steering wheel INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1169 of 2395

SEF028Z

Component DescriptionNBEC0398The power steering oil pressure switch is attached to the power

steering high-pressure tube and detects a power steering load.

When a power steering load is detected, it signals the ECM. The

ECM adjusts the IACV-AAC valve to increase the idle speed and

adjust for the increased load.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0399Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is fully turned. ON

ECM Terminals and Reference ValueNBEC0687Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

47 R/BPower steering oil

pressure switch[Engine is running]

ISteering wheel is being turned.0 - 1.0V

[Engine is running]

ISteering wheel is not being turned.Approximately 5V

POWER STEERING OIL PRESSURE SWITCH

Component Description

EC-634

Page 1184 of 2395

Fuel Pressure RegulatorNBEC0408

Fuel pressure at idling kPa (kg/cm2, psi)

Vacuum hose is connected. Approximately 235 (2.4, 34)

Vacuum hose is disconnected. Approximately 294 (3.0, 43)

Idle Speed and Ignition TimingNBEC0409

Target idle speed*1 No-load*2 (in ªPº or Nº position) 750±50 rpm

Air conditioner: ON In ªPº or Nº position 825 rpm or more

Ignition timing*1 In ªPº or Nº position 15ɱ5É BTDC

Throttle position sensor idle position0.15 - 0.85V

*1: Throttle position sensor harness connector connected

*2: Under the following conditions:

IAir conditioner switch: OFF

IElectric load: OFF (Lights, heater fan & rear window defogger)

ISteering wheel: Kept in straight-ahead position

Mass Air Flow SensorNBEC0411

Supply voltageBattery voltage (11 - 14)V

Output voltage at idle1.2 - 1.8*V

Mass air flow (Using CONSULT-II or GST)2.0 - 6.0 g´m/sec at idle*

7.0 - 20.0 g´m/sec at 2,500 rpm*

*: Engine is warmed up to normal operating temperature and running under no-load.

Engine Coolant Temperature SensorNBEC0412

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Heated Oxygen Sensor 1 Heater (Front)NBEC0414

Resistance [at 25ÉC (77ÉF)]2.3 - 4.3W

Fuel PumpNBEC0415

Resistance [at 25ÉC (77ÉF)]0.2 - 5.0W

IACV-AAC ValveNBEC0416

Resistance [at 20ÉC (68ÉF)]Approximately 20 - 24W

InjectorNBEC0417

Resistance [at 20ÉC (68ÉF)]13.5 - 17.5W

ResistorNBEC0418

Resistance [at 25ÉC (77ÉF)]Approximately 2.2 kW

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pressure Regulator

EC-649

Page 1214 of 2395

MEL304D

ReplacementNBEL0010For removal and installation of spiral cable, refer to RS-18,

ªInstallation Ð Air Bag Module and Spiral Cableº.

IEach switch can be replaced without removing combination

switch base.

MEL326G

ITo remove combination switch base, remove base attaching

screw.

SEL151V

IBefore installing the steering wheel, align the steering wheel

guide pins with the screws which secure the combination

switch as shown in the left figure.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

COMBINATION SWITCH

Replacement

EL-29

Page 1571 of 2395

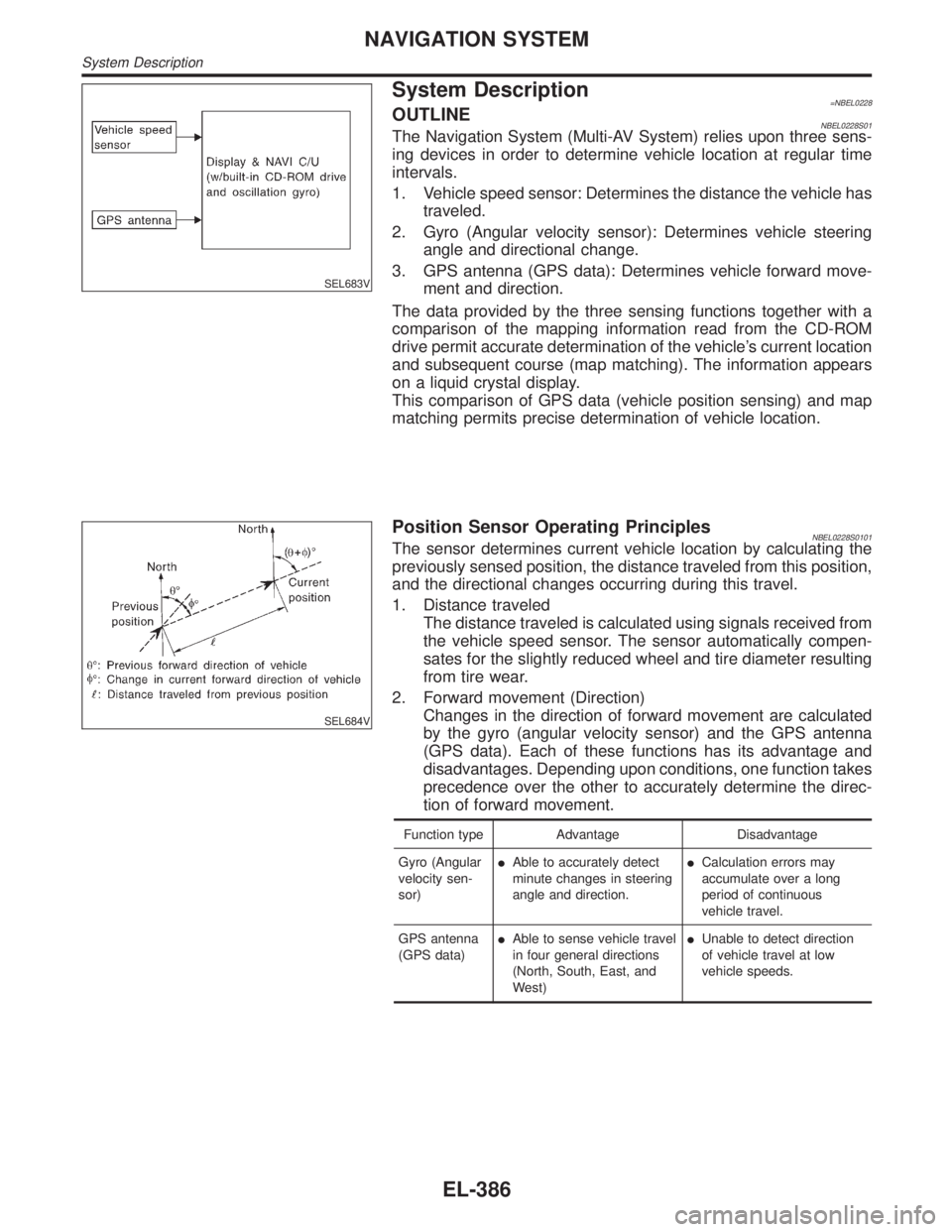

SEL683V

System Description=NBEL0228OUTLINENBEL0228S01The Navigation System (Multi-AV System) relies upon three sens-

ing devices in order to determine vehicle location at regular time

intervals.

1. Vehicle speed sensor: Determines the distance the vehicle has

traveled.

2. Gyro (Angular velocity sensor): Determines vehicle steering

angle and directional change.

3. GPS antenna (GPS data): Determines vehicle forward move-

ment and direction.

The data provided by the three sensing functions together with a

comparison of the mapping information read from the CD-ROM

drive permit accurate determination of the vehicle's current location

and subsequent course (map matching). The information appears

on a liquid crystal display.

This comparison of GPS data (vehicle position sensing) and map

matching permits precise determination of vehicle location.

SEL684V

Position Sensor Operating PrinciplesNBEL0228S0101The sensor determines current vehicle location by calculating the

previously sensed position, the distance traveled from this position,

and the directional changes occurring during this travel.

1. Distance traveled

The distance traveled is calculated using signals received from

the vehicle speed sensor. The sensor automatically compen-

sates for the slightly reduced wheel and tire diameter resulting

from tire wear.

2. Forward movement (Direction)

Changes in the direction of forward movement are calculated

by the gyro (angular velocity sensor) and the GPS antenna

(GPS data). Each of these functions has its advantage and

disadvantages. Depending upon conditions, one function takes

precedence over the other to accurately determine the direc-

tion of forward movement.

Function type Advantage Disadvantage

Gyro (Angular

velocity sen-

sor)IAble to accurately detect

minute changes in steering

angle and direction.ICalculation errors may

accumulate over a long

period of continuous

vehicle travel.

GPS antenna

(GPS data)IAble to sense vehicle travel

in four general directions

(North, South, East, and

West)IUnable to detect direction

of vehicle travel at low

vehicle speeds.

NAVIGATION SYSTEM

System Description

EL-386

Page 1610 of 2395

Possible cause Drive condition Service procedure

AreaSlippery road surfaceOn wet, icy, or gravel road where

frequent wheel slippage occurs, dis-

tance calculations may be errone-

ous. The position marker may show

the vehicle to be in inaccurate posi-

tion.

If the position marker does not

move to the correct position

even after the vehicle has been

driven approximately 10 km (6

miles), perform ªADJUST CUR-

RENT LOCATIONº (EL-411). If

necessary, perform ªSPEED

CALIBRATIONº (EL-409). Slanted areaHilly areas where the road has

banked curves. When the vehicle

enters these banked curves, there

may be an error in steering angle

measurement. The position marker

may show the vehicle to be in inac-

curate position.

Map

dataMap display for a given road does not appear.

SEL699V

When the vehicle is driven on a

newly constructed road that does

not appear on the existing map.

Map marking and calibration are not

possible. The position marker may

indicate inaccurate position in close

proximity to the actual position.

Subsequently, when the vehicle is

driven on a road which is available

as map data, the position marker

may still indicate an inaccurate posi-

tion.

The vehicle is driven on a road whose course

has been altered (usually to improve the road or

to eliminate some hazard).

SEL700V

When the map data shown on the

display and the actual conditions are

different. Map matching will not be

possible. The position marker may

indicate inaccurate position in close

proximity to the actual position. If

the vehicle is driven on the indicated

road, further errors may occur.

Vehicle Use of tire chains (Stormy weather)Tire chains will affect distance sens-

ing. The position marker may indi-

cate inaccurate position.If the position marker does not

move to the correct position

even after the vehicle has been

driven approximately 10 km (6

miles), perform ªSPEED CALI-

BRATIONº (EL-409). After

removing the tire chains, sens-

ing accuracy may recover by

itself.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

This Condition is Not Abnormal (Cont'd)

EL-425

Page 1613 of 2395

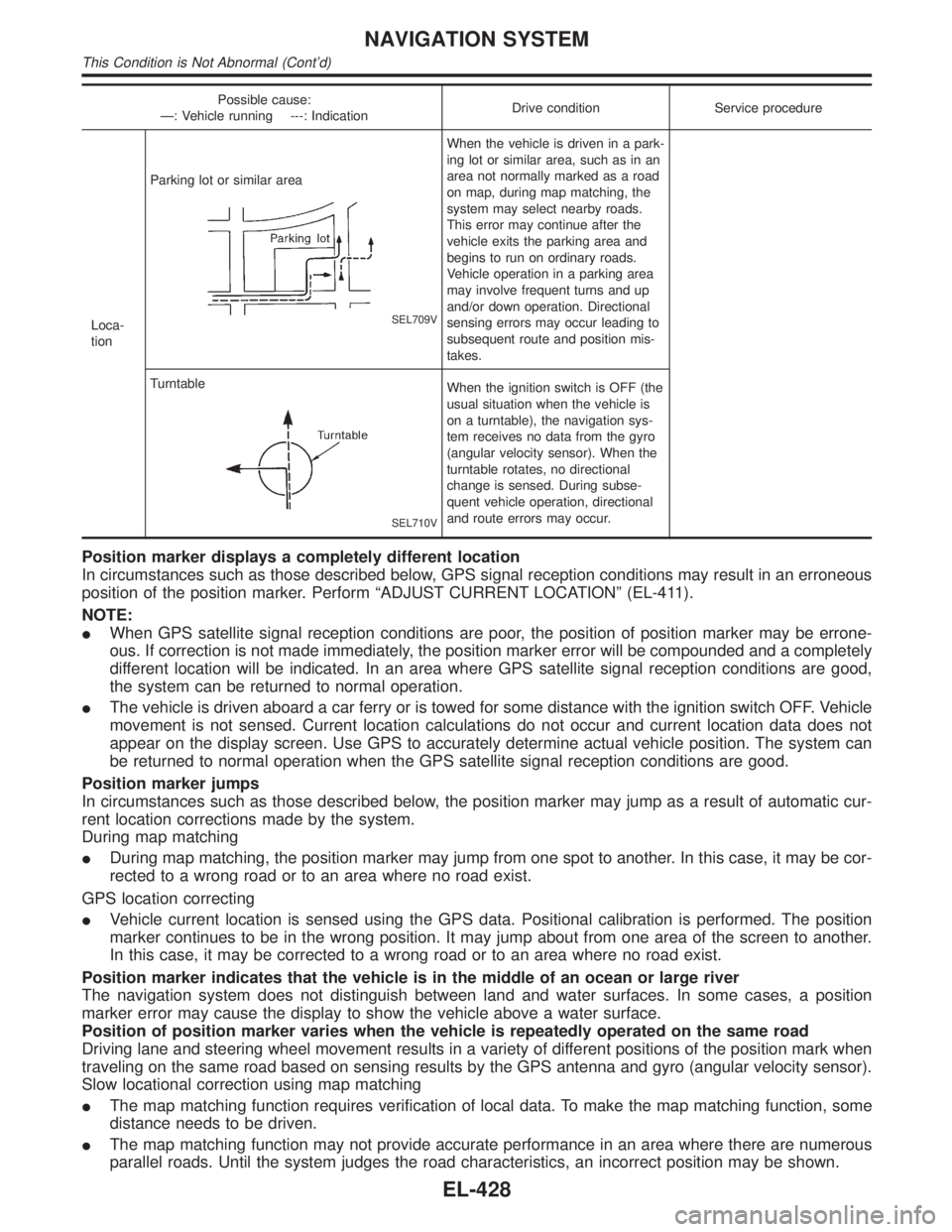

Possible cause:

Ð: Vehicle running ---: IndicationDrive condition Service procedure

Loca-

tionParking lot or similar area

SEL709V

When the vehicle is driven in a park-

ing lot or similar area, such as in an

area not normally marked as a road

on map, during map matching, the

system may select nearby roads.

This error may continue after the

vehicle exits the parking area and

begins to run on ordinary roads.

Vehicle operation in a parking area

may involve frequent turns and up

and/or down operation. Directional

sensing errors may occur leading to

subsequent route and position mis-

takes.

Turntable

SEL710V

When the ignition switch is OFF (the

usual situation when the vehicle is

on a turntable), the navigation sys-

tem receives no data from the gyro

(angular velocity sensor). When the

turntable rotates, no directional

change is sensed. During subse-

quent vehicle operation, directional

and route errors may occur.

Position marker displays a completely different location

In circumstances such as those described below, GPS signal reception conditions may result in an erroneous

position of the position marker. Perform ªADJUST CURRENT LOCATIONº (EL-411).

NOTE:

IWhen GPS satellite signal reception conditions are poor, the position of position marker may be errone-

ous. If correction is not made immediately, the position marker error will be compounded and a completely

different location will be indicated. In an area where GPS satellite signal reception conditions are good,

the system can be returned to normal operation.

IThe vehicle is driven aboard a car ferry or is towed for some distance with the ignition switch OFF. Vehicle

movement is not sensed. Current location calculations do not occur and current location data does not

appear on the display screen. Use GPS to accurately determine actual vehicle position. The system can

be returned to normal operation when the GPS satellite signal reception conditions are good.

Position marker jumps

In circumstances such as those described below, the position marker may jump as a result of automatic cur-

rent location corrections made by the system.

During map matching

IDuring map matching, the position marker may jump from one spot to another. In this case, it may be cor-

rected to a wrong road or to an area where no road exist.

GPS location correcting

IVehicle current location is sensed using the GPS data. Positional calibration is performed. The position

marker continues to be in the wrong position. It may jump about from one area of the screen to another.

In this case, it may be corrected to a wrong road or to an area where no road exist.

Position marker indicates that the vehicle is in the middle of an ocean or large river

The navigation system does not distinguish between land and water surfaces. In some cases, a position

marker error may cause the display to show the vehicle above a water surface.

Position of position marker varies when the vehicle is repeatedly operated on the same road

Driving lane and steering wheel movement results in a variety of different positions of the position mark when

traveling on the same road based on sensing results by the GPS antenna and gyro (angular velocity sensor).

Slow locational correction using map matching

IThe map matching function requires verification of local data. To make the map matching function, some

distance needs to be driven.

IThe map matching function may not provide accurate performance in an area where there are numerous

parallel roads. Until the system judges the road characteristics, an incorrect position may be shown.

NAVIGATION SYSTEM

This Condition is Not Abnormal (Cont'd)

EL-428

Page 1702 of 2395

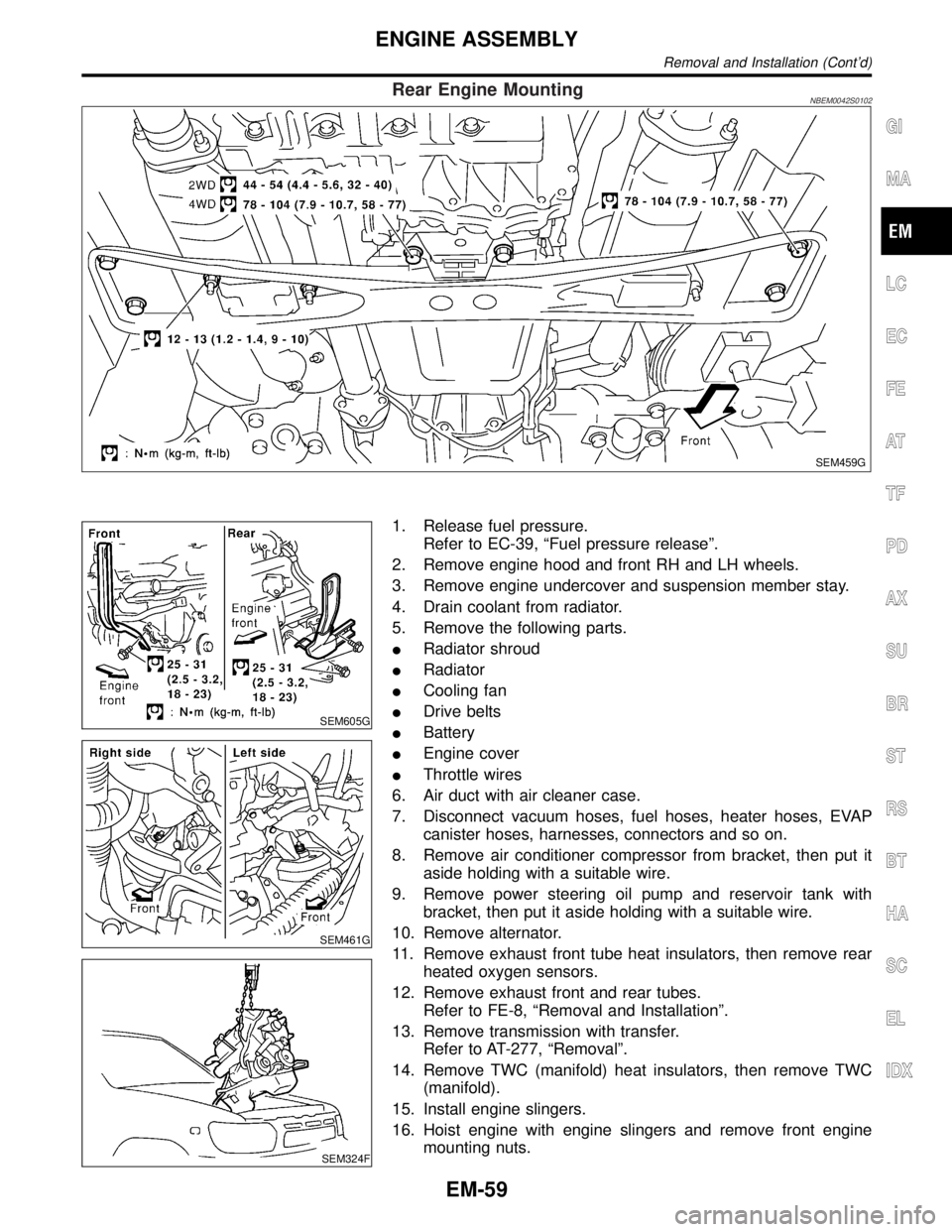

Rear Engine MountingNBEM0042S0102

SEM459G

SEM605G

SEM461G

SEM324F

1. Release fuel pressure.

Refer to EC-39, ªFuel pressure releaseº.

2. Remove engine hood and front RH and LH wheels.

3. Remove engine undercover and suspension member stay.

4. Drain coolant from radiator.

5. Remove the following parts.

IRadiator shroud

IRadiator

ICooling fan

IDrive belts

IBattery

IEngine cover

IThrottle wires

6. Air duct with air cleaner case.

7. Disconnect vacuum hoses, fuel hoses, heater hoses, EVAP

canister hoses, harnesses, connectors and so on.

8. Remove air conditioner compressor from bracket, then put it

aside holding with a suitable wire.

9. Remove power steering oil pump and reservoir tank with

bracket, then put it aside holding with a suitable wire.

10. Remove alternator.

11. Remove exhaust front tube heat insulators, then remove rear

heated oxygen sensors.

12. Remove exhaust front and rear tubes.

Refer to FE-8, ªRemoval and Installationº.

13. Remove transmission with transfer.

Refer to AT-277, ªRemovalº.

14. Remove TWC (manifold) heat insulators, then remove TWC

(manifold).

15. Install engine slingers.

16. Hoist engine with engine slingers and remove front engine

mounting nuts.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-59

Page 1745 of 2395

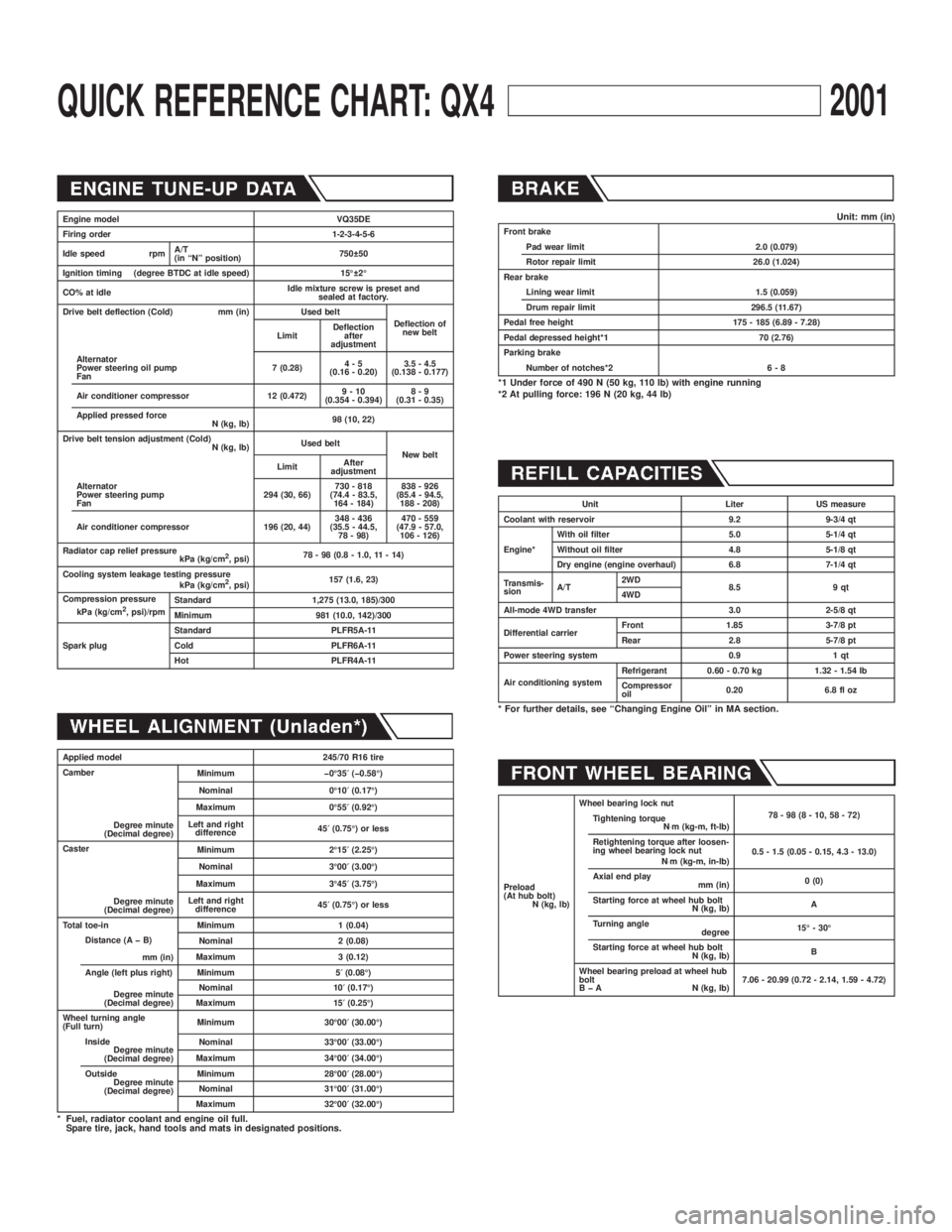

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1748 of 2395

PrecautionsNBGI0001Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

SGI646

PRECAUTIONS FOR SUPPLEMENTAL RESTRAINT

SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBGI0001S01The Supplemental Restraint System such as ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº used along with a seat belt, helps to

reduce the risk or severity of injury to the driver and front passen-

ger for certain types of collision. The SRS system composition

which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag

module (located in the center of the steering wheel), front pas-

senger air bag module (located on the instrument panel on

passenger side), seat belt pre-tensioners, a diagnosis sensor

unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag

module (located in the outer side of front seat), satellite sensor,

diagnosis sensor unit (one of components of air bags for a

frontal collision), wiring harness, warning lamp (one of compo-

nents of air bags for a frontal collision).

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance must be performed by an authorized INFINITI

dealer.

IImproper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

Spiral cable and wiring harnesses covered with yellow

insulation tape either just before the harness connectors

or for the complete harness are related to the SRS.

PRECAUTIONS FOR IVIS (INFINITI VEHICLE

IMMOBILIZER SYSTEM Ð NATS)

NBGI0001S08IVIS (NATS) will immobilize the engine if someone tries to start it

without the registered key of IVIS (NATS).

Both of the originally supplied ignition key IDs have been IVIS

(NATS) registered.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions

GI-3

Page 1755 of 2395

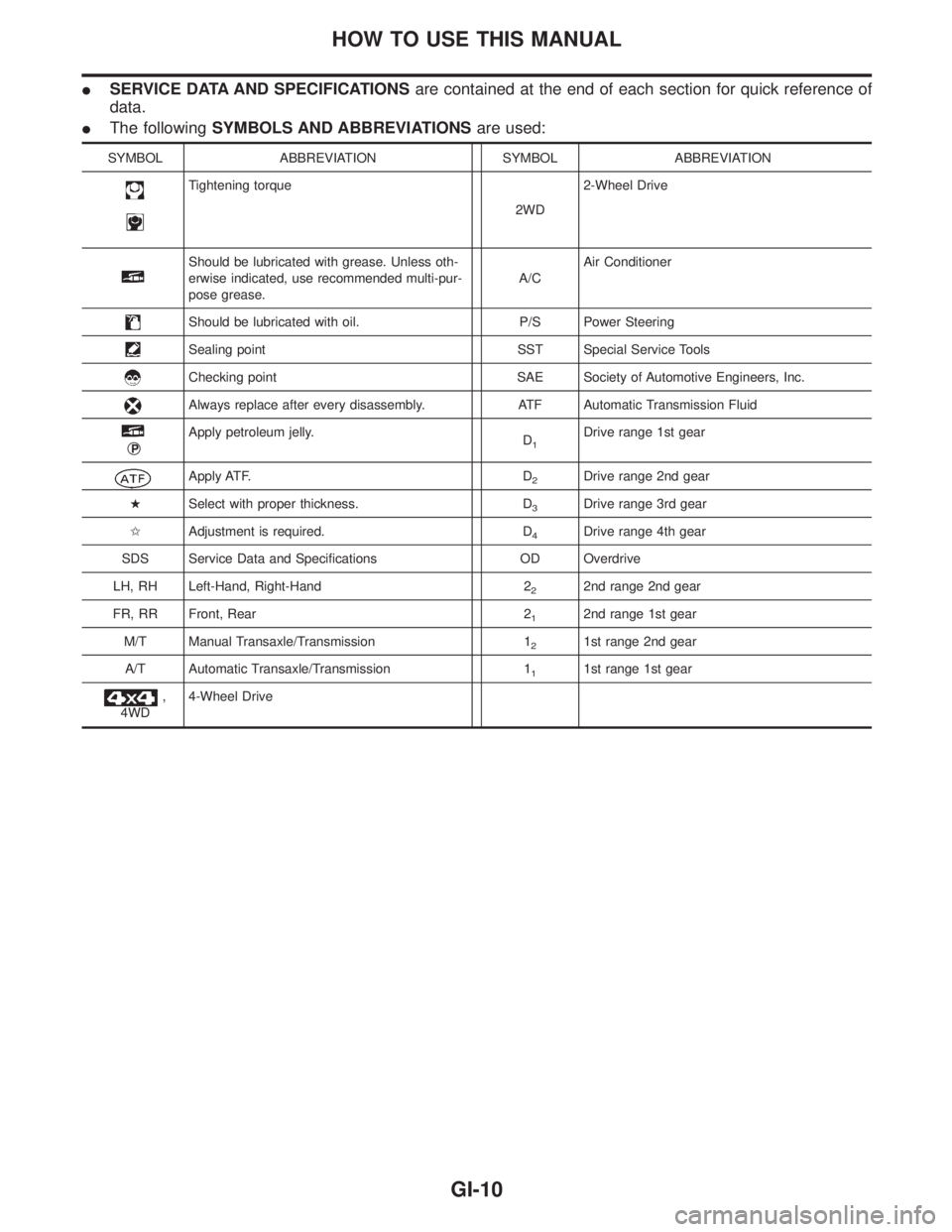

ISERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

IThe followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

qP

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

HSelect with proper thickness. D

3Drive range 3rd gear

IAdjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

,

4WD4-Wheel Drive

HOW TO USE THIS MANUAL

GI-10