torque INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1745 of 2395

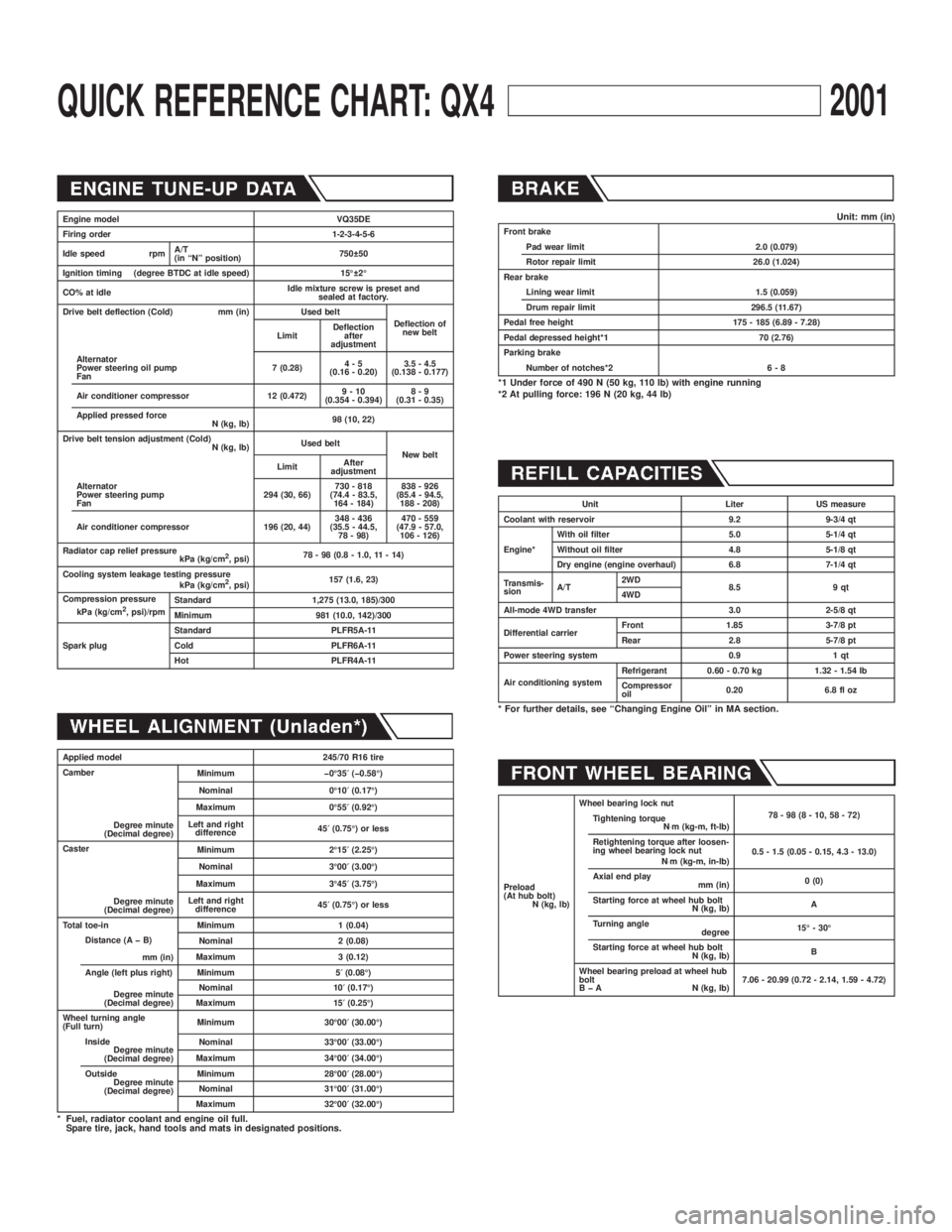

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1747 of 2395

Wheels & Tires ..........................................................44

LIFTING POINTS AND TOW TRUCK TOWING...........45

Screw Jack ................................................................45

Garage Jack and Safety Stand .................................46

2-pole Lift ...................................................................47

Tow Truck Towing ......................................................472WD MODELS.........................................................48

4WD MODELS.........................................................48

VEHICLE RECOVERY..............................................49

TIGHTENING TORQUE OF STANDARD BOLTS........50

SAE J1930 TERMINOLOGY LIST................................51

SAE J1930 Terminology List .....................................51

CONTENTS(Cont'd)

GI-2

Page 1754 of 2395

NBGI0002

IThe captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

IALPHABETICAL INDEXis provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

IA QUICK REFERENCE INDEX, a black tab (e.g.

) is provided on the first page. You can quickly find

the first page of each section by mating it to the section's black tab.

ITHE CONTENTSare listed on the first page of each section.

ITHE TITLEis indicated on the upper portion of each page and shows the part or system.

ITHE PAGE NUMBERof each section consists of two letters which designate the particular section and a

number (e.g. ªBR-5º).

ITHE LARGE ILLUSTRATIONSare exploded views (See below.) and contain tightening torques, lubrica-

tion points, section number of thePARTS CATALOG(e.g. SEC. 440) and other information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriatePARTS CATALOG.

SBR364AC

ITHE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

ITheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

ªExampleº

Tightening torque:

59 - 78 N´m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

ITROUBLE DIAGNOSESare included in sections dealing with complicated components.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO USE THIS MANUAL

GI-9

Page 1755 of 2395

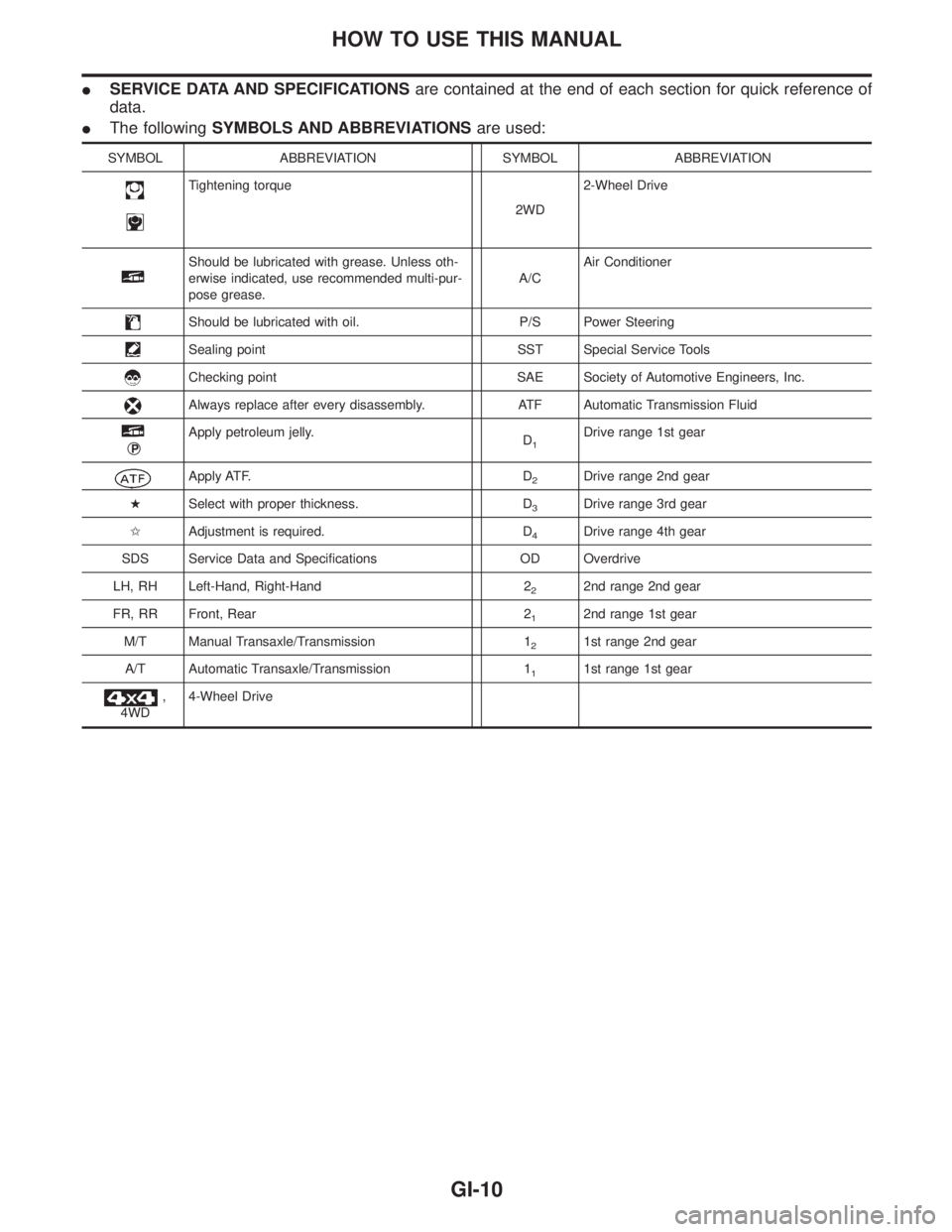

ISERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

IThe followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

qP

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

HSelect with proper thickness. D

3Drive range 3rd gear

IAdjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

,

4WD4-Wheel Drive

HOW TO USE THIS MANUAL

GI-10

Page 1795 of 2395

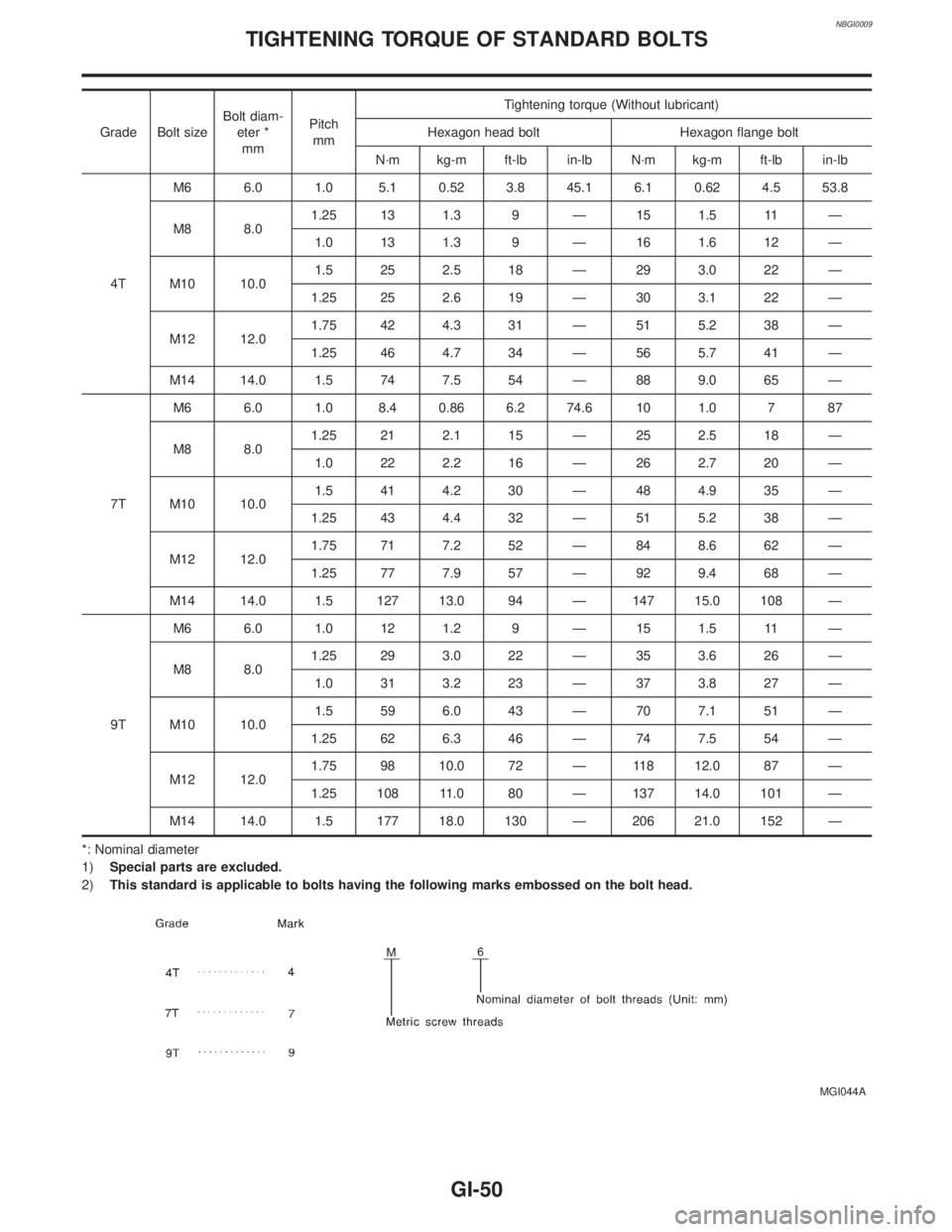

NBGI0009

Grade Bolt sizeBolt diam-

eter *

mmPitch

mmTightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N´m kg-m ft-lb in-lb N´m kg-m ft-lb in-lb

4TM6 6.0 1.0 5.1 0.52 3.8 45.1 6.1 0.62 4.5 53.8

M8 8.01.25 13 1.3 9 Ð 15 1.5 11 Ð

1.0 13 1.3 9 Ð 16 1.6 12 Ð

M10 10.01.5 25 2.5 18 Ð 29 3.0 22 Ð

1.25 25 2.6 19 Ð 30 3.1 22 Ð

M12 12.01.75 42 4.3 31 Ð 51 5.2 38 Ð

1.25 46 4.7 34 Ð 56 5.7 41 Ð

M14 14.0 1.5 74 7.5 54 Ð 88 9.0 65 Ð

7TM6 6.0 1.0 8.4 0.86 6.2 74.6 10 1.0 7 87

M8 8.01.25 21 2.1 15 Ð 25 2.5 18 Ð

1.0 22 2.2 16 Ð 26 2.7 20 Ð

M10 10.01.5 41 4.2 30 Ð 48 4.9 35 Ð

1.25 43 4.4 32 Ð 51 5.2 38 Ð

M12 12.01.75 71 7.2 52 Ð 84 8.6 62 Ð

1.25 77 7.9 57 Ð 92 9.4 68 Ð

M14 14.0 1.5 127 13.0 94 Ð 147 15.0 108 Ð

9TM6 6.0 1.0 12 1.2 9 Ð 15 1.5 11 Ð

M8 8.01.25 29 3.0 22 Ð 35 3.6 26 Ð

1.0 31 3.2 23 Ð 37 3.8 27 Ð

M10 10.01.5 59 6.0 43 Ð 70 7.1 51 Ð

1.25 62 6.3 46 Ð 74 7.5 54 Ð

M12 12.01.75 98 10.0 72 Ð 118 12.0 87 Ð

1.25 108 11.0 80 Ð 137 14.0 101 Ð

M14 14.0 1.5 177 18.0 130 Ð 206 21.0 152 Ð

*: Nominal diameter

1)Special parts are excluded.

2)This standard is applicable to bolts having the following marks embossed on the bolt head.

MGI044A

TIGHTENING TORQUE OF STANDARD BOLTS

GI-50

Page 1799 of 2395

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

temWU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter

systemWU-TWC system ***

Wide open throttle position switch WOTP switch Full switch

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-54

Page 1805 of 2395

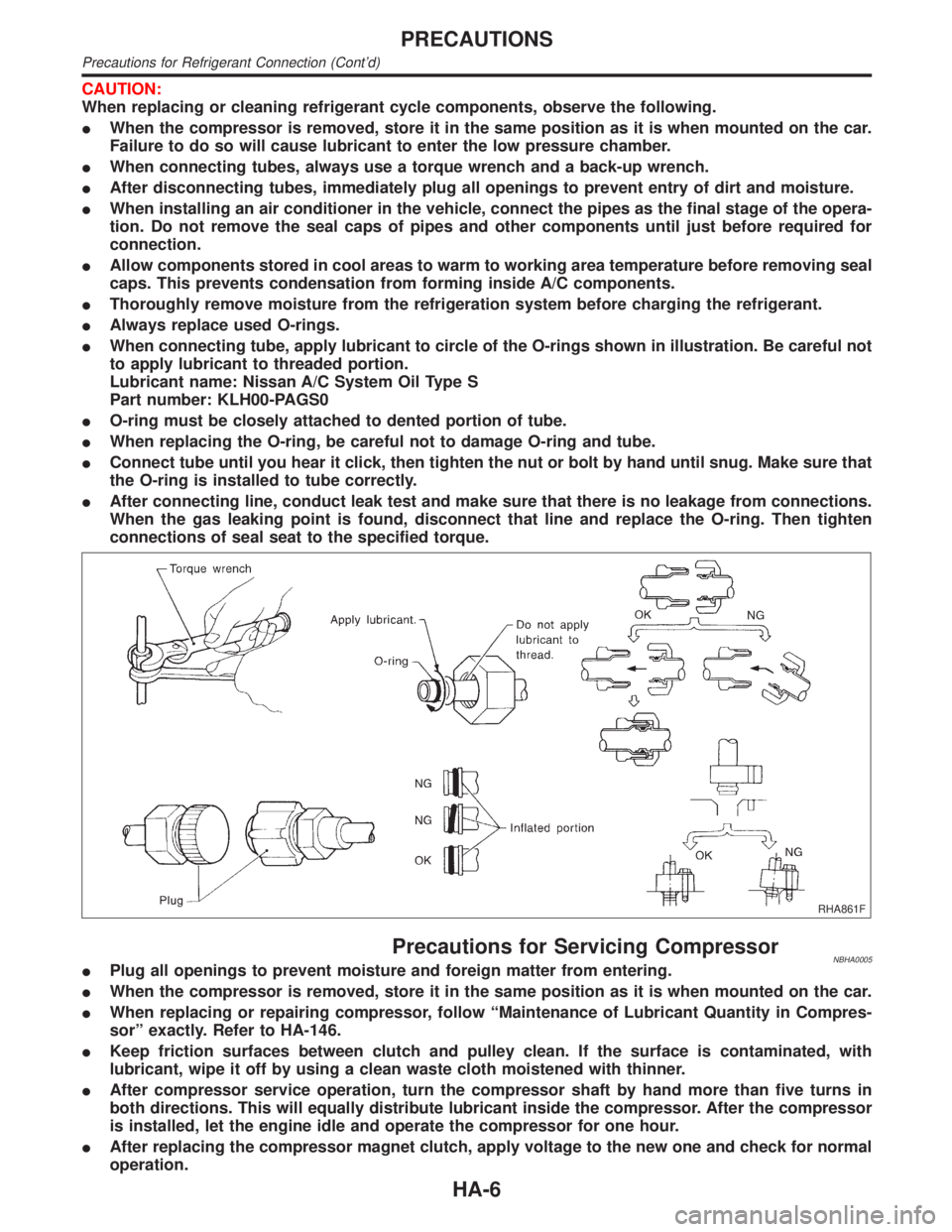

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

IWhen connecting tubes, always use a torque wrench and a back-up wrench.

IAfter disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

IWhen installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

IAllow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

IThoroughly remove moisture from the refrigeration system before charging the refrigerant.

IAlways replace used O-rings.

IWhen connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

IO-ring must be closely attached to dented portion of tube.

IWhen replacing the O-ring, be careful not to damage O-ring and tube.

IConnect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

IAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNBHA0005IPlug all openings to prevent moisture and foreign matter from entering.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

IWhen replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-146.

IKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

IAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

IAfter replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-6

Page 1947 of 2395

Lubricant Adjusting Procedure for Components

Replacement Except Compressor

=NBHA0071S0201After replacing any of the following major components, add the

correct amount of lubricant to the system.

Amount of lubricant to be added

Part replacedLubricant to be added to

system

Remarks

Amount of lubricant

m(US fl oz, Imp fl oz)

Evaporator 75 (2.5, 2.6) Ð

Condenser 75 (2.5, 2.6) Ð

Liquid tank 5 (0.2, 0.2)Add if compressor is not

replaced. *1

In case of refrigerant

leak30 (1.0, 1.1) Large leak

Ð Small leak *2

*1: If compressor is replaced, addition of lubricant is included in the table.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjusting Procedure for Compressor

Replacement

NBHA0071S02021. Before connecting ACR4 to vehicle, check ACR4 gauges. No

refrigerant pressure should be displayed. If NG, recover refrig-

erant from equipment lines.

2. Connect ACR4 to vehicle. Confirm refrigerant purity in supply

tank using ACR4 and refrigerant identifier. If NG, refer to

ªCONTAMINATED REFRIGERANTº, HA-2.

3. Confirm refrigerant purity in vehicle A/C system using ACR4

and refrigerant identifier. If NG, refer to ªCONTAMINATED

REFRIGERANTº, HA-2.

4. Discharge refrigerant into the refrigerant recovery/recycling

equipment. Measure lubricant discharged into the recovery/

recycling equipment.

5. Remove the drain plug of the ªoldº (removed) compressor.

Drain the lubricant into a graduated container and record the

amount of drained lubricant.

6. Remove the drain plug and drain the lubricant from the ªnewº

compressor into a separate, clean container.

7. Measure an amount of new lubricant installed equal to amount

drained from ªoldº compressor. Add this lubricant to ªnewº com-

pressor through the suction port opening.

8. Measure an amount of new lubricant equal to the amount

recovered during discharging. Add this lubricant to ªnewº com-

pressor through the suction port opening.

9. Torque the drain plug.

18 - 19 N´m (1.8 - 1.9 kg-m, 13 - 14 ft-lb)

10. If the liquid tank also needs to be replaced, add an additional

5m(0.2 US fl oz, 0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m(0.2 US fl oz, 0.2 Imp fl oz) of lubri-

cant if only replacing the compressor.

SERVICE PROCEDURE

Maintenance of Lubricant Quantity in Compressor (Cont'd)

HA-148

Page 1951 of 2395

CoilNBHA0075S03Check coil for loose connection or cracked insulation.

RHA142E

INSTALLATIONNBHA0076IInstall the field coil.

Be sure to align the coil's pin with the hole in the com-

pressor's front head.

IInstall the field coil harness clip using a screwdriver.

RHA143EA

IInstall the pulley assembly using the installer and a hand

press, and then install the snap ring using snap ring pliers.

RHA127F

IInstall the clutch disc on the drive shaft, together with the

original shim(s). Press the clutch disc down by hand.

RHA086E

IUsing the holder to prevent clutch disc rotation, tighten the bolt

to 14 N´m (1.4 kg-m, 10 ft-lb) torque.

After tightening the bolt, check that the pulley rotates

smoothly.

SERVICE PROCEDURE

Compressor Clutch (Cont'd)

HA-152

Page 1952 of 2395

RHA087E

ICheck clearance around the entire periphery of clutch disc.

Disc-to-pulley clearance:

0.3 - 0.6 mm (0.012 - 0.024 in)

If the specified clearance is not obtained, replace adjusting

spacer and readjust.

Break-in OperationNBHA0076S01When replacing compressor clutch assembly, always carry out the

break-in operation. This is done by engaging and disengaging the

clutch about thirty times. Break-in operation raises the level of

transmitted torque.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDURE

Compressor Clutch (Cont'd)

HA-153