oil pressure INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 8 of 2395

19. A/T Does Not Shift: 22-> 11, When Selector

Lever²2²->²1²Position .........................................255

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................256

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................257

A/T SHIFT LOCK SYSTEM.........................................265

Description ...............................................................265

Wiring Diagram - SHIFT -........................................266

Diagnostic Procedure ..............................................267

KEY INTERLOCK CABLE..........................................271

Components.............................................................271

Removal ...................................................................271

Installation ................................................................272

ON-VEHICLE SERVICE..............................................273

Control Valve Assembly and Accumulators .............273

Revolution Sensor Replacement .............................274

Turbine Revolution Sensor Replacement................274

Rear Oil Seal Replacement .....................................274

Rear Oil Seal and Companion Flange Oil Seal

Replacement ............................................................275

Parking Components Inspection..............................275

Park/Neutral Position Switch Adjustment ................276

Manual Control Linkage Adjustment........................276

REMOVAL AND INSTALLATION...............................277

Removal ...................................................................277

Installation ................................................................278

OVERHAUL.................................................................281

Components.............................................................281

Oil Channel ..............................................................284

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................285

DISASSEMBLY............................................................286

REPAIR FOR COMPONENT PARTS.........................297Oil Pump ..................................................................297

Control Valve Assembly ...........................................301

Control Valve Upper Body .......................................307

Control Valve Lower Body .......................................312

Reverse Clutch ........................................................314

High Clutch ..............................................................317

Forward and Overrun Clutches ...............................320

Low & Reverse Brake..............................................324

Forward Clutch Drum Assembly ..............................328

Rear Internal Gear and Forward Clutch Hub ..........330

Band Servo Piston Assembly ..................................333

Parking Pawl Components ......................................337

ASSEMBLY..................................................................339

Assembly (1) ............................................................339

Adjustment ...............................................................347

Assembly (2) ............................................................349

SERVICE DATA AND SPECIFICATIONS (SDS).......356

General Specifications .............................................356

Shift Schedule..........................................................356

Stall Revolution ........................................................356

Line Pressure...........................................................356

Return Springs .........................................................357

Accumulator O-ring ..................................................358

Clutches and Brakes ...............................................358

Oil Pump and Low One-way Clutch ........................360

Total End Play..........................................................360

Reverse Clutch Drum End Play ..............................361

Removal and Installation .........................................361

Shift Solenoid Valves ...............................................361

Solenoid Valves .......................................................361

A/T Fluid Temperature Sensor.................................361

Turbine Revolution Sensor ......................................361

Revolution Sensor ...................................................362

Dropping Resistor ....................................................362GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

AT-3

Page 15 of 2395

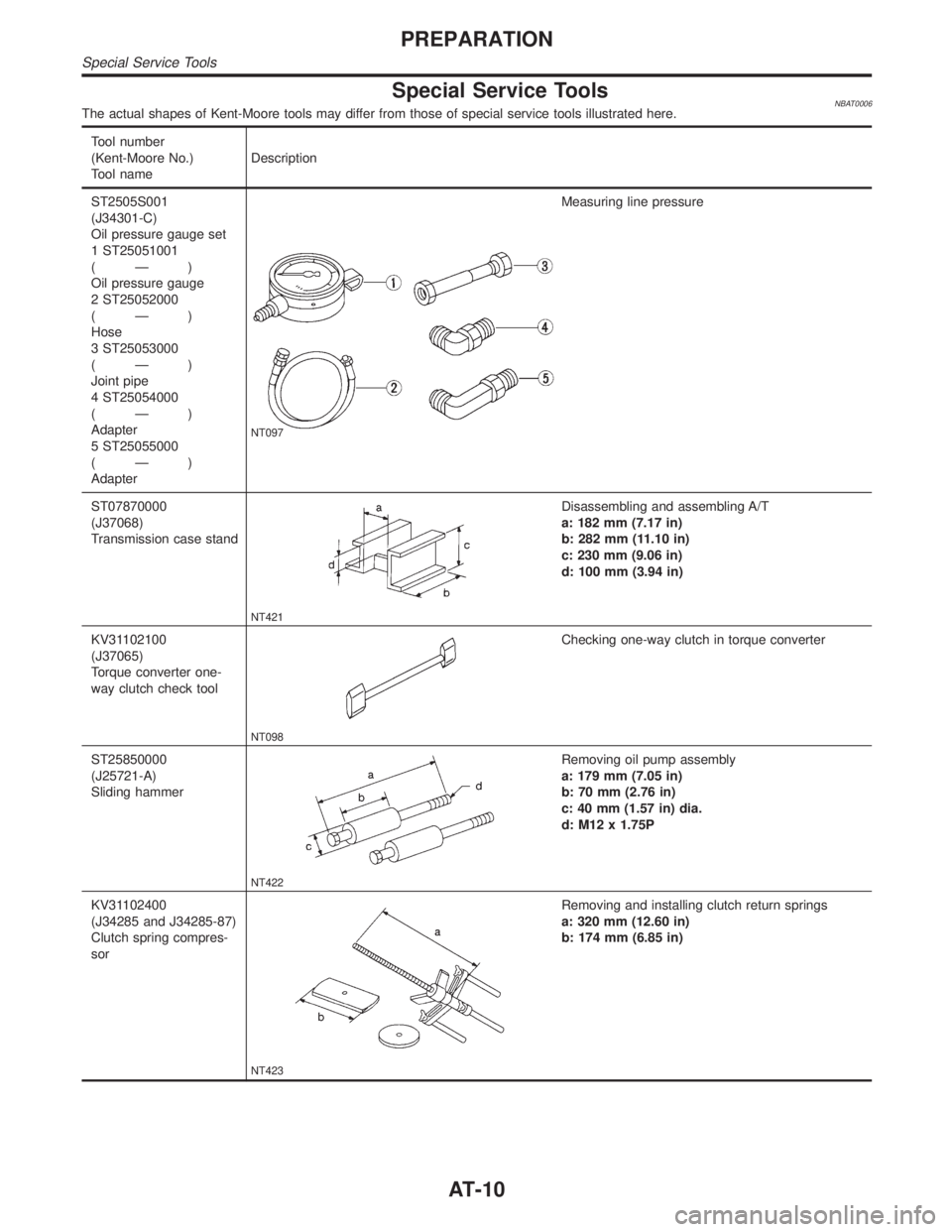

Special Service ToolsNBAT0006The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST2505S001

(J34301-C)

Oil pressure gauge set

1 ST25051001

(Ð)

Oil pressure gauge

2 ST25052000

(Ð)

Hose

3 ST25053000

(Ð)

Joint pipe

4 ST25054000

(Ð)

Adapter

5 ST25055000

(Ð)

Adapter

NT097

Measuring line pressure

ST07870000

(J37068)

Transmission case stand

NT421

Disassembling and assembling A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

(J37065)

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in torque converter

ST25850000

(J25721-A)

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

KV31102400

(J34285 and J34285-87)

Clutch spring compres-

sor

NT423

Removing and installing clutch return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

PREPARATION

Special Service Tools

AT-10

Page 22 of 2395

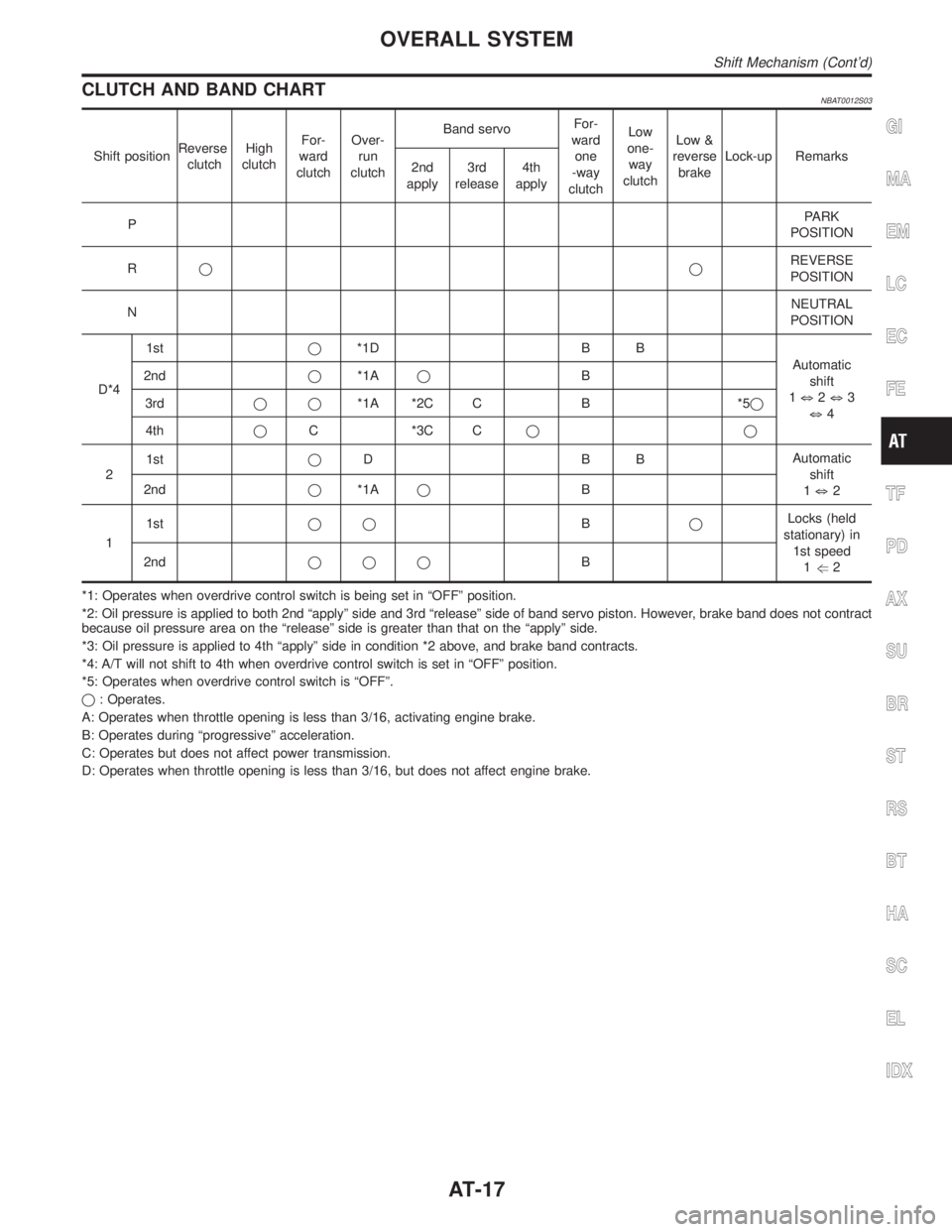

CLUTCH AND BAND CHARTNBAT0012S03

Shift positionReverse

clutchHigh

clutchFor-

ward

clutchOver-

run

clutchBand servoFor-

ward

one

-way

clutchLow

one-

way

clutchLow &

reverse

brakeLock-up Remarks

2nd

apply3rd

release4th

apply

PPARK

POSITION

RqqREVERSE

POSITION

NNEUTRAL

POSITION

D*41stq*1D B B

Automatic

shift

1k2k3

k4 2ndq*1AqB

3rdqq*1A *2C C B *5q

4thqC *3C Cqq

21stqDBBAutomatic

shift

1k2 2ndq*1AqB

11stqqBqLocks (held

stationary) in

1st speed

1g2 2ndqqqB

*1: Operates when overdrive control switch is being set in ªOFFº position.

*2: Oil pressure is applied to both 2nd ªapplyº side and 3rd ªreleaseº side of band servo piston. However, brake band does not contract

because oil pressure area on the ªreleaseº side is greater than that on the ªapplyº side.

*3: Oil pressure is applied to 4th ªapplyº side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control switch is set in ªOFFº position.

*5: Operates when overdrive control switch is ªOFFº.

q: Operates.

A: Operates when throttle opening is less than 3/16, activating engine brake.

B: Operates during ªprogressiveº acceleration.

C: Operates but does not affect power transmission.

D: Operates when throttle opening is less than 3/16, but does not affect engine brake.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-17

Page 34 of 2395

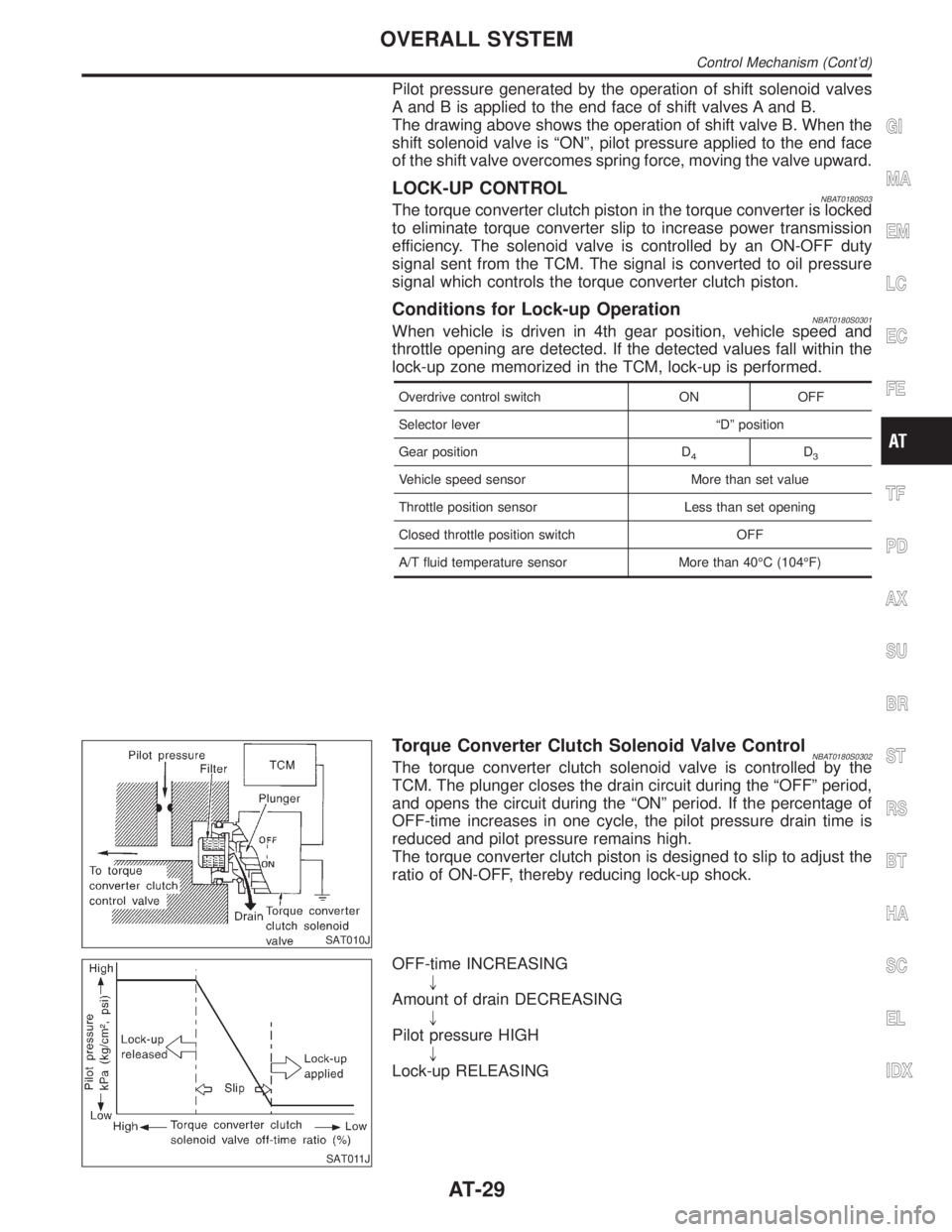

Pilot pressure generated by the operation of shift solenoid valves

A and B is applied to the end face of shift valves A and B.

The drawing above shows the operation of shift valve B. When the

shift solenoid valve is ªONº, pilot pressure applied to the end face

of the shift valve overcomes spring force, moving the valve upward.

LOCK-UP CONTROLNBAT0180S03The torque converter clutch piston in the torque converter is locked

to eliminate torque converter slip to increase power transmission

efficiency. The solenoid valve is controlled by an ON-OFF duty

signal sent from the TCM. The signal is converted to oil pressure

signal which controls the torque converter clutch piston.

Conditions for Lock-up OperationNBAT0180S0301When vehicle is driven in 4th gear position, vehicle speed and

throttle opening are detected. If the detected values fall within the

lock-up zone memorized in the TCM, lock-up is performed.

Overdrive control switch ON OFF

Selector lever ªDº position

Gear position D

4D3

Vehicle speed sensor More than set value

Throttle position sensor Less than set opening

Closed throttle position switch OFF

A/T fluid temperature sensor More than 40ÉC (104ÉF)

SAT010J

Torque Converter Clutch Solenoid Valve ControlNBAT0180S0302The torque converter clutch solenoid valve is controlled by the

TCM. The plunger closes the drain circuit during the ªOFFº period,

and opens the circuit during the ªONº period. If the percentage of

OFF-time increases in one cycle, the pilot pressure drain time is

reduced and pilot pressure remains high.

The torque converter clutch piston is designed to slip to adjust the

ratio of ON-OFF, thereby reducing lock-up shock.

SAT011J

OFF-time INCREASING

"

Amount of drain DECREASING

"

Pilot pressure HIGH

"

Lock-up RELEASING

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Control Mechanism (Cont'd)

AT-29

Page 36 of 2395

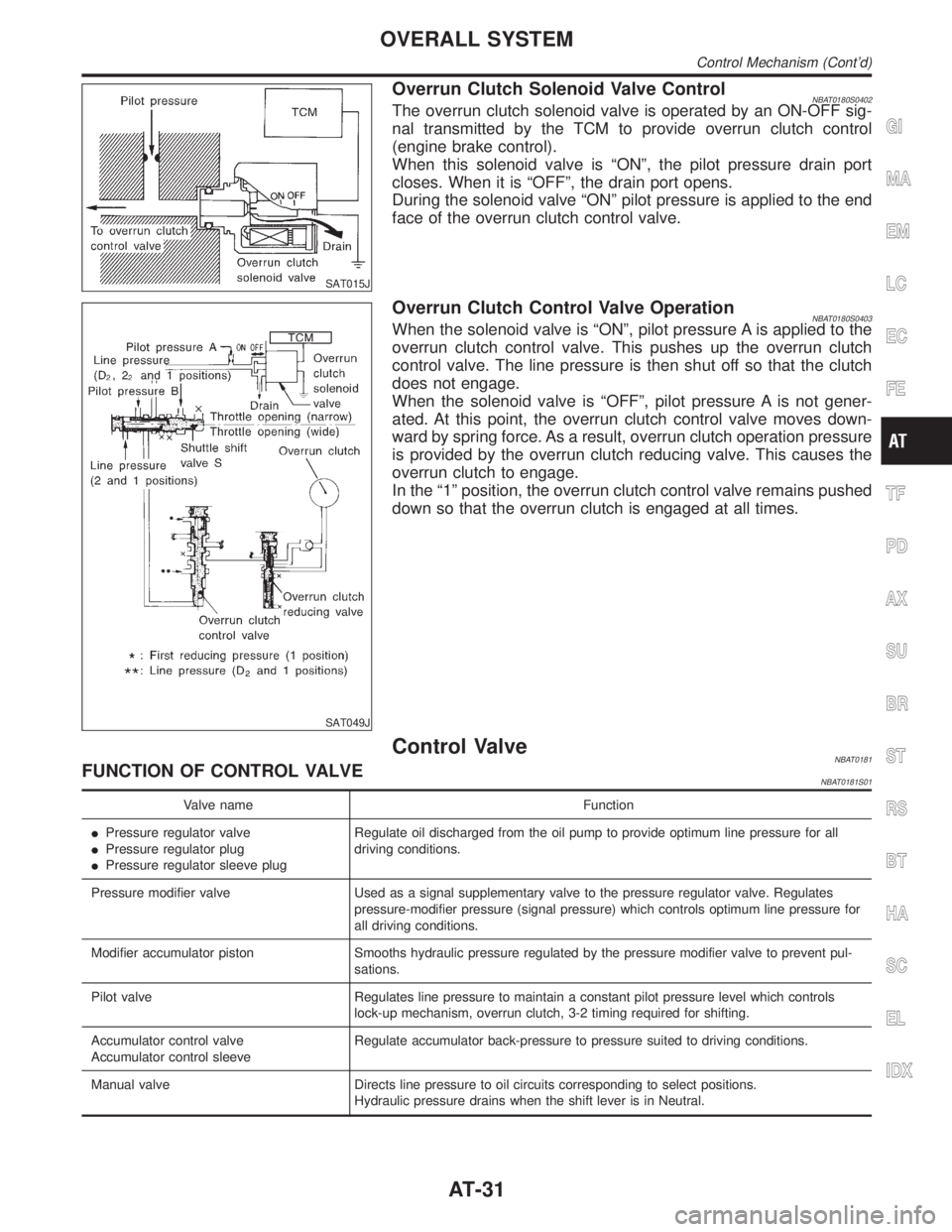

SAT015J

Overrun Clutch Solenoid Valve ControlNBAT0180S0402The overrun clutch solenoid valve is operated by an ON-OFF sig-

nal transmitted by the TCM to provide overrun clutch control

(engine brake control).

When this solenoid valve is ªONº, the pilot pressure drain port

closes. When it is ªOFFº, the drain port opens.

During the solenoid valve ªONº pilot pressure is applied to the end

face of the overrun clutch control valve.

SAT049J

Overrun Clutch Control Valve OperationNBAT0180S0403When the solenoid valve is ªONº, pilot pressure A is applied to the

overrun clutch control valve. This pushes up the overrun clutch

control valve. The line pressure is then shut off so that the clutch

does not engage.

When the solenoid valve is ªOFFº, pilot pressure A is not gener-

ated. At this point, the overrun clutch control valve moves down-

ward by spring force. As a result, overrun clutch operation pressure

is provided by the overrun clutch reducing valve. This causes the

overrun clutch to engage.

In the ª1º position, the overrun clutch control valve remains pushed

down so that the overrun clutch is engaged at all times.

Control ValveNBAT0181FUNCTION OF CONTROL VALVENBAT0181S01

Valve name Function

IPressure regulator valve

IPressure regulator plug

IPressure regulator sleeve plugRegulate oil discharged from the oil pump to provide optimum line pressure for all

driving conditions.

Pressure modifier valve Used as a signal supplementary valve to the pressure regulator valve. Regulates

pressure-modifier pressure (signal pressure) which controls optimum line pressure for

all driving conditions.

Modifier accumulator piston Smooths hydraulic pressure regulated by the pressure modifier valve to prevent pul-

sations.

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls

lock-up mechanism, overrun clutch, 3-2 timing required for shifting.

Accumulator control valve

Accumulator control sleeveRegulate accumulator back-pressure to pressure suited to driving conditions.

Manual valve Directs line pressure to oil circuits corresponding to select positions.

Hydraulic pressure drains when the shift lever is in Neutral.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Control Mechanism (Cont'd)

AT-31

Page 37 of 2395

Valve name Function

Shift valve A Simultaneously switches three oil circuits using output pressure of shift solenoid valve

A to meet driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st,2nd,3rd,4th gears/4th

,3rd,2nd,1st gears) in combination with shift valve B.

Shift valve B Simultaneously switches three oil circuits using output pressure of shift solenoid valve

B in relation to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st,2nd,3rd,4th gears/4th

,3rd,2nd,1st gears) in combination with shift valve A.

Shuttle shift valve S Switches hydraulic circuits to provide 3-2 timing control and overrun clutch control in

relation to the throttle opening.

Inactivates the overrun clutch to prevent interlocking in 4th gear when the throttle is

wide open.

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simulta-

neously with application of the brake band in 4th gear. (Interlocking occurs if the

overrun clutch engages during D

4gear operation.)

4-2 relay valve Memorizes that the transmission is in 4th gear. Prevents the transmission from down-

shifting from 4th gear to 3rd and then to 2nd in combination with 4-2 sequence valve

and shift valves A and B when downshifting from 4th to 2nd gear.

4-2 sequence valve Prevents band servo pressure from draining before high clutch operating pressure

and band servo releasing pressure drain (from the same circuit) during downshifting

from 4th to 2nd gear.

Servo charger valve An accumulator and a one-way orifice are used in the 2nd gear band servo oil circuit

to dampen shifting shock when shifting from 1st to 2nd gear.

To maintain adequate flow rate when downshifting from 4th or 3rd gear to 2nd gear,

the servo charger valve directs 2nd gear band servo hydraulic pressure to the circuit

without going through the one-way orifice when downshifting from 3rd or a higher

gear.

3-2 timing valve Prevents a late operation of the brake band when shifting selector lever from ªDº to

ª1º or ª2º position while driving in D

3.

ª1º reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when down-

shifting from the ª1º position 2nd gear to 1st gear.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In ª1º and ª2º positions, line pressure acts on the overrun clutch reducing valve to

increase the pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control valve,

torque converter clutch control plug and

torque converter clutch control sleeveActivate or inactivate the lock-up function.

Also provide smooth lock-up through transient application and release of the lock-up

system.

Shuttle shift valve D Switches hydraulic circuits so that output pressure of the torque converter clutch sole-

noid valve acts on the lock-up valve in the ªDº position of 2nd, 3rd and 4th gears. (In

the ªDº position 1st gear, lock-up is inhibited.)

ILock-up control is not affected in ªDº position 2nd, 3rd or 4th gears, unless output

pressure of the torque converter clutch solenoid valve is generated by a signal

from the control unit.

OVERALL SYSTEM

Control Valve (Cont'd)

AT-32

Page 67 of 2395

SAT209GA

Line Pressure TestNBAT0023ILocation of line pressure test ports.

IAlways replace line pressure plugs as they are self-seal-

ing bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENBAT0023S011. Check A/T fluid and engine oil levels. If necessary, add fluid

and oil.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

SAT518GB

SAT519GB

3. Install pressure gauge to corresponding line pressure port.

SAT513G

4. Set parking brake and block wheels.

IContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test

AT-62

Page 68 of 2395

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

IWhen measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure:

Refer to SDS, AT-356.

JUDGEMENT OF LINE PRESSURE TESTNBAT0023S02

Judgement Suspected parts

At idleLine pressure is low in all posi-

tions.IOil pump wear

IControl piston damage

IPressure regulator valve or plug sticking

ISpring for pressure regulator valve damaged

IFluid pressure leakage between oil strainer and pressure regulator valve

IClogged strainer

Line pressure is low in particu-

lar position.IFluid pressure leakage between manual valve and particular clutch

IFor example, line pressure is:

Ð Low in ªRº and ª1º positions, but

Ð Normal in ªDº and ª2º positions.

Then, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-17.

Line pressure is high.IMal-adjustment of throttle position sensor

IFluid temperature sensor damaged

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure modifier valve sticking

IPressure regulator valve or plug sticking

IOpen in dropping resistor circuit

At stall speedLine pressure is low.IMal-adjustment of throttle position sensor

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure regulator valve or plug sticking

IPressure modifier valve sticking

IPilot valve sticking

SAT786A

Road TestNBAT0024DESCRIPTIONNBAT0024S01IThe purpose of the test is to determine overall performance of

A/T and analyze causes of problems.

IThe road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-63

Page 91 of 2395

Items Symptom Condition Diagnostic Item Reference Page

Slips/Will Not

EngageVehicle will not

run in D, 1, 2

positions (but

runs in R posi-

tion). Clutch slips.

Very poor accel-

eration.

AT-230ON vehicle1. Fluid level AT-59

2. Line pressure test AT-62

3. Line pressure solenoid valve AT-162

4. Control valve assembly AT-273

5. Accumulator N-D AT-273

OFF vehicle6. Reverse clutch AT-314

7. High clutch AT-317

8. Forward clutch AT-320

9. Forward one-way clutch AT-330

10. Low one-way clutch AT-328

Clutches or

brakes slip some-

what in starting.ON vehicle1. Fluid level AT-59

2. Manual control linkage adjustment AT-276

3. Throttle position sensor (Adjustment) EC-174

4. Line pressure test AT-62

5. Line pressure solenoid valve AT-162

6. Control valve assembly AT-273

7. Accumulator N-D AT-273

OFF vehicle8. Forward clutch AT-320

9. Reverse clutch AT-314

10. Low & reverse brake AT-324

11. Oil pump AT-297

12. Torque converter AT-286

No creep at all.

AT-227, 230ON vehicle1. Fluid level AT-59

2. Line pressure test AT-62

3. Control valve assembly AT-273

OFF vehicle4. Forward clutch AT-320

5. Oil pump AT-297

6. Torque converter AT-286

Almost no shock

or clutches slip-

ping in change

from D

1to D2.ON vehicle1. Fluid level AT-59

2. Throttle position sensor (Adjustment) EC-174

3. Line pressure test AT-62

4. Accumulator servo release AT-273

5. Control valve assembly AT-273

OFF vehicle 6. Brake band AT-333

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-86

Page 93 of 2395

Items Symptom Condition Diagnostic Item Reference Page

Slips/Will Not

EngageRaces extremely

fast or slips in

changing from D

4or D3to D1when

depressing pedal.ON vehicle1. Fluid level AT-59

2. Throttle position sensor (Adjustment) EC-174

3. Line pressure test AT-62

4. Line pressure solenoid valve AT-162

5. Control valve assembly AT-273

OFF vehicle6. Forward clutch AT-320

7. Forward one-way clutch AT-330

8. Low one-way clutch AT-328

Vehicle will not

run in any posi-

tion.ON vehicle1. Fluid level AT-59

2. Manual control linkage adjustment AT-276

3. Line pressure test AT-62

4. Line pressure solenoid valve AT-162

OFF vehicle5. Oil pump AT-297

6. High clutch AT-317

7. Brake band AT-333

8. Low & reverse brake AT-324

9. Torque converter AT-286

10. Parking pawl components AT-337

NOT USEDEngine cannot be

started in P and N

positions.

AT-221ON vehicle1. Ignition switch and starter EL-9, and SC-10

2. Manual control linkage adjustment AT-276

3. Park/neutral position (PNP) switch

adjustmentAT-276

Engine starts in

positions other

than P and N.

AT-221ON vehicle1. Manual control linkage adjustment AT-276

2. Park/neutral position (PNP) switch

adjustmentAT-276

Transmission

noise in P and N

positions.ON vehicle1. Fluid level AT-59

2. Line pressure test AT-62

3. Throttle position sensor (Adjustment) EC-174

4. Vehicle speed sensor´A/T (Revolution

sensor) and vehicle speed sensor´MTRAT- 111 , 1 9 7

5. Engine speed signal AT-116

OFF vehicle6. Oil pump AT-297

7. Torque converter AT-286

Vehicle moves

when changing

into P position or

parking gear does

not disengage

when shifted out

of P position.

AT-222ON vehicle 1. Manual control linkage adjustment AT-276

OFF vehicle 2. Parking pawl components AT-337

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-88