engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 719 of 2395

10 CHECK THROTTLE POSITION SENSOR

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Check voltage between ECM terminal 91 (Throttle position sensor signal) and ground.

Voltage measurement must be made with throttle position sensor installed in vehicle.

MTBL0231

OK or NG

OK©GO TO 12.

NG©GO TO 11.

11 ADJUST CLOSED THROTTLE POSITION SWITCH

Adjust closed throttle position switch. Refer to ªBasic Inspectionº, EC-101.

MTBL0655

OK or NG

OK©GO TO 12.

NG©Replace throttle position sensor. To adjust it, perform ªBasic Inspectionº, EC-101.

DTC P0120 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

EC-184

Page 720 of 2395

12 CHECK MASS AIR FLOW SENSOR

1. Reconnect harness connectors disconneted.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 61 (Mass air flow sensor signal) and ground.

SEF298X

4. If the voltage is out of specification, disconnect mass air flow sensor harness connector and connect it again.

Then repeat above check.

OK or NG

OK©GO TO 13.

NG©Replace mass air flow sensor.

13 CHECK CRANKSHAFT POSITION SENSOR (POS)

1. Install all removed parts.

2. Perform ªDTC Confirmation Procedureº for DTC P0335 and P1336. Refer to EC-336, 519.

OK or NG

OK©GO TO 14.

NG©Replace crankshaft position sensor (POS).

14 CHECK CRANKSHAFT POSITION SENSOR (REF)

Perform ªDTC Confirmation Procedureº for DTC P1335. Refer to EC-511.

OK or NG

OK©GO TO 15.

NG©Replace crankshaft position sensor (REF).

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0120 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

EC-185

Page 722 of 2395

DescriptionNBEC0081NOTE:

If DTC P0125 is displayed with P0115, first perform the trouble

diagnosis for DTC P0115. Refer to EC-169.

SEF594K

COMPONENT DESCRIPTIONNBEC0081S01The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

SEF012P

Engine coolant

temperature ÉC (ÉF)Voltage* V Resistance kW

þ10 (14) 4.4 9.2

20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260

*: These data are reference values and are measured between ECM terminal 70

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNBEC0082Malfunction is detected when voltage sent to ECM from the sen-

sor is not practical, even when some time has passed after start-

ing the engine, or engine coolant temperature is insufficient for

closed loop fuel control.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0125 ENGINE COOLANT TEMPERATURE SENSOR (ECTS)

Description

EC-187

Page 723 of 2395

Possible CauseNBEC0431IHarness or connectors

(High resistance in the circuit)

IEngine coolant temperature sensor

IThermostat

SEF174Y

DTC Confirmation ProcedureNBEC0083CAUTION:

Be careful not to overheat engine.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0083S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Check that ªCOOLAN TEMP/Sº is above 10ÉC (50ÉF).

If it is above 10ÉC (50ÉF), the test result will be OK.

If it is below 10ÉC (50ÉF), go to following step.

4) Start engine and run it for 65 minutes at idle speed.

If ªCOOLAN TEMP/Sº increases to more than 10ÉC (50ÉF)

within 65 minutes, stop engine because the test result will

be OK.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-190.

WITH GSTNBEC0083S02Follow the procedure ªWITH CONSULT-IIº above.

DTC P0125 ENGINE COOLANT TEMPERATURE SENSOR (ECTS)

Possible Cause

EC-188

Page 724 of 2395

Wiring DiagramNBEC0084

MEC945C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0125 ENGINE COOLANT TEMPERATURE SENSOR (ECTS)

Wiring Diagram

EC-189

Page 725 of 2395

Diagnostic ProcedureNBEC0085

1 CHECK ECTS POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector F112, F28.

SEF370Z

3. Turn ignition switch ªONº.

4. Check voltage between ECTS harness connector F28 terminal 3 and ground with CONSULT-II or tester.

SEF371Z

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F112, F28

IHarness for open or short between ECM and engine coolant temperature sensor

©Repair harness or connectors.

3 CHECK ECTS GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between ECTS terminal 2 and engine ground.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

DTC P0125 ENGINE COOLANT TEMPERATURE SENSOR (ECTS)

Diagnostic Procedure

EC-190

Page 726 of 2395

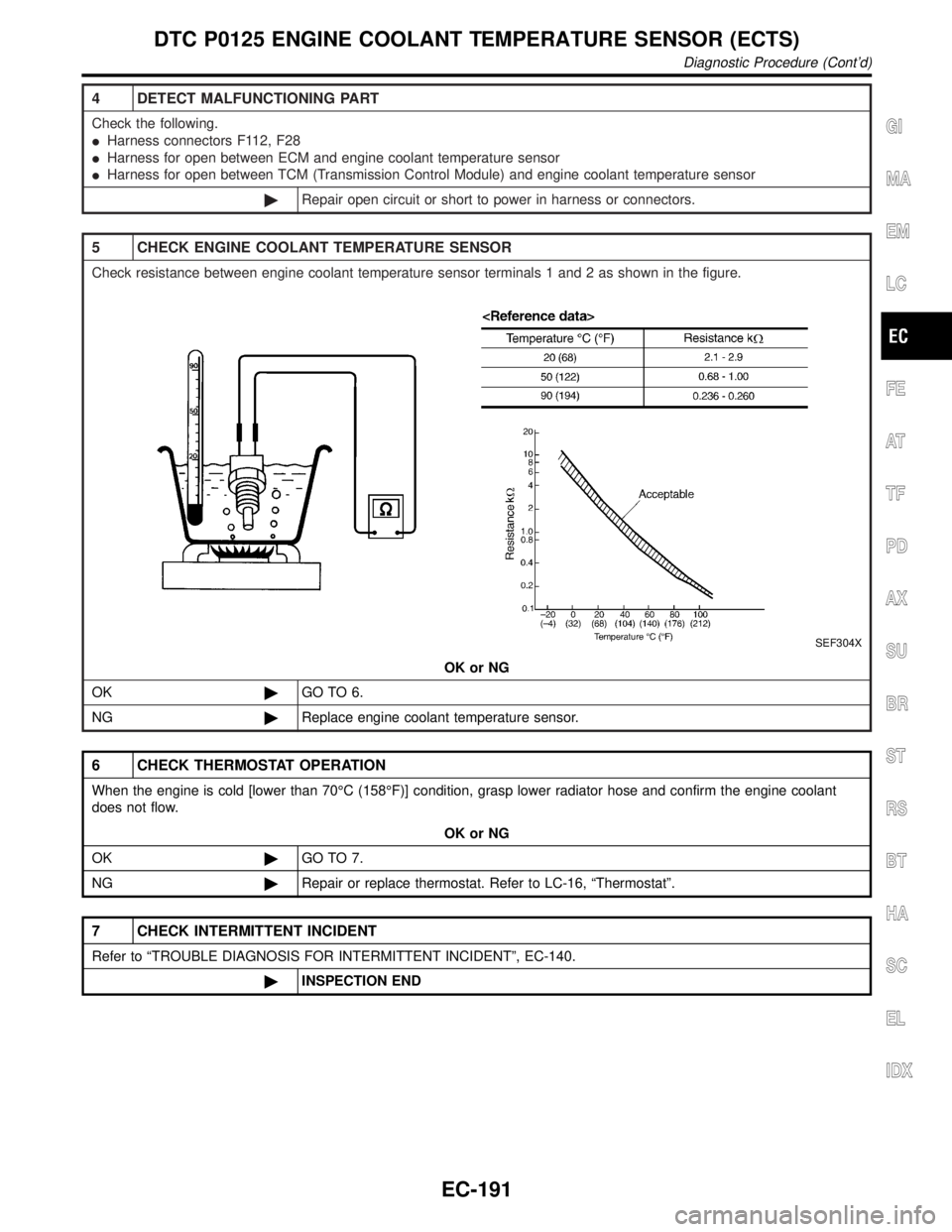

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F112, F28

IHarness for open between ECM and engine coolant temperature sensor

IHarness for open between TCM (Transmission Control Module) and engine coolant temperature sensor

©Repair open circuit or short to power in harness or connectors.

5 CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check resistance between engine coolant temperature sensor terminals 1 and 2 as shown in the figure.

SEF304X

OK or NG

OK©GO TO 6.

NG©Replace engine coolant temperature sensor.

6 CHECK THERMOSTAT OPERATION

When the engine is cold [lower than 70ÉC (158ÉF)] condition, grasp lower radiator hose and confirm the engine coolant

does not flow.

OK or NG

OK©GO TO 7.

NG©Repair or replace thermostat. Refer to LC-16, ªThermostatº.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0125 ENGINE COOLANT TEMPERATURE SENSOR (ECTS)

Diagnostic Procedure (Cont'd)

EC-191

Page 727 of 2395

SEF463R

SEF288D

Component DescriptionNBEC0086The heated oxygen sensor 1 (front) is placed into the front tube. It

detects the amount of oxygen in the exhaust gas compared to the

outside air. The heated oxygen sensor 1 (front) has a closed-end

tube made of ceramic zirconia. The zirconia generates voltage from

approximately 1V in richer conditions to 0V in leaner conditions.

The heated oxygen sensor 1 (front) signal is sent to the ECM. The

ECM adjusts the injection pulse duration to achieve the ideal air-

fuel ratio. The ideal air-fuel ratio occurs near the radical change

from 1V to 0V.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0087Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S1 (B1)

HO2S1 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 - 1.0V

HO2S1 MNTR

(B1)

HO2S1 MNTR

(B2)LEAN+,RICH

Changes more than 5 times during

10 seconds.

ECM Terminals and Reference ValueNBEC0652Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 GHeated oxygen sensor

1 (front) (bank 1)[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.0 - Approximately 1.0V (Peri-

odically change)

SEF059V

DTC P0130, P0150 HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1)/(BANK 2)

(CIRCUIT)

Component Description

EC-192

Page 728 of 2395

![INFINITI QX4 2001 Factory Service Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

62 G/BHeated oxygen sensor

1 (front) (bank 2)[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.0 - Approximately 1.0V (Peri-

od INFINITI QX4 2001 Factory Service Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

62 G/BHeated oxygen sensor

1 (front) (bank 2)[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.0 - Approximately 1.0V (Peri-

od](/img/42/57027/w960_57027-727.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

62 G/BHeated oxygen sensor

1 (front) (bank 2)[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.0 - Approximately 1.0V (Peri-

odically change)

SEF059V

SEF237U

On Board Diagnosis LogicNBEC0089Under the condition in which the heated oxygen sensor 1 (front)

signal is not input, the ECM circuits will read a continuous approxi-

mately 0.3V. Therefore, for this diagnosis, the time that output

voltage is within 200 to 400 mV range is monitored, and the diag-

nosis checks that this time is not inordinately long.

Malfunction is detected when the voltage from the sensor is con-

stantly approx. 0.3V.

Possible CauseNBEC0432IHarness or connectors

(The sensor circuit is open or shorted.)

IHeated oxygen sensor 1 (front)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0130, P0150 HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1)/(BANK 2)

(CIRCUIT)

ECM Terminals and Reference Value (Cont'd)

EC-193

Page 729 of 2395

SEF332Z

DTC Confirmation ProcedureNBEC0090

SEF333Z

SEF645Y

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 11V at idle.

WITH CONSULT-IINBEC0090S011) Start engine and warm it up to normal operating temperature.

2) Select ªHO2S1 (B1)/(B2) P0130/P0150º of ªHO2S1º in ªDTC

WORK SUPPORTº mode with CONSULT-II.

3) Touch ªSTARTº.

4) Let it idle for at least 3 minutes.

NOTE:

Never raise engine speed above 3,600 rpm after this step. If

the engine speed limit is exceeded, return to step 4.

5) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 10 to 60 seconds.)

ENG SPEED 1,500 - 2,800 rpm

Vehicle speed 70 - 100 km/h (43 - 62 MPH)

B/FUEL SCHDL 3.0 - 10 msec

Selector lever Suitable position

If ªTESTINGº is not displayed after 5 minutes, retry from

step 2.

6) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-198.

During this test, P1148 and P1168 may be stored in ECM.

SEF308XB

Overall Function CheckNBEC0091Use this procedure to check the overall function of the heated oxy-

gen sensor 1 (front) circuit. During this check, a 1st trip DTC might

not be confirmed.

WITH GSTNBEC0091S011) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 63 (HO2S1 bank

1 right signal) or 62 (HO2S1 bank 2 left signal) and engine

ground.

DTC P0130, P0150 HEATED OXYGEN SENSOR 1 (FRONT) (BANK 1)/(BANK 2)

(CIRCUIT)

DTC Confirmation Procedure

EC-194