torque INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2051 of 2395

SPD893

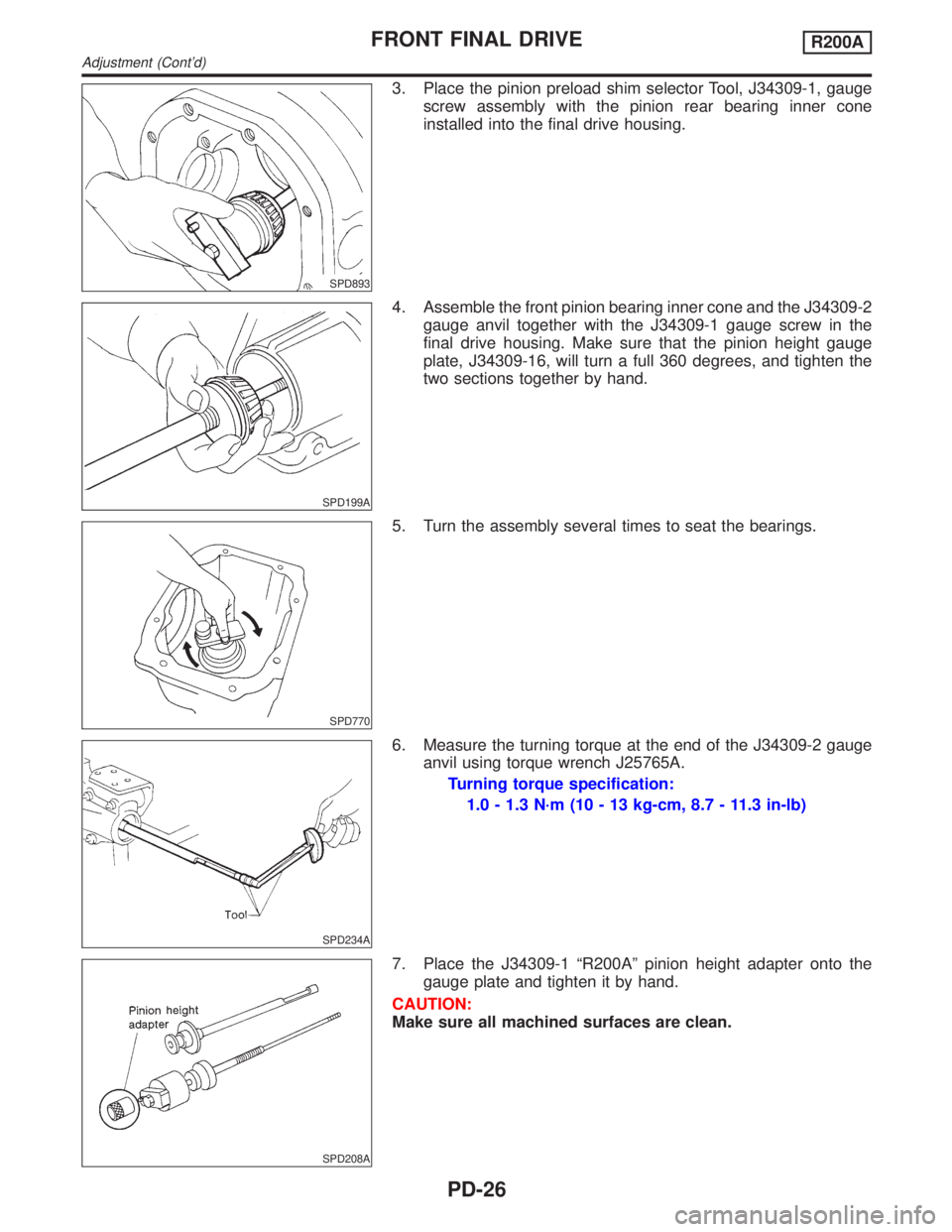

3. Place the pinion preload shim selector Tool, J34309-1, gauge

screw assembly with the pinion rear bearing inner cone

installed into the final drive housing.

SPD199A

4. Assemble the front pinion bearing inner cone and the J34309-2

gauge anvil together with the J34309-1 gauge screw in the

final drive housing. Make sure that the pinion height gauge

plate, J34309-16, will turn a full 360 degrees, and tighten the

two sections together by hand.

SPD770

5. Turn the assembly several times to seat the bearings.

SPD234A

6. Measure the turning torque at the end of the J34309-2 gauge

anvil using torque wrench J25765A.

Turning torque specification:

1.0 - 1.3 N´m (10 - 13 kg-cm, 8.7 - 11.3 in-lb)

SPD208A

7. Place the J34309-1 ªR200Aº pinion height adapter onto the

gauge plate and tighten it by hand.

CAUTION:

Make sure all machined surfaces are clean.

FRONT FINAL DRIVER200A

Adjustment (Cont'd)

PD-26

Page 2058 of 2395

SPD581

4. Place pinion front bearing inner cone in final drive housing.

SPD680

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Install front oil seal.

Tool number:

KV38100500 (J25273)

SPD658

6. Place drive pinion bearing spacer, drive pinion bearing adjust-

ing washer and drive pinion in final drive housing.

SPD681

7. Insert companion flange into drive pinion by tapping the com-

panion flange with a soft hammer.

SPD478A

8. Tighten pinion nut to the specified torque.

The threaded portion of drive pinion and pinion nut should be

free from oil or grease.

Tool number: KV38108300 (J44195)

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Assembly (Cont'd)

PD-33

Page 2063 of 2395

Preparation

SPECIAL SERVICE TOOLSNBPD0029The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

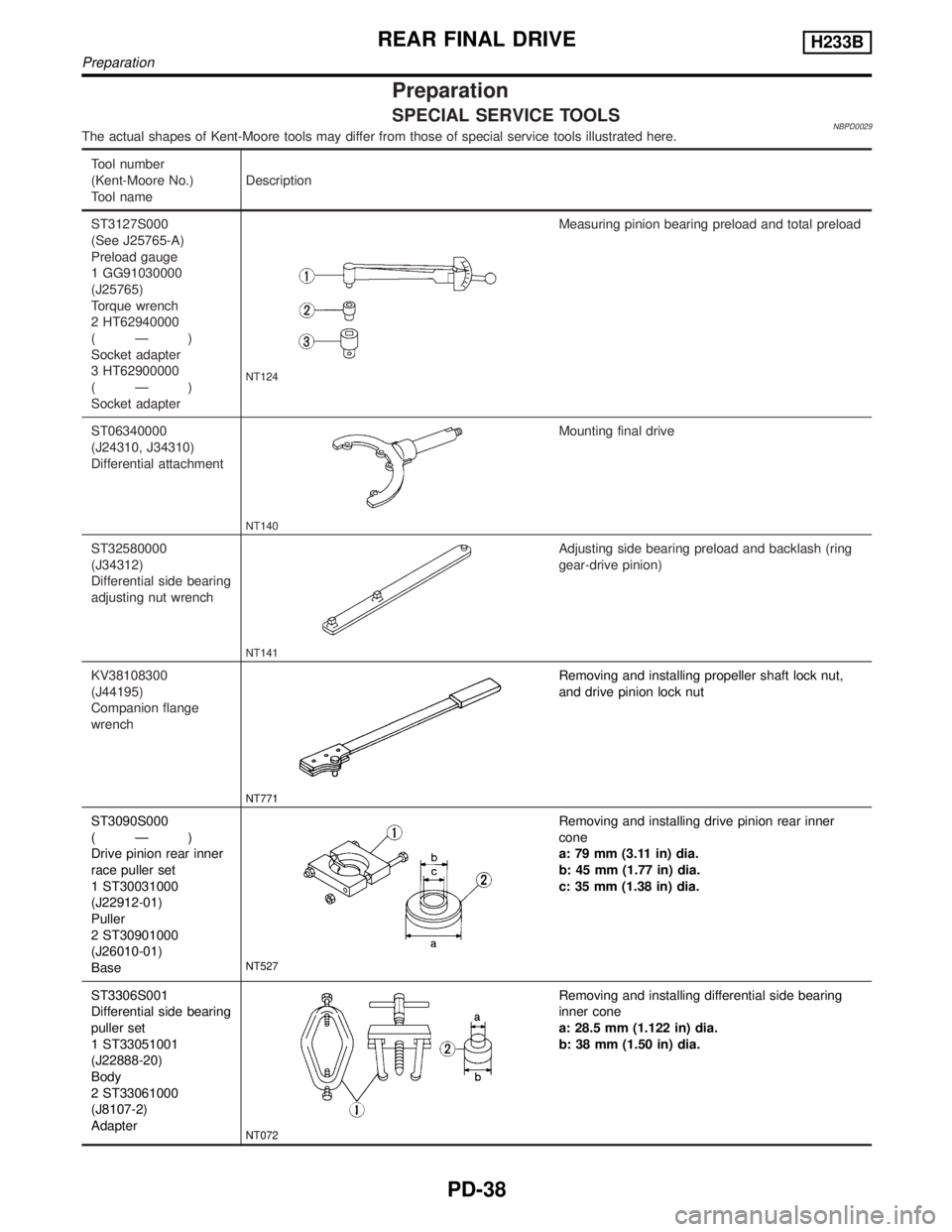

ST3127S000

(See J25765-A)

Preload gauge

1 GG91030000

(J25765)

Torque wrench

2 HT62940000

(Ð)

Socket adapter

3 HT62900000

(Ð)

Socket adapter

NT124

Measuring pinion bearing preload and total preload

ST06340000

(J24310, J34310)

Differential attachment

NT140

Mounting final drive

ST32580000

(J34312)

Differential side bearing

adjusting nut wrench

NT141

Adjusting side bearing preload and backlash (ring

gear-drive pinion)

KV38108300

(J44195)

Companion flange

wrench

NT771

Removing and installing propeller shaft lock nut,

and drive pinion lock nut

ST3090S000

(Ð)

Drive pinion rear inner

race puller set

1 ST30031000

(J22912-01)

Puller

2 ST30901000

(J26010-01)

Base

NT527

Removing and installing drive pinion rear inner

cone

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35 mm (1.38 in) dia.

ST3306S001

Differential side bearing

puller set

1 ST33051001

(J22888-20)

Body

2 ST33061000

(J8107-2)

Adapter

NT072

Removing and installing differential side bearing

inner cone

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

REAR FINAL DRIVEH233B

Preparation

PD-38

Page 2065 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

(J25269-18)

Side bearing discs

(2 Req'd)

NT135

Selecting pinion height adjusting washer

KV381052S0

(Ð)

Rear axle shaft dummy

1 KV38105210

(Ð)

Torque wrench side

2 KV38105220

(Ð)

Vice side

NT142

Checking differential torque on limited slip differen-

tial

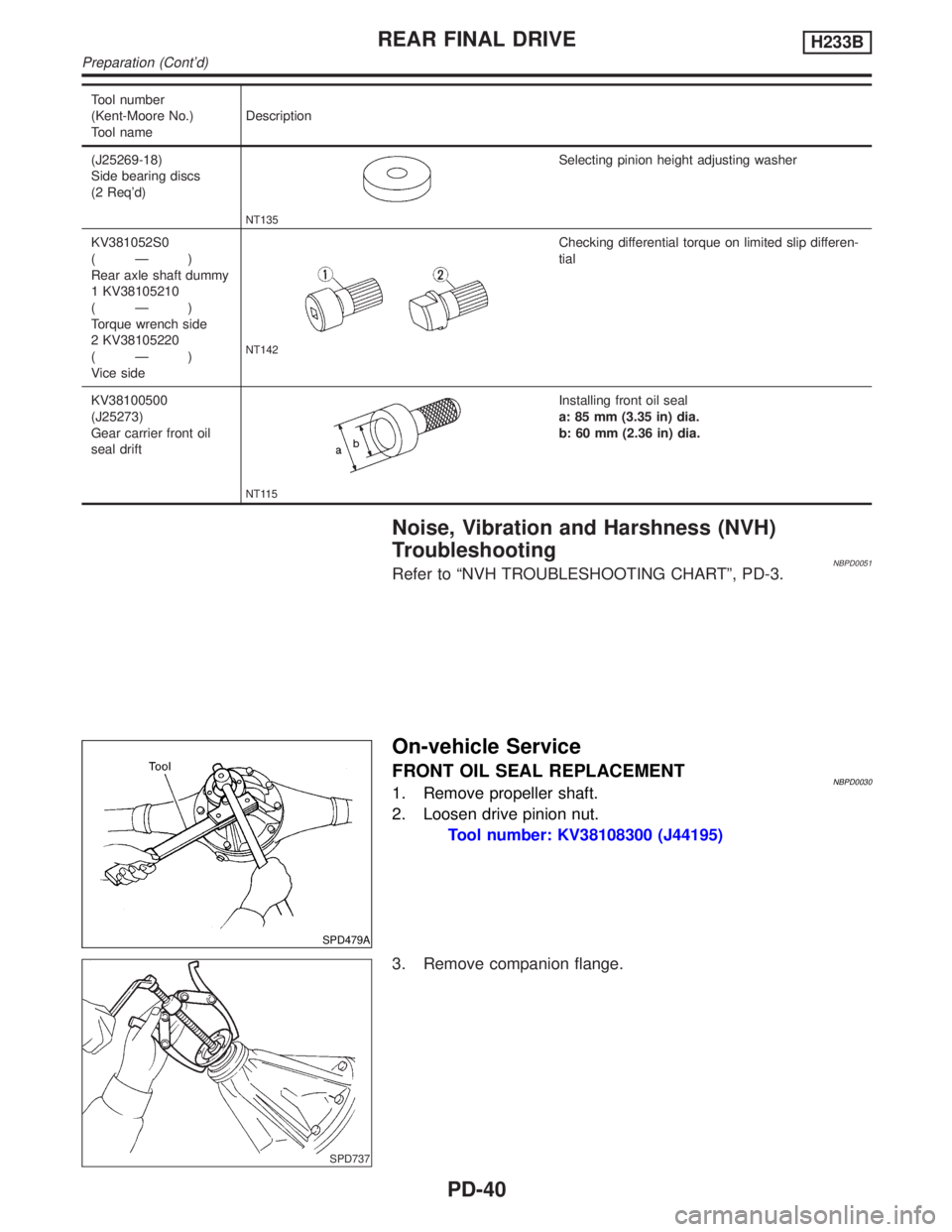

KV38100500

(J25273)

Gear carrier front oil

seal drift

NT115

Installing front oil seal

a: 85 mm (3.35 in) dia.

b: 60 mm (2.36 in) dia.

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBPD0051Refer to ªNVH TROUBLESHOOTING CHARTº, PD-3.

SPD479A

On-vehicle Service

FRONT OIL SEAL REPLACEMENTNBPD00301. Remove propeller shaft.

2. Loosen drive pinion nut.

Tool number: KV38108300 (J44195)

SPD737

3. Remove companion flange.

REAR FINAL DRIVEH233B

Preparation (Cont'd)

PD-40

Page 2072 of 2395

SPD025

4. Drive out pinion mate shaft lock pin, with punch from ring gear

side.

Lock pin is calked at pin hole mouth on differential case.

InspectionNBPD0034RING GEAR AND DRIVE PINIONNBPD0034S01Check gear teeth for scoring, cracking or chipping.

If any damaged part is evident, replace ring gear and drive pinion

as a set (hypoid gear set).

SPD530-A

DIFFERENTIAL CASE ASSEMBLYNBPD0034S02Check mating surfaces of differential case, side gears, pinion mate

gears, pinion mate shaft, and thrust washers.

SPD715

BEARINGNBPD0034S031. Thoroughly clean bearing.

2. Check bearings for wear, scratches, pitting or flaking.

Check tapered roller bearing for smooth rotation. If damaged,

replace outer race and inner cone as a set.

SPD415

Limited Slip Differential

PREPARATION FOR DISASSEMBLYNBPD0035Checking Differential TorqueNBPD0035S01Measure differential torque with Tool.

If it is not within the specifications, inspect components of limited

slip differential.

Differential torque:

88 - 108 N´m (9 - 11 kg-m, 65 - 80 ft-lb)

Tool number: A KV38105210 ( Ð )

Tool number: B KV38105220 ( Ð )

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Disassembly (Cont'd)

PD-47

Page 2078 of 2395

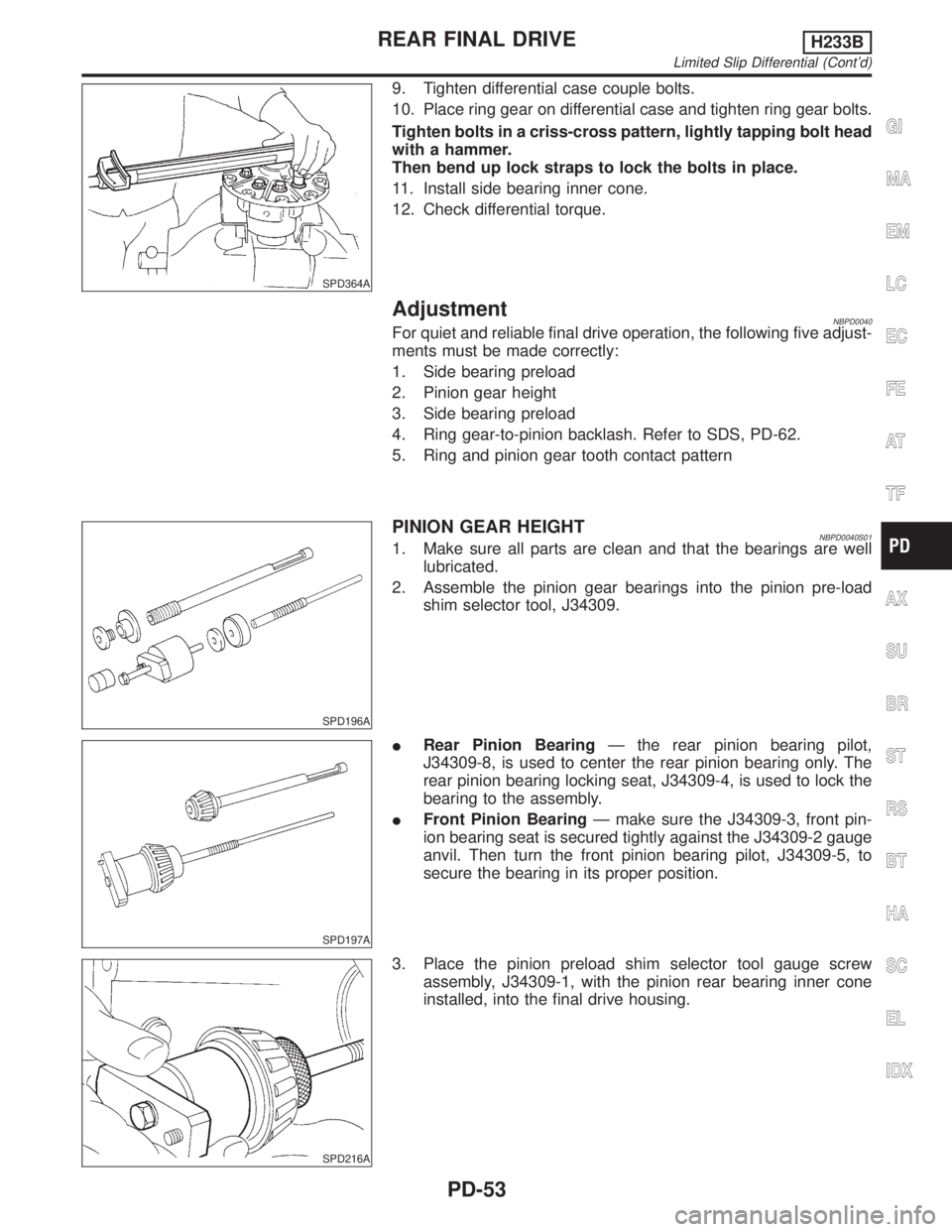

SPD364A

9. Tighten differential case couple bolts.

10. Place ring gear on differential case and tighten ring gear bolts.

Tighten bolts in a criss-cross pattern, lightly tapping bolt head

with a hammer.

Then bend up lock straps to lock the bolts in place.

11. Install side bearing inner cone.

12. Check differential torque.

AdjustmentNBPD0040For quiet and reliable final drive operation, the following five adjust-

ments must be made correctly:

1. Side bearing preload

2. Pinion gear height

3. Side bearing preload

4. Ring gear-to-pinion backlash. Refer to SDS, PD-62.

5. Ring and pinion gear tooth contact pattern

SPD196A

PINION GEAR HEIGHTNBPD0040S011. Make sure all parts are clean and that the bearings are well

lubricated.

2. Assemble the pinion gear bearings into the pinion pre-load

shim selector tool, J34309.

SPD197A

IRear Pinion BearingÐ the rear pinion bearing pilot,

J34309-8, is used to center the rear pinion bearing only. The

rear pinion bearing locking seat, J34309-4, is used to lock the

bearing to the assembly.

IFront Pinion BearingÐ make sure the J34309-3, front pin-

ion bearing seat is secured tightly against the J34309-2 gauge

anvil. Then turn the front pinion bearing pilot, J34309-5, to

secure the bearing in its proper position.

SPD216A

3. Place the pinion preload shim selector tool gauge screw

assembly, J34309-1, with the pinion rear bearing inner cone

installed, into the final drive housing.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Limited Slip Differential (Cont'd)

PD-53

Page 2079 of 2395

SPD217A

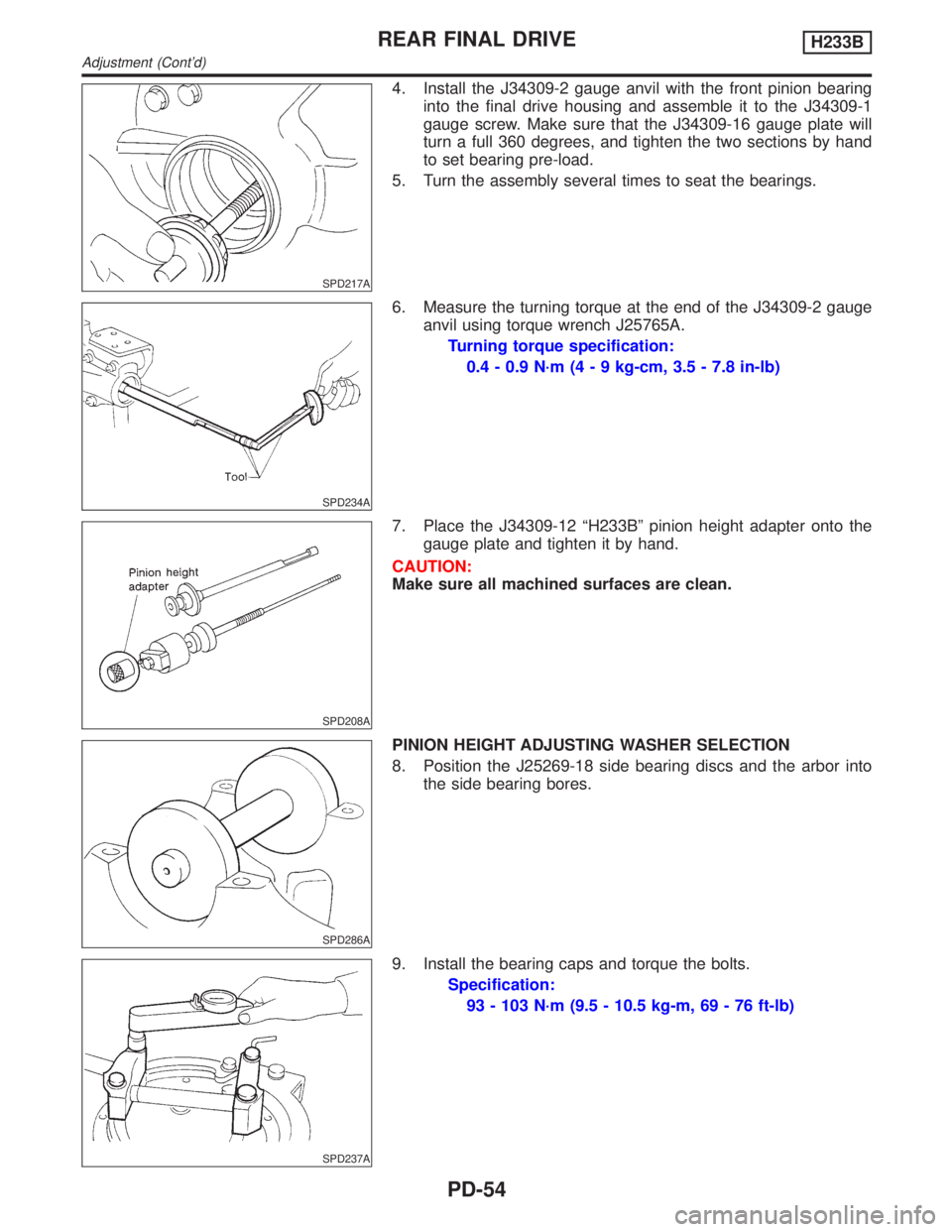

4. Install the J34309-2 gauge anvil with the front pinion bearing

into the final drive housing and assemble it to the J34309-1

gauge screw. Make sure that the J34309-16 gauge plate will

turn a full 360 degrees, and tighten the two sections by hand

to set bearing pre-load.

5. Turn the assembly several times to seat the bearings.

SPD234A

6. Measure the turning torque at the end of the J34309-2 gauge

anvil using torque wrench J25765A.

Turning torque specification:

0.4 - 0.9 N´m (4 - 9 kg-cm, 3.5 - 7.8 in-lb)

SPD208A

7. Place the J34309-12 ªH233Bº pinion height adapter onto the

gauge plate and tighten it by hand.

CAUTION:

Make sure all machined surfaces are clean.

SPD286A

PINION HEIGHT ADJUSTING WASHER SELECTION

8. Position the J25269-18 side bearing discs and the arbor into

the side bearing bores.

SPD237A

9. Install the bearing caps and torque the bolts.

Specification:

93 - 103 N´m (9.5 - 10.5 kg-m, 69 - 76 ft-lb)

REAR FINAL DRIVEH233B

Adjustment (Cont'd)

PD-54

Page 2084 of 2395

SPD581

4. Place pinion front bearing inner cone in gear carrier.

SPD291A

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Install front oil seal.

Tool number:

A ST30720000 (J25405)

B KV38102510 ( Ð )

SPD935-A

6. Install drive pinion bearing spacer, pinion bearing adjusting

shim and drive pinion in gear carrier.

SPD697

7. Insert companion flange into drive pinion by tapping the com-

panion flange with a soft hammer.

SPD481A

8. Tighten pinion nut to the specified torque.

The threaded portion of drive pinion and pinion nut should be

free from oil or grease.

Tool number: KV38108300 (J44195)

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Assembly (Cont'd)

PD-59

Page 2087 of 2395

Service Data and Specifications (SDS)

H233B=NBPD0042General SpecificationsNBPD0042S01

Rear final drive2WD 4WD

Standard Optional

H233B

2-pinion LSD

Gear ratio4.363

Number of teeth (Ring gear/drive pinion) 48/11

Oil capacity (Approx.)(US pt, lmp pt) 2.8 (5-7/8, 4-7/8)

Ring Gear RunoutNBPD0042S02

Ring gear runout limit mm (in)0.08 (0.0031)

Side Gear AdjustmentNBPD0042S03

Side gear backlash (Clearance between side gear and differential case) mm (in) 0.10 - 0.20 (0.0039 - 0.0079)

Available side

gear thrust

washersThickness mm (in) Part number*

1.75 (0.0689)

1.80 (0.0709)

1.85 (0.0728)38424-T5000

38424-T5001

38424-T5002

*: Always check with the Parts Department for the latest parts information.

Differential Torque Adjustment (LSD models)NBPD0042S04

Differential torque N´m (kg-m, ft-lb) 88 - 108 (9 - 11, 65 - 80)

Number of discs and plates (One

side)Friction disc 2

Friction plate 9

Spring plate 2

Wear limit of plate and disc mm (in) 0.1 (0.004)

Allowable warpage of friction disc and plate mm (in) 0.08 (0.0031)

Available discs

and platesPlate name Thickness mm (in) Part number*

Friction disc1.48 - 1.52 (0.0583 - 0.0598)

1.38 - 1.42 (0.0543 - 0.0559)

1.58 - 1.62 (0.0622 - 0.0638)38433-C6002 (Standard type)

38433-C6004 (Adjusting type)

38433-C6003 (Adjusting type)

Friction plate1.48 - 1.52 (0.0583 - 0.0598)

1.38 - 1.42 (0.0543 - 0.0559)

1.58 - 1.62 (0.0622 - 0.0638)38432-C6001

38432-C6002

38432-C6003

Spring plate 1.48 - 1.52 (0.0583 - 0.0598) 38435-S9200

*: Always check with the Parts Department for the latest parts information.

Total Preload AdjustmentNBPD0042S05

Total preload N´m (kg-cm, in-lb) P1+ [0.3 - 0.4 (3 - 4, 2.6 - 3.5)]

Ring gear backlash mm (in) 0.13 - 0.18 (0.0051 - 0.0071)

Side bearing adjusting methodSide adjuster

P1: Drive pinion preload

REAR FINAL DRIVEH233B

Service Data and Specifications (SDS)

PD-62

Page 2184 of 2395

Special Service ToolsNBST0003The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV48100700

(J26364)

Torque adapter

NT169

Measuring pinion rotating torque

ST35300000

(Ð)

Drift

NT073

Installing power steering oil pump oil seal

a: 59 mm (2.32 in) dia.

b: 45 mm (1.77 in) dia.

ST27180001

(J25726-A)

Steering wheel puller

NT544

Removing steering wheel

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV48103500

(J26357 and J26357-10)

Pressure gauge

NT547

Measuring oil pressure

KV48102500

(Ð)

Pressure gauge adapter

NT542

Measuring oil pressure

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

PREPARATION

Special Service Tools

ST-3