elec INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 932 of 2395

8) Stop vehicle.

9) Select ªMODE 3º with GST.

IIf P0455 is displayed on the screen, go to ªDiagnostic

Procedureº, EC-397.

IIf P0440 or P1440 is displayed on the screen, go to ªDiagnos-

tic Procedureº, for DTC P0440, EC-355.

IIf P1447 is displayed on the screen, go to ªDiagnostic Proce-

dureº for DTC P1447, EC-564.

IIf P0455, P0440, P1440 and P1447 are not displayed on the

screen, go to the following step.

10) Select ªMODE 1º with GST.

IIf SRT of EVAP system is set, the result will be OK.

IIf SRT of EVAP system is not set, go to step 6.

Diagnostic ProcedureNBEC0647

1 CHECK FUEL FILLER CAP DESIGN

1. Turn ignition switch ªOFFº.

2. Check for genuine NISSAN fuel filler cap design.

SEF915U

OK or NG

OK©GO TO 2.

NG©Replace with genuine NISSAN fuel filler cap.

2 CHECK FUEL FILLER CAP INSTALLATION

Check that the cap is tightened properly by rotating the cap clockwise.

OK or NG

OK©GO TO 3.

NG©IOpen fuel filler cap, then clean cap and fuel filler neck threads using air blower.

IRetighten until ratcheting sound is heard.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0455 EVAP CONTROL SYSTEM (GROSS LEAK)

DTC Confirmation Procedure (Cont'd)

EC-397

Page 935 of 2395

9 CHECK FOR EVAP LEAK

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªEVAP SYSTEM CLOSEº of ªWORK SUPPORTº mode with CONSULT-II.

3. Touch ªSTARTº and apply pressure into the EVAP line until the pressure indicator reaches the middle of the bar graph.

NOTE:

INever use compressed air or a high pressure pump.

IDo not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in the system.

PEF917U

4. Using EVAP leak detector, locate the EVAP leak. For the leak detector, refer to the instruction manual for more details.

Refer to ªEVAPORATIVE EMISSION LINE DRAWINGº, EC-36.

SEF200U

OK or NG

OK©GO TO 11.

NG©Repair or replace.

DTC P0455 EVAP CONTROL SYSTEM (GROSS LEAK)

Diagnostic Procedure (Cont'd)

EC-400

Page 942 of 2395

SEF018S

Component DescriptionNBEC0616The fuel level sensor is mounted in the fuel level sensor unit. The

sensor detects a fuel level in the fuel tank and transmits a signal

to the ECM.

It consists of two parts, one is mechanical float and the other side

is variable resistor. Fuel level sensor output voltage changes

depending on the movement of the fuel mechanical float.

On Board Diagnostic LogicNBEC0617When the vehicle is parked, naturally the fuel level in the fuel tank

is stable. It means that output signal of the fuel level sensor does

not change. If ECM senses sloshing signal from the sensor, fuel

level sensor malfunction is detected.

Malfunction is detected when even though the vehicle is parked, a

signal being varied is sent from the fuel level sensor to ECM.

Possible CauseNBEC0618IFuel level sensor circuit

(The fuel level sensor circuit is open or shorted.)

IFuel level sensor

SEF195Y

DTC Confirmation ProcedureNBEC0619NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0619S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait maximum of 2 consecutive minutes.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-409.

WITH GSTNBEC0619S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0460 FUEL LEVEL SENSOR FUNCTION (SLOSH)

Component Description

EC-407

Page 947 of 2395

5) Turn ignition switch ªOFFº and wait at least 10 seconds then

turn ªONº.

6) Select ªFUEL LEVEL SEº in ªDATA MONITORº mode with

CONSULT-II.

7) Check ªFUEL LEVEL SEº output voltage and note it.

8) Select ªFUEL PUMPº in ªACTIVE TESTº mode with CON-

SULT-II.

9) Touch ªONº and drain fuel approximately 30(7-7/8 US gal,

6-5/8 Imp gal) and stop it.

10) Fill fuel into the fuel tank for 30(7-7/8 US gal, 6-5/8 Imp gal).

11) Check ªFUEL LEVEL SEº output voltage and note it.

12) Check ªFUEL LEVEL SEº output voltage and confirm whether

the voltage changes more than 0.03V during step 7 to 11.

If NG, check the fuel level sensor, refer to EL-108, ªFUEL

LEVEL SENSOR UNIT CHECKº.

SEF615X

WITH GSTNBEC0625S02NOTE:

Start from step 11, if it is possible to confirm that the fuel

cannot be drained by 30(7-7/8 US gal, 6-5/8 Imp gal) in

advance.

1) Prepare a fuel container and a spare hose.

2) Release fuel pressure from fuel line, refer to ªFuel Pressure

Releaseº, EC-39.

3) Remove the fuel feed hose on the fuel level sensor unit.

4) Connect a spare fuel hose where the fuel feed hose was

removed.

5) Turn ignition switch ªOFFº.

6) Set voltmeters probe between ECM terminal 83 (fuel level

sensor signal) and ground.

7) Turn ignition switch ªONº.

8) Check voltage between ECM terminal 83 and ground and note

it.

9) Drain fuel by 30(7-7/8 US gal, 6-5/8 Imp gal) from the fuel

tank using proper equipment.

10) Fill fuel into the fuel tank for 30(7-7/8 US gal, 6-5/8 Imp gal).

11) Confirm that the voltage between ECM terminal 83 and ground

changes more than 0.03V during step8-10.

If NG, check component of fuel level sensor, refer to EL-108,

ªFUEL LEVEL SENSOR UNIT CHECKº.

DTC P0461 FUEL LEVEL SENSOR FUNCTION

Overall Function Check (Cont'd)

EC-412

Page 948 of 2395

SEF018S

Component DescriptionNBEC0626The fuel level sensor is mounted in the fuel level sensor unit. The

sensor detects a fuel level in the fuel tank and transmits a signal

to the ECM.

It consists of two parts, one is mechanical float and the other side

is variable resistor. Fuel level sensor output voltage changes

depending on the movement of the fuel mechanical float.

On Board Diagnostic LogicNBEC0627ECM receives two signals from the fuel level sensor circuit.

One is fuel level sensor power supply circuit, and the other is fuel

level sensor ground circuit.

This diagnosis indicates the former, to detect open or short circuit

malfunction.

Malfunction is detected when an excessively low or high voltage is

sent from the sensor is sent to ECM.

Possible CauseNBEC0628IFuel level sensor circuit

(The fuel level sensor circuit is open or shorted.)

IFuel level sensor

DTC Confirmation ProcedureNBEC0629NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 11V at ignition switch ªONº.

SEF195Y

WITH CONSULT-IINBEC0629S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-415.

WITH GSTNBEC0629S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0464 FUEL LEVEL SENSOR CIRCUIT

Component Description

EC-413

Page 953 of 2395

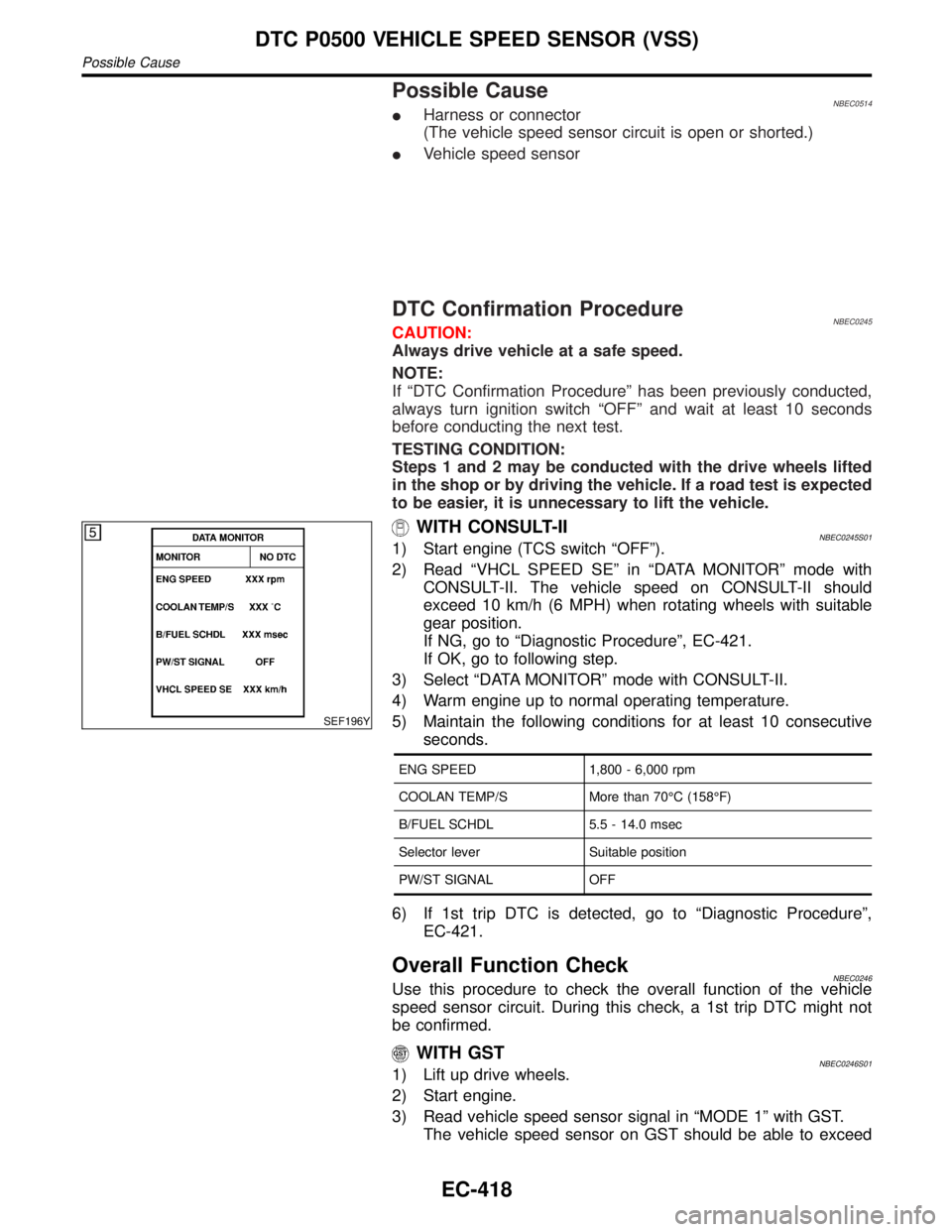

Possible CauseNBEC0514IHarness or connector

(The vehicle speed sensor circuit is open or shorted.)

IVehicle speed sensor

DTC Confirmation ProcedureNBEC0245CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels lifted

in the shop or by driving the vehicle. If a road test is expected

to be easier, it is unnecessary to lift the vehicle.

SEF196Y

WITH CONSULT-IINBEC0245S011) Start engine (TCS switch ªOFFº).

2) Read ªVHCL SPEED SEº in ªDATA MONITORº mode with

CONSULT-II. The vehicle speed on CONSULT-II should

exceed 10 km/h (6 MPH) when rotating wheels with suitable

gear position.

If NG, go to ªDiagnostic Procedureº, EC-421.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Warm engine up to normal operating temperature.

5) Maintain the following conditions for at least 10 consecutive

seconds.

ENG SPEED 1,800 - 6,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 5.5 - 14.0 msec

Selector lever Suitable position

PW/ST SIGNAL OFF

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-421.

Overall Function CheckNBEC0246Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a 1st trip DTC might not

be confirmed.

WITH GSTNBEC0246S011) Lift up drive wheels.

2) Start engine.

3) Read vehicle speed sensor signal in ªMODE 1º with GST.

The vehicle speed sensor on GST should be able to exceed

DTC P0500 VEHICLE SPEED SENSOR (VSS)

Possible Cause

EC-418

Page 959 of 2395

SEF058Y

PROCEDURE FOR MALFUNCTION ANBEC0253S01TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V with ignition switch ªONº.

With CONSULT-IINBEC0253S01011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Perform ªIdle Air Volume Learningº (see EC-57).

4) Turn ignition switch ªOFFº and wait at least 10 seconds.

5) Turn ignition switch ªONº.

6) Select ªDATA MONITORº mode with CONSULT-II.

7) Start engine and let it idle.

8) Keep engine speed at 2,500 rpm for three seconds, then let it

idle for three seconds.

Do not rev engine to more than 3,000 rpm.

9) Perform step 4 once more.

10) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-426.

With GSTNBEC0253S0102Follow the procedure ªWith CONSULT-IIº above.

SEF174Y

PROCEDURE FOR MALFUNCTION BNBEC0253S02TESTING CONDITION:

IBefore performing the following procedure, confirm that

battery voltage is more than 11V at idle.

IAlways perform the test at a temperature above þ10ÉC

(14ÉF).

With CONSULT-IINBEC0253S02011) Open engine hood.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Perform ªIdle Air Volume Learningº (see EC-57).

5) Turn ignition switch ªOFFº and wait at least 10 seconds.

6) Turn ignition switch ªONº again and select ªDATA MONITORº

mode with CONSULT-II

7) Start engine and run it for at least 1 minute at idle speed.

8) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-426.

With GSTNBEC0253S0202Follow the procedure ªWith CONSULT-IIº above.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

DTC Confirmation Procedure (Cont'd)

EC-424

Page 967 of 2395

SEF197Y

SEF198Y

DTC Confirmation ProcedureNBEC0260CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0260S011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº, wait at least 10 seconds and then

start engine.

3) Select ªCLSD THL/P SWº in ªDATA MONITORº mode.

If ªCLSD THL/P SWº is not available, go to step 5.

4) Check the signal under the following conditions.

Condition Signal indication

Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

If the result is NG, go to ªDiagnostic Procedureº, EC-435.

If OK, go to following step.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Drive the vehicle for at least 5 consecutive seconds under the

following condition.

THRTL POS SEN More than 2.5V

VHCL SPEED SE More than 5 km/h (3 MPH)

Selector lever Suitable position

Driving locationDriving vehicle uphill (Increased engine load)

will help maintain the driving conditions

required for this test.

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-435.

SEF345X

Overall Function CheckNBEC0261Use this procedure to check the overall function of the closed

throttle position switch circuit. During this check, a 1st trip DTC

might not be confirmed.

WITH GSTNBEC0261S011) Start engine and warm it up to normal operating temperature.

2) Check the voltage between ECM terminal 56 (Closed throttle

position switch signal) and ground under the following condi-

tions.

At idle: Battery voltage

DTC P0510 CLOSED THROTTLE POSITION SWITCH

DTC Confirmation Procedure

EC-432

Page 971 of 2395

4 CHECK IGNITION TIMING AND ENGINE IDLE SPEED

Check the following items. Refer to ªBasic Inspectionº, EC-101.

MTBL0656

Models with CONSULT-II©GO TO 6.

Models without CON-

SULT-II©GO TO 6.

5 CHECK THROTTLE POSITION SWITCH

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Remove vacuum hose connected to throttle opener.

4. Connect suitable vacuum hose to vacuum pump and the throttle opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ªONº.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check indication of ªCLSD THL/P SWº under the following conditions.

Measurement must be made with throttle position switch installed in vehicle.

MTBL0355

OK or NG

OK (With CONSULT-II)©GO TO 8.

OK (Without CONSULT-

II)©GO TO 9.

NG©GO TO 7.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-436

Page 973 of 2395

7 ADJUST THROTTLE POSITION SWITCH

Check the following items. Refer to ªBasic Inspectionº, EC-101.

MTBL0655

Is it possible to adjust closed throttle position switch?

YesorNo

Yes (With CONSULT-II)©GO TO 9.

Yes (Without CONSULT-

II)©GO TO 9.

No©Replace throttle position switch.

8 CHECK THROTTLE POSITION SENSOR

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check voltage of ªTHRTL POS SENº under the following conditins.

Voltage measurement must be made with throttle position sensor installed in vehicle.

MTBL0230

OK or NG

OK©GO TO 10.

NG©Replace throttle position sensor.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-438