dead battery INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 653 of 2395

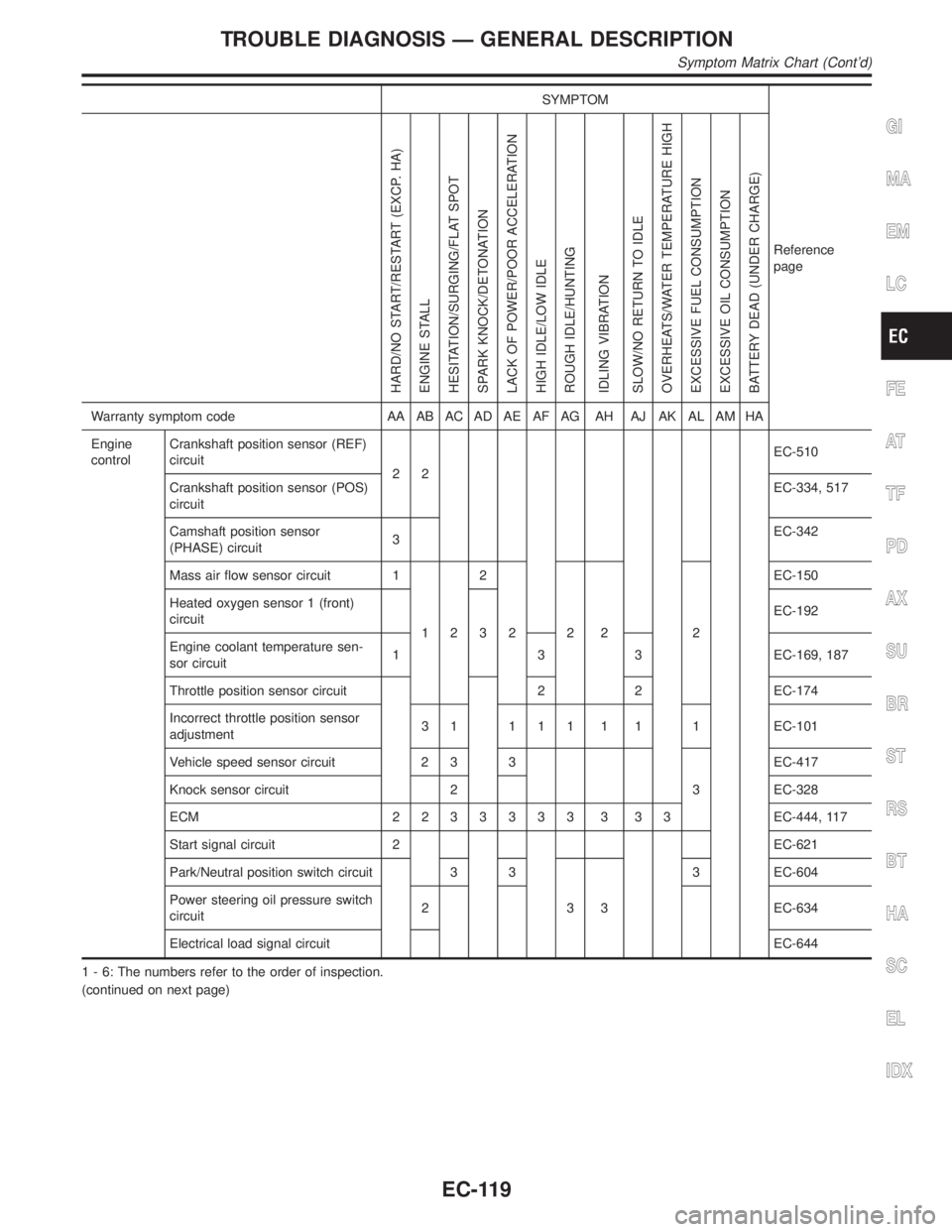

Symptom Matrix ChartNBEC0041SYSTEM Ð BASIC ENGINE CONTROL SYSTEMNBEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 2 2 3 2EC-625

Fuel pressure regulator system3344444 4 4 4EC-40

Injector circuit11232 2 2 2EC-616

Evaporative emission system

3344444 4 4 4EC-32

Air Positive crankcase ventilation sys-

tem1 EC-38

Incorrect idle speed adjustment 1 1 1 1 1 EC-101

IACV-AAC valve circuit1123322 2 2 2 2EC-422

Ignition Incorrect ignition timing adjustment33111 1 1 1EC-101

Ignition circuit 1 1 2 2 2 2 2 2 EC-499

Main power supply and ground circuit

22333 3 32

3EC-142

Air conditioner circuit 3 3 2 HA section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart

EC-118

Page 654 of 2395

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine

controlCrankshaft position sensor (REF)

circuit

22EC-510

Crankshaft position sensor (POS)

circuitEC-334, 517

Camshaft position sensor

(PHASE) circuit3EC-342

Mass air flow sensor circuit 1

122

222 2EC-150

Heated oxygen sensor 1 (front)

circuit

3EC-192

Engine coolant temperature sen-

sor circuit1 3 3 EC-169, 187

Throttle position sensor circuit 2 2 EC-174

Incorrect throttle position sensor

adjustment3 1 1 1 1 1 1 1 EC-101

Vehicle speed sensor circuit 2 3 3

3EC-417

Knock sensor circuit 2 EC-328

ECM 2233333 3 33EC-444, 117

Start signal circuit 2 EC-621

Park/Neutral position switch circuit 3 3

333 EC-604

Power steering oil pressure switch

circuit2 EC-634

Electrical load signal circuitEC-644

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-119

Page 655 of 2395

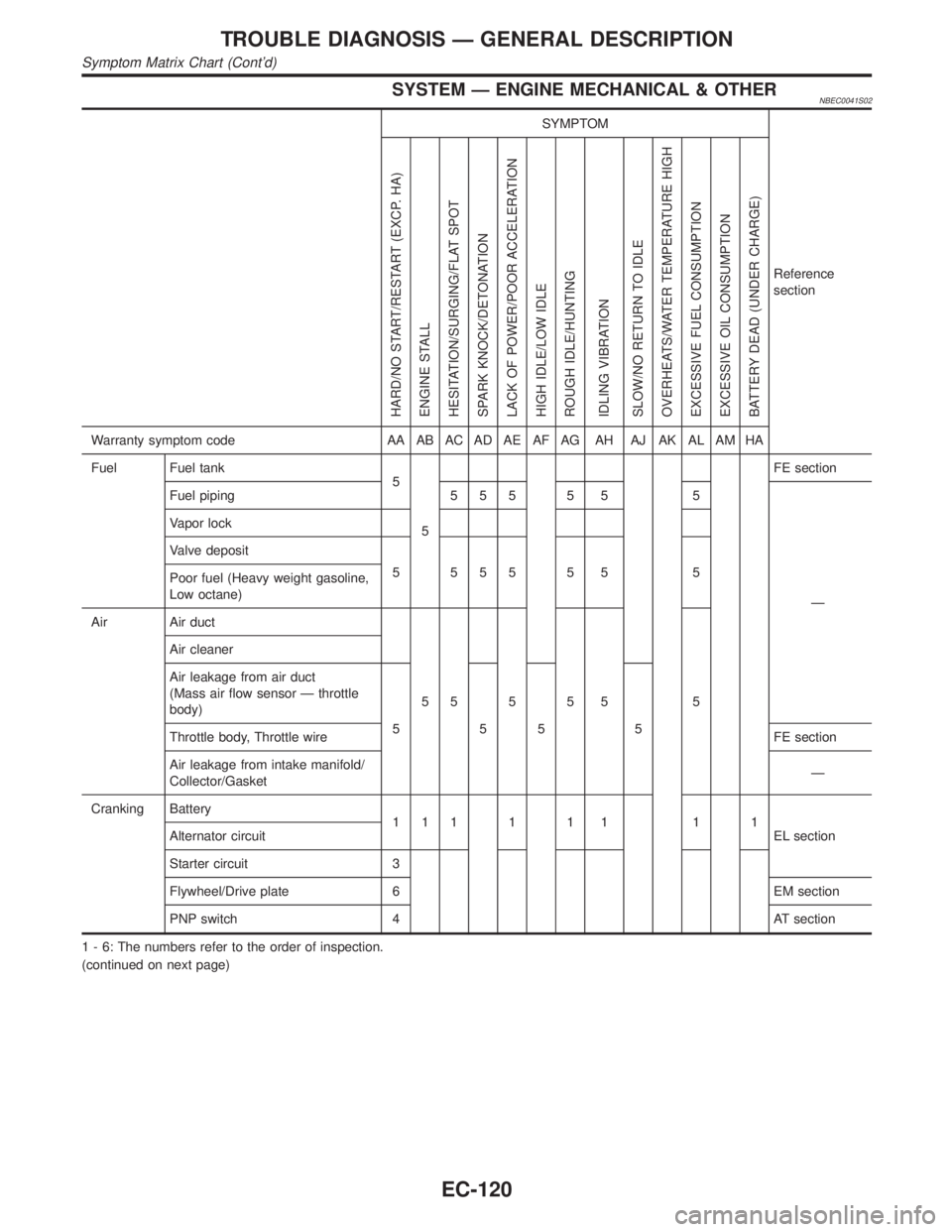

SYSTEM Ð ENGINE MECHANICAL & OTHERNBEC0041S02

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 5 5 5

Poor fuel (Heavy weight gasoline,

Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð throttle

body)

555 5

Throttle body, Throttle wireFE section

Air leakage from intake manifold/

Collector/GasketÐ

Cranking Battery

111111 11

EL section Alternator circuit

Starter circuit 3

Flywheel/Drive plate 6 EM section

PNP switch 4 AT section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-120

Page 656 of 2395

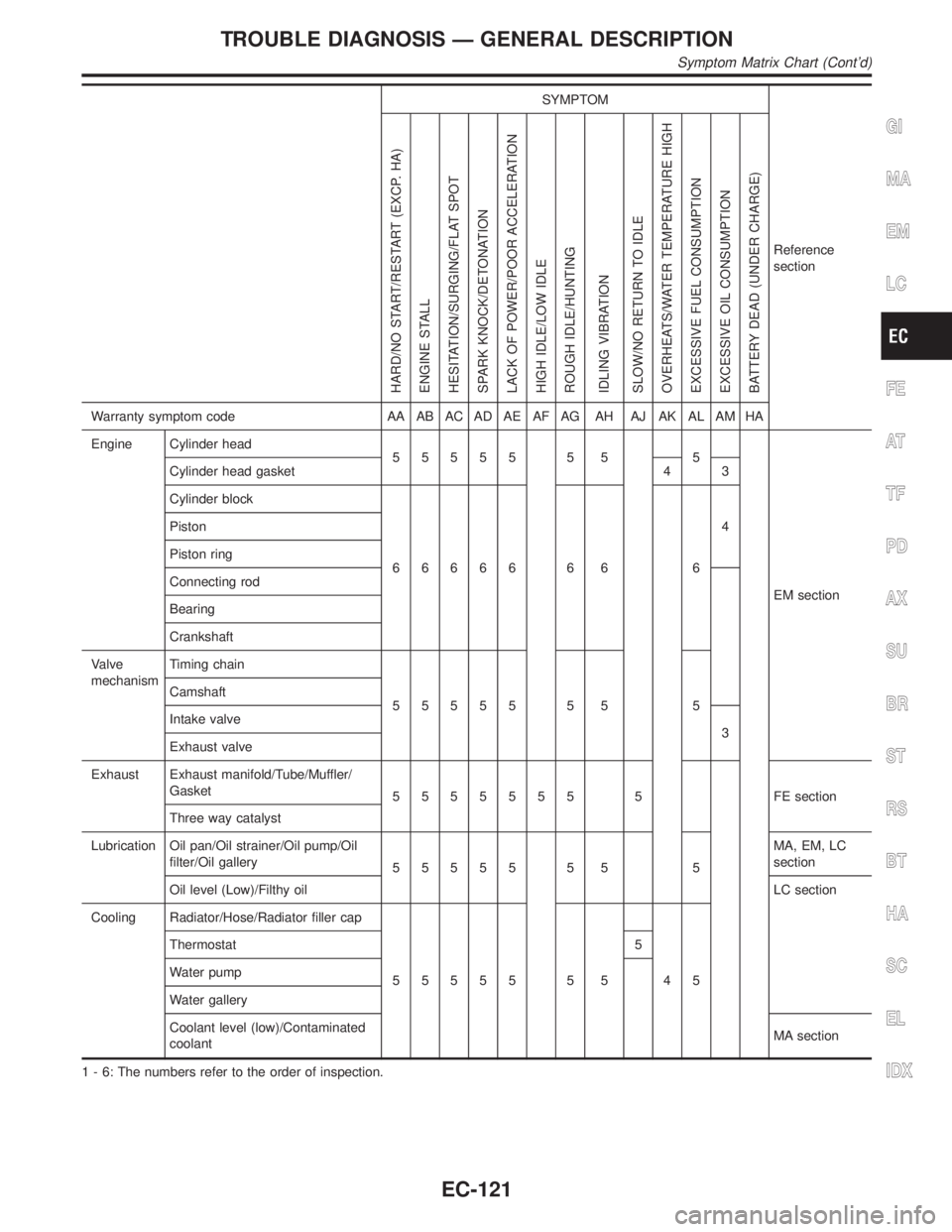

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 5 5 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 6 6 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mechanismTiming chain

55555 5 5 5 Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

5555555 5 FEsection

Three way catalyst

Lubrication Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 5 5 5MA, EM, LC

section

Oil level (Low)/Filthy oilLC section

Cooling Radiator/Hose/Radiator filler cap

55555 5 5 45 Thermostat 5

Water pump

Water gallery

Coolant level (low)/Contaminated

coolantMA section

1 - 6: The numbers refer to the order of inspection.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-121

Page 657 of 2395

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

IVIS (INFINITI Vehicle Immobilizer System Ð

NATS)11EC-74 or EL

section

1 - 6: The numbers refer to the order of inspection.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0042Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in

spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM

according to the signals input from the camshaft position sensor and other ignition timing related sensors.

IIf the real-time diagnosis results are NG and the on board diagnostic system results are OK when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as

the CONSULT-II value.

POS COUNTIEngine: Running 179 - 181

MAS A/F SE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 1.2 - 1.8V

2,500 rpm 1.6 - 2.2V

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

HO2S1 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S1 MNTR (B1)

HO2S1 MNTR (B2)LEAN+,RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

HO2S2 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN+,RICH

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-122

Page 870 of 2395

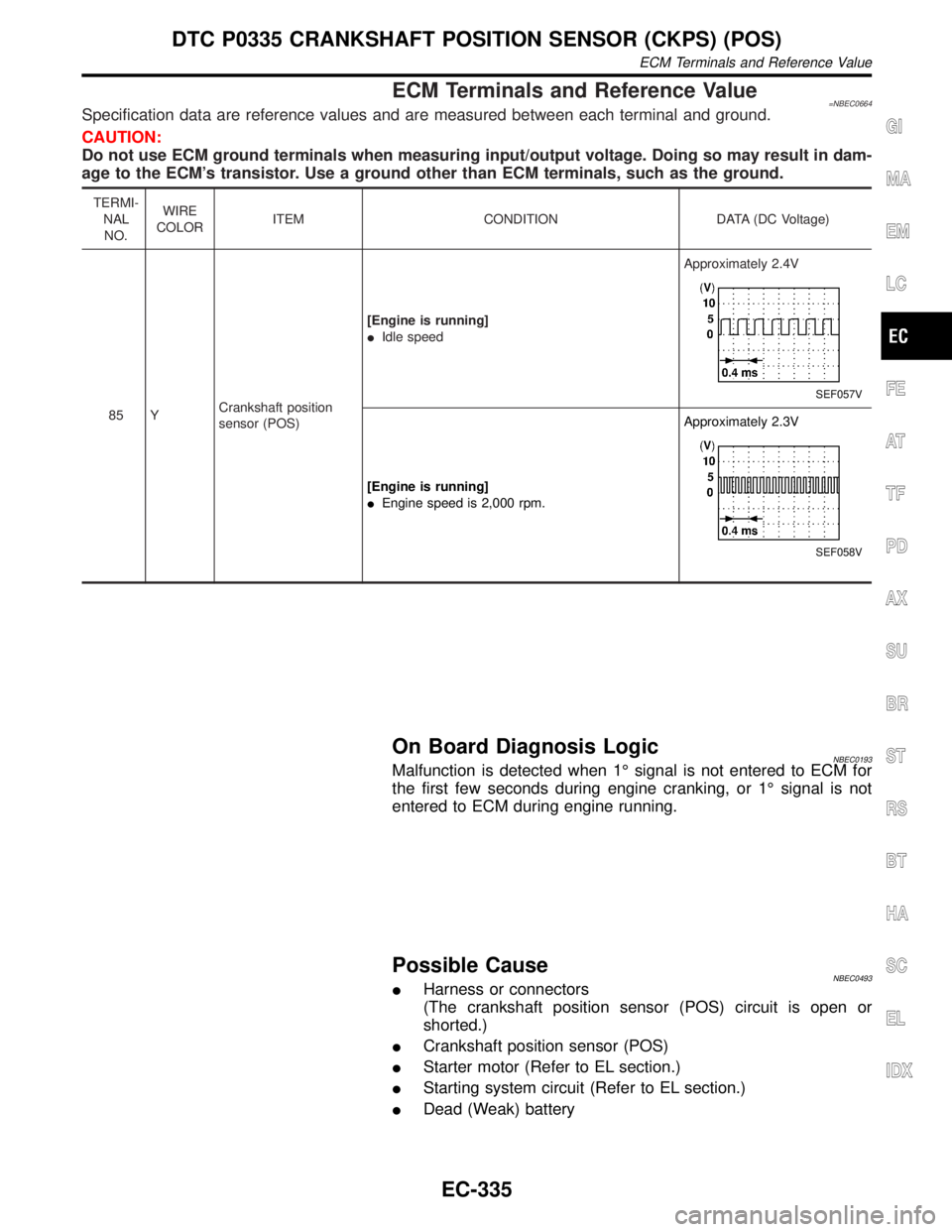

ECM Terminals and Reference Value=NBEC0664Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 YCrankshaft position

sensor (POS)[Engine is running]

IIdle speedApproximately 2.4V

SEF057V

[Engine is running]

IEngine speed is 2,000 rpm.Approximately 2.3V

SEF058V

On Board Diagnosis LogicNBEC0193Malfunction is detected when 1É signal is not entered to ECM for

the first few seconds during engine cranking, or 1É signal is not

entered to ECM during engine running.

Possible CauseNBEC0493IHarness or connectors

(The crankshaft position sensor (POS) circuit is open or

shorted.)

ICrankshaft position sensor (POS)

IStarter motor (Refer to EL section.)

IStarting system circuit (Refer to EL section.)

IDead (Weak) battery

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

ECM Terminals and Reference Value

EC-335

Page 878 of 2395

![INFINITI QX4 2001 Factory Service Manual Possible CauseNBEC0494IHarness or connectors

[The camshaft position sensor (PHASE) circuit is open or

shorted.]

ICamshaft position sensor (PHASE)

IStarter motor (Refer to SC section.)

IStarting system INFINITI QX4 2001 Factory Service Manual Possible CauseNBEC0494IHarness or connectors

[The camshaft position sensor (PHASE) circuit is open or

shorted.]

ICamshaft position sensor (PHASE)

IStarter motor (Refer to SC section.)

IStarting system](/img/42/57027/w960_57027-877.png)

Possible CauseNBEC0494IHarness or connectors

[The camshaft position sensor (PHASE) circuit is open or

shorted.]

ICamshaft position sensor (PHASE)

IStarter motor (Refer to SC section.)

IStarting system circuit (Refer to SC section.)

IDead (Weak) battery

DTC Confirmation ProcedureNBEC0200NOTE:

IPerform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st

trip DTC cannot be confirmed, perform ªPROCEDURE

FOR MALFUNCTION B AND Cº.

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

SEF013Y

PROCEDURE FOR MALFUNCTION ANBEC0200S01With CONSULT-IINBEC0200S01011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Crank engine for at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-345.

With GSTNBEC0200S0102Follow the procedure ªWith CONSULT-IIº above.

SEF058Y

PROCEDURE FOR MALFUNCTION B AND CNBEC0200S02With CONSULT-IINBEC0200S02011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-345.

With GSTNBEC0200S0202Follow the procedure ªWith CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)

Possible Cause

EC-343

Page 975 of 2395

System DescriptionNBEC0264This circuit line (LAN) is used to control the smooth shifting up and down of A/T during the hard acceleration/

deceleration.

Pulse signals are exchanged between ECM and TCM (Transmission Control Module).

Be sure to erase the malfunction information such as DTC not only in TCM but also ECM after the A/T

related repair.

ECM Terminals and Reference ValueNBEC0672Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

114 G/RCommunication line

(LAN)[Engine is running]

IIdle speedApproximately 2V

On Board Diagnosis LogicNBEC0266Malfunction is detected when ECM receives incorrect voltage from

TCM (Transmission Control Module) continuously.

Possible CauseNBEC0517IHarness or connectors

[The communication line circuit between ECM and TCM

(Transmission Control Module) is open or shorted.]

ITCM

IDead (Weak) battery

SEF058Y

DTC Confirmation ProcedureNBEC0267NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

WITH CONSULT-IINBEC0267S011) Turn ignition switch ªONº.

DTC P0600 A/T COMMUNICATION LINE

System Description

EC-440

Page 1046 of 2395

On Board Diagnosis LogicNBEC0576Malfunction is detected when

(Malfunction A)120É signal is not entered to ECM for the first few

seconds during engine cranking,

(Malfunction B)120É signal is not entered to ECM during engine

running,

(Malfunction C)120É signal cycle excessively changes during

engine running.

FAIL-SAFE MODENBEC0576S01When the ECM enters the fail-safe mode, the MIL illuminates.

Detected items Engine operating condition in fail-safe mode

Crankshaft position sensor (REF)

circuitCompression TDC signal (120É signal) is controlled by camshaft position sensor (PHASE)

signal and crankshaft position sensor (POS) signal. Ignition timing will be delayed 0É to 2É.

Possible CauseNBEC0577IHarness or connectors

(The crankshaft position sensor (REF) circuit is open or

shorted.)

ICrankshaft position sensor (REF)

IStarter motor (Refer to SC section.)

IStarting system circuit (Refer to SC section.)

IDead (Weak) battery

DTC Confirmation ProcedureNBEC0578NOTE:

IPerform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st

trip DTC cannot be confirmed, perform ªPROCEDURE

FOR MALFUNCTION B AND Cº.

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

SEF013Y

PROCEDURE FOR MALFUNCTION ANBEC0578S01With CONSULT-IINBEC0578S01011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Crank engine for at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-514.

With GSTNBEC0578S0102Follow the procedure ªWith CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1335 CRANKSHAFT POSITION SENSOR (CKPS) (REF)

On Board Diagnosis Logic

EC-511

Page 1138 of 2395

Component DescriptionNBEC0361The malfunction information related to A/T (Automatic Transmission) is transferred through the line (circuit)

from TCM (Transmission control module) to ECM. Therefore, be sure to erase the malfunction information such

as DTC not only in TCM (Transmission control module) but also ECM after the A/T related repair.

On Board Diagnosis LogicNBEC0363Malfunction is detected when an incorrect signal from TCM (Trans-

mission control module) is sent to ECM.

Possible CauseNBEC0594IHarness or connectors

[The communication line circuit between ECM and TCM

(Transmission control module) is open or shorted.]

IDead (Weak) battery

ITCM (Transmission control module)

SEF058Y

DTC Confirmation ProcedureNBEC0364NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

WITH CONSULT-IINBEC0364S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 40 seconds.

4) If 1st trip DTC is detected, go to ªDTC P0600 A/T COMMUNI-

CATION LINE Diagnostic Procedureº, EC-443.

WITH GSTNBEC0364S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINE

Component Description

EC-603