seat adjustment INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1967 of 2395

S/VCSW - Wiring diagram ...........................EC-493

Swirl control valve control solenoid

valve .........................................................EC-458

Swirl control valve control vacuum

check switch .............................................EC-493

SWL/V - Wiring diagram ..............................EC-458

Symbols and abbreviations .............................GI-10

Symptom matrix chart...................................EC-118

System readiness test (SRT) code ................EC-61

T

2-4WD shift solenoid valve............................TF-111

Tachometer .....................................................EL-94

Tail lamp ..........................................................EL-61

TAIL/L - Wiring diagram ..................................EL-63

TCM circuit diagram ........................................AT-13

TCM inspection table ......................................AT-92

TFTS - Wiring diagram .................................EC-311

THEFT - Wiring diagram ...............................EL-300

Theft warning system....................................EL-294

Thermometer .................................................EL-110

Thermostat ......................................................LC-16

Three way catalyst function (Left bank) .......EC-347

Three way catalyst function (Right

bank) .........................................................EC-347

Three way catalyst precautions.........................GI-6

Throttle bodies ...............................................EM-12

Throttle position sensor (TPS) .....................EC-174

Throttle position sensor adjustment .............EC-101

Throttle position switch ...........EC-431, AT-184, 264

Tie-rod .............................................................ST-21

Tie-rod ball joints.............................................ST-21

Tightening torque of standard bolts.................GI-50

Timing chain ...................................................EM-20

Tire rotation ....................................................MA-24

Tire size ...........................................................GI-44

TLID - Wiring diagram ..................................EL-179

Tooth contact (front final drive 4WD) .............PD-29

Tooth contact diff. ...........................................PD-56

Torque converter installation .........................AT-278

Torque convertor clutch solenoid

valve ..................................................AT-152, 161

Tow truck towing ..............................................GI-47

Towing point.....................................................GI-49

TP/SW - Wiring diagram ..............................EC-434

TPS - Wiring diagram...................................EC-180

Transfer control unit inspection table..............TF-55

Transfer dropping resistor .............................TF-112

Transfer fluid replacement (Part time

4WD model) ...............................................MA-22

Transfer fluid temperature sensor .................TF-111

Transfer motor ...............................................TF-117

Transfer motor relay ......................................TF-113

Transfer serial number ....................................GI-43

TRANSMT - Wiring diagram .........................EL-325

Tread-FR&RR (Dimensions)............................GI-43

Trim .................................................................BT-28

Trouble diagnoses ...........................................GI-34

Trunk lid opener, electric...............................EL-178Turbine revolution sensor..............................AT-202

TURN - Wiring diagram ..................................EL-77

Turn signal lamp .............................................EL-75

Two trip detection logic ..................................EC-59

Two-pole lift .....................................................GI-47

U

Under body .....................................................BT-60

V

Vacuum cut valve ...........................................EC-32

Vacuum cut valve bypass valve.....EC-32, 585, 591

Vacuum hose (brake system).........................BR-21

Vacuum hose drawing (Engine control) .........EC-26

Valve clearance ..............................................EM-52

Valve guide.....................................................EM-43

Valve seat.......................................................EM-45

Valve spring....................................................EM-46

Vehicle identification number...........................GI-42

Vehicle recovery (freeing a stuck

vehicle) .........................................................GI-49

Vehicle speed sensor (VSS) ........................EC-417

VENT/V - Wiring diagram ............EC-376, 555, 576

Ventilation air filter ........................................HA-159

VIAS .............................................................EC-610

VIAS - Wiring diagram .................................EC-610

Viscosity number (SAE) .................................MA-12

VSS - Wiring diagram ..................................EC-420

W

Wait detection switch ....................................TF-112

WARN - Wiring diagram................................EL-115

Warning chime ..............................................EL-125

Warning lamps ..............................................EL-114

Washer, front .................................................EL-136

Washer, rear..................................................EL-141

Water pump ....................................................LC-12

Water temperature gauge ...............................EL-94

Weatherstrip - See Exterior ............................BT-35

Wheel balance ...............................................MA-24

Wheel bearing (front)........................................AX-4

Wheel bearing (rear) ......................................AX-18

Wheel hub (front)..............................................AX-6

Wheel sensors (ABS)...............................BR-56, 80

Wheel size .......................................................GI-44

Wheelarch height .............................................SU-5

Wheelbase (Dimensions) ................................GI-43

Wide open & closed throttle position

switch ........................................................EC-174

Width (Dimensions) .........................................GI-43

WINDOW - Wiring diagram ..........................EL-245

Window, door ..................................................BT-18

Window, rear side ...........................................BT-55

Window, side - See Rear side window ...........BT-55

ALPHABETICAL INDEX

IDX-8

Page 2049 of 2395

AdjustmentNBPD0020For quiet and reliable final drive operation, the following five adjust-

ments must be made correctly:

1. Side bearing preload

2. Pinion gear height

3. Pinion bearing preload

4. Ring gear-to-pinion backlash. Refer to SDS, PD-37.

5. Ring and pinion gear tooth contact pattern

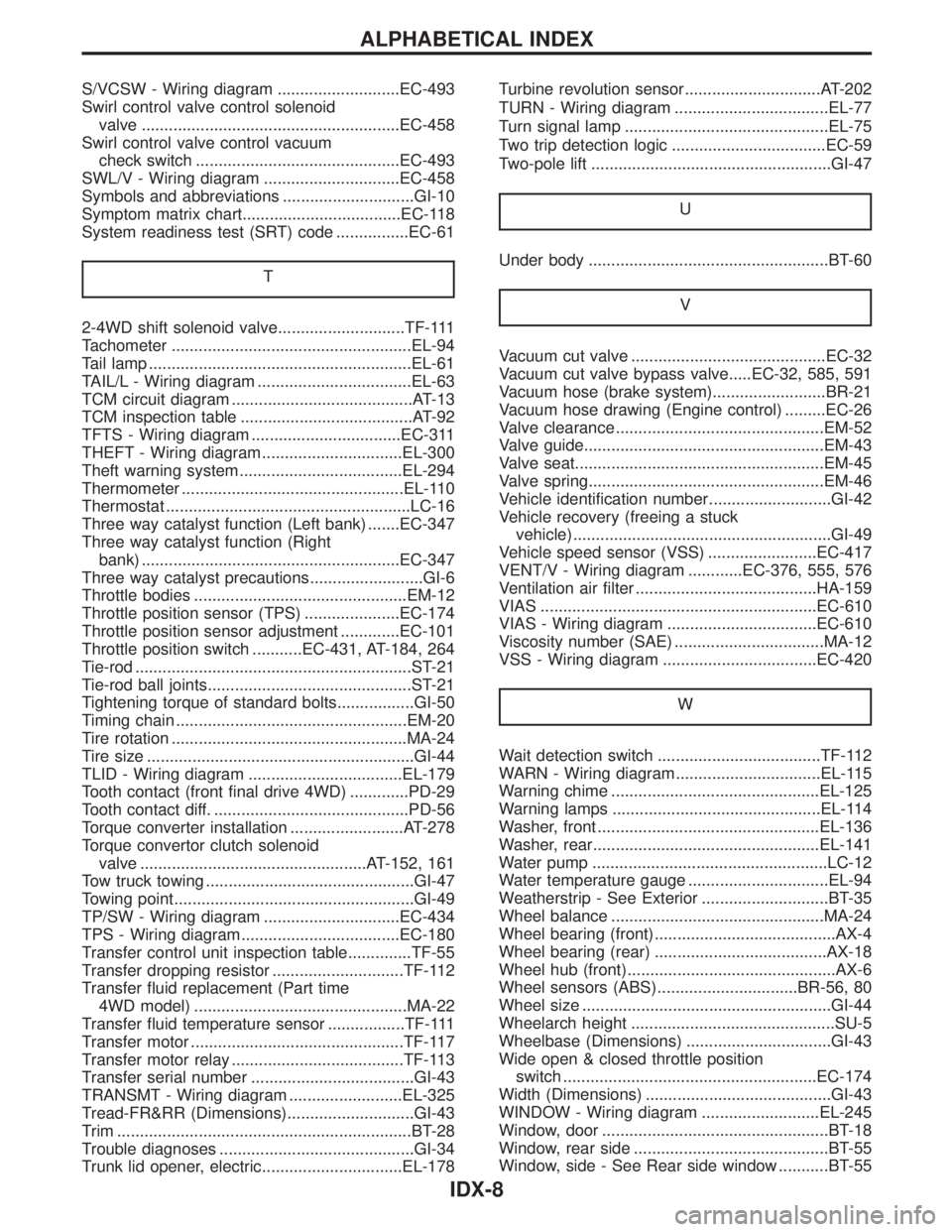

SPD527

SIDE BEARING PRELOADNBPD0020S01A selection of carrier side bearing adjusting washer is

required for successful completion of this procedure.

1. Make sure all parts are clean and that the bearings are well

lubricated with light oil or ªDEXRON

TMº type automatic trans-

mission fluid.

2. Place the differential carrier, with side bearings and bearing

races installed, into the final drive housing.

SPD894

3. Put the side bearing spacer in place.

CAUTION:

Side bearing spacer is placed on either the right or left

depending upon final drive gear ratio. Be sure to replace it on

the correct side.

SPD986

4. Using Tool, install original carrier side bearing preload shims

on the carrier end, opposite the ring gear.

Tool number: KV38100600 (J25267)

SPD526

5. Install the side bearing caps in their correct locations and

torque the bearing cap retaining bolts.

Specification:

88 - 98 N´m (9 - 10 kg-m, 65 - 72 ft-lb)

6. Turn the carrier several times to seat the bearings.

FRONT FINAL DRIVER200A

Adjustment

PD-24

Page 2050 of 2395

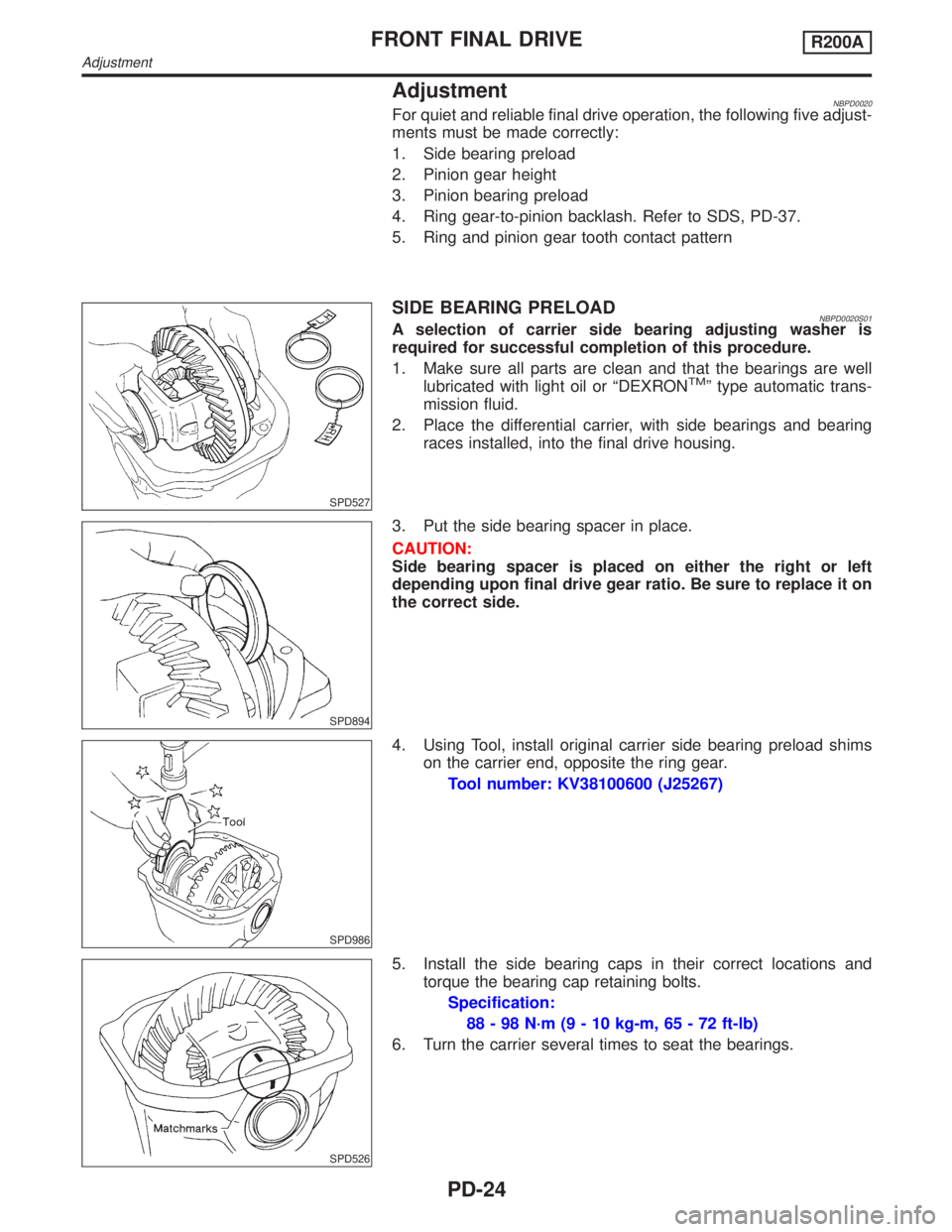

SPD194A

7. Measure the turning torque of the carrier at the ring gear retain-

ing bolts with a spring gauge, J8129.

Specification:

34.3 - 39.2 N (3.5 - 4.0 kg, 7.7 - 8.8 lb) of pulling force

at the ring gear bolt

SPD772

8. If the carrier turning torque is not within the specification range,

increase or decrease the total thickness of the side bearing

adjusting washers until the turning torque is correct. If the

turning torque is less than the specified range, install washers

of greater thickness; if the turning torque is greater than the

specification, install thinner washers. See the SDS section for

washer dimensions and part numbers.

9. Record the total amount of washer thickness required for the

correct carrier side bearing preload.

SPD668

10. Remove the carrier from the final drive housing, saving the

selected preload washers for later use during the assembly of

the final drive unit.

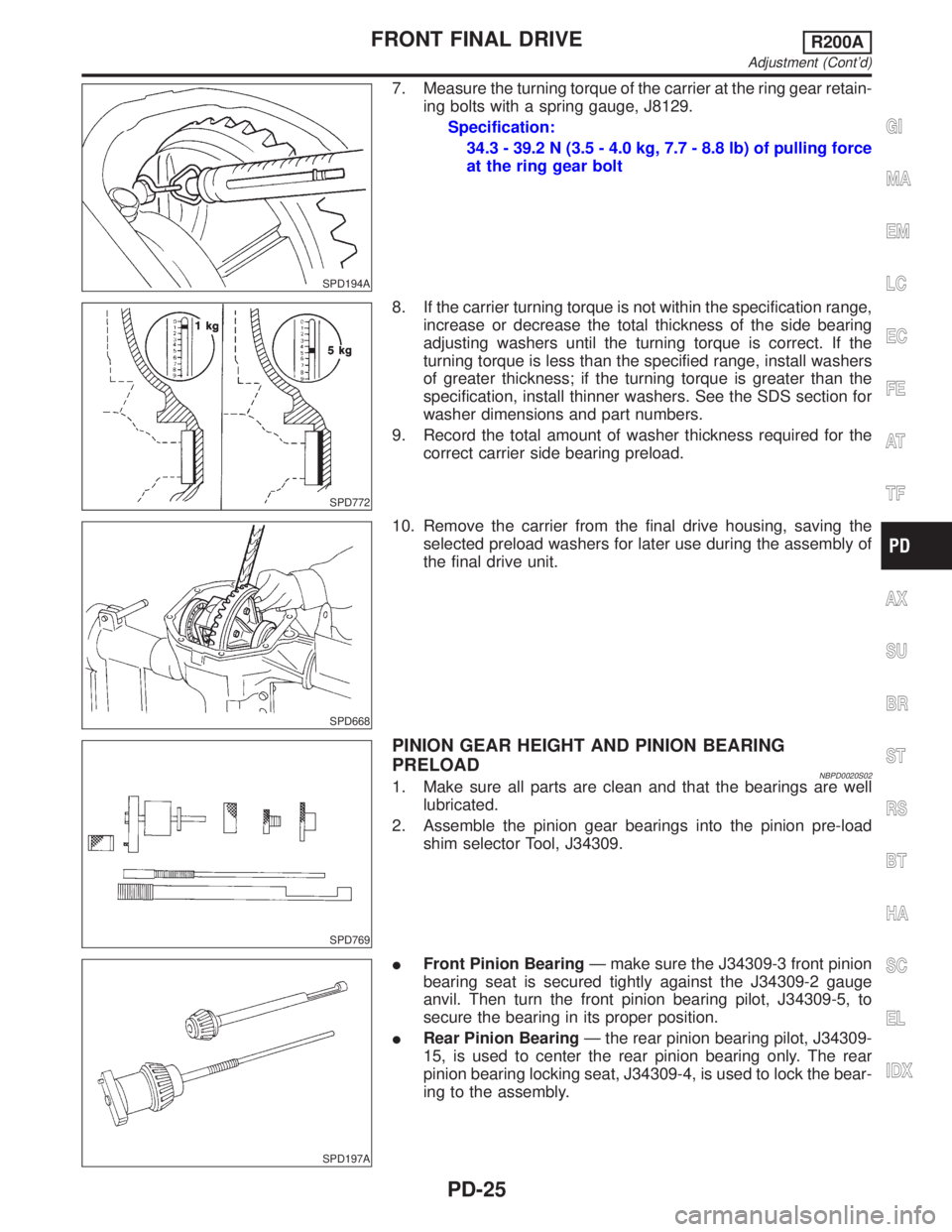

SPD769

PINION GEAR HEIGHT AND PINION BEARING

PRELOAD

NBPD0020S021. Make sure all parts are clean and that the bearings are well

lubricated.

2. Assemble the pinion gear bearings into the pinion pre-load

shim selector Tool, J34309.

SPD197A

IFront Pinion BearingÐ make sure the J34309-3 front pinion

bearing seat is secured tightly against the J34309-2 gauge

anvil. Then turn the front pinion bearing pilot, J34309-5, to

secure the bearing in its proper position.

IRear Pinion BearingÐ the rear pinion bearing pilot, J34309-

15, is used to center the rear pinion bearing only. The rear

pinion bearing locking seat, J34309-4, is used to lock the bear-

ing to the assembly.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Adjustment (Cont'd)

PD-25

Page 2051 of 2395

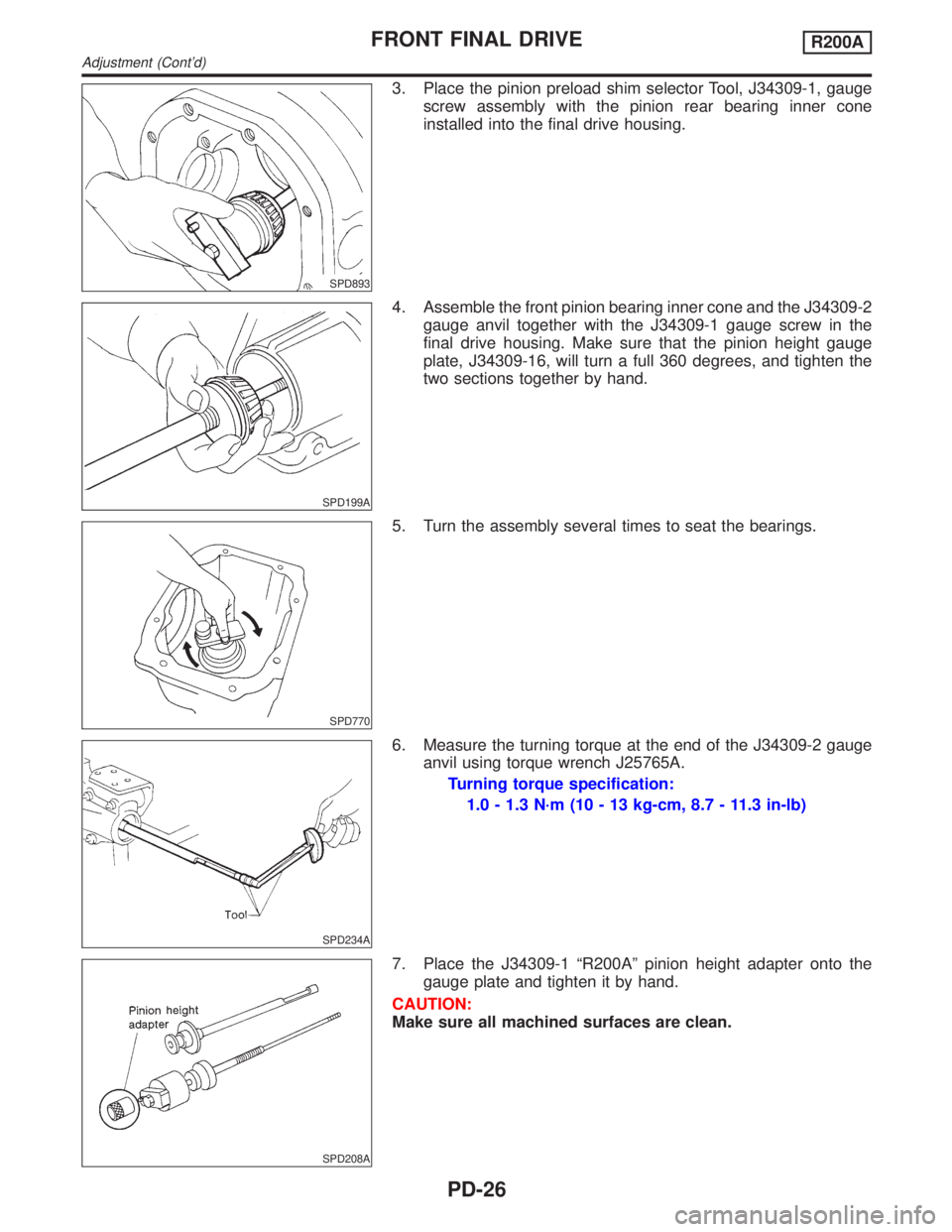

SPD893

3. Place the pinion preload shim selector Tool, J34309-1, gauge

screw assembly with the pinion rear bearing inner cone

installed into the final drive housing.

SPD199A

4. Assemble the front pinion bearing inner cone and the J34309-2

gauge anvil together with the J34309-1 gauge screw in the

final drive housing. Make sure that the pinion height gauge

plate, J34309-16, will turn a full 360 degrees, and tighten the

two sections together by hand.

SPD770

5. Turn the assembly several times to seat the bearings.

SPD234A

6. Measure the turning torque at the end of the J34309-2 gauge

anvil using torque wrench J25765A.

Turning torque specification:

1.0 - 1.3 N´m (10 - 13 kg-cm, 8.7 - 11.3 in-lb)

SPD208A

7. Place the J34309-1 ªR200Aº pinion height adapter onto the

gauge plate and tighten it by hand.

CAUTION:

Make sure all machined surfaces are clean.

FRONT FINAL DRIVER200A

Adjustment (Cont'd)

PD-26

Page 2052 of 2395

SPD209A

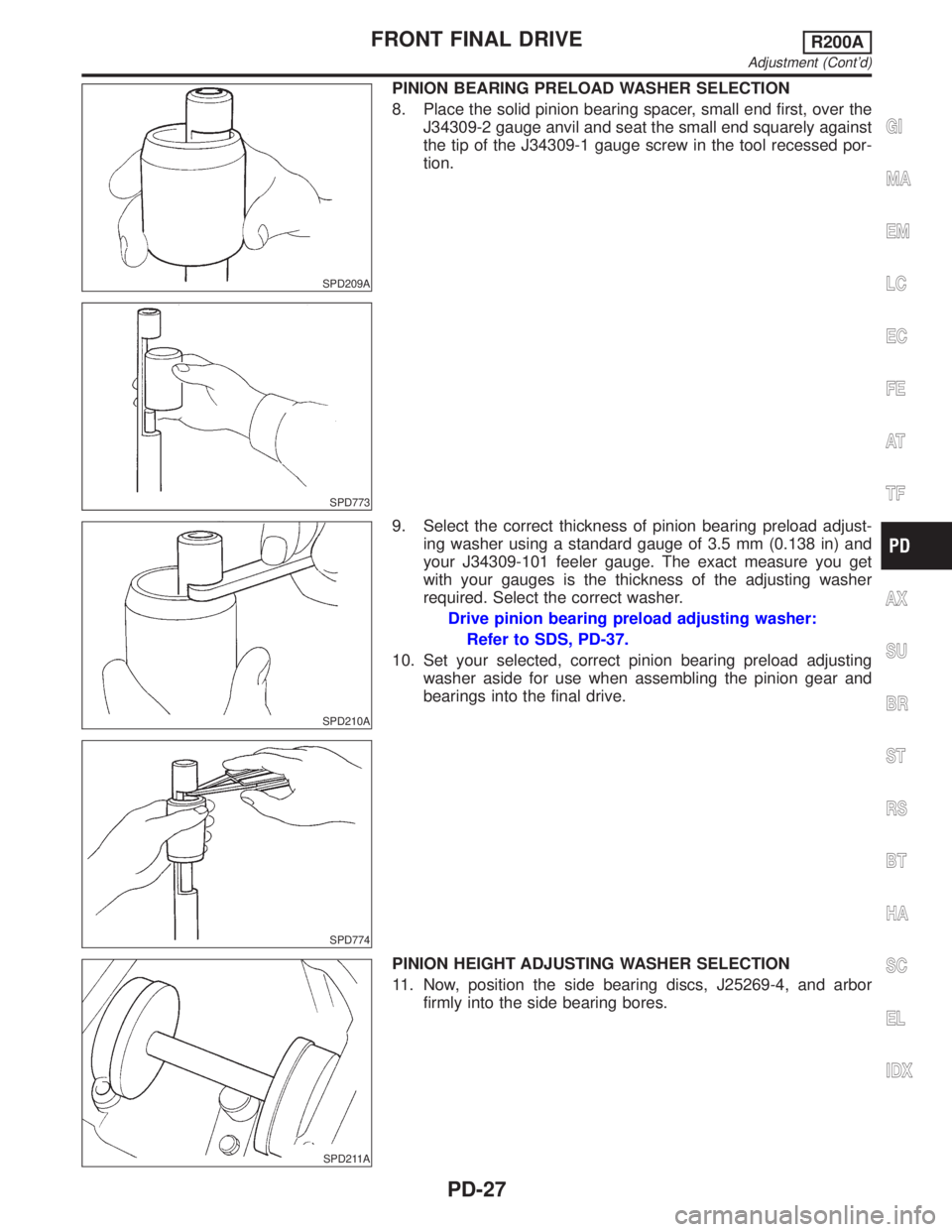

PINION BEARING PRELOAD WASHER SELECTION

8. Place the solid pinion bearing spacer, small end first, over the

J34309-2 gauge anvil and seat the small end squarely against

the tip of the J34309-1 gauge screw in the tool recessed por-

tion.

SPD773

SPD210A

SPD774

9. Select the correct thickness of pinion bearing preload adjust-

ing washer using a standard gauge of 3.5 mm (0.138 in) and

your J34309-101 feeler gauge. The exact measure you get

with your gauges is the thickness of the adjusting washer

required. Select the correct washer.

Drive pinion bearing preload adjusting washer:

Refer to SDS, PD-37.

10. Set your selected, correct pinion bearing preload adjusting

washer aside for use when assembling the pinion gear and

bearings into the final drive.

SPD211A

PINION HEIGHT ADJUSTING WASHER SELECTION

11. Now, position the side bearing discs, J25269-4, and arbor

firmly into the side bearing bores.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Adjustment (Cont'd)

PD-27

Page 2078 of 2395

SPD364A

9. Tighten differential case couple bolts.

10. Place ring gear on differential case and tighten ring gear bolts.

Tighten bolts in a criss-cross pattern, lightly tapping bolt head

with a hammer.

Then bend up lock straps to lock the bolts in place.

11. Install side bearing inner cone.

12. Check differential torque.

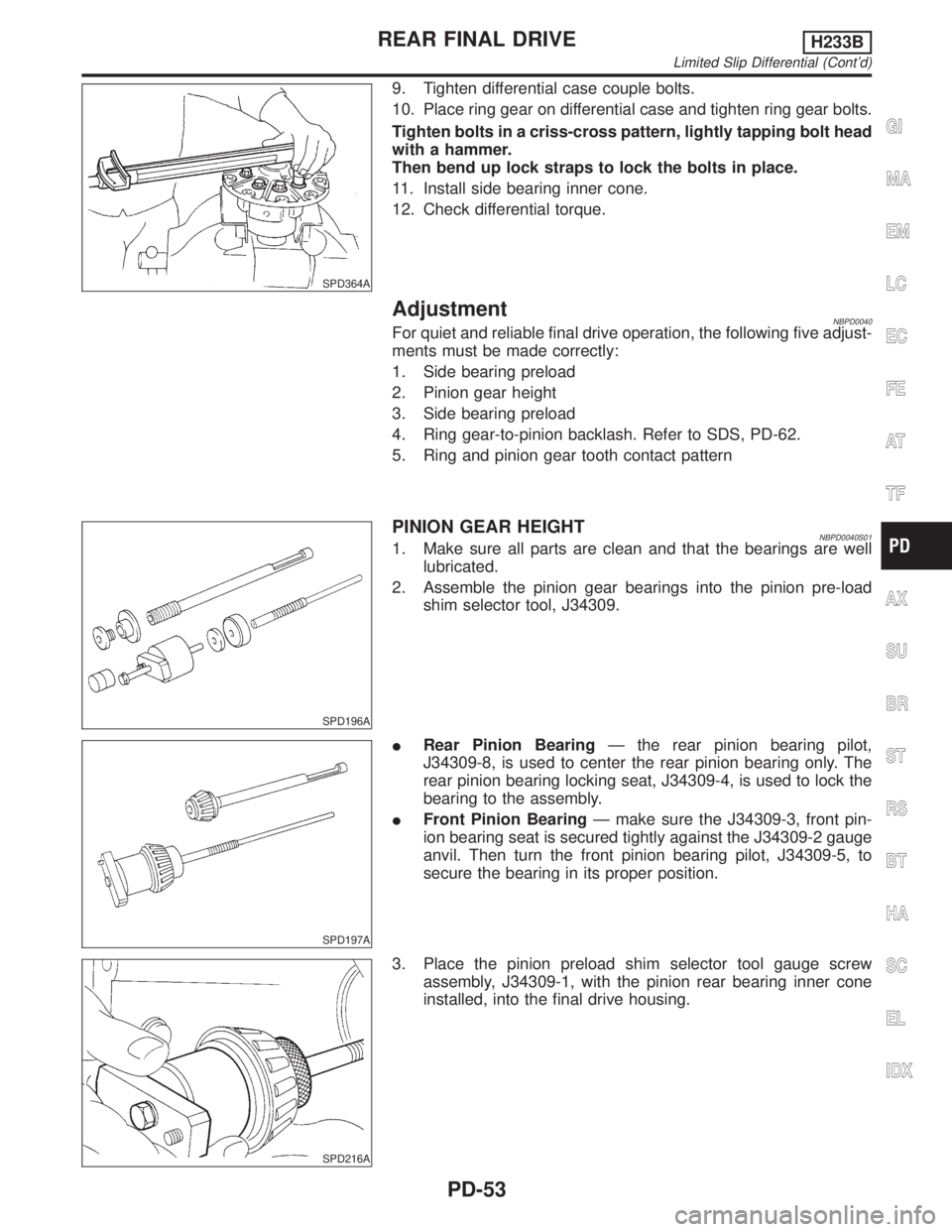

AdjustmentNBPD0040For quiet and reliable final drive operation, the following five adjust-

ments must be made correctly:

1. Side bearing preload

2. Pinion gear height

3. Side bearing preload

4. Ring gear-to-pinion backlash. Refer to SDS, PD-62.

5. Ring and pinion gear tooth contact pattern

SPD196A

PINION GEAR HEIGHTNBPD0040S011. Make sure all parts are clean and that the bearings are well

lubricated.

2. Assemble the pinion gear bearings into the pinion pre-load

shim selector tool, J34309.

SPD197A

IRear Pinion BearingÐ the rear pinion bearing pilot,

J34309-8, is used to center the rear pinion bearing only. The

rear pinion bearing locking seat, J34309-4, is used to lock the

bearing to the assembly.

IFront Pinion BearingÐ make sure the J34309-3, front pin-

ion bearing seat is secured tightly against the J34309-2 gauge

anvil. Then turn the front pinion bearing pilot, J34309-5, to

secure the bearing in its proper position.

SPD216A

3. Place the pinion preload shim selector tool gauge screw

assembly, J34309-1, with the pinion rear bearing inner cone

installed, into the final drive housing.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR FINAL DRIVEH233B

Limited Slip Differential (Cont'd)

PD-53

Page 2079 of 2395

SPD217A

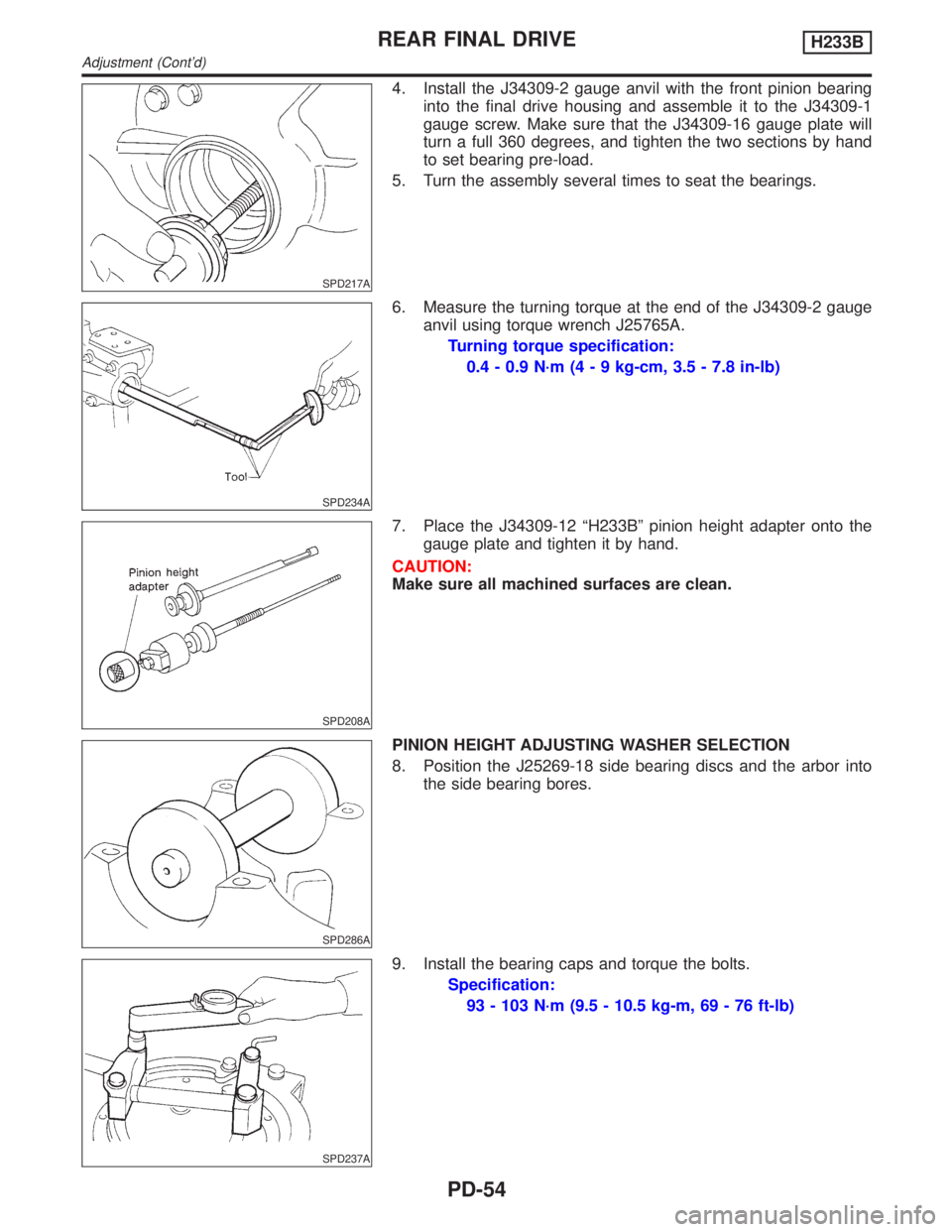

4. Install the J34309-2 gauge anvil with the front pinion bearing

into the final drive housing and assemble it to the J34309-1

gauge screw. Make sure that the J34309-16 gauge plate will

turn a full 360 degrees, and tighten the two sections by hand

to set bearing pre-load.

5. Turn the assembly several times to seat the bearings.

SPD234A

6. Measure the turning torque at the end of the J34309-2 gauge

anvil using torque wrench J25765A.

Turning torque specification:

0.4 - 0.9 N´m (4 - 9 kg-cm, 3.5 - 7.8 in-lb)

SPD208A

7. Place the J34309-12 ªH233Bº pinion height adapter onto the

gauge plate and tighten it by hand.

CAUTION:

Make sure all machined surfaces are clean.

SPD286A

PINION HEIGHT ADJUSTING WASHER SELECTION

8. Position the J25269-18 side bearing discs and the arbor into

the side bearing bores.

SPD237A

9. Install the bearing caps and torque the bolts.

Specification:

93 - 103 N´m (9.5 - 10.5 kg-m, 69 - 76 ft-lb)

REAR FINAL DRIVEH233B

Adjustment (Cont'd)

PD-54

Page 2182 of 2395

STEERING SYSTEM

SECTION

ST

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Precautions for Steering System .................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart.........................................6

ON-VEHICLE SERVICE..................................................7

Checking Steering Wheel Play ....................................7

Checking Neutral Position on Steering Wheel ............7

PRE-CHECKING........................................................7

CHECKING...............................................................7

Front Wheel Turning Angle ..........................................7

Checking Gear Housing Movement ............................8

Adjusting Rack Retainer ..............................................8

Checking and Adjusting Drive Belts ............................8

Checking Fluid Level ...................................................8

Checking Fluid Leakage ..............................................8

Bleeding Hydraulic System..........................................9

Checking Steering Wheel Turning Force ....................9

Checking Hydraulic System.......................................10

STEERING WHEEL AND STEERING COLUMN......... 11

Components............................................................... 11

Removal and Installation ........................................... 11

STEERING WHEEL................................................. 11

STEERING COLUMN...............................................12

Disassembly and Assembly .......................................13

Inspection...................................................................14

TILT MECHANISM...................................................14

STEERING TRANSFER GEAR.....................................15

Removal .....................................................................15

Installation ..................................................................16

Inspection...................................................................16

POWER STEERING GEAR AND LINKAGE................17

Components...............................................................17

Removal and Installation ...........................................18

Disassembly...............................................................19

Inspection...................................................................20

BOOT.....................................................................20

RACK.....................................................................20

PINION ASSEMBLY.................................................20

GEAR HOUSING CYLINDER....................................20

TIE-ROD OUTER AND INNER SOCKETS..................21

Assembly ...................................................................21

Adjustment .................................................................24

POWER STEERING OIL PUMP....................................27

Components...............................................................27

Pre-disassembly Inspection .......................................27

Disassembly...............................................................28

Inspection...................................................................29

Assembly ...................................................................29

SERVICE DATA AND SPECIFICATIONS (SDS).........32

General Specifications ...............................................32

Steering Wheel ..........................................................32

Steering Column ........................................................32

Steering Transfer Gear ..............................................32

Steering Gear and Linkage .......................................33

Power Steering ..........................................................33

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

Page 2236 of 2395

TRANSFER

SECTION

TF

CONTENTS

PRECAUTIONS...............................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............3

Precautions ..................................................................3

Service Notice..............................................................4

Wiring Diagrams and Trouble Diagnosis .....................4

PREPARATION...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools ...........................................9

ALL-MODE 4WD SYSTEM...........................................10

Cross-sectional View .................................................10

Control System .......................................................... 11

ALL-MODE 4WD TRANSFER BASIC CONTROL........12

HYDRAULIC CONTROL CIRCUITS...........................12

OUTLINE................................................................12

CONTROL SYSTEM DIAGRAM................................13

INDICATIONS OF 4WD WARNING LAMP..................13

Location of Electrical Parts ........................................14

Description of Electrical Parts ...................................15

TRANSFER MOTOR................................................15

WAIT DETECTION SWITCH.....................................15

2-4WD SHIFT SOLENOID VALVE.............................16

LINE PRESSURE SWITCH.......................................16

Circuit Diagram for Quick Pinpoint Check.................17

Wiring Diagram - TF -................................................18

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................27

Trouble Diagnosis without CONSULT-II ....................27

DESCRIPTION........................................................27

SELF-DIAGNOSTIC PROCEDURE............................28

INDICATIONS OF 4WD WARNING LAMP..................29

Trouble Diagnosis with CONSULT-II .........................30

SELF-DIAGNOSIS...................................................30

SELF-DIAGNOSTIC ITEMS......................................31

DATA MONITOR......................................................33

DATA MONITOR ITEMS...........................................34

REFERENCE VALUE IN DATA MONITOR MODE......36

WORK SUPPORT....................................................38

CLUTCH FORCE RELEASE LIMIT ADJUSTMENT.....39

TROUBLE DIAGNOSIS - INTRODUCTION..................41Introduction ................................................................41

DESCRIPTION........................................................41

DIAGNOSTIC WORKSHEET.....................................41

Work Flow ..................................................................43

HOW TO PERFORM TROUBLE DIAGNOSES FOR

QUICK AND ACCURATE REPAIR

.............................43

TROUBLE DIAGNOSIS - BASIC INSPECTION...........44

Listen to Customer Complaints .................................44

Transfer Fluid Check .................................................44

Road Test...................................................................44

PREPARATION FOR ROAD TEST............................44

1. CHECK BEFORE ENGINE IS STARTED...............45

2. CHECK AT IDLE..................................................47

3. CRUISE TEST.....................................................51

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................54

Transfer Control Unit Terminals and Reference

Value ..........................................................................54

REMOVAL AND INSTALLATION OF TRANSFER

CONTROL UNIT

......................................................54

INSPECTION OF TRANSFER CONTROL UNIT..........54

TRANSFER CONTROL UNIT INSPECTION TABLE....55

VEHICLE SPEED SENSOR (FRONT

REVOLUTION SENSOR)..............................................61

Diagnostic Procedure ................................................61

4WD SOLENOID VALVE...............................................64

Diagnostic Procedure ................................................64

2-4WD SHIFT SOLENOID VALVE AND 4WD

SHIFT SWITCH..............................................................66

Diagnostic Procedure ................................................66

TRANSFER MOTOR AND TRANSFER MOTOR

RELAY...........................................................................70

Diagnostic Procedure ................................................70

TRANSFER FLUID TEMPERATURE SENSOR............73

Diagnostic Procedure ................................................73

ATP SWITCH, WAIT DETECTION SWITCH AND

NEUTRAL-4LO SWITCH...............................................76

Diagnostic Procedure ................................................76

CLUTCH PRESSURE SWITCH....................................80

Diagnostic Procedure ................................................80

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX