oil capacity INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1812 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

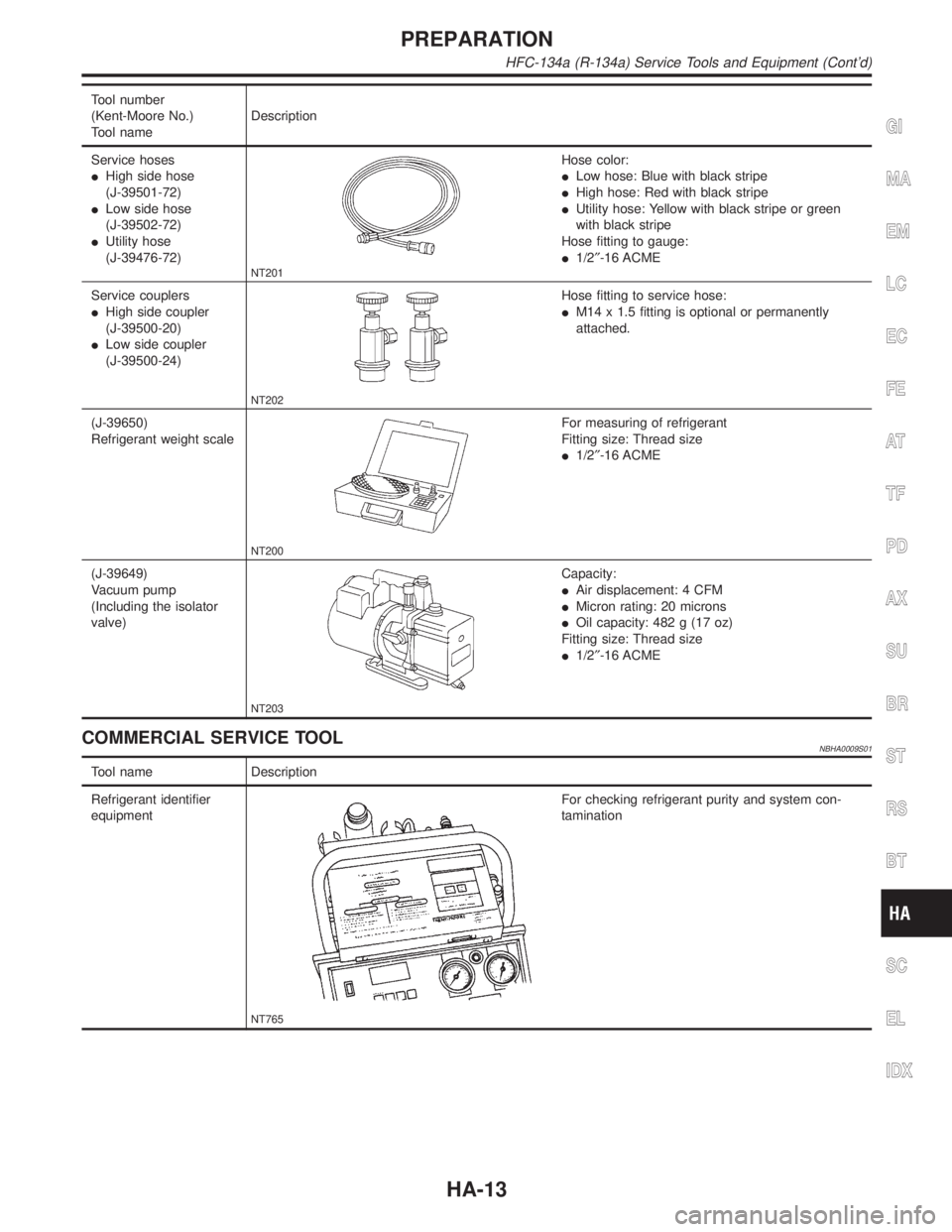

Service hoses

IHigh side hose

(J-39501-72)

ILow side hose

(J-39502-72)

IUtility hose

(J-39476-72)

NT201

Hose color:

ILow hose: Blue with black stripe

IHigh hose: Red with black stripe

IUtility hose: Yellow with black stripe or green

with black stripe

Hose fitting to gauge:

I1/2²-16 ACME

Service couplers

IHigh side coupler

(J-39500-20)

ILow side coupler

(J-39500-24)

NT202

Hose fitting to service hose:

IM14 x 1.5 fitting is optional or permanently

attached.

(J-39650)

Refrigerant weight scale

NT200

For measuring of refrigerant

Fitting size: Thread size

I1/2²-16 ACME

(J-39649)

Vacuum pump

(Including the isolator

valve)

NT203

Capacity:

IAir displacement: 4 CFM

IMicron rating: 20 microns

IOil capacity: 482 g (17 oz)

Fitting size: Thread size

I1/2²-16 ACME

COMMERCIAL SERVICE TOOLNBHA0009S01

Tool name Description

Refrigerant identifier

equipment

NT765

For checking refrigerant purity and system con-

tamination

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment (Cont'd)

HA-13

Page 1959 of 2395

CompressorNBHA0081

ModelCALSONIC make V-6

TypeV-6 variable displacement

Displacement

cm

3(cu in)/rev.Max. 184 (11.228)

Min. 14.5 (0.885)

Cylinder bore x stroke

mm (in)37 (1.46) x [2.3 - 28.6 (0.091 - 1.126)]

Direction of rotationClockwise (viewed from drive end)

Drive beltPoly V

LubricantNBHA0082

ModelCALSONIC make V-6

NameNissan A/C System Oil Type S

Part number*KLH00-PAGS0

Capacity

m(US fl oz, Imp fl oz)Total in system 200 (6.8, 7.0)

Compressor (Service part) charging amount 200 (6.8, 7.0)

*: Always check with the Parts Department for the latest parts information.

RefrigerantNBHA0083

TypeHFC-134a (R-134a)

Capacity

kg (lb)0.60 - 0.70 (1.32 - 1.54)

Engine Idling Speed (When A/C is ON)NBHA0084IRefer to EC-649, ªIdle Speed and Ignition Timingº.

Belt TensionNBHA0085IRefer to MA-29, ªEngine Maintenanceº.

SERVICE DATA AND SPECIFICATIONS (SDS)

Compressor

HA-160

Page 1965 of 2395

LSV (Load sensing valve) ..............................BR-12

Lubricant (R134a) A/C..................................HA-146

Lubricants .......................................................MA-11

Lubrication circuit (engine) ...............................LC-3

Lubrication-locks, hinges and hood

latches ........................................................MA-27

Luggage room lamp ........................................EL-88

M

MAFS - Wiring diagram................................EC-154

Magnet clutch .......................................HA-104, 150

MAIN - Wiring diagram.................................EC-142

Main oil pump (Transfer)...............................TF-131

Mainshaft (Transfer) ......................................TF-125

Maintenance (engine) ....................................MA-13

MAJOR OVERHALL......................................AT-281

Major overhaul (Transfer) .............................TF-120

Malfunction indicator lamp (MIL) ....................EC-74

Mass air flow sensor (MAFS) .......................EC-150

Master cylinder (brake) ..................................BR-16

Meter ...............................................................EL-94

METER - Wiring diagram................................EL-99

MIL & Data link connectors circuit ...............EC-648

MIL/DL - Wiring diagram ..............................EC-648

MIRROR - Wiring diagram............................EL-177

Mirror defogger .............................................EL-151

Mirror, door......................................................BT-56

Mirror, out side ................................................BT-56

Misfire ...........................................................EC-320

Mode door control linkage adjustment ...........HA-81

Mode door motor ............................................HA-75

Model variation ................................................GI-41

Molding - See Exterior ....................................BT-35

MULTI - Wiring diagram ................................EL-274

Multi-remote control system..........................EL-270

Multiplex communication ..............................HA-142

Multiport fuel injection (MFI) system ..............EC-28

Multiport fuel injection precautions ....................GI-6

N

NATS (Nissan anti-theft system)...................EL-328

NATS (Nissan anti-theft system)

precautions ....................................................GI-3

NATS - Wiring diagram .................................EL-330

NAVI - wiring diagram ...................................EL-394

Navigation System ........................................EL-385

Neutral-4LO switch ........................................TF-112

NVH troubleshooting (AX) ..........................AX-3, 18

NVH troubleshooting (BR)................................BR-6

NVH troubleshooting (PD)................................PD-3

NVH troubleshooting (ST).................................ST-6

NVH troubleshooting (SU) .........................SU-3, 15O

Oil change (capacity) .....................................MA-11

Oil filter (Transfer) .........................................TF-118

Oil pan (engine) .............................................EM-15

Oil pressure (engine) ........................................LC-4

Oil pump (A/T) ...............................................AT-297

Oil pump (engine) .............................................LC-5

Oil pump regulator valve (engine) ....................LC-6

Oil seal replacement (engine)........................EM-35

Oil seal replacement (front final drive

4WD) ...........................................................PD-15

Oil seal replacement (front of final

drive) ...........................................................PD-40

On board diagnostic system ..........................EC-59

Out side mirror ................................................BT-56

Overdrive control switch ................................AT-263

Overrun clutch ...............................................AT-320

Overrun clutch solenoid valve .......................AT-189

P

P/ANT - Wiring diagram ................................EL-170

Park/Neutral position switch .........................EC-604

Park/neutral position switch (A/T) .........AT-103, 263

Parking brake control .....................................BR-30

Parking lamp ...................................................EL-61

PCV (positive crankcase ventilation) .............EC-38

PGC/V - Wiring diagram ......................EC-370, 544

PHASE - Wiring diagram .............................EC-342

Pinion bearing preload diff. ............................PD-25

Pinion gear height diff. .............................PD-25, 53

Piston assembly .............................................EM-71

Piston pin inspection ......................................EM-63

Piston ring inspection.....................................EM-64

Piston to bore clearance ................................EM-66

Planetary carrier (Transfer) ...........................TF-134

PNP/SW - Wiring diagram ...........................EC-607

POS - Wiring diagram ..................................EC-517

POWER - Wiring diagram...............................EL-10

Power antenna ..............................................EL-169

Power door lock ............................................EL-254

Power door mirror .........................................EL-177

Power seat ....................................................EL-181

Power steering fluid level .....................MA-27, ST-8

Power steering gear........................................ST-17

Power steering hydraulic pressure .................ST-10

Power steering oil pressure switch ..............EC-634

Power steering oil pump .................................ST-27

Power steering system bleeding.......................ST-9

Power supply routing ........................................EL-9

Power transistor & ignition coil.....................EC-499

Power window ...............................................EL-241

PRE/SE - Wiring diagram ............................EC-384

Precations for Leak detection dye ...................HA-3

Precautions (General) .......................................GI-5

Pressure test (A/T) ..........................................AT-62

Propeller shaft ..................................................PD-3

ALPHABETICAL INDEX

IDX-6

Page 2006 of 2395

NBMA0005

Fluids and LubricantsNBMA0005S01

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp measure Liter

Engine oilDrain and

refillWith oil filter 5-1/4 qt 4-3/8 qt 5.0

IAPI Certification Mark*1

IAPI grade SG/SH, Energy Conserv-

ingI&IIorAPIgrade SJ, Energy

Conserving*1

IILSAC grade GF-I & GF-II*1 Without oil

filter5-1/8 qt 4-1/4 qt 4.8

Dry engine

(Engine overhaul)7-1/4 qt 6 qt 6.8

Cooling system (With reservoir) 9-3/4 qt 8-1/8 qt 9.2Genuine Nissan anti-freeze coolant or

equivalent

All-mode 4WD transfer fluid 3-1/8 qt 2-5/8 qt 3.0Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*2

Differential

carrier gear

oilFront (4WD) 3-7/8 pt 3-1/4 pt 1.85Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear:

Use only LSD gear oil API GL-5 and

SAE 80W-90*5 approved for Nissan

LSD*6. Rear 5-7/8 pt 4-7/8 pt 2.8

Automatic transmission fluid2WD

9 qt 7-1/2 qt 8.5Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*3 4WD

Power steering fluid Ð Ð Ð Genuine NISSAN PSF II or equivalent*7

Brake fluid Ð Ð ÐGenuine Nissan Brake Fluid*4 or

equivalent DOT 3 (U.S. FMVSS No.

116)

Propeller shaft grease Ð Ð ÐNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Outside the continental United States and Alaska contact an authorized INFINITI dealership for more information regarding suitable

fluids, including recommended brand(s) of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: DEXRONTMIII/MERCONTMor equivalent may also be used. Outside the continental United States and Alaska contact an autho-

rized INFINITI dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTMIII/MERCONTM

Automatic Transmission Fluid.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF).

*6: Contact an INFINITI dealer for a list of approved oils.

*7: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, DEXRON

TMIII/MERCONTMor equivalent ATF may also be

used.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-11

Page 2013 of 2395

SMA096D

Changing Engine OilNBMA0015WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait for more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity

IAPI grade SG or SH, Energy ConservingI&IIorAPIgrade

SJ, Energy Conserving

IAPI Certification Mark

IILSAC grade GF-I & GF-II

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº, MA-11.

Oil capacity (Approximately):

Unit:(US qt, Imp qt)

Drain and refillWith oil filter change 5.0 (5-1/4, 4-3/8)

Without oil filter change 4.8 (5-1/8, 4-1/4)

Dry engine (engine overhaul) 6.8 (7-1/4, 6)

CAUTION:

IBe sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

JMA122D

5. Warm up engine and check area around drain plug and oil fil-

ter for oil leakage.

6. Stop engine and wait for more than 10 minutes.

7. Check oil level.

SMA097D

Changing Oil FilterNBMA00161. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

The filter is a full-flow cartridge type and is provided with a relief

valve.

Refer to LC-7, ªOil Filterº.

ENGINE MAINTENANCE

Changing Engine Oil

MA-18

Page 2017 of 2395

2WD, 4WD model

8.5(9 US qt, 7-1/2 Imp qt)

Drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to MA-21, ªChecking A/T

Fluidº. If fluid is still dirty, repeat steps 2 through 5.

SMA439B

Checking All-mode 4WD Transfer FluidNBMA0022Check for oil leakage and fluid level.

A/T fluid is used for the all-mode 4WD transfer in the factory.

Never start engine while checking fluid level.

Filler plug:

: 10 - 20 N´m (1.0 - 2.0 kg-m, 87 - 174 in-lb)

SMA444B

Changing All-mode 4WD Transfer FluidNBMA0023When changing all-mode 4WD transfer fluid completely, A/T fluid

may be used.

Fluid grade:

Nissan Matic ªDº (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid.

Refer to ªFluids and Lubricantsº, ªRECOMMENDED

FLUIDS AND LUBRICANTSº, MA-11.

Fluid capacity:

3.0(3-1/8 US qt, 2-5/8 Imp qt)

Drain plug:

: 10 - 20 N´m (1.0 - 2.0 kg-m, 87 - 174 in-lb)

CHASSIS AND BODY MAINTENANCE

Changing A/T Fluid (Cont'd)

MA-22

Page 2019 of 2395

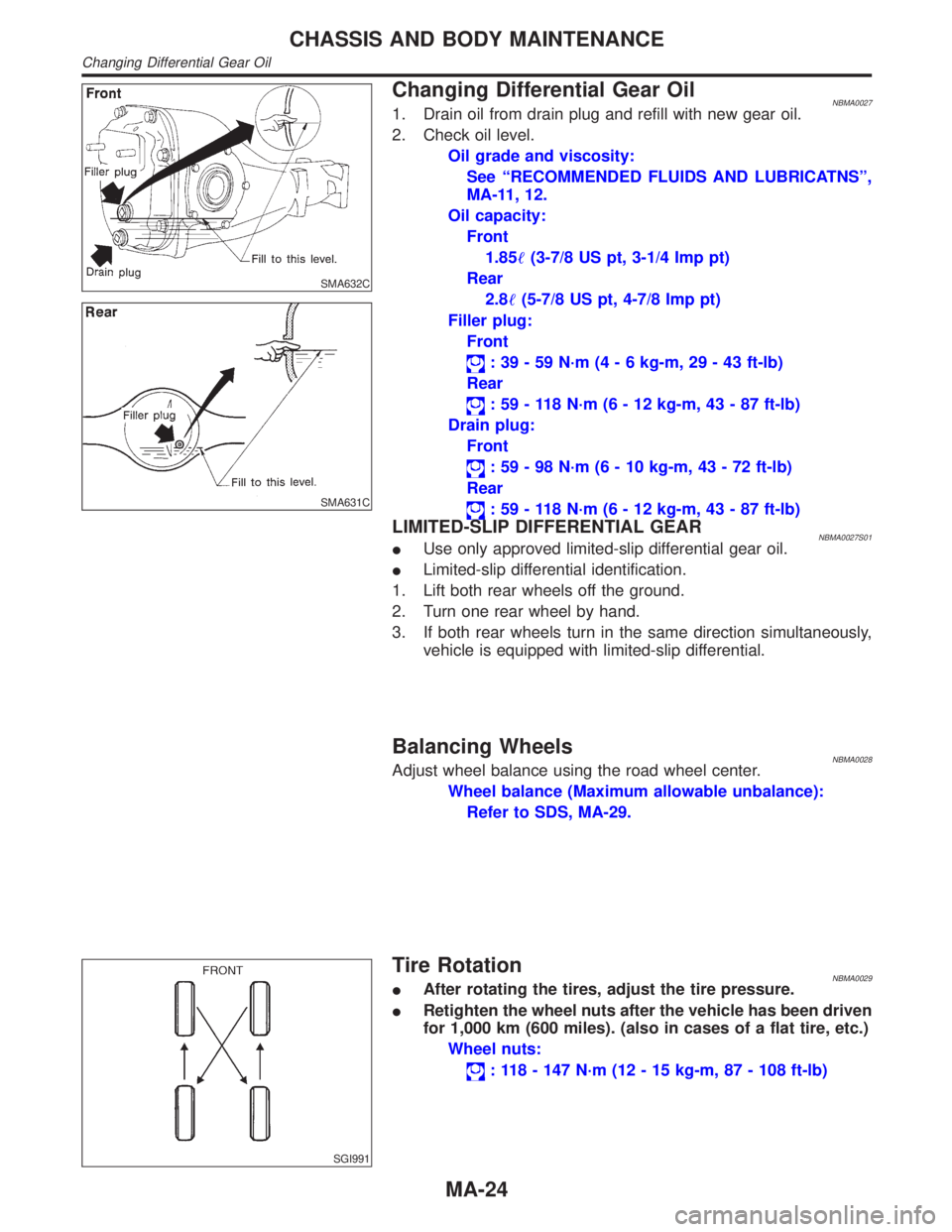

SMA632C

SMA631C

Changing Differential Gear OilNBMA00271. Drain oil from drain plug and refill with new gear oil.

2. Check oil level.

Oil grade and viscosity:

See ªRECOMMENDED FLUIDS AND LUBRICATNSº,

MA-11, 12.

Oil capacity:

Front

1.85(3-7/8 US pt, 3-1/4 Imp pt)

Rear

2.8(5-7/8 US pt, 4-7/8 Imp pt)

Filler plug:

Front

: 39 - 59 N´m (4 - 6 kg-m, 29 - 43 ft-lb)

Rear

: 59 - 118 N´m (6 - 12 kg-m, 43 - 87 ft-lb)

Drain plug:

Front

: 59 - 98 N´m (6 - 10 kg-m, 43 - 72 ft-lb)

Rear

: 59 - 118 N´m (6 - 12 kg-m, 43 - 87 ft-lb)

LIMITED-SLIP DIFFERENTIAL GEARNBMA0027S01IUse only approved limited-slip differential gear oil.

ILimited-slip differential identification.

1. Lift both rear wheels off the ground.

2. Turn one rear wheel by hand.

3. If both rear wheels turn in the same direction simultaneously,

vehicle is equipped with limited-slip differential.

Balancing WheelsNBMA0028Adjust wheel balance using the road wheel center.

Wheel balance (Maximum allowable unbalance):

Refer to SDS, MA-29.

SGI991

Tire RotationNBMA0029IAfter rotating the tires, adjust the tire pressure.

IRetighten the wheel nuts after the vehicle has been driven

for 1,000 km (600 miles). (also in cases of a flat tire, etc.)

Wheel nuts:

: 118 - 147 N´m (12 - 15 kg-m, 87 - 108 ft-lb)

CHASSIS AND BODY MAINTENANCE

Changing Differential Gear Oil

MA-24

Page 2061 of 2395

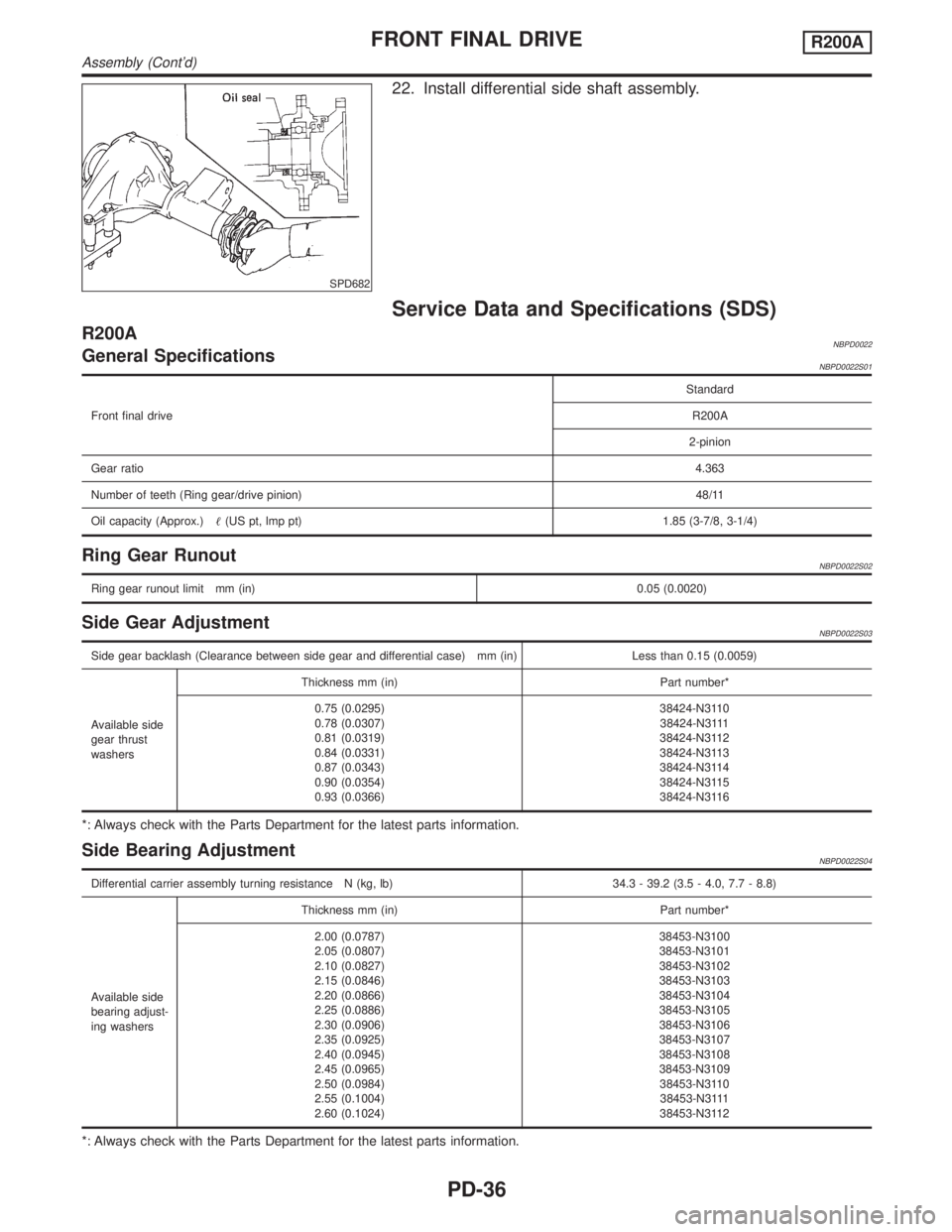

SPD682

22. Install differential side shaft assembly.

Service Data and Specifications (SDS)

R200ANBPD0022General SpecificationsNBPD0022S01

Front final driveStandard

R200A

2-pinion

Gear ratio4.363

Number of teeth (Ring gear/drive pinion)48/11

Oil capacity (Approx.)(US pt, lmp pt) 1.85 (3-7/8, 3-1/4)

Ring Gear RunoutNBPD0022S02

Ring gear runout limit mm (in)0.05 (0.0020)

Side Gear AdjustmentNBPD0022S03

Side gear backlash (Clearance between side gear and differential case) mm (in) Less than 0.15 (0.0059)

Available side

gear thrust

washersThickness mm (in) Part number*

0.75 (0.0295)

0.78 (0.0307)

0.81 (0.0319)

0.84 (0.0331)

0.87 (0.0343)

0.90 (0.0354)

0.93 (0.0366)38424-N3110

38424-N3111

38424-N3112

38424-N3113

38424-N3114

38424-N3115

38424-N3116

*: Always check with the Parts Department for the latest parts information.

Side Bearing AdjustmentNBPD0022S04

Differential carrier assembly turning resistance N (kg, lb) 34.3 - 39.2 (3.5 - 4.0, 7.7 - 8.8)

Available side

bearing adjust-

ing washersThickness mm (in) Part number*

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)

2.25 (0.0886)

2.30 (0.0906)

2.35 (0.0925)

2.40 (0.0945)

2.45 (0.0965)

2.50 (0.0984)

2.55 (0.1004)

2.60 (0.1024)38453-N3100

38453-N3101

38453-N3102

38453-N3103

38453-N3104

38453-N3105

38453-N3106

38453-N3107

38453-N3108

38453-N3109

38453-N3110

38453-N3111

38453-N3112

*: Always check with the Parts Department for the latest parts information.

FRONT FINAL DRIVER200A

Assembly (Cont'd)

PD-36

Page 2087 of 2395

Service Data and Specifications (SDS)

H233B=NBPD0042General SpecificationsNBPD0042S01

Rear final drive2WD 4WD

Standard Optional

H233B

2-pinion LSD

Gear ratio4.363

Number of teeth (Ring gear/drive pinion) 48/11

Oil capacity (Approx.)(US pt, lmp pt) 2.8 (5-7/8, 4-7/8)

Ring Gear RunoutNBPD0042S02

Ring gear runout limit mm (in)0.08 (0.0031)

Side Gear AdjustmentNBPD0042S03

Side gear backlash (Clearance between side gear and differential case) mm (in) 0.10 - 0.20 (0.0039 - 0.0079)

Available side

gear thrust

washersThickness mm (in) Part number*

1.75 (0.0689)

1.80 (0.0709)

1.85 (0.0728)38424-T5000

38424-T5001

38424-T5002

*: Always check with the Parts Department for the latest parts information.

Differential Torque Adjustment (LSD models)NBPD0042S04

Differential torque N´m (kg-m, ft-lb) 88 - 108 (9 - 11, 65 - 80)

Number of discs and plates (One

side)Friction disc 2

Friction plate 9

Spring plate 2

Wear limit of plate and disc mm (in) 0.1 (0.004)

Allowable warpage of friction disc and plate mm (in) 0.08 (0.0031)

Available discs

and platesPlate name Thickness mm (in) Part number*

Friction disc1.48 - 1.52 (0.0583 - 0.0598)

1.38 - 1.42 (0.0543 - 0.0559)

1.58 - 1.62 (0.0622 - 0.0638)38433-C6002 (Standard type)

38433-C6004 (Adjusting type)

38433-C6003 (Adjusting type)

Friction plate1.48 - 1.52 (0.0583 - 0.0598)

1.38 - 1.42 (0.0543 - 0.0559)

1.58 - 1.62 (0.0622 - 0.0638)38432-C6001

38432-C6002

38432-C6003

Spring plate 1.48 - 1.52 (0.0583 - 0.0598) 38435-S9200

*: Always check with the Parts Department for the latest parts information.

Total Preload AdjustmentNBPD0042S05

Total preload N´m (kg-cm, in-lb) P1+ [0.3 - 0.4 (3 - 4, 2.6 - 3.5)]

Ring gear backlash mm (in) 0.13 - 0.18 (0.0051 - 0.0071)

Side bearing adjusting methodSide adjuster

P1: Drive pinion preload

REAR FINAL DRIVEH233B

Service Data and Specifications (SDS)

PD-62

Page 2180 of 2395

BatteryNBSC0014

Applied area USA Canada

Type80D26R

Capacity V-AH12-65

Cold cranking current A

(For reference value)582

StarterNBSC0015

TypeM0T50371

MITSUBISHI make

Reduction gear type

System voltage12V

No-loadTerminal voltage 11.0V

Current Less than 90A

Revolution More than 2,700 rpm

Minimum diameter of commutator28.8 mm (1.134 in)

Minimum length of brush7.0 mm (0.276 in)

Brush spring tension18.3 - 24.8 N (1.87 - 2.53 kg, 4.11 - 5.58 lb)

Movement ªº in height of pinion assembly 0.5 - 2.0 mm (0.020 - 0.079 in)

AlternatorNBSC0016

TypeLR1110-712

HITACHI make

Nominal rating12V-110A

Ground polarityNegative

Minimum revolution under no-load (When 13.5 volts is applied) Less than 1,000 rpm

Hot output current (When 13.5 volts is applied)More than 35A/1,300 rpm

More than 85A/2,500 rpm

More than 110A/5,000 rpm

Regulated output voltage14.1 - 14.7V

Minimum length of brushMore than 6.0 mm (0.236 in)

Brush spring pressure 1.0 - 3.43 N (102 - 350 g, 3.60 - 12.34 oz)

Slip ring minimum outer diameter More than 26.0 mm (1.024 in)

Rotor (Field coil) resistance2.31W

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Battery

SC-29