warning INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2013 of 2395

SMA096D

Changing Engine OilNBMA0015WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait for more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity

IAPI grade SG or SH, Energy ConservingI&IIorAPIgrade

SJ, Energy Conserving

IAPI Certification Mark

IILSAC grade GF-I & GF-II

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº, MA-11.

Oil capacity (Approximately):

Unit:(US qt, Imp qt)

Drain and refillWith oil filter change 5.0 (5-1/4, 4-3/8)

Without oil filter change 4.8 (5-1/8, 4-1/4)

Dry engine (engine overhaul) 6.8 (7-1/4, 6)

CAUTION:

IBe sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

JMA122D

5. Warm up engine and check area around drain plug and oil fil-

ter for oil leakage.

6. Stop engine and wait for more than 10 minutes.

7. Check oil level.

SMA097D

Changing Oil FilterNBMA00161. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

The filter is a full-flow cartridge type and is provided with a relief

valve.

Refer to LC-7, ªOil Filterº.

ENGINE MAINTENANCE

Changing Engine Oil

MA-18

Page 2091 of 2395

DIAGNOSTIC PROCEDURE 7..................................53

DIAGNOSTIC PROCEDURE 8 (CONTINUED

FROM DIAGNOSTIC PROCEDURE 6)

......................55

Trouble Diagnoses:²AIR BAG²Warning Lamp

Does Not Turn Off .....................................................56

DIAGNOSTIC PROCEDURE 9..................................56

Trouble Diagnoses:²AIR BAG²Warning Lamp

Does Not Turn On .....................................................58

DIAGNOSTIC PROCEDURE 10................................58

Collision Diagnosis ....................................................59

FOR FRONTAL COLLISION.....................................59

FOR SIDE COLLISION.............................................61

CONTENTS(Cont'd)

RS-2

Page 2092 of 2395

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBRS0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTION FOR SEAT BELT SERVICENBRS0002CAUTION:

IBefore removing the seat belt pre-tensioner assembly, turn the ignition switch off, disconnect both

battery cables and wait at least 3 minutes.

IDo not use electrical test equipment for seat belt pre-tensioner connector.

IAfter replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner connector, check the system function. Refer to ªSRS Operation Checkº (RS-38) for details.

IDo not use disassemble buckle or seat belt assembly.

IReplace anchor bolts if they are deformed or worn out.

INever oil tongue and buckle.

IIf any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

IIf webbing is cut, frayed, or damaged, replace seat belt assembly.

IWhen replacing seat belt assembly, use a genuine seat belt assembly.

After A CollisionNBRS0002S01WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly if:

IThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

IThe seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

IThe seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for dam-

age or distortion and repair as necessary before installing a new seat belt assembly.

IAnchor bolts are deformed or worn out.

IThe seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SEAT BELTS

Precautions

RS-3

Page 2096 of 2395

Seat Belt Inspection=NBRS0029AFTER A COLLISIONNBRS0029S01WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly if:

IThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

IThe seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

IThe seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for dam-

age or distortion and repair as necessary before installing a new seat belt assembly.

IAnchor bolts are deformed or worn out.

IThe seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKSNBRS0029S021. Check the seat belt warning lamp/chime for proper operation as follows:

a. Switch ignition ON. The seat belt warning lamp should illuminate. Also, the seat belt warning chime should

sound for about seven seconds.

b. Fasten driver's seat belt. The seat belt warning lamp should go out and the chime (if sounding) should

stop.

2. If the air bag warning lamp is blinking, conduct self-diagnosis using CONSULT-II, and air bag warning lamp.

Refer to ªSRS Operation Checkº, RS-38.

3. Check that the seat belt retractor, seat belt anchor and buckle bolts are securely attached.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Ensure guide swiv-

els freely and that belt lays flat and does not bind in guide. Ensure height adjuster operates properly and

holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Ensure that belt returns smoothly and completely into the retractor. If the seat

belt does not returns smoothly, wipe the inside of the loops with a clean paper cloth etc. because dirt built

up in the loops of the upper anchors can cause the seat belts to retractor slowly.

SRS353

c. Fasten the seat belt. Pull firmly on belt and buckle to ensure belt remains latched. Unfasten seat belt.

Ensure belt releases freely and buckle button returns to original position.

6. For center (non-retractable) seat belts, check that the seat belt are accessible. Check seat belt webbing

for twists, tears or other damage. Fasten the seat belt. Pull firmly on belt and buckle to ensure belt remains

latched. Unfasten seat belts. Ensure belt releases freely and buckle button returns to original position.

7. Repeat steps above as necessary to check the other seat belts.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SEAT BELTS

Seat Belt Inspection

RS-7

Page 2097 of 2395

SEAT BELT RETRACTOR ON-VEHICLE CHECKNBRS0029S03Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)NBRS0029S0301NOTE:

All seat belt retractors are of the Emergency Locking Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the belt from extending any further. All 3-point type seat belt retractors except

the driver's seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also called child

restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt is fully

extended. When the belt is then retracted partially, the ALR mode automatically locks the seat belt in a spe-

cific position so the belt cannot be extended any further. To cancel the ALR mode, allow the seat belt to fully

wind back into the retractor.

Check the seat belt retractors using the following test(s) to determine if a retractor assembly is operating

properly.

ELR Function Stationary CheckNBRS0029S0302Grasp the shoulder belt and pull forward quickly. The retractor should lock and prevent the belt from extend-

ing further.

ALR Function Stationary CheckNBRS0029S03041. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the belt partially. A clicking noise should be heard as the belt retracts indicating that the retractor

is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The belt must lock and not extend any further. If NG,

replace the retractor assembly.

4. Allow the entire length of the belt to retract to cancel the automatic locking mode.

ELR Function Moving CheckNBRS0029S0303WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example,

a large, empty parking lot). Road surface must be paved and dry. DO NOT perform the following test

on wet or gravel roads or on public streets and highways. This could result in an accident and seri-

ous personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event the retractor does not

lock, apply brakes firmly and make a very hard stop.

During stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

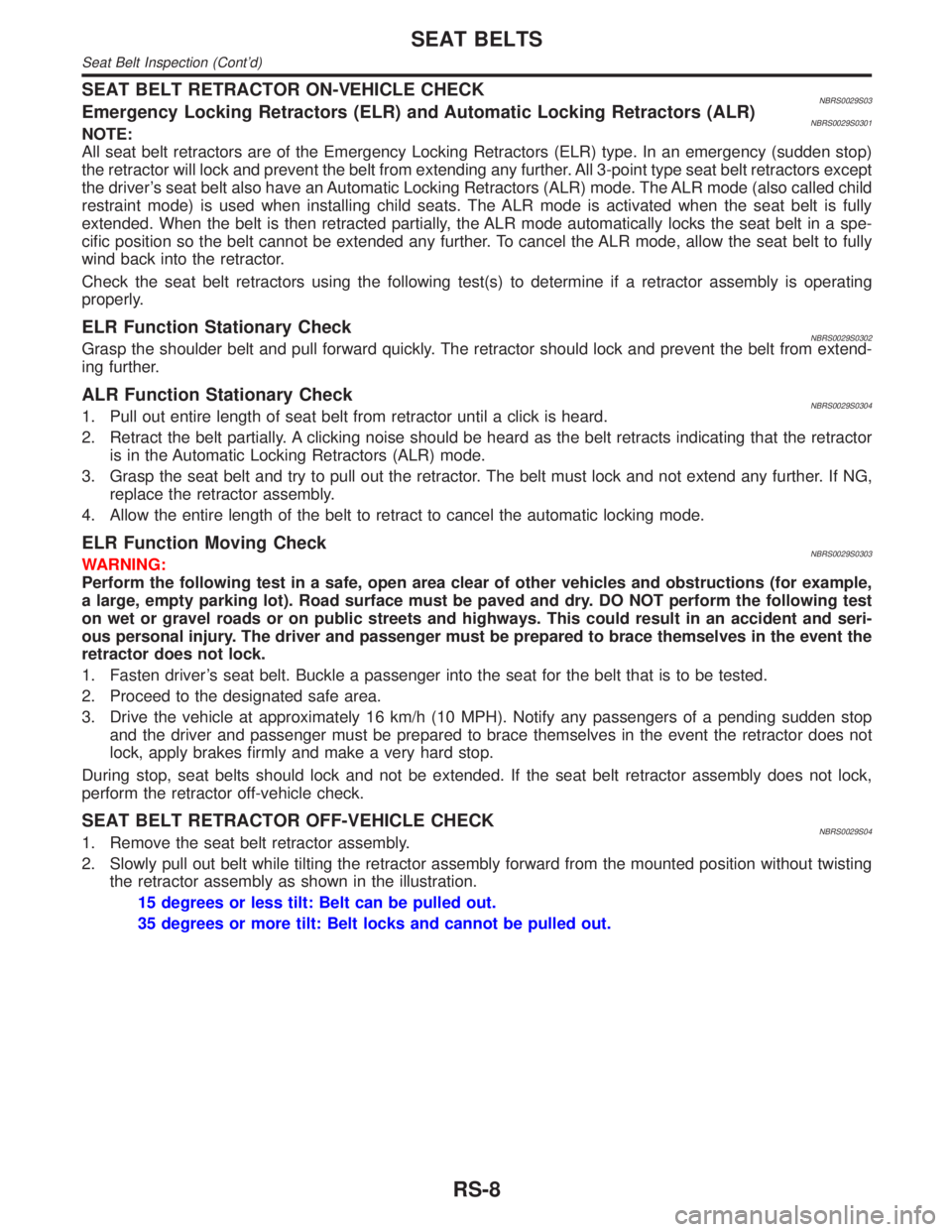

SEAT BELT RETRACTOR OFF-VEHICLE CHECKNBRS0029S041. Remove the seat belt retractor assembly.

2. Slowly pull out belt while tilting the retractor assembly forward from the mounted position without twisting

the retractor assembly as shown in the illustration.

15 degrees or less tilt: Belt can be pulled out.

35 degrees or more tilt: Belt locks and cannot be pulled out.

SEAT BELTS

Seat Belt Inspection (Cont'd)

RS-8

Page 2099 of 2395

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBRS0005The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICENBRS0006IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

IBefore servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

IDiagnosis sensor unit must always be installed with their arrow marks ªgº pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

IThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

IHandle air bag module carefully. Always place driver and passenger air bag modules with the pad side

facing upward and side air bag module (built-in type) standing with the stud bolt side setting bottom.

IConduct self-diagnosis to check entire SRS for proper function after replacing any components.

IAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSISNBRS0007When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Precautions

RS-10

Page 2103 of 2395

SRS797-A

Maintenance ItemsNBRS0011CAUTION:

Do not use electrical test equipment to check SRS circuit.

1. Check operation of ªAIR BAGº warning lamp.

After turning ignition key to ªONº position, air bag warning lamp

illuminates. The ªAIR BAGº warning lamp will go off after about

7 seconds if no malfunction is detected. If any of the following

warning lamp conditions occur, immediately check the air bag

or seat belt pre-tensioner system. Refer to RS-38 for details.

IThe ªAIR BAGº warning lamp does not illuminate when the

ignition switch is turned ªONº.

IThe ªAIR BAGº warning lamp does not go off about 7 seconds

after the ignition switch is turned ªONº.

IThe ªAIR BAGº warning lamp blinks after about 7 seconds after

the ignition switch is turned ªONº.

2. Visually check SRS components.

1) Diagnosis sensor unit

ICheck diagnosis sensor unit and bracket for dents, cracks and

deformities.

ICheck connectors for damage, and terminals for deformities.

2) Air bag module and steering wheel

IRemove air bag module from steering wheel, instrument panel

or seatback. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

IInstall driver air bag module to steering wheel to check fit or

alignment with the wheel.

ICheck steering wheel for excessive free play.

IInstall passenger air bag module to instrument panel to check

fit or alignment with the instrument panel.

IInstall side air bag module to seatback to check fit and align-

ment with the seat.

3) Spiral cable

ICheck spiral cable for dents, cracks, or deformities.

ICheck connectors and protective tape for damage.

ICheck steering wheel for noise, binding or heavy operation.

4) Main harness, air bag harness, body harness, side air bag

module sub-harness

ICheck connectors for poor connections, damage, and termi-

nals for deformities.

ICheck harnesses for binding, chafing or cut.

5) Seat belt pre-tensioner

ICheck harness cover and connectors for damage, terminals

for deformities, and harness for binding.

ICheck belts for damage and anchors for loose mounting.

ICheck retractor for smooth operation.

IPerform self-diagnosis for seat belt pre-tensioner using air bag

warning lamp or CONSULT-II. Refer to ªSRS Operation Checkº

for details. (RS-38)

6) Satellite sensor

ICheck satellite sensor (including bracket portion) for dents,

cracks or deformities.

ICheck connectors for damage, and terminals for deformities.

CAUTION:

Replace previously used special bolts and ground bolt with

new ones.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Maintenance Items

RS-14

Page 2108 of 2395

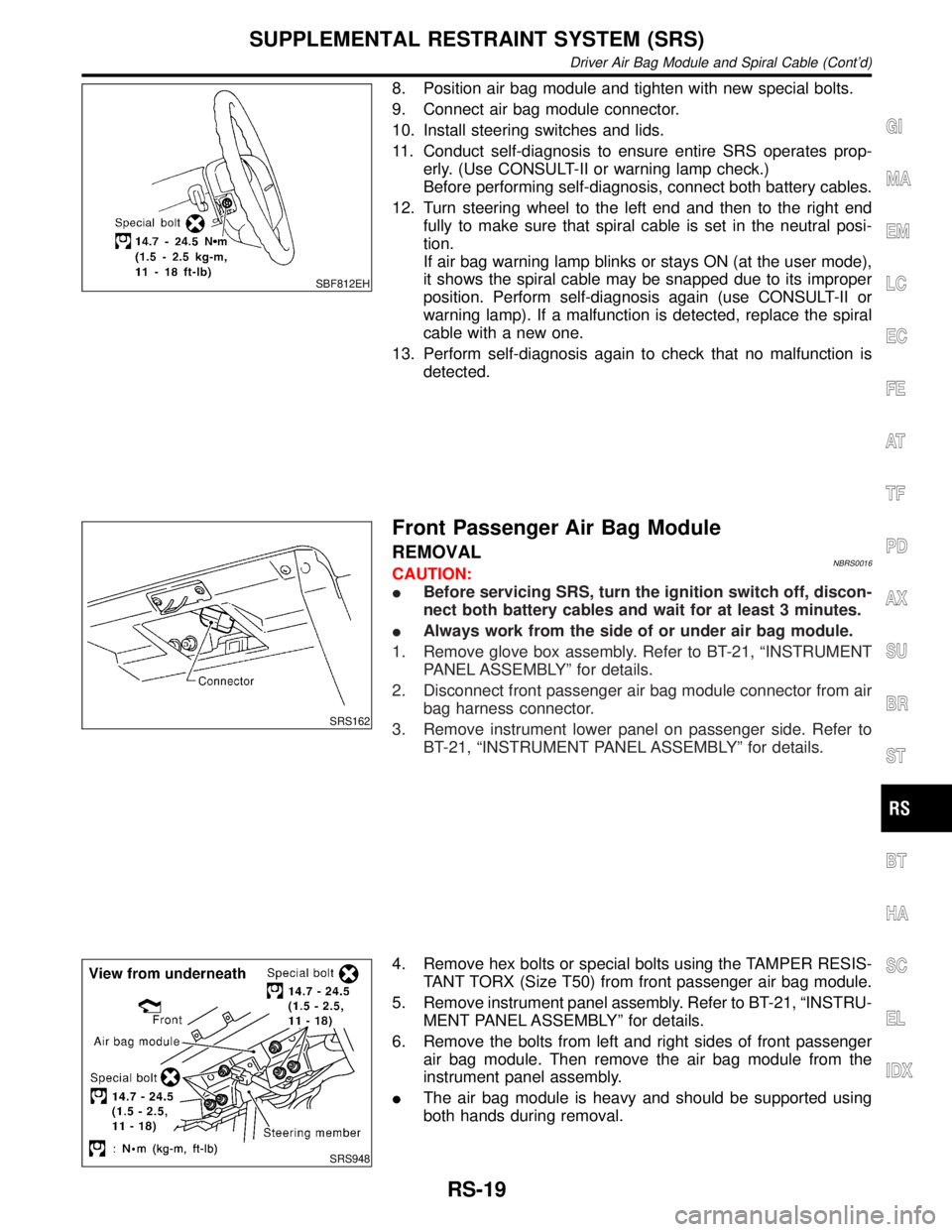

SBF812EH

8. Position air bag module and tighten with new special bolts.

9. Connect air bag module connector.

10. Install steering switches and lids.

11. Conduct self-diagnosis to ensure entire SRS operates prop-

erly. (Use CONSULT-II or warning lamp check.)

Before performing self-diagnosis, connect both battery cables.

12. Turn steering wheel to the left end and then to the right end

fully to make sure that spiral cable is set in the neutral posi-

tion.

If air bag warning lamp blinks or stays ON (at the user mode),

it shows the spiral cable may be snapped due to its improper

position. Perform self-diagnosis again (use CONSULT-II or

warning lamp). If a malfunction is detected, replace the spiral

cable with a new one.

13. Perform self-diagnosis again to check that no malfunction is

detected.

SRS162

Front Passenger Air Bag Module

REMOVALNBRS0016CAUTION:

IBefore servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait for at least 3 minutes.

IAlways work from the side of or under air bag module.

1. Remove glove box assembly. Refer to BT-21, ªINSTRUMENT

PANEL ASSEMBLYº for details.

2. Disconnect front passenger air bag module connector from air

bag harness connector.

3. Remove instrument lower panel on passenger side. Refer to

BT-21, ªINSTRUMENT PANEL ASSEMBLYº for details.

SRS948

4. Remove hex bolts or special bolts using the TAMPER RESIS-

TANT TORX (Size T50) from front passenger air bag module.

5. Remove instrument panel assembly. Refer to BT-21, ªINSTRU-

MENT PANEL ASSEMBLYº for details.

6. Remove the bolts from left and right sides of front passenger

air bag module. Then remove the air bag module from the

instrument panel assembly.

IThe air bag module is heavy and should be supported using

both hands during removal.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Driver Air Bag Module and Spiral Cable (Cont'd)

RS-19

Page 2110 of 2395

SRS162

4. Install instrument lower panel on passenger side.

5. Connect air bag module connector to air bag harness connec-

tor.

6. Install glove box assembly.

7. Connect both battery cables.

8. Conduct self-diagnosis to ensure entire SRS operates prop-

erly. (Use CONSULT-II or warning lamp check.)

SRS682

Side Air Bag Module

REMOVALNBRS0036CAUTION:

IBefore servicing SRS, turn the ignition switch OFF, dis-

connect both battery cables and wait at least 3 minutes.

IAlways work from the rear of the air bag module.

1. Remove seatback board.

IWhen using a clip removal tool to remove the seatback

board, take care not to damage the air bag harness.

2. Disconnect side air bag module connector by sliding tab.

SRS683

3. Pull up the seatback trim.

4. Remove the nuts securing the inner cloth with seatback frame.

Then pull up the inner cloth.

5. Remove seatback trim. Refer to BT-41, ªFRONT SEATº for

details.

SRS684

6. Remove the torx nuts coated with bonding agent from the side

air bag module.

7. Remove side air bag connector. Side air bag module can then

be removed.

SRS623

CAUTION:

IAlways place the air bag module stading with the stud bolt

side setting bottom.

IDo not attempt to disassemble air bag module.

IThe torx nuts are coated with bonding agent. Do not use

old nuts after removal; replace with new coated nuts.

IDo not insert any foreign objects (screwdriver, etc.) into

air bag module connector.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Passenger Air Bag Module (Cont'd)

RS-21

Page 2111 of 2395

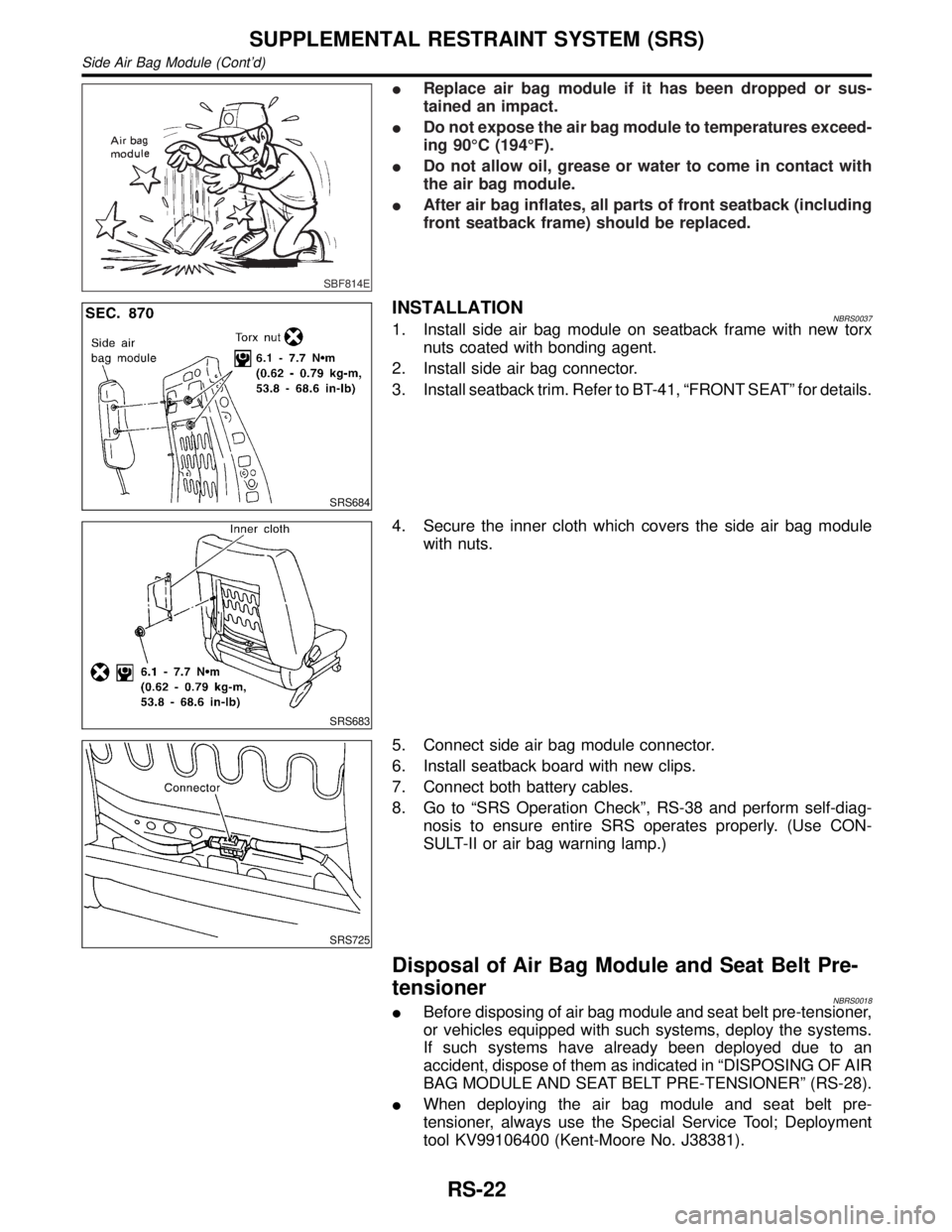

SBF814E

IReplace air bag module if it has been dropped or sus-

tained an impact.

IDo not expose the air bag module to temperatures exceed-

ing 90ÉC (194ÉF).

IDo not allow oil, grease or water to come in contact with

the air bag module.

IAfter air bag inflates, all parts of front seatback (including

front seatback frame) should be replaced.

SRS684

INSTALLATIONNBRS00371. Install side air bag module on seatback frame with new torx

nuts coated with bonding agent.

2. Install side air bag connector.

3. Install seatback trim. Refer to BT-41, ªFRONT SEATº for details.

SRS683

4. Secure the inner cloth which covers the side air bag module

with nuts.

SRS725

5. Connect side air bag module connector.

6. Install seatback board with new clips.

7. Connect both battery cables.

8. Go to ªSRS Operation Checkº, RS-38 and perform self-diag-

nosis to ensure entire SRS operates properly. (Use CON-

SULT-II or air bag warning lamp.)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner

NBRS0018IBefore disposing of air bag module and seat belt pre-tensioner,

or vehicles equipped with such systems, deploy the systems.

If such systems have already been deployed due to an

accident, dispose of them as indicated in ªDISPOSING OF AIR

BAG MODULE AND SEAT BELT PRE-TENSIONERº (RS-28).

IWhen deploying the air bag module and seat belt pre-

tensioner, always use the Special Service Tool; Deployment

tool KV99106400 (Kent-Moore No. J38381).

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Side Air Bag Module (Cont'd)

RS-22