Vacuum cut INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 631 of 2395

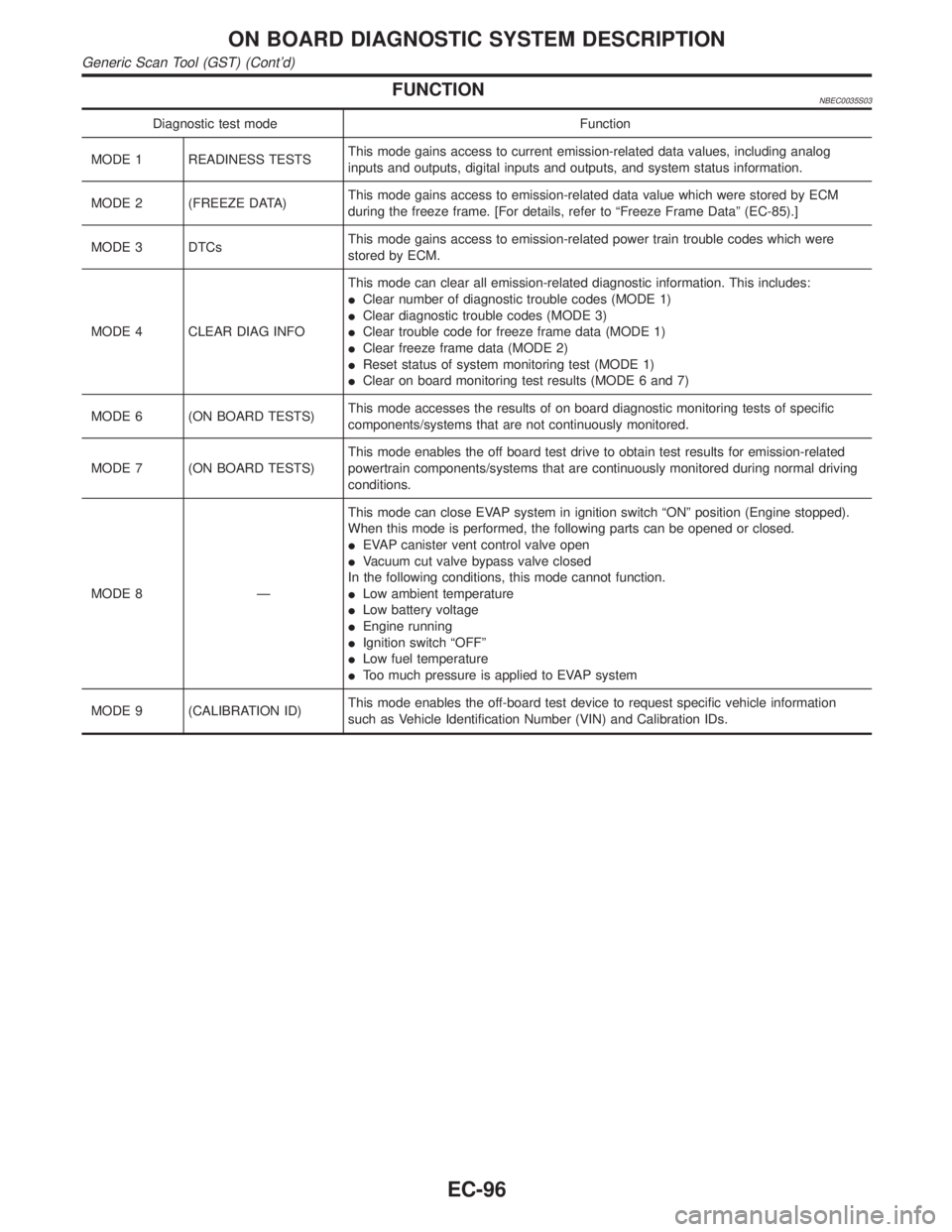

FUNCTIONNBEC0035S03

Diagnostic test mode Function

MODE 1 READINESS TESTSThis mode gains access to current emission-related data values, including analog

inputs and outputs, digital inputs and outputs, and system status information.

MODE 2 (FREEZE DATA)This mode gains access to emission-related data value which were stored by ECM

during the freeze frame. [For details, refer to ªFreeze Frame Dataº (EC-85).]

MODE 3 DTCsThis mode gains access to emission-related power train trouble codes which were

stored by ECM.

MODE 4 CLEAR DIAG INFOThis mode can clear all emission-related diagnostic information. This includes:

IClear number of diagnostic trouble codes (MODE 1)

IClear diagnostic trouble codes (MODE 3)

IClear trouble code for freeze frame data (MODE 1)

IClear freeze frame data (MODE 2)

IReset status of system monitoring test (MODE 1)

IClear on board monitoring test results (MODE 6 and 7)

MODE 6 (ON BOARD TESTS)This mode accesses the results of on board diagnostic monitoring tests of specific

components/systems that are not continuously monitored.

MODE 7 (ON BOARD TESTS)This mode enables the off board test drive to obtain test results for emission-related

powertrain components/systems that are continuously monitored during normal driving

conditions.

MODE 8 ÐThis mode can close EVAP system in ignition switch ªONº position (Engine stopped).

When this mode is performed, the following parts can be opened or closed.

IEVAP canister vent control valve open

IVacuum cut valve bypass valve closed

In the following conditions, this mode cannot function.

ILow ambient temperature

ILow battery voltage

IEngine running

IIgnition switch ªOFFº

ILow fuel temperature

IToo much pressure is applied to EVAP system

MODE 9 (CALIBRATION ID)This mode enables the off-board test device to request specific vehicle information

such as Vehicle Identification Number (VIN) and Calibration IDs.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Generic Scan Tool (GST) (Cont'd)

EC-96

Page 636 of 2395

Basic InspectionNBEC0038Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

IHeadlamp switch is OFF,

IAir conditioner switch is OFF,

IRear window defogger switch is OFF,

ISteering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

IHarness connectors for improper connections

IVacuum hoses for splits, kinks and improper connections

IWiring for improper connections, pinches and cuts

IAir cleaner clogging

IHoses and ducts for leaks

SEF983U

©GO TO 2.

2 CHECK THROTTLE OPENER OPERATION-I

Confirm that there is a clearance between throttle drum and stopper.

SEF950Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection

EC-101

Page 651 of 2395

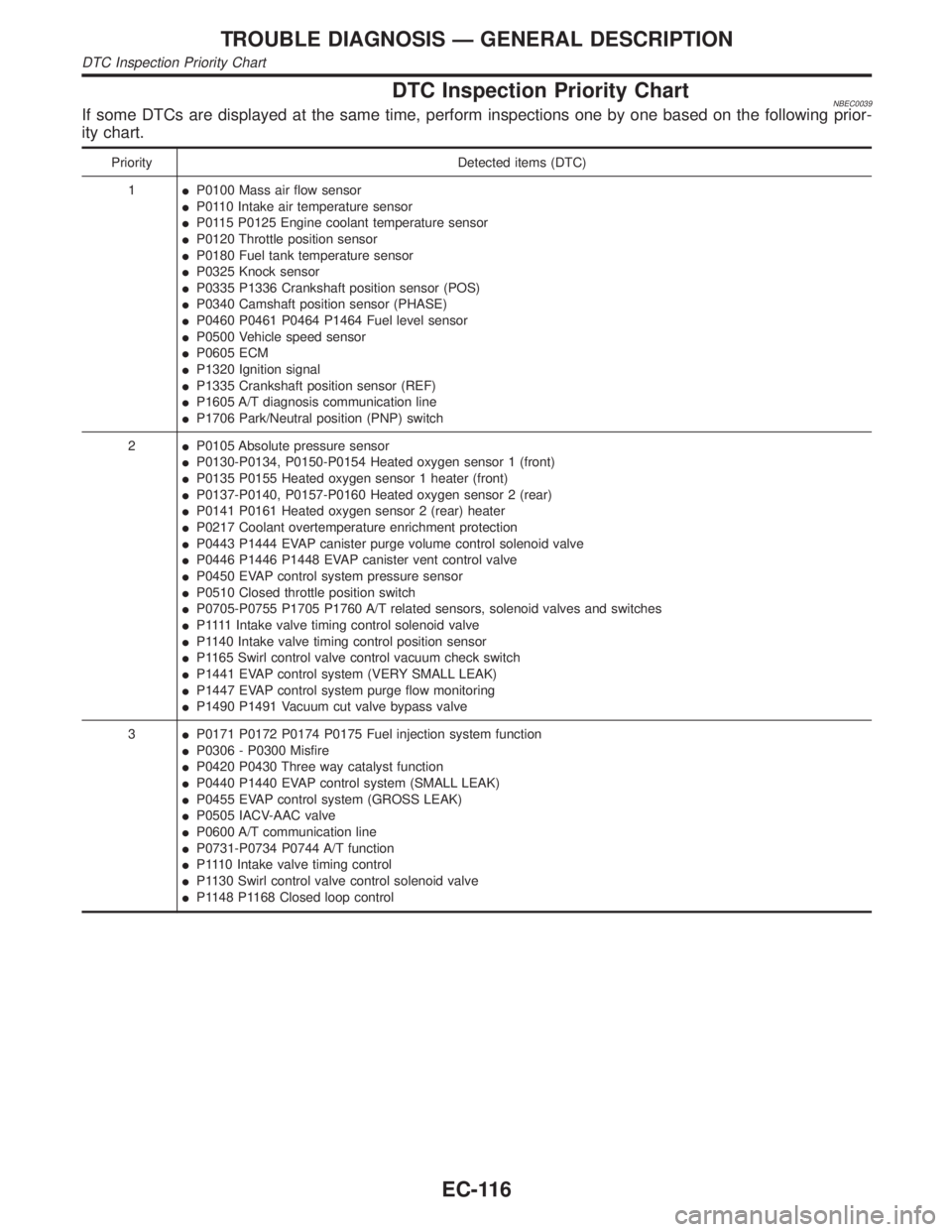

DTC Inspection Priority ChartNBEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 P0125 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0180 Fuel tank temperature sensor

IP0325 Knock sensor

IP0335 P1336 Crankshaft position sensor (POS)

IP0340 Camshaft position sensor (PHASE)

IP0460 P0461 P0464 P1464 Fuel level sensor

IP0500 Vehicle speed sensor

IP0605 ECM

IP1320 Ignition signal

IP1335 Crankshaft position sensor (REF)

IP1605 A/T diagnosis communication line

IP1706 Park/Neutral position (PNP) switch

2IP0105 Absolute pressure sensor

IP0130-P0134, P0150-P0154 Heated oxygen sensor 1 (front)

IP0135 P0155 Heated oxygen sensor 1 heater (front)

IP0137-P0140, P0157-P0160 Heated oxygen sensor 2 (rear)

IP0141 P0161 Heated oxygen sensor 2 (rear) heater

IP0217 Coolant overtemperature enrichment protection

IP0443 P1444 EVAP canister purge volume control solenoid valve

IP0446 P1446 P1448 EVAP canister vent control valve

IP0450 EVAP control system pressure sensor

IP0510 Closed throttle position switch

IP0705-P0755 P1705 P1760 A/T related sensors, solenoid valves and switches

IP 1111Intake valve timing control solenoid valve

IP1140 Intake valve timing control position sensor

IP1165 Swirl control valve control vacuum check switch

IP1441 EVAP control system (VERY SMALL LEAK)

IP1447 EVAP control system purge flow monitoring

IP1490 P1491 Vacuum cut valve bypass valve

3IP0171 P0172 P0174 P0175 Fuel injection system function

IP0306 - P0300 Misfire

IP0420 P0430 Three way catalyst function

IP0440 P1440 EVAP control system (SMALL LEAK)

IP0455 EVAP control system (GROSS LEAK)

IP0505 IACV-AAC valve

IP0600 A/T communication line

IP0731-P0734 P0744 A/T function

IP1110 Intake valve timing control

IP1130 Swirl control valve control solenoid valve

IP1148 P1168 Closed loop control

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

DTC Inspection Priority Chart

EC-116

Page 665 of 2395

![INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

25 W/G Tachometer[Engine is running]

IWarm-up condition

IIdle speed7-8VH

SEF579X

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

25 W/G Tachometer[Engine is running]

IWarm-up condition

IIdle speed7-8VH

SEF579X

[Engine is running]

IWarm-up condition

IEngine speed is 2,500](/img/42/57027/w960_57027-664.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

25 W/G Tachometer[Engine is running]

IWarm-up condition

IIdle speed7-8VH

SEF579X

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpm.7-8VH

SEF580X

26 L/BECM relay

(Self shutt-off)[Engine is running]

[Ignition switch ªOFFº]

IFor a few seconds after turning ignition switch

ªOFFº0 - 1.5V

[Ignition switch ªOFFº]

IA few seconds passed after turning ignition

switch ªOFFºBATTERY VOLTAGE

(11 - 14V)

27 LG Air conditioner relay[Engine is running]

IBoth A/C switch and blower switch are ªONº

(Compressor is operating).0 - 1.0V

[Engine is running]

IA/C switch is ªOFFº.BATTERY VOLTAGE

(11 - 14V)

28 R/L Fuel pump relay[Ignition switch ªONº]

IFor 1 second after turning ignition switch ªONº

[Engine is running]0 - 1.5V

[Ignition switch ªONº]

I1 second passed after turning ignition switch

ªONº.BATTERY VOLTAGE

(11 - 14V)

29 GSwirl control valve con-

trol solenoid valve[Engine is running]

IIdle speed

IEngine coolant temperature is between 15 to

50ÉC (59 to 122ÉF).0 - 1.0V

[Engine is running]

IIdle speed

IEngine coolant temperature is above 55ÉC

(131ÉF).BATTERY VOLTAGE

(11 - 14V)

38 OR MIL[Ignition switch ªONº]0 - 1.0V

[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

39 G/WVacuum cut valve

bypass valve[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

40 G/YEVAP canister vent

control valve[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

ECM Terminals and Reference Value (Cont'd)

EC-130

Page 666 of 2395

![INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 B/Y Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]9 - 12V

43 R Ignition switch[Ignition switch ªOFFº]0V

INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 B/Y Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]9 - 12V

43 R Ignition switch[Ignition switch ªOFFº]0V](/img/42/57027/w960_57027-665.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 B/Y Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]9 - 12V

43 R Ignition switch[Ignition switch ªOFFº]0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

44 L PNP switch[Ignition switch ªONº]

IGear position is ªPº or ªNº.Approximately 0V

[Ignition switch ªONº]

IExcept the above gear positionBATTERY VOLTAGE

(11 - 14V)

45 B/RAir conditioner switch

signal[Engine is running]

IBoth A/C switch and blower switch are ªONº.Approximately 0V

[Engine is running]

IA/C switch is ªOFFº.Approximately 5V

47 R/BPower steering oil

pressure switch[Engine is running]

ISteering wheel is being turned.0 - 1.0V

[Engine is running]

ISteering wheel is not being turned.Approximately 5V

48 B ECM ground[Engine is running]

IIdle speedEngine ground

51 BR A/C cut signal[Engine is running]

IAir conditioner is operating.0 - 0.5V

52 PU Electrical load signal[Engine is running]

IRear window defogger: ON

IHi-beam headlamp: ONBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IElectrical load: OFF0V

55 W/BSwirl control valve con-

trol vacuum check

switch[Engine is running]

IIdle speed

IEngine coolant temperature is between 15 to

50ÉC (59 to 122ÉF).Approximately 5V

[Engine is running]

IIdle speed

IEngine coolant temperature is above 55ÉC

(131ÉF).0 - 1.0V

56 OR/LThrottle position switch

(Closed position)[Engine is running]

IAccelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IAccelerator pedal depressedApproximately 0V

57 B ECM ground[Engine is running]

IIdle speedEngine ground

58 B/P Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

59 BFuel level sensor

ground[Engine is running]

IIdle speedApproximately 0V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

ECM Terminals and Reference Value (Cont'd)

EC-131

Page 887 of 2395

On Board Diagnosis LogicNBEC0218NOTE:

If DTC P0440 is displayed with P1448, perform trouble diagno-

sis for DTC P1448 first. (See EC-573.)

This diagnosis detects leaks in the EVAP purge line using engine

intake manifold vacuum.

If pressure does not increase, the ECM will check for leaks in the

line between the fuel tank and EVAP canister purge volume con-

trol solenoid valve, under the following ªVacuum testº conditions.

The vacuum cut valve bypass valve is opened to clear the line

between the fuel tank and the EVAP canister purge volume control

solenoid valve. The EVAP canister vent control valve will then be

closed to shut the EVAP purge line off. The EVAP canister purge

volume control solenoid valve is opened to depressurize the EVAP

purge line using intake manifold vacuum. After this occurs, the

EVAP canister purge volume control solenoid valve will be closed.

SEF373Z

Malfunction is detected when EVAP control system has a leak,

EVAP control system does not operate properly.

CAUTION:

IUse only a genuine NISSAN fuel filler cap as a replace-

ment. If an incorrect fuel filler cap is used, the MIL may

come on.

IIf the fuel filler cap is not tightened properly, the MIL may

come on.

IUse only a genuine NISSAN rubber tube as a replacement.

Possible CauseNBEC0510IIncorrect fuel tank vacuum relief valve

IIncorrect fuel filler cap used

IFuel filler cap remains open or fails to close.

IForeign matter caught in fuel filler cap.

ILeak is in line between intake manifold and EVAP canister

purge volume control solenoid valve.

IForeign matter caught in EVAP canister vent control valve.

IEVAP canister or fuel tank leaks

IEVAP purge line (pipe and rubber tube) leaks

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

On Board Diagnosis Logic

EC-352

Page 894 of 2395

7 CHECK FOR EVAP LEAK

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Apply 12 volts DC to EVAP canister vent control valve. The valve will close. (Continue to apply 12 volts until the end of

test.)

SEF598U

3. Apply 12 volts DC to vacuum cut valve bypass valve. The valve will open. (Continue to apply 12V until the end of test.)

SEF599U

4. Pressurize the EVAP line using pressure pump with 1.3 to 2.7 kPa (10 to 20 mmHg, 0.39 to 0.79 inHg), then remove

pump and EVAP service port adapter.

NOTE:

INever use compressed air or a high pressure pump.

IDo not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in the system.

5. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to ªEVAPORATIVE EMISSION LINE DRAWINGº, EC-36.

SEF200U

OK or NG

OK©GO TO 8.

NG©Repair or replace.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

Diagnostic Procedure (Cont'd)

EC-359

Page 936 of 2395

10 CHECK FOR EVAP LEAK

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Apply 12 volts DC to EVAP canister vent control valve. The valve will close. (Continue to apply 12 volts until the end of

test.)

SEF598U

3. Apply 12 volts DC to vacuum cut valve bypass valve. The valve will open. (Continue to apply 12V until the end of test.)

SEF599U

4. Pressurize the EVAP line using pressure pump with 1.3 to 2.7 kPa (10 to 20 mmHg, 0.39 to 0.79 inHg), then remove

pump and EVAP service port adapter.

NOTE:

INever use compressed air or a high pressure pump.

IDo not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in the system.

5. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to ªEVAPORATIVE EMISSION LINE DRAWINGº, EC-36.

SEF200U

OK or NG

OK©GO TO 12.

NG©Repair or replace.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0455 EVAP CONTROL SYSTEM (GROSS LEAK)

Diagnostic Procedure (Cont'd)

EC-401

Page 994 of 2395

SEF002Z

COMPONENT DESCRIPTIONNBEC0523S02Swirl Control Valve Control Solenoid ValveNBEC0523S0201The swirl control valve control solenoid valve responds to signals

from the ECM. When the ECM sends an ON (ground) signal, the

solenoid valve is bypassed to apply intake manifold vacuum to the

swirl control valve actuator. This operation closes the swirl control

valve. When the ECM sends an OFF signal, the vacuum signal is

cut and the swirl control valve opens.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0524Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

SWRL CONT S/VIEngine speed: IdleEngine coolant temperature is

between 15ÉC (59ÉF) to 50ÉC

(122ÉF).ON

Engine coolant temperature is

above 55ÉC (131ÉF).OFF

ECM Terminals and Reference ValueNBEC0673Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

29 GSwirl control valve con-

trol solenoid valve[Engine is running]

IIdle speed

IEngine coolant temperature is between 15 to

50ÉC (59 to 122ÉF).0 - 1.0V

[Engine is running]

IIdle speed

IEngine coolant temperature is above 55ÉC

(131ÉF).BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNBEC0526Malfunction is detected when

(Malfunction A)An improper voltage signal is sent to ECM through

swirl control valve control solenoid valve,

(Malfunction B)The vacuum signal is not sent to swirl control

valve under specified driving conditions, even though swirl control

valve control solenoid valve is ON,

(Malfunction C)The vacuum signal is sent to swirl control valve

even though swirl control valve control solenoid valve is OFF.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Description (Cont'd)

EC-459

Page 1063 of 2395

place or refilling/draining fuel until the output voltage condition

of the ªFUEL LEVEL SEº meets within the range above and

leave the vehicle for more than 1 hour. Then start from step 1).

3) Turn ignition switch ªOFFº and wait at least 5 seconds.

4) Turn ignition switch ªONº.

5) Select ªEVAP VERY/SML LEAK P1441º of ªEVAPORATIVE

SYSTEMº in ªDTC WORK SUPPORTº mode with CONSULT-

II.

Follow the instruction displayed.

6) Make sure that ªOKº is displayed.

If ªNGº is displayed, refer to ªDiagnostic Procedureº, EC-529.

NOTE:

IIf the engine speed cannot be maintained within the range

displayed on CONSULT-II screen, go to ªBasic

inspectionº, EC-101.

IMake sure that EVAP hoses are connected to EVAP canis-

ter purge volume control solenoid valve properly.

OVERALL FUNCTION CHECKNBEC0317S05With GST

Use this procedure to check the overall function of the EVAP very

small leak function. During this check, a 1st trip DTC might not be

confirmed.

SEF462UA

CAUTION:

INever use compressed air, doing so may damage the

EVAP system.

IDo not start engine.

IDo not exceeded 4.12 kPa (0.042 kg/cm

2, 0.6 psi).

1) Attach the EVAP service port adapter securely to the EVAP

service port.

2) Set the pressure pump and a hose.

3) Also set a vacuum gauge via 3-way connector and a hose.

4) Turn ignition switch ªONº.

5) Connect GST and select mode 8.

6) Using mode 8 control the EVAP canister vent control valve

(close) and vacuum cut valve bypass valve (open).

7) Apply pressure and make sure the following conditions are

satisfied.

Pressure to be applied: 2.7 kPa (20 mmHg, 0.79 inHg)

Time to be waited after the pressure drawn in to the EVAP

system and the pressure to be dropped: 60 seconds and

the pressure should not be dropped more than 0.4 kPa (3

mmHg, 0.12 inHg)

If NG, go to diagnostic procedure, EC-529.

NOTE:

For more information, refer to GST instruction manual.

DTC P1441 EVAP CONTROL SYSTEM (VERY SMALL LEAK)

DTC Confirmation Procedure (Cont'd)

EC-528