INFINITI QX4 2001 Factory Service Manual

QX4 2001

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57027/w960_57027-0.png

INFINITI QX4 2001 Factory Service Manual

Trending: oil filter, service indicator, keyless, towing, fuel type, fuse box location, engine coolant

Page 1171 of 2395

Diagnostic ProcedureNBEC0402

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check ªPW/ST SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF228Y

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine.

2. Check voltage between ECM terminal 47 and ground under the following conditions.

SEF363X

OK or NG

OK©INSPECTION END

NG©GO TO 4.

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure

EC-636

Page 1172 of 2395

4 CHECK POWER STEERING OIL PRESSURE SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

SEF028Z

3. Check harness continuity between power steering oil pressure switch terminal 2 and engine ground. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connectors.

5 CHECK POWER STEERING OIL PRESSURE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 47 and power steering oil pressure switch terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK POWER STEERING OIL PRESSURE SWITCH

1. Disconnect power steering oil pressure switch harness connector then start engine.

2. Check continuity between power steering oil pressure switch terminals 1 and 2 under the following conditions.

SEF364X

OK or NG

OK©GO TO 7.

NG©Replace power steering oil pressure switch.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure (Cont'd)

EC-637

Page 1173 of 2395

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure (Cont'd)

EC-638

Page 1174 of 2395

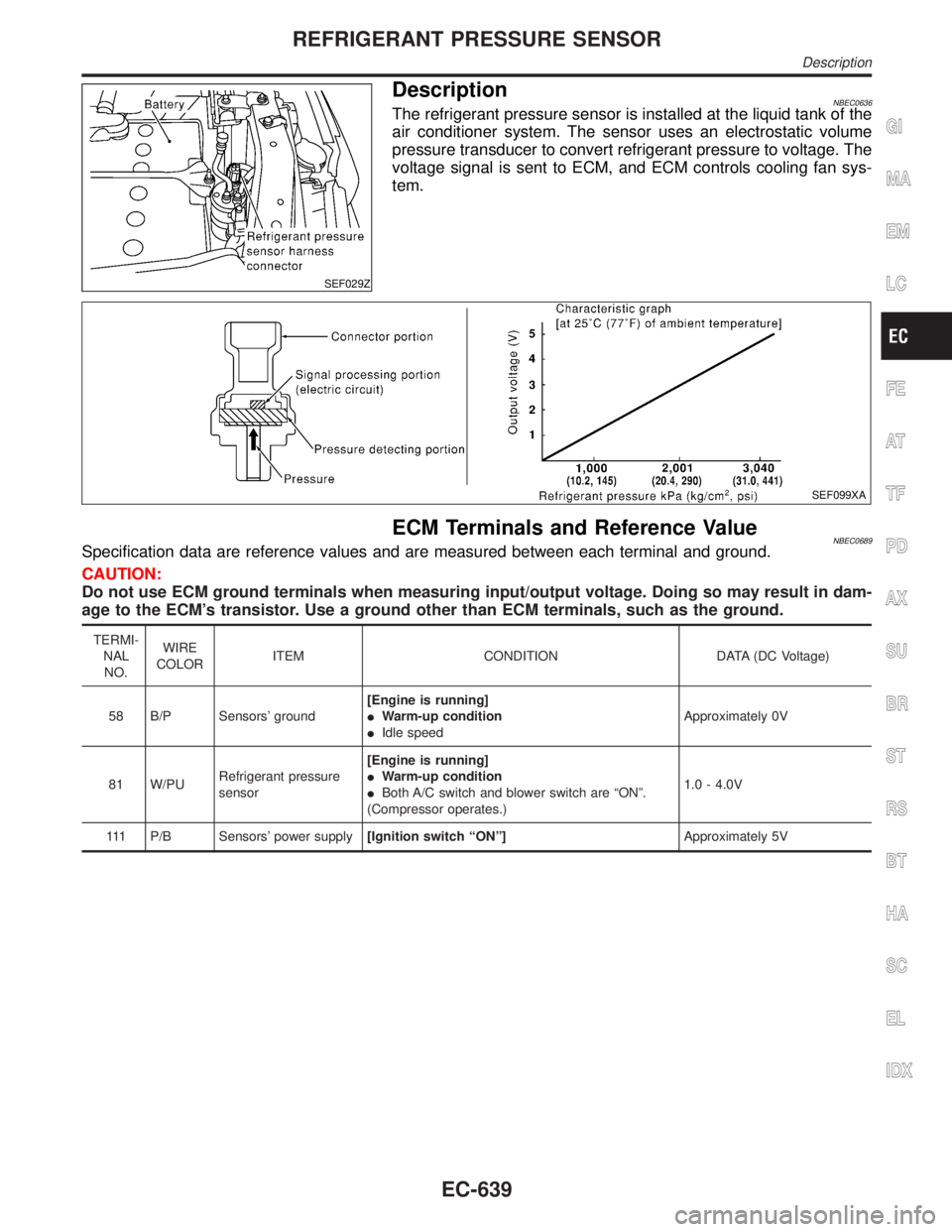

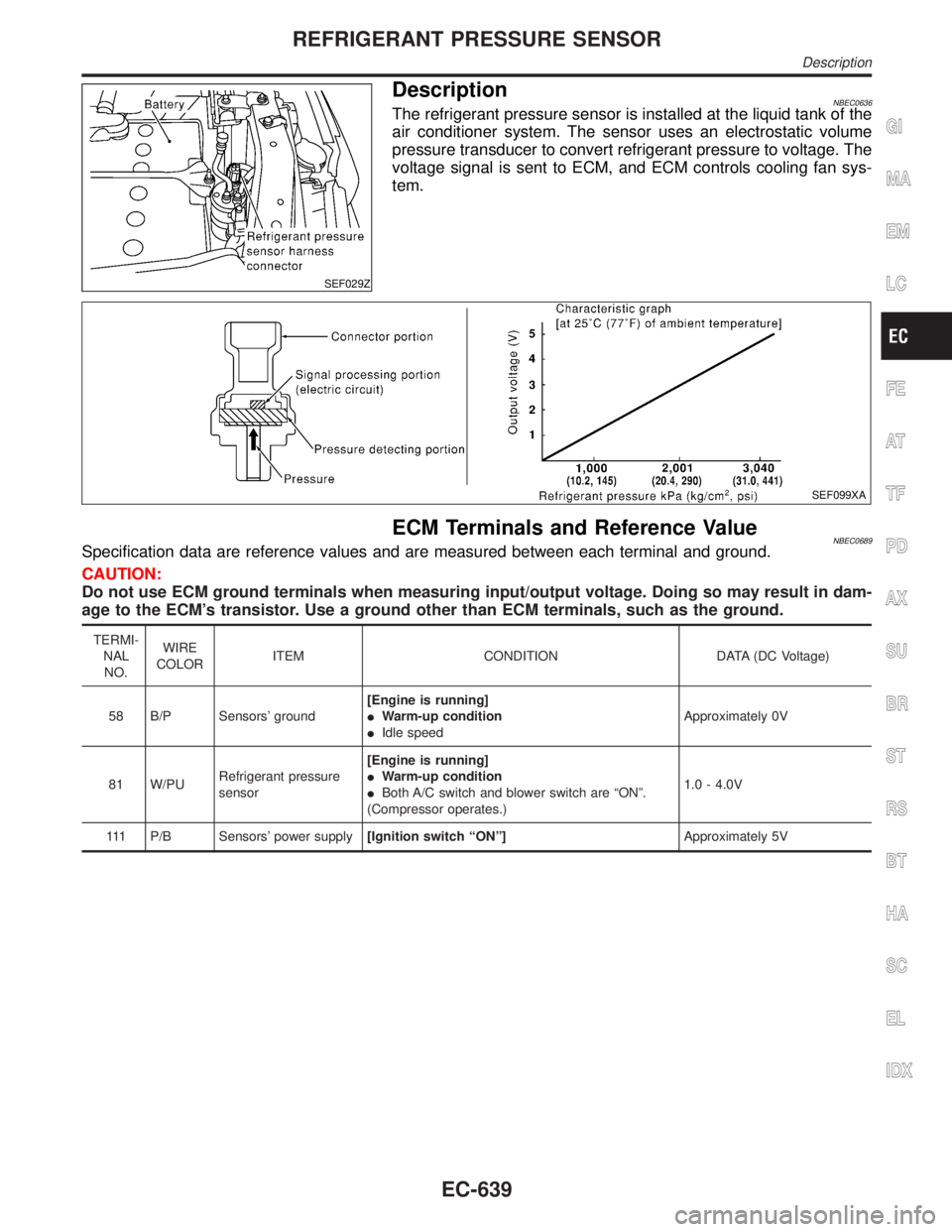

SEF029Z

DescriptionNBEC0636The refrigerant pressure sensor is installed at the liquid tank of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan sys-

tem.

SEF099XA

ECM Terminals and Reference ValueNBEC0689Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B/P Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

81 W/PURefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IBoth A/C switch and blower switch are ªONº.

(Compressor operates.)1.0 - 4.0V

111 P/B Sensors' power supply[Ignition switch ªONº]Approximately 5V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REFRIGERANT PRESSURE SENSOR

Description

EC-639

Page 1175 of 2395

Wiring DiagramNBEC0637

MEC982C

REFRIGERANT PRESSURE SENSOR

Wiring Diagram

EC-640

Page 1176 of 2395

Diagnostic ProcedureNBEC0638

1 CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ªONº.

3. Check voltage between ECM terminal 81 and ground with CONSULT-II or tester.

SEF617XA

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn A/C switch and blower switch ªOFFº.

2. Stop engine.

3. Disconnect refrigerant pressure sensor harness connector.

SEF029Z

4. Turn ignition switch ªONº.

5. Check voltage between refrigerant pressure sensor terminal 1 and ground with CONSULT-II or tester.

SEF030Z

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REFRIGERANT PRESSURE SENSOR

Diagnostic Procedure

EC-641

Page 1177 of 2395

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair harness or connectors.

4 CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between refrigerant pressure sensor terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M33, F22

IHarness connectors F23, M32

IHarness for open between ECM and refrigerant pressure sensor

IHarness for open between TCM (Transmission control module) and refrigerant pressure sensor

©Repair open circuit or short to power in harness or connectors.

6 CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 81 and refrigerant pressure sensor terminal 2. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M94, F27

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK REFRIGERANT PRESSURE SENSOR

Refer to HA-14, ªRefrigerant pressure sensorº.

OK or NG

OK©GO TO 9.

NG©Replace refrigerant pressure sensor.

9 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

REFRIGERANT PRESSURE SENSOR

Diagnostic Procedure (Cont'd)

EC-642

Page 1178 of 2395

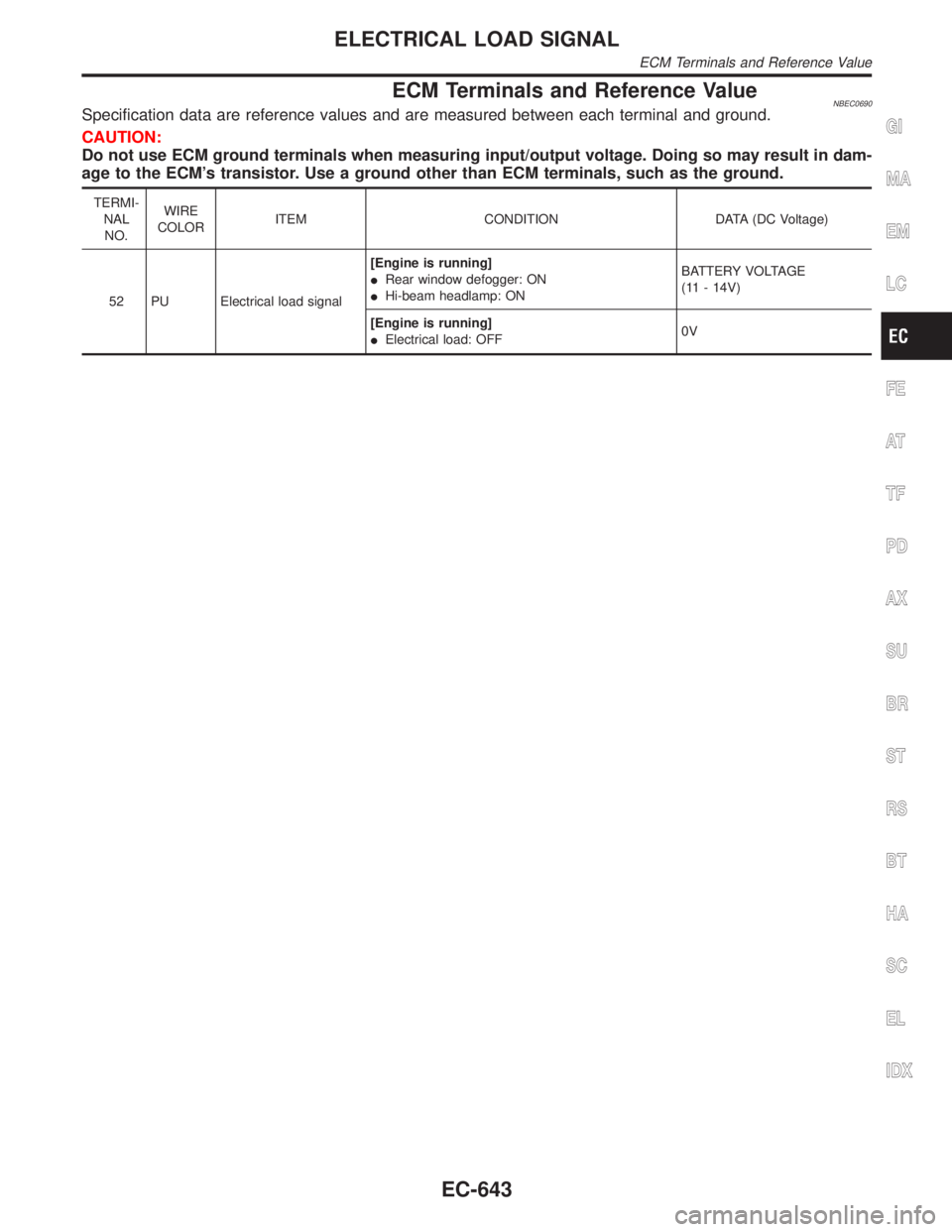

ECM Terminals and Reference ValueNBEC0690Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

52 PU Electrical load signal[Engine is running]

IRear window defogger: ON

IHi-beam headlamp: ONBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IElectrical load: OFF0V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ELECTRICAL LOAD SIGNAL

ECM Terminals and Reference Value

EC-643

Page 1179 of 2395

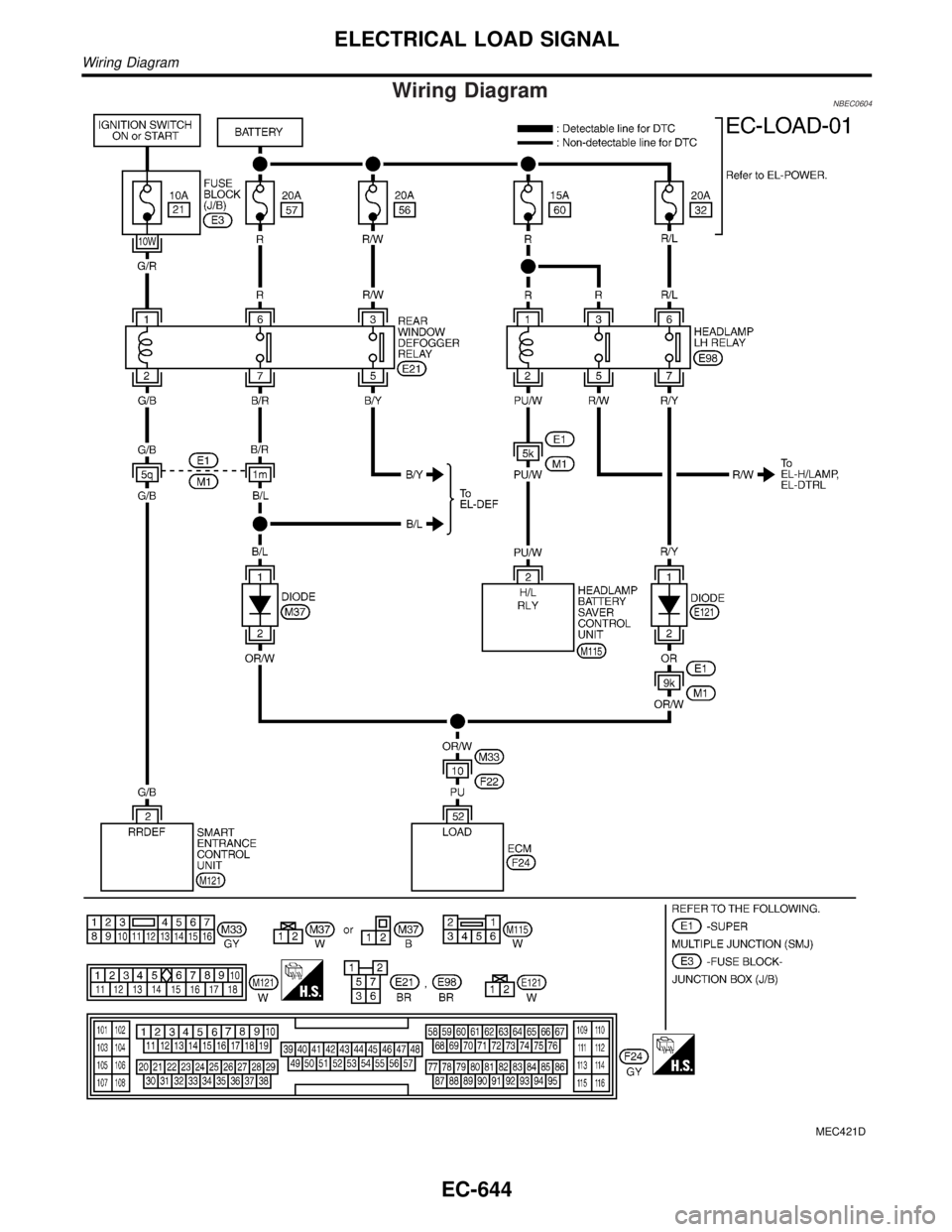

Wiring DiagramNBEC0604

MEC421D

ELECTRICAL LOAD SIGNAL

Wiring Diagram

EC-644

Page 1180 of 2395

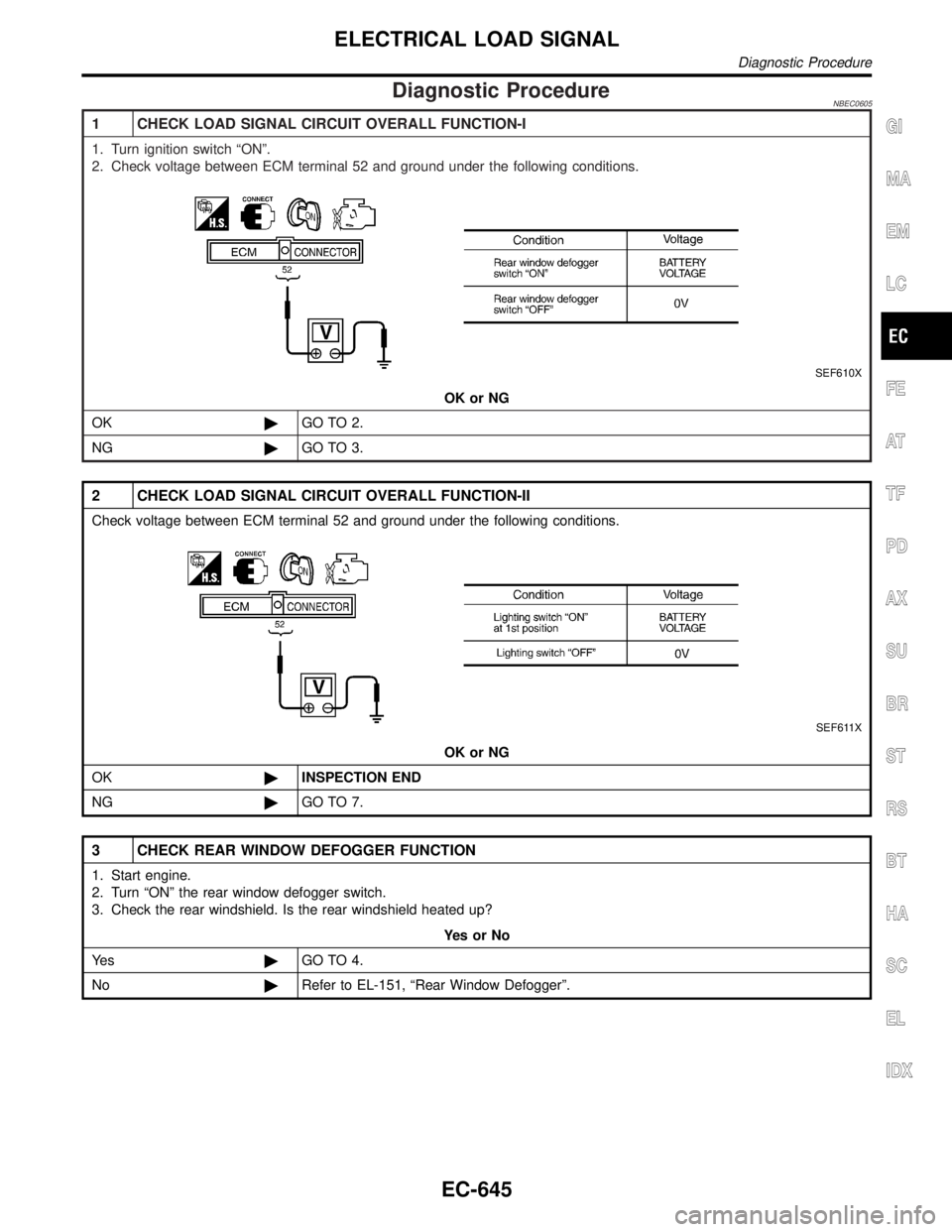

Diagnostic ProcedureNBEC0605

1 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-I

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 52 and ground under the following conditions.

SEF610X

OK or NG

OK©GO TO 2.

NG©GO TO 3.

2 CHECK LOAD SIGNAL CIRCUIT OVERALL FUNCTION-II

Check voltage between ECM terminal 52 and ground under the following conditions.

SEF611X

OK or NG

OK©INSPECTION END

NG©GO TO 7.

3 CHECK REAR WINDOW DEFOGGER FUNCTION

1. Start engine.

2. Turn ªONº the rear window defogger switch.

3. Check the rear windshield. Is the rear windshield heated up?

YesorNo

Ye s©GO TO 4.

No©Refer to EL-151, ªRear Window Defoggerº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ELECTRICAL LOAD SIGNAL

Diagnostic Procedure

EC-645

Trending: ignition, alternator circuit, hood open, change wheel, coolant reservoir, horn, bulb