torque INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2185 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(See J25765-A)

1 GG91030000

(J25765-A)

Torque wrench

2 HT62940000

(Ð)

Socket adapter

3 HT62900000

(Ð)

Socket adapter

NT541

Measuring turning torque

KV48104400

(Ð)

Rack seal ring reformer

NT550

Reforming teflon ring

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)

KV48103400

(Ð)

Torque adapter

NT236

Measuring steering transfer gear rotating

torque

KV48104200

(Ð)

Rear cover wrench

NT540

Removing and installing gear housing end

cover

a: 4 mm (0.16 in) dia.

b: 5 mm (0.20 in)

c: 3 mm (0.12 in) dia.

d: 5 mm (0.20 in)

(J43995)

Steering lock nut wrench

NT838

Adjusting steering pinion rotating torque

(J43996)

Steering rack adjustment

wrench

NT839

Adjusting steering pinion rotating torque

(J-44372)

Spring gauge

LST024

Measuring steering wheel turning force

PREPARATION

Special Service Tools (Cont'd)

ST-4

Page 2187 of 2395

NBST0043

NVH Troubleshooting ChartNBST0043S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-8

ST-9

ST-21

ST-21

ST-21

ST-8

ST-7

ST-9

MA-13

Ð

ST-13

ST-8

ST-13

ST-13

ST-17

PD-3

PD-3

AX-3

AX-3

SU-3

SU-3

SU-3

BR-6

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symp-

tomSTEERINGNoise´´´´´´´´´ ´´´´´´´´

Shake´´´ ´ ´´´´´´

Vibration´´´´´ ´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-6

Page 2197 of 2395

SST847C

InstallationNBST00221. Set wheels in the straight-ahead position.

2. Install transfer gear assembly.

3. Install column lower joint while aligning groove with protrusions

on the steering gear rear cover cap.

4. Tighten bolt while aligning groove on steering gear. Before

tightening bolt, ensure it is inserted correctly.

SST848C

5. When attaching steering column upper and lower joint to trans-

fer gear, it must be positioned as shown in figure at left.

SST707CA

InspectionNBST0024Do not disassemble steering transfer gear assembly.

ICheck that steering transfer gear assembly operates smoothly.

Also check for grease leakage, deformation and damage.

Replace steering transfer gear assembly if necessary.

ICheck rotating torque at input shaft in 360É and in both direc-

tions.

Rotating torque:

0.25 - 0.69 N´m (2.5 - 7.0 kg-cm, 2.2 - 6.1 in-lb)

If rotating torque is out of specification, replace steering trans-

fer gear assembly.

STEERING TRANSFER GEAR

Installation

ST-16

Page 2199 of 2395

Removal and InstallationNBST0027

SST614C

1. Gear and linkage assembly

2. Rack mounting insulator3. Gear housing mounting bracket 4. Cotter pin

SFA756B

CAUTION:

IThe rotation of the spiral cable (SRS ªAIR BAGº compo-

nent part) is limited. If the steering gear must be removed,

set the front wheels in the straight-ahead direction. Do not

rotate the steering column while the steering gear is

removed.

IRemove the steering wheel before removing the steering

lower joint to avoid damaging the SRS spiral cable.

IDetach tie-rod outer sockets from knuckle arms with Tool.

SST615C

IInstall pipe connector.

IObserve specified tightening torque when tightening high-pres-

sure and low-pressure pipe connectors. Excessive tightening

will damage threads of connector or O-ring.

Connector tightening torque:

Low-pressure side ª1º

30 - 35 N´m (3.1 - 3.6 kg-m, 22 - 26 ft-lb)

High-pressure side ª2º

30 - 35 N´m (3.1 - 3.6 kg-m, 22 - 26 ft-lb)

IThe O-ring in low-pressure pipe connector is larger than that

POWER STEERING GEAR AND LINKAGE

Removal and Installation

ST-18

Page 2200 of 2395

in high-pressure connector. Take care to install the proper

O-ring.

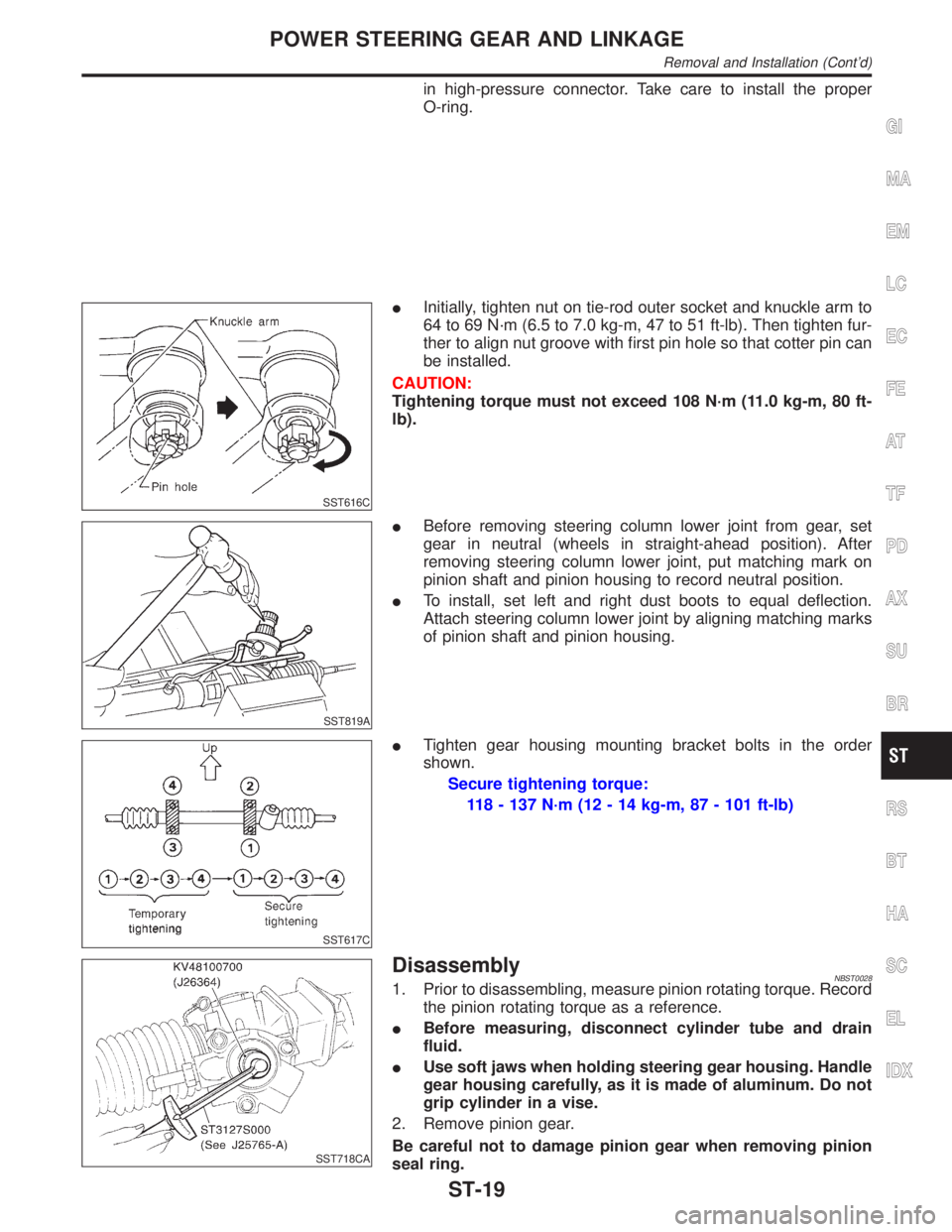

SST616C

IInitially, tighten nut on tie-rod outer socket and knuckle arm to

64 to 69 N´m (6.5 to 7.0 kg-m, 47 to 51 ft-lb). Then tighten fur-

ther to align nut groove with first pin hole so that cotter pin can

be installed.

CAUTION:

Tightening torque must not exceed 108 N´m (11.0 kg-m, 80 ft-

lb).

SST819A

IBefore removing steering column lower joint from gear, set

gear in neutral (wheels in straight-ahead position). After

removing steering column lower joint, put matching mark on

pinion shaft and pinion housing to record neutral position.

ITo install, set left and right dust boots to equal deflection.

Attach steering column lower joint by aligning matching marks

of pinion shaft and pinion housing.

SST617C

ITighten gear housing mounting bracket bolts in the order

shown.

Secure tightening torque:

118 - 137 N´m (12 - 14 kg-m, 87 - 101 ft-lb)

SST718CA

DisassemblyNBST00281. Prior to disassembling, measure pinion rotating torque. Record

the pinion rotating torque as a reference.

IBefore measuring, disconnect cylinder tube and drain

fluid.

IUse soft jaws when holding steering gear housing. Handle

gear housing carefully, as it is made of aluminum. Do not

grip cylinder in a vise.

2. Remove pinion gear.

Be careful not to damage pinion gear when removing pinion

seal ring.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont'd)

ST-19

Page 2202 of 2395

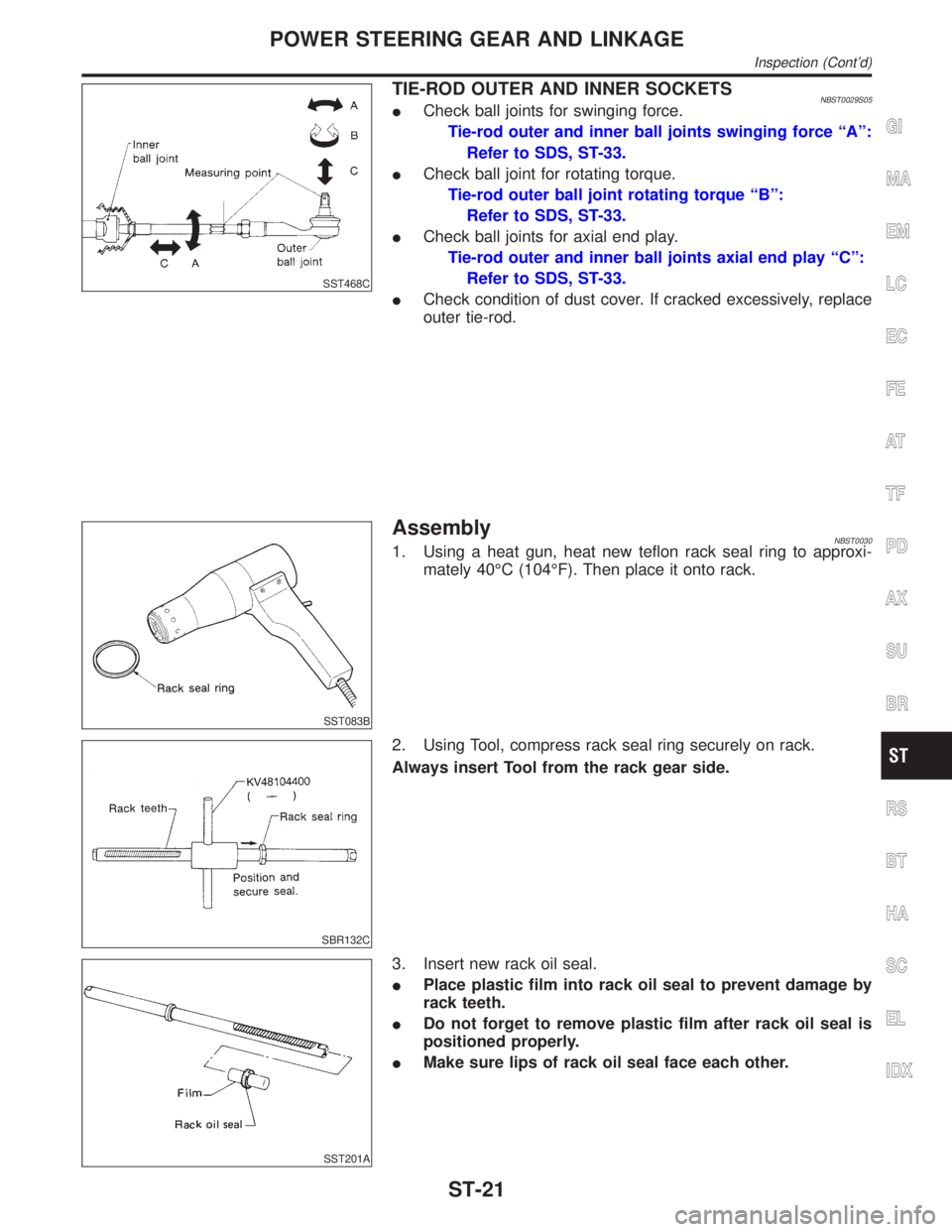

SST468C

TIE-ROD OUTER AND INNER SOCKETSNBST0029S05ICheck ball joints for swinging force.

Tie-rod outer and inner ball joints swinging force ªAº:

Refer to SDS, ST-33.

ICheck ball joint for rotating torque.

Tie-rod outer ball joint rotating torque ªBº:

Refer to SDS, ST-33.

ICheck ball joints for axial end play.

Tie-rod outer and inner ball joints axial end play ªCº:

Refer to SDS, ST-33.

ICheck condition of dust cover. If cracked excessively, replace

outer tie-rod.

SST083B

AssemblyNBST00301. Using a heat gun, heat new teflon rack seal ring to approxi-

mately 40ÉC (104ÉF). Then place it onto rack.

SBR132C

2. Using Tool, compress rack seal ring securely on rack.

Always insert Tool from the rack gear side.

SST201A

3. Insert new rack oil seal.

IPlace plastic film into rack oil seal to prevent damage by

rack teeth.

IDo not forget to remove plastic film after rack oil seal is

positioned properly.

IMake sure lips of rack oil seal face each other.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Inspection (Cont'd)

ST-21

Page 2205 of 2395

SST609C

14. Ensure that the rack is centered. Install rear cover cap so that

its protrusion is positioned as shown in figure.

Be careful not to damage worm ring and oil seal.

15. Install retainer, spring and adjusting screw temporarily.

SST135C

16. Install new lock plate.

IAttach lock plate 2 to side rod inner socket 1.

IApply locking sealant to inner socket threads 3.

Screw inner socket into rack 4 and tighten to specified torque.

IClinch two places of lock plate at rack's groove.

CAUTION:

To prevent scratching the boot, remove burrs from lock plate.

SST655C

17. Tighten outer socket lock nut.

Tie-rod length ªLº:

Refer to SDS, ST-33.

18. Measure rack stroke.

Rack stroke ªSº:

Refer to SDS, ST-33.

SST967A

19. Before installing boot, coat the contact surfaces between boot

and tie-rod with grease.

SST619C

AdjustmentNBST0031Adjust pinion rotating torque as follows:

1. Set rack to the neutral position without fluid in the gear.

2. Coat the adjusting screw with locking sealant and screw it in.

3. Lightly tighten lock nut.

4. Tighten adjusting screw to a torque of 4.9 to 5.9 N´m (50 to 60

kg-cm, 43 to 52 in-lb).

5. Loosen adjusting screw, then retighten it to 0.2 N´m (2 kg-cm,

1.7 in-lb).

POWER STEERING GEAR AND LINKAGE

Assembly (Cont'd)

ST-24

Page 2206 of 2395

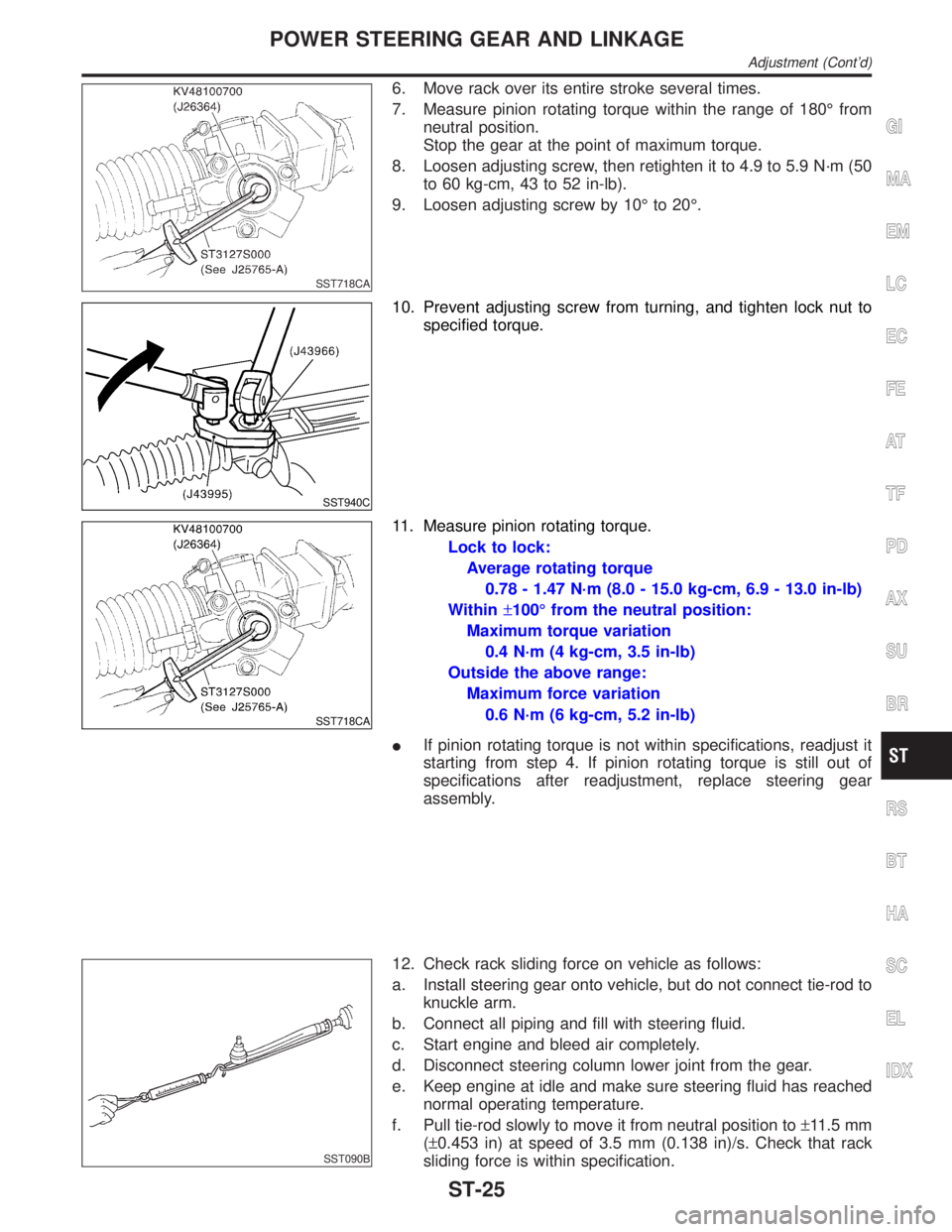

SST718CA

6. Move rack over its entire stroke several times.

7. Measure pinion rotating torque within the range of 180É from

neutral position.

Stop the gear at the point of maximum torque.

8. Loosen adjusting screw, then retighten it to 4.9 to 5.9 N´m (50

to 60 kg-cm, 43 to 52 in-lb).

9. Loosen adjusting screw by 10É to 20É.

SST940C

10. Prevent adjusting screw from turning, and tighten lock nut to

specified torque.

SST718CA

11. Measure pinion rotating torque.

Lock to lock:

Average rotating torque

0.78 - 1.47 N´m (8.0 - 15.0 kg-cm, 6.9 - 13.0 in-lb)

Within±100É from the neutral position:

Maximum torque variation

0.4 N´m (4 kg-cm, 3.5 in-lb)

Outside the above range:

Maximum force variation

0.6 N´m (6 kg-cm, 5.2 in-lb)

IIf pinion rotating torque is not within specifications, readjust it

starting from step 4. If pinion rotating torque is still out of

specifications after readjustment, replace steering gear

assembly.

SST090B

12. Check rack sliding force on vehicle as follows:

a. Install steering gear onto vehicle, but do not connect tie-rod to

knuckle arm.

b. Connect all piping and fill with steering fluid.

c. Start engine and bleed air completely.

d. Disconnect steering column lower joint from the gear.

e. Keep engine at idle and make sure steering fluid has reached

normal operating temperature.

f. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Adjustment (Cont'd)

ST-25

Page 2212 of 2395

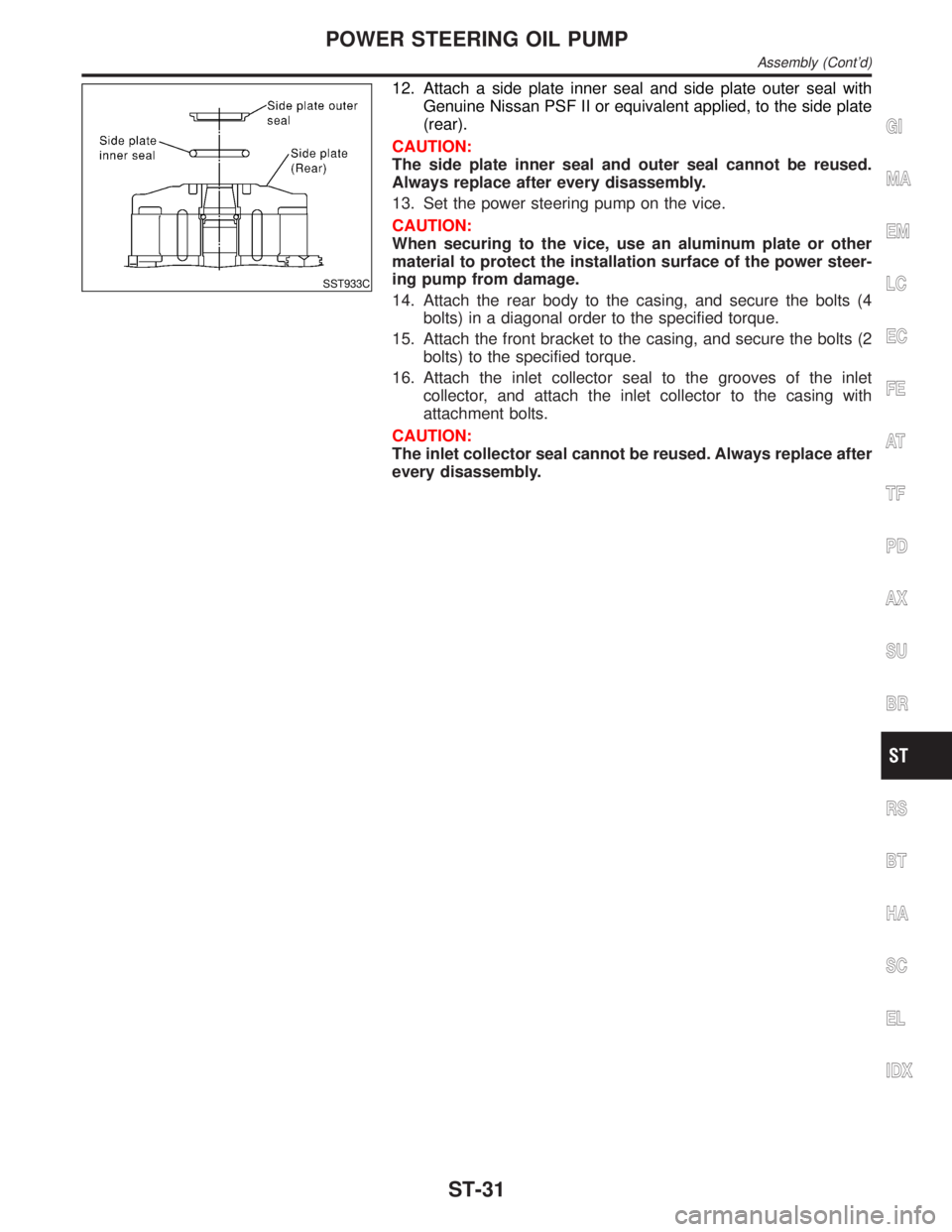

SST933C

12. Attach a side plate inner seal and side plate outer seal with

Genuine Nissan PSF II or equivalent applied, to the side plate

(rear).

CAUTION:

The side plate inner seal and outer seal cannot be reused.

Always replace after every disassembly.

13. Set the power steering pump on the vice.

CAUTION:

When securing to the vice, use an aluminum plate or other

material to protect the installation surface of the power steer-

ing pump from damage.

14. Attach the rear body to the casing, and secure the bolts (4

bolts) in a diagonal order to the specified torque.

15. Attach the front bracket to the casing, and secure the bolts (2

bolts) to the specified torque.

16. Attach the inlet collector seal to the grooves of the inlet

collector, and attach the inlet collector to the casing with

attachment bolts.

CAUTION:

The inlet collector seal cannot be reused. Always replace after

every disassembly.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PUMP

Assembly (Cont'd)

ST-31

Page 2213 of 2395

General SpecificationsNBST0037

Applied modelAll

Steering modelPower steering

Steering gear typePR32K

Steering overall gear ratio 17.2

Turns of steering wheel

(Lock to lock)3.09

Steering column type Collapsible, tilt

Steering WheelNBST0038Unit: mm (in)

Steering wheel axial play0 (0)

Steering wheel play35 (1.38) or less

Movement of gear housing±2(±0.08) or less

Steering ColumnNBST0039Unit: mm (in)

Steering column length ªL1º 716.7 - 718.7 (28.22 - 28.30)

Steering column lower shaft length ªL

2º 178 - 180 (7.01 - 7.09)

Steering column upper joint length ªL

3º 430.7 - 432.7 (16.96 - 17.04)

SST739C

Steering Transfer GearNBST0041

Rotating torque0.25 - 0.69 N´m (2.5 - 7.0 kg-cm, 2.2 - 6.1 in-lb)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications

ST-32