frayed, worn, cracked or oily. MA-13

Engine oil levelCheck the level on the dipstick after parking the vehicle on a level spot and

turning off the engine.MA-18

Power steering fluid

level and linesCheck the level on the dipstick with the engine off. Check the lines for

improper attachment, leaks, cracks, etc.MA-27

Automatic transmis-

sion fluid levelCheck the level on the dipstick after putting the selector lever in ªPº with the

engine idling.MA-21

Exhaust systemMake sure there are no loose supports, cracks or holes. If the sound of the

exhaust seems unusual or there is a smell of exhaust fumes, immediately

locate the trouble and correct it.MA-21

UnderbodyThe underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these

substances, otherwise rust will form on the floor pan, frame, fuel lines and

around the exhaust system. At the end of winter, the underbody should be

thoroughly flushed with plain water, being careful to clean those areas where

mud and dirt can easily accumulate.Ð

Fluid leaksCheck under the vehicle for fuel, oil, water or other fluid leaks after the

vehicle has been parked for a while. Water dripping from the air conditioner

after use is normal. If you should notice any leaks or gasoline fumes are

evident, check for the cause and correct it immediately.Ð

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

GENERAL MAINTENANCE

MA-5

Page 2002 of 2395

![INFINITI QX4 2001 Factory Service Manual Schedule 1NBMA0004S01EMISSION CONTROL SYSTEM MAINTENANCENBMA0004S0101

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATION INFINITI QX4 2001 Factory Service Manual Schedule 1NBMA0004S01EMISSION CONTROL SYSTEM MAINTENANCENBMA0004S0101

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATION](/img/42/57027/w960_57027-2001.png)

Schedule 1NBMA0004S01EMISSION CONTROL SYSTEM MAINTENANCENBMA0004S0101

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section

- Page or

- Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.5

(12)

611.25

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

2433.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Drive beltsI* I* MA-13

Air cleaner filter NOTE (1) [R] [R] MA-17

EVAP vapor linesI* I* MA-20

Fuel linesI* I* MA-16

Fuel filter* NOTE (2)MA-16

Engine coolant NOTE (3)R* MA-14

Engine oil RRRRRRRRRRRRRRRRMA-18

Engine oil filter (Use part No.

15208-31U00 or equivalent.)RRRRRRRRRRRRRRRRMA-18

Spark plugs (PLATINUM-TIPPED

type)Replace every 105,000 miles (169,000 km) MA-19

Intake & exhaust valve clearance* NOTE (4)EM-52, ªValve

Clearanceº

NOTE:

(1) If operating mainly in dusty conditions, more frequent maintenance may be required.

(2) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event, replace the filter.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

HMaintenance items and intervals with ª*º are recommended by INFINITI for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the

emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE

Schedule 1

MA-7

Page 2004 of 2395

![INFINITI QX4 2001 Factory Service Manual Schedule 2NBMA0004S02EMISSION CONTROL SYSTEM MAINTENANCENBMA0004S0201

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATION INFINITI QX4 2001 Factory Service Manual Schedule 2NBMA0004S02EMISSION CONTROL SYSTEM MAINTENANCENBMA0004S0201

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATION](/img/42/57027/w960_57027-2003.png)

Schedule 2NBMA0004S02EMISSION CONTROL SYSTEM MAINTENANCENBMA0004S0201

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Section

- Page

or

- Content Title Perform at number of miles, kilometers

or months, whichever comes first.Miles x 1,000

(km x 1,000)

Months7.5

(12)

615

(24)

1222.5

(36)

1830

(48)

2437.5

(60)

3045

(72)

3652.5

(84)

4260

(96)

48

Drive beltsI* I* MA-13

Air cleaner filter[R] [R] MA-17

EVAP vapor linesI* I* MA-20

Fuel linesI* I* MA-16

Fuel filter* NOTE (1)MA-16

Engine coolant NOTE (2)R* MA-14

Engine oilRRRRRRRRMA-18

Engine oil filter (Use part No. 15208-

31U00 or equivalent.)RRRRRRRRMA-18

Spark plugs (PLATINUM-TIPPED type) Replace every 105,000 miles (169,000 km) MA-19

Intake & exhaust valve clearance* NOTE (3)EM-52, ªValve Clear-

anceº

NOTE:

(1) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event, replace the filter.

(2) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(3) If valve noise increases, inspect valve clearance.

HMaintenance items and intervals with ª*º are recommended by INFINITI for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the

emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE

Schedule 2

MA-9

Page 2006 of 2395

NBMA0005

Fluids and LubricantsNBMA0005S01

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp measure Liter

Engine oilDrain and

refillWith oil filter 5-1/4 qt 4-3/8 qt 5.0

IAPI Certification Mark*1

IAPI grade SG/SH, Energy Conserv-

ingI&IIorAPIgrade SJ, Energy

Conserving*1

IILSAC grade GF-I & GF-II*1 Without oil

filter5-1/8 qt 4-1/4 qt 4.8

Dry engine

(Engine overhaul)7-1/4 qt 6 qt 6.8

Cooling system (With reservoir) 9-3/4 qt 8-1/8 qt 9.2Genuine Nissan anti-freeze coolant or

equivalent

All-mode 4WD transfer fluid 3-1/8 qt 2-5/8 qt 3.0Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*2

Differential

carrier gear

oilFront (4WD) 3-7/8 pt 3-1/4 pt 1.85Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear:

Use only LSD gear oil API GL-5 and

SAE 80W-90*5 approved for Nissan

LSD*6. Rear 5-7/8 pt 4-7/8 pt 2.8

Automatic transmission fluid2WD

9 qt 7-1/2 qt 8.5Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*3 4WD

Power steering fluid Ð Ð Ð Genuine NISSAN PSF II or equivalent*7

Brake fluid Ð Ð ÐGenuine Nissan Brake Fluid*4 or

equivalent DOT 3 (U.S. FMVSS No.

116)

Propeller shaft grease Ð Ð ÐNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Outside the continental United States and Alaska contact an authorized INFINITI dealership for more information regarding suitable

fluids, including recommended brand(s) of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: DEXRONTMIII/MERCONTMor equivalent may also be used. Outside the continental United States and Alaska contact an autho-

rized INFINITI dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTMIII/MERCONTM

Automatic Transmission Fluid.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF).

*6: Contact an INFINITI dealer for a list of approved oils.

*7: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, DEXRON

TMIII/MERCONTMor equivalent ATF may also be

used.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-11

Page 2007 of 2395

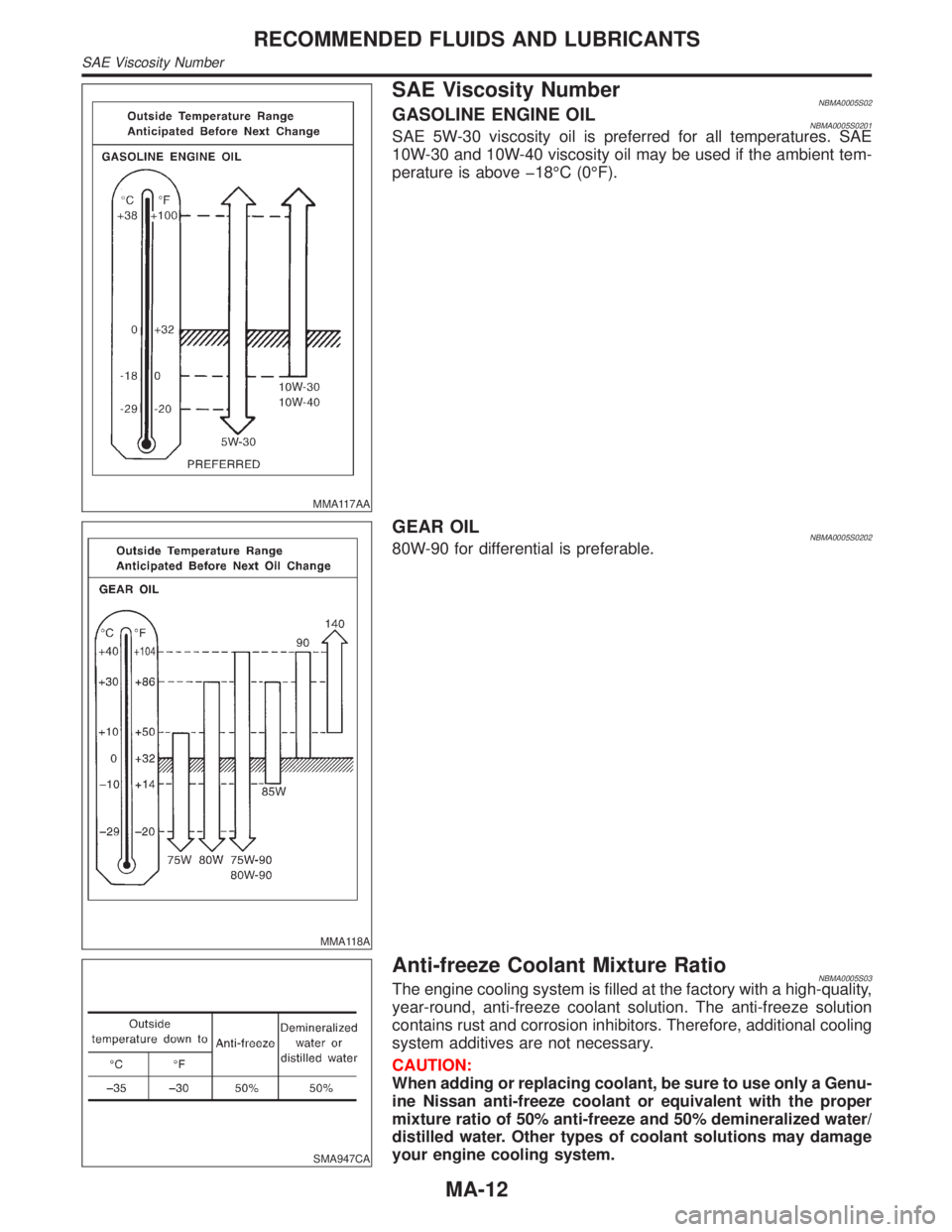

MMA117AA

SAE Viscosity NumberNBMA0005S02GASOLINE ENGINE OILNBMA0005S0201SAE 5W-30 viscosity oil is preferred for all temperatures. SAE

10W-30 and 10W-40 viscosity oil may be used if the ambient tem-

perature is above þ18ÉC (0ÉF).

MMA118A

GEAR OILNBMA0005S020280W-90 for differential is preferable.

SMA947CA

Anti-freeze Coolant Mixture RatioNBMA0005S03The engine cooling system is filled at the factory with a high-quality,

year-round, anti-freeze coolant solution. The anti-freeze solution

contains rust and corrosion inhibitors. Therefore, additional cooling

system additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only a Genu-

ine Nissan anti-freeze coolant or equivalent with the proper

mixture ratio of 50% anti-freeze and 50% demineralized water/

distilled water. Other types of coolant solutions may damage

your engine cooling system.

RECOMMENDED FLUIDS AND LUBRICANTS

SAE Viscosity Number

MA-12

Page 2009 of 2395

SMA857C

SMA858C

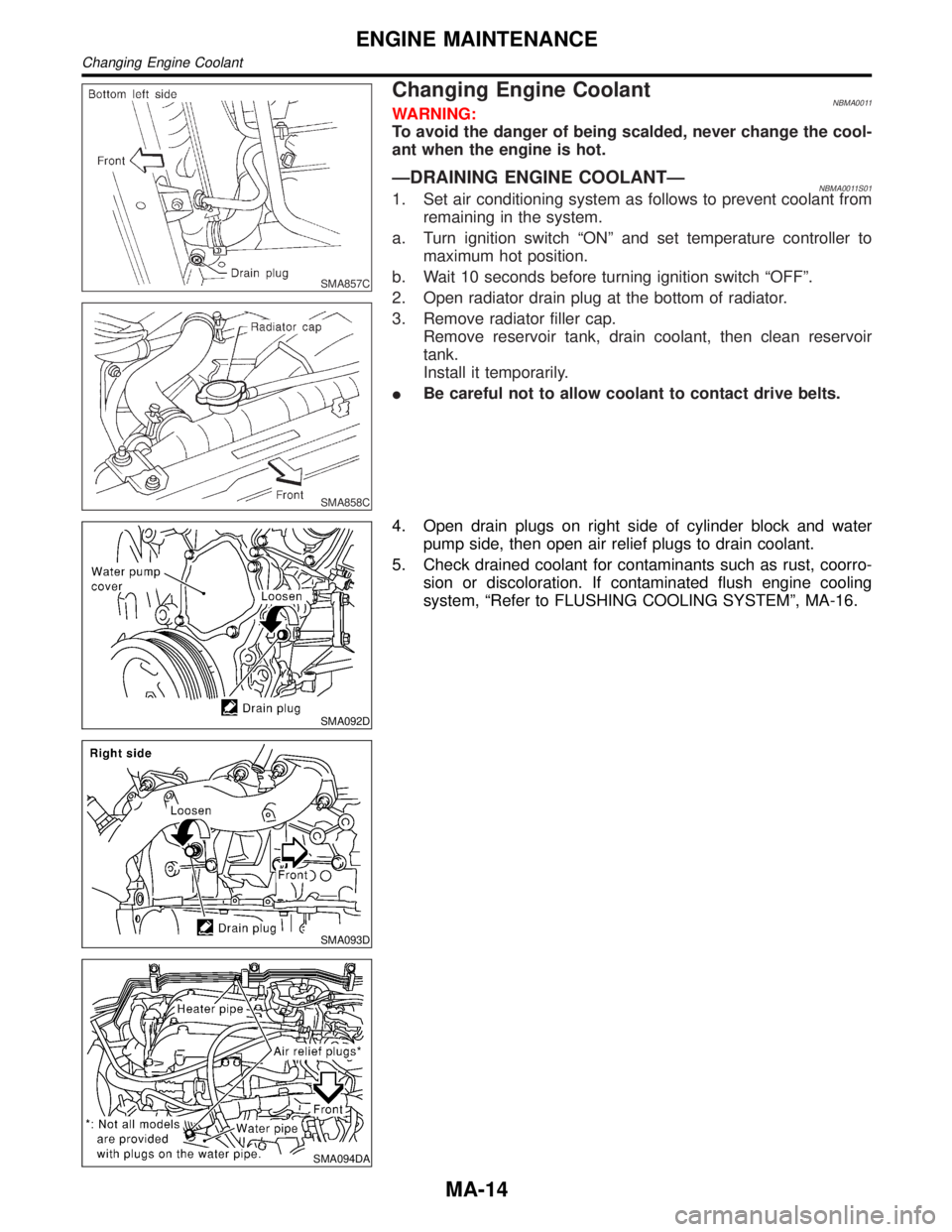

Changing Engine CoolantNBMA0011WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

ÐDRAINING ENGINE COOLANTÐNBMA0011S011. Set air conditioning system as follows to prevent coolant from

remaining in the system.

a. Turn ignition switch ªONº and set temperature controller to

maximum hot position.

b. Wait 10 seconds before turning ignition switch ªOFFº.

2. Open radiator drain plug at the bottom of radiator.

3. Remove radiator filler cap.

Remove reservoir tank, drain coolant, then clean reservoir

tank.

Install it temporarily.

IBe careful not to allow coolant to contact drive belts.

SMA092D

SMA093D

SMA094DA

4. Open drain plugs on right side of cylinder block and water

pump side, then open air relief plugs to drain coolant.

5. Check drained coolant for contaminants such as rust, coorro-

sion or discoloration. If contaminated flush engine cooling

system, ªRefer to FLUSHING COOLING SYSTEMº, MA-16.

ENGINE MAINTENANCE

Changing Engine Coolant

MA-14

Page 2010 of 2395

SMA182B

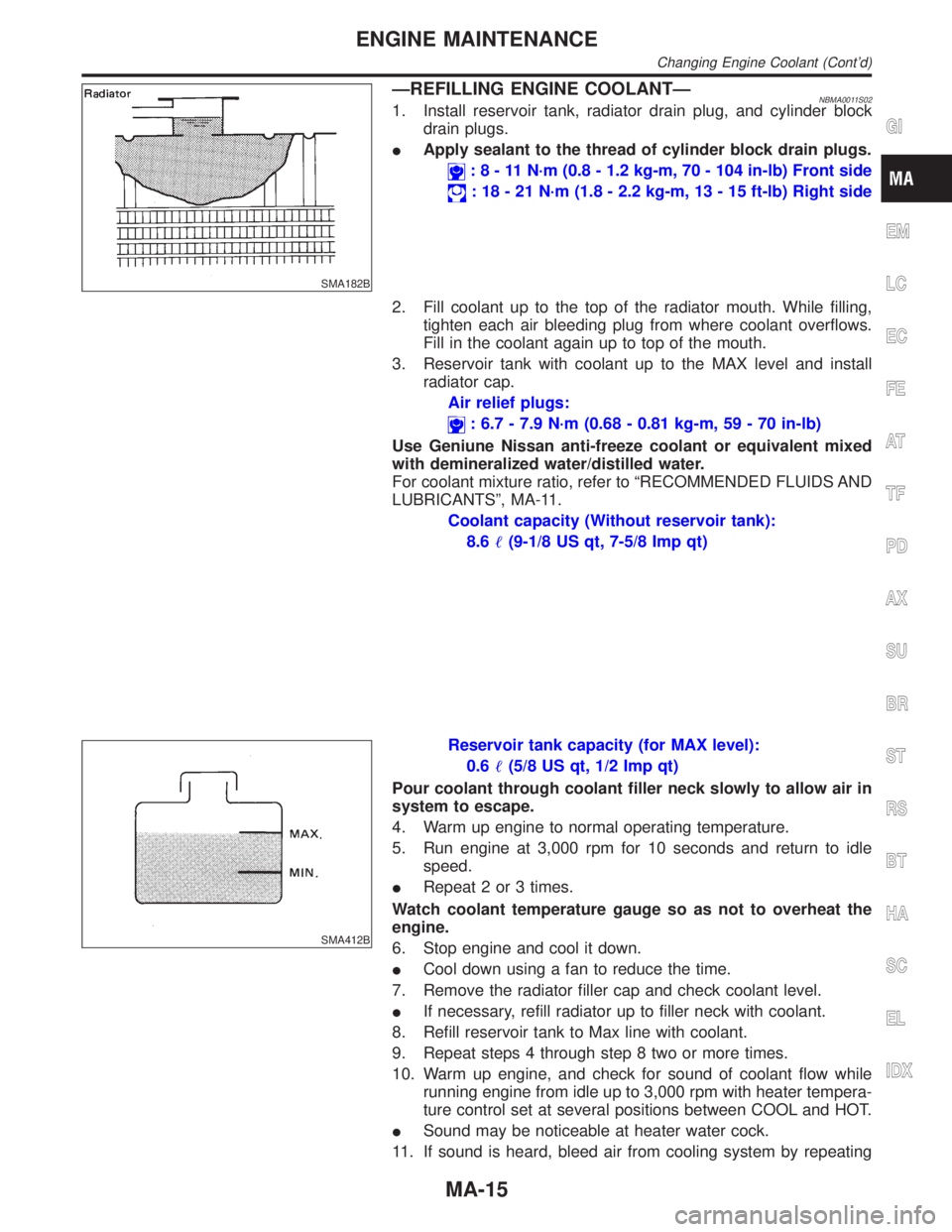

ÐREFILLING ENGINE COOLANTÐNBMA0011S021. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

IApply sealant to the thread of cylinder block drain plugs.

:8-11N´m(0.8 - 1.2 kg-m, 70 - 104 in-lb) Front side

: 18 - 21 N´m (1.8 - 2.2 kg-m, 13 - 15 ft-lb) Right side

2. Fill coolant up to the top of the radiator mouth. While filling,

tighten each air bleeding plug from where coolant overflows.

Fill in the coolant again up to top of the mouth.

3. Reservoir tank with coolant up to the MAX level and install

radiator cap.

Air relief plugs:

: 6.7 - 7.9 N´m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

Use Geniune Nissan anti-freeze coolant or equivalent mixed

with demineralized water/distilled water.

For coolant mixture ratio, refer to ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-11.

Coolant capacity (Without reservoir tank):

8.6(9-1/8 US qt, 7-5/8 Imp qt)

SMA412B

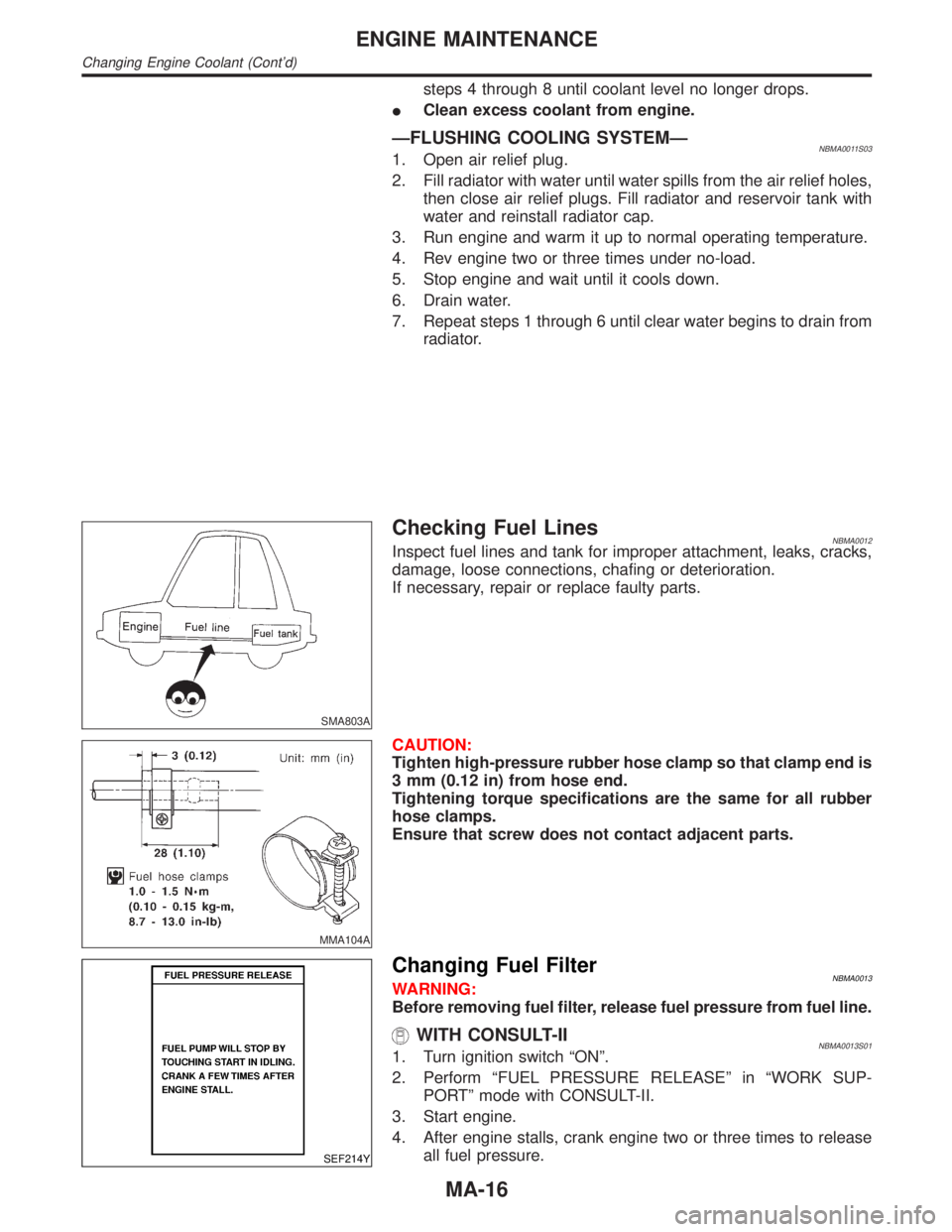

Reservoir tank capacity (for MAX level):

0.6(5/8 US qt, 1/2 Imp qt)

Pour coolant through coolant filler neck slowly to allow air in

system to escape.

4. Warm up engine to normal operating temperature.

5. Run engine at 3,000 rpm for 10 seconds and return to idle

speed.

IRepeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

6. Stop engine and cool it down.

ICool down using a fan to reduce the time.

7. Remove the radiator filler cap and check coolant level.

IIf necessary, refill radiator up to filler neck with coolant.

8. Refill reservoir tank to Max line with coolant.

9. Repeat steps 4 through step 8 two or more times.

10. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

ISound may be noticeable at heater water cock.

11. If sound is heard, bleed air from cooling system by repeating

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE MAINTENANCE

Changing Engine Coolant (Cont'd)

MA-15

Page 2011 of 2395

steps 4 through 8 until coolant level no longer drops.

IClean excess coolant from engine.

ÐFLUSHING COOLING SYSTEMÐNBMA0011S031. Open air relief plug.

2. Fill radiator with water until water spills from the air relief holes,

then close air relief plugs. Fill radiator and reservoir tank with

water and reinstall radiator cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from

radiator.

SMA803A

Checking Fuel LinesNBMA0012Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

SEF214Y

Changing Fuel FilterNBMA0013WARNING:

Before removing fuel filter, release fuel pressure from fuel line.

WITH CONSULT-IINBMA0013S011. Turn ignition switch ªONº.

2. Perform ªFUEL PRESSURE RELEASEº in ªWORK SUP-

PORTº mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank engine two or three times to release

all fuel pressure.

ENGINE MAINTENANCE

Changing Engine Coolant (Cont'd)

MA-16