INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1131 of 2395

3 CHECK VACUUM CUT VALVE BYPASS VALVE OPERATION

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Remove vacuum cut valve and vacuum cut valve bypass valve as an assembly.

3. Apply vacuum to port A and check that there is no suction from port B.

4. Apply vacuum to port B and check that there is suction from port A.

5. Blow air in port B and check that there is a resistance to flow out of port A.

6. Disconnect vacuum cut valve bypass valve harness connector.

7. Supply battery voltage to the terminal.

8. Blow air in port A and check that air flows freely out of port B.

9. Blow air in port B and check that air flows freely out of port A.

SEF914U

OK or NG

OK©GO TO 4.

NG©GO TO 7.

4 CHECK EVAP PURGE LINE

Check EVAP purge line between EVAP canister and fuel tank for clogging or disconnection.

OK or NG

OK©GO TO 5.

NG©Repair it.

5 CHECK EVAP PURGE PORT

Check EVAP purge port of fuel tank for clogging.

OK or NG

OK©GO TO 6.

NG©Clean EVAP purge port.

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-596

Page 1132 of 2395

6 CHECK EVAP CANISTER

1. Pinch the fresh air hose.

2. Blow air into portAand check that it flows freely out of portB.

AEC630A

OK or NG

OK©GO TO 12.

NG©Replace EVAP canister.

7 CHECK BYPASS HOSE

Check bypass hoses for clogging.

OK or NG

OK©GO TO 8.

NG©Repair or replace hoses.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-597

Page 1133 of 2395

8 CHECK VACUUM CUT VALVE BYPASS VALVE

With CONSULT-II

1. Perform ªVC/V BYPASS/Vº in ªACTIVE TESTº mode.

2. Check air passage continuity and operation delay time under the following conditions.

SEF016Z

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF358X

OK or NG

OK©GO TO 9.

NG©Replace vacuum cut valve bypass valve.

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-598

Page 1134 of 2395

9 CHECK VACUUM CUT VALVE

Check vacuum cut valve as follows:

SEF379Q

a. Plug portCandDwith fingers.

b. Apply vacuum to portAand check that there is no suction from portB.

c. Apply vacuum to portBand check that there is suction from portA.

d. Blow air in portBand check that there is a resistance to flow out of portA.

e. Open portCandD.

f. Blow air in portAcheck that air flows freely out of portC.

g. Blow air in portBcheck that air flows freely out of portD.

OK or NG

OK©GO TO 10.

NG©Replace vacuum cut valve.

10 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR HOSE

1. Turn ignition switch ªOFFº.

2. Check disconnection or improper connection of hose connected to EVAP control system pressure sensor.

OK or NG

OK©GO TO 11.

NG©Repair or replace.

11 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

SEF495R

2. Check connectors for water.

Water should not exist.

OK or NG

OK©GO TO 12.

NG©Replace EVAP control system pressure sensor.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-599

Page 1135 of 2395

12 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Remove EVAP control system pressure sensor with its harness connector connected.

CAUTION:

INever apply force to the air hole protector of the sensor if equipped.

SEF799W

2. Remove hose from EVAP control system pressure sensor.

3. Turn ignition switch ªONº.

4. Use pump to apply vacuum and pressure to EVAP control system pressure sensor as shown in figure.

CAUTION:

IAlways calibrate the vacuum pump gauge when using it.

IDo not apply below þ20 kPa (þ150 mmHg, þ5.91 inHg) or over 20 kPa (150 mmHg, 5.91 inHg) of pressure.

5. Check input voltage between ECM terminal 84 and ground.

SEF342X

CAUTION:

IDiscard and EVAP control system pressure sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

OK or NG

OK©GO TO 13.

NG©Replace EVAP control system pressure sensor.

13 CHECK RUBBER TUBE FOR CLOGGING

1. Disconnect rubber tube connected to EVAP canister vent control valve.

2. Check the rubber tube for clogging.

OK or NG

OK©GO TO 14.

NG©Clean the rubber tube using an air blower.

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-600

Page 1136 of 2395

14 CHECK EVAP CANISTER VENT CONTROL VALVE-I

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portionBof EVAP canister vent control valve for being rusted.

SEF337X

OK or NG

OK©GO TO 15.

NG©Replace EVAP canister vent control valve.

15 CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT-II

1. Reconnect harness disconnected connectors.

2. Turn ignition switch ON.

3. Perform ªVENT CONTROL/Vº in ªACTIVE TESTº mode.

4. Check air passage continuity and operation delay time.

SEF991Y

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF339X

Make sure new O-ring is installed properly.

OK or NG

OK©GO TO 17.

NG©GO TO 16.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-601

Page 1137 of 2395

16 CHECK EVAP CANISTER VENT CONTROL VALVE-III

1. Clean the air passage (PortionAtoB) of EVAP canister vent control valve using an air blower.

2. Perform the Test No. 15 again.

OK or NG

OK©GO TO 17.

NG©Replace EVAP canister vent control valve.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-602

Page 1138 of 2395

Component DescriptionNBEC0361The malfunction information related to A/T (Automatic Transmission) is transferred through the line (circuit)

from TCM (Transmission control module) to ECM. Therefore, be sure to erase the malfunction information such

as DTC not only in TCM (Transmission control module) but also ECM after the A/T related repair.

On Board Diagnosis LogicNBEC0363Malfunction is detected when an incorrect signal from TCM (Trans-

mission control module) is sent to ECM.

Possible CauseNBEC0594IHarness or connectors

[The communication line circuit between ECM and TCM

(Transmission control module) is open or shorted.]

IDead (Weak) battery

ITCM (Transmission control module)

SEF058Y

DTC Confirmation ProcedureNBEC0364NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

WITH CONSULT-IINBEC0364S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 40 seconds.

4) If 1st trip DTC is detected, go to ªDTC P0600 A/T COMMUNI-

CATION LINE Diagnostic Procedureº, EC-443.

WITH GSTNBEC0364S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINE

Component Description

EC-603

Page 1139 of 2395

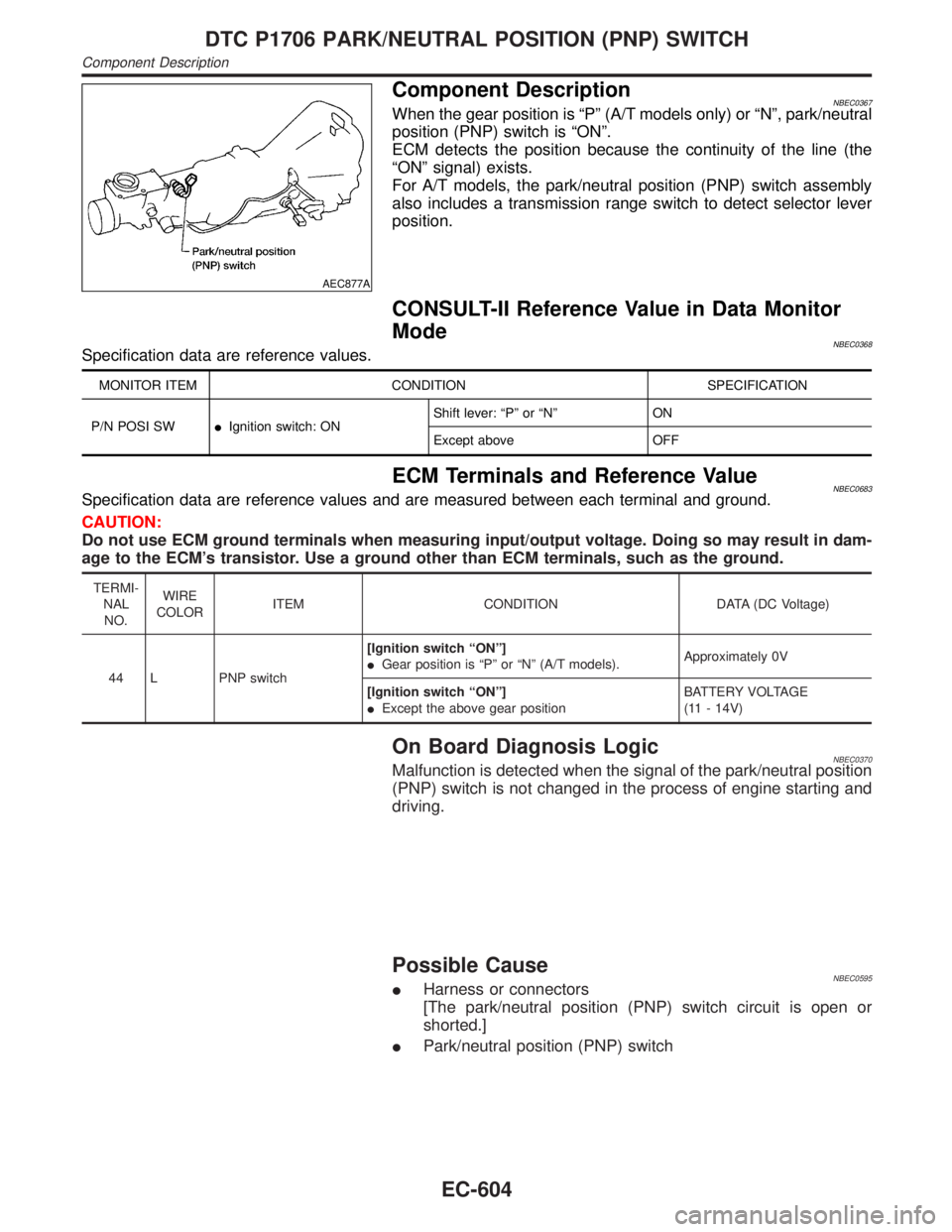

AEC877A

Component DescriptionNBEC0367When the gear position is ªPº (A/T models only) or ªNº, park/neutral

position (PNP) switch is ªONº.

ECM detects the position because the continuity of the line (the

ªONº signal) exists.

For A/T models, the park/neutral position (PNP) switch assembly

also includes a transmission range switch to detect selector lever

position.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0368Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SWIIgnition switch: ONShift lever: ªPº or ªNº ON

Except above OFF

ECM Terminals and Reference ValueNBEC0683Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

44 L PNP switch[Ignition switch ªONº]

IGear position is ªPº or ªNº (A/T models).Approximately 0V

[Ignition switch ªONº]

IExcept the above gear positionBATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNBEC0370Malfunction is detected when the signal of the park/neutral position

(PNP) switch is not changed in the process of engine starting and

driving.

Possible CauseNBEC0595IHarness or connectors

[The park/neutral position (PNP) switch circuit is open or

shorted.]

IPark/neutral position (PNP) switch

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCH

Component Description

EC-604

Page 1140 of 2395

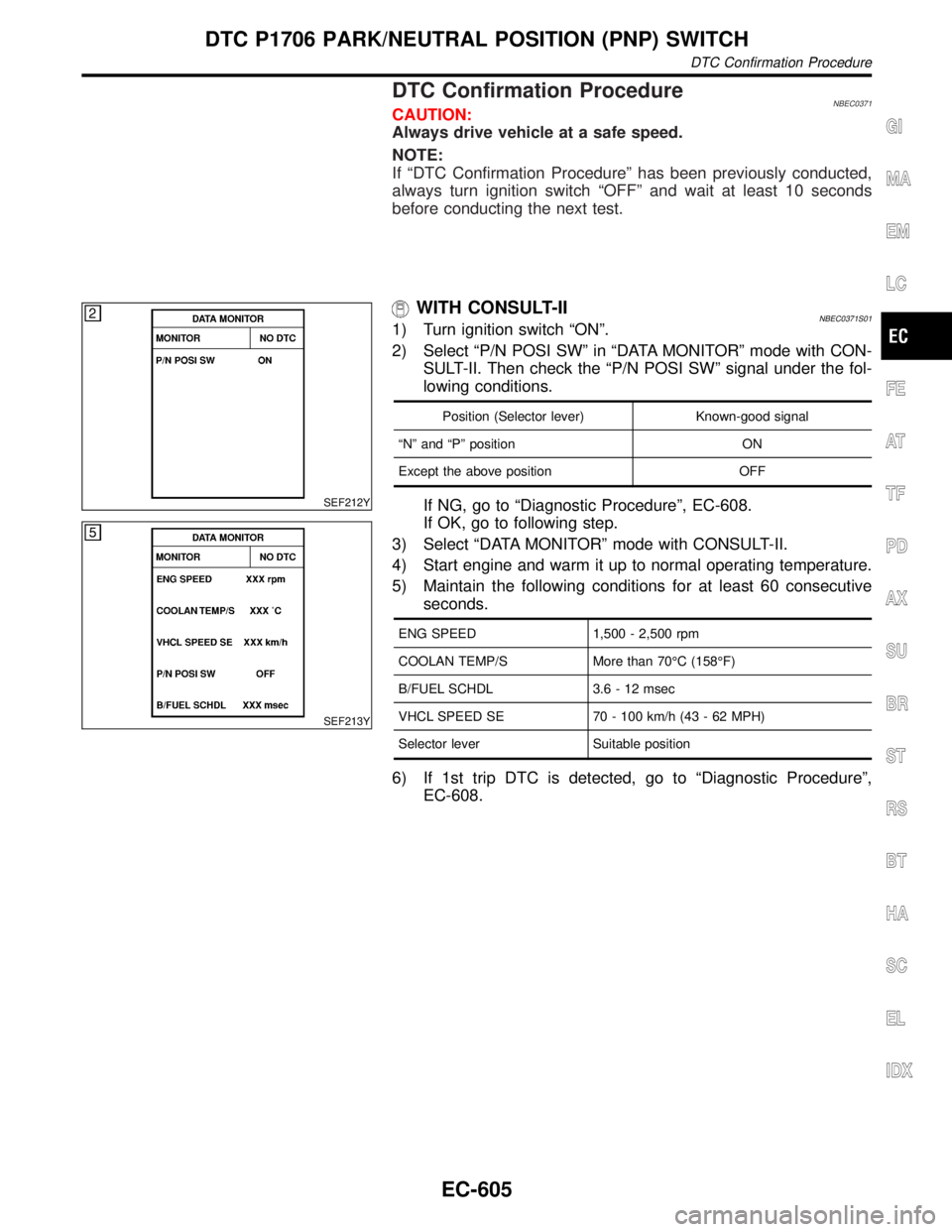

DTC Confirmation ProcedureNBEC0371CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

SEF212Y

SEF213Y

WITH CONSULT-IINBEC0371S011) Turn ignition switch ªONº.

2) Select ªP/N POSI SWº in ªDATA MONITORº mode with CON-

SULT-II. Then check the ªP/N POSI SWº signal under the fol-

lowing conditions.

Position (Selector lever) Known-good signal

ªNº and ªPº position ON

Except the above position OFF

If NG, go to ªDiagnostic Procedureº, EC-608.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Start engine and warm it up to normal operating temperature.

5) Maintain the following conditions for at least 60 consecutive

seconds.

ENG SPEED 1,500 - 2,500 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.6 - 12 msec

VHCL SPEED SE 70 - 100 km/h (43 - 62 MPH)

Selector lever Suitable position

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-608.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCH

DTC Confirmation Procedure

EC-605