Battery replace INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 589 of 2395

28 CHECK HEATED OXYGEN SENSOR 1 (FRONT) (BANK 2) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) (bank 2) harness connector.

4. Check harness continuity between ECM terminal 62 and front heated oxygen sensor LH harness connector terminal 1.

Refer to Wiring Diagram, EC-197.

Continuity should exist.

OK or NG

OK©GO TO 30.

NG©GO TO 29.

29 REPAIR OR REPLACE

Repair or replace harness between ECM and heated oxygen sensor 1 (front).

©GO TO 3.

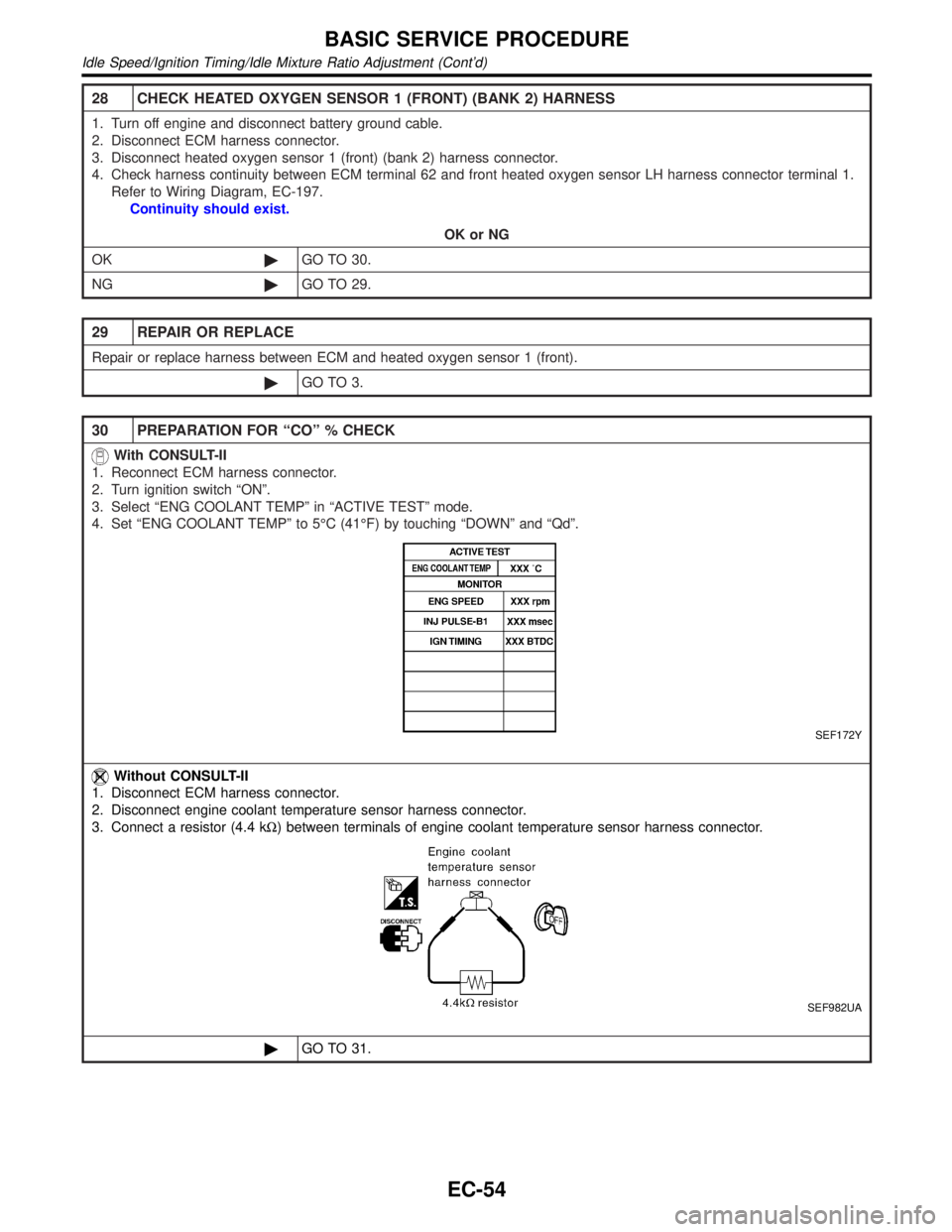

30 PREPARATION FOR ªCOº % CHECK

With CONSULT-II

1. Reconnect ECM harness connector.

2. Turn ignition switch ªONº.

3. Select ªENG COOLANT TEMPº in ªACTIVE TESTº mode.

4. Set ªENG COOLANT TEMPº to 5ÉC (41ÉF) by touching ªDOWNº and ªQdº.

SEF172Y

Without CONSULT-II

1. Disconnect ECM harness connector.

2. Disconnect engine coolant temperature sensor harness connector.

3. Connect a resistor (4.4 kW) between terminals of engine coolant temperature sensor harness connector.

SEF982UA

©GO TO 31.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-54

Page 592 of 2395

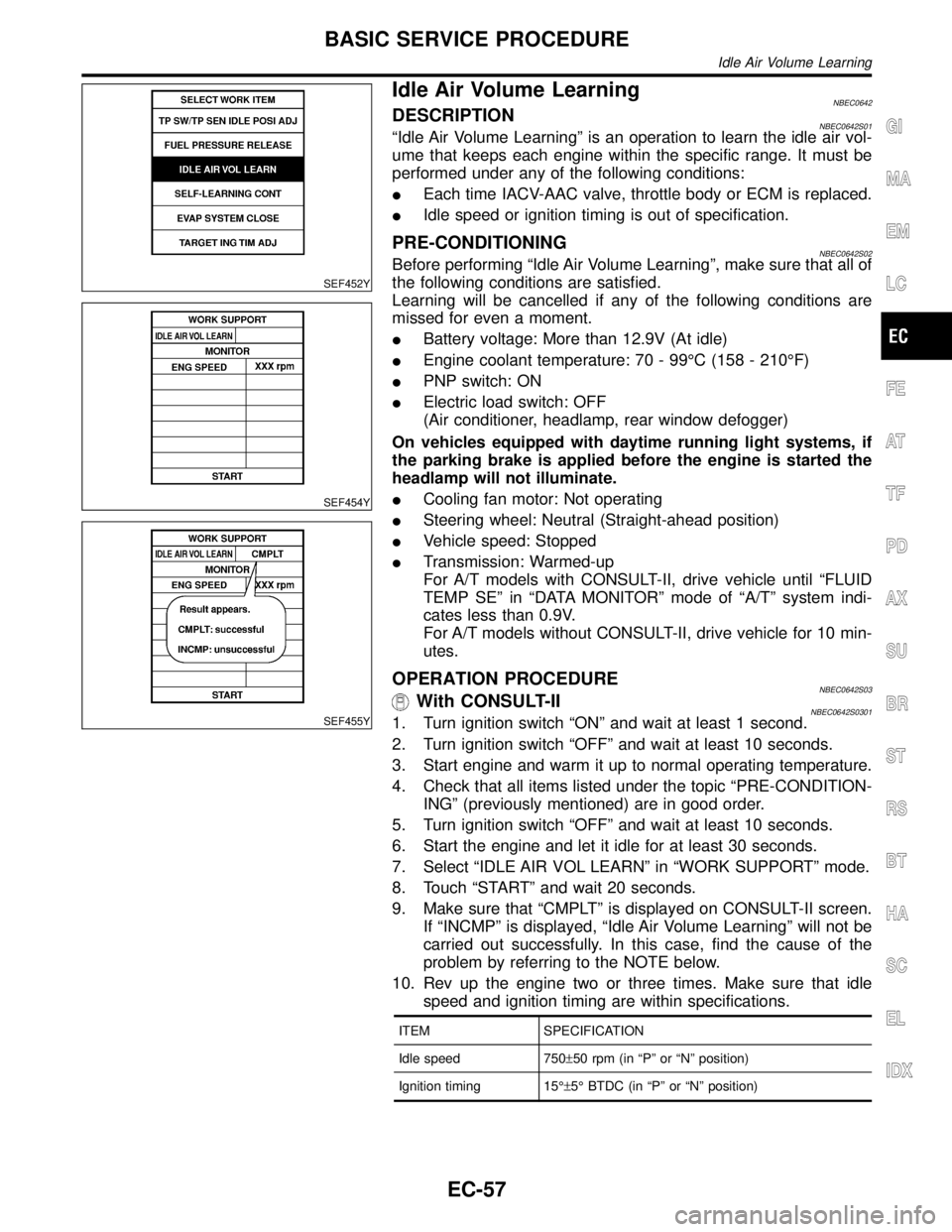

SEF452Y

Idle Air Volume LearningNBEC0642

SEF454Y

SEF455Y

DESCRIPTIONNBEC0642S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

IEach time IACV-AAC valve, throttle body or ECM is replaced.

IIdle speed or ignition timing is out of specification.

PRE-CONDITIONINGNBEC0642S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

IBattery voltage: More than 12.9V (At idle)

IEngine coolant temperature: 70 - 99ÉC (158 - 210ÉF)

IPNP switch: ON

IElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime running light systems, if

the parking brake is applied before the engine is started the

headlamp will not illuminate.

ICooling fan motor: Not operating

ISteering wheel: Neutral (Straight-ahead position)

IVehicle speed: Stopped

ITransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until ªFLUID

TEMP SEº in ªDATA MONITORº mode of ªA/Tº system indi-

cates less than 0.9V.

For A/T models without CONSULT-II, drive vehicle for 10 min-

utes.

OPERATION PROCEDURENBEC0642S03With CONSULT-IINBEC0642S03011. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

8. Touch ªSTARTº and wait 20 seconds.

9. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Air Volume Learning

EC-57

Page 1188 of 2395

Schematic ................................................................255

Wiring Diagram - D/LOCK -.....................................256

Trouble Diagnoses...................................................261

MULTI-REMOTE CONTROL SYSTEM.......................270

Component Parts and Harness Connector

Location ...................................................................270

System Description ..................................................270

Schematic ................................................................273

Wiring Diagram - MULTI - .......................................274

Trouble Diagnoses...................................................277

ID Code Entry Procedure ........................................289

Remote Controller Battery Replacement.................293

THEFT WARNING SYSTEM.......................................294

Component Parts and Harness Connector

Location ...................................................................294

System Description ..................................................295

Schematic ................................................................298

Wiring Diagram - THEFT -.......................................300

Trouble Diagnoses...................................................306

SMART ENTRANCE CONTROL UNIT.......................319

Description ...............................................................319

Schematic ................................................................322

Smart Entrance Control Unit Inspection Table ........324

INTEGRATED HOMELINK TRANSMITTER...............325

Wiring Diagram - TRNSMT - ...................................325

Trouble Diagnoses...................................................326

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM -

NATS)...........................................................................328

Component Parts and Harness Connetor

Location ...................................................................328

System Description ..................................................329

System Composition ................................................329

Wiring Diagram - NATS -.........................................330

CONSULT-II .............................................................331

Trouble Diagnoses...................................................334

How to Replace IVIS (NATS) IMMU .......................347

INFINITI COMMUNICATOR (IVCS)............................348

Precaution ................................................................348

Communicator Response Center Telephone

Number for Technicians ...........................................348

Component Parts and Harness Connector

Location ...................................................................349System Description ..................................................350

Schematic ................................................................358

Wiring Diagram - IVCS -..........................................359

CONSULT-II .............................................................363

Trouble Diagnoses...................................................368

Trouble Diagnoses for Intermittent Incident ............377

Demonstration Mode ...............................................379

System Setting (When IVCS Unit is Replaced) ......381

NAVIGATION SYSTEM...............................................385

Component Parts Location ......................................385

System Description ..................................................386

Schematic ................................................................393

Wiring Diagram - NAVI - ..........................................394

Self-diagnosis Mode ................................................397

Confirmation/Adjustment Mode ...............................400

Setting Mode............................................................410

Trouble diagnoses ...................................................417

This Condition is Not Abnormal ...............................423

Program Loading .....................................................432

Initialization ..............................................................433

ELECTRICAL UNITS LOCATION...............................436

Engine Compartment ...............................................436

Passenger Compartment .........................................438

HARNESS LAYOUT....................................................440

How to Read Harness Layout .................................440

Outline......................................................................441

Main Harness...........................................................442

Engine Room Harness ............................................444

Engine Control Harness ..........................................446

Body Harness LH ....................................................448

Body Harness RH ....................................................449

Back Door Harness .................................................450

Engine and Transmission Harness..........................451

Room Lamp Harness...............................................452

Air Bag Harness ......................................................453

Front Door Harness .................................................454

Rear Door Harness..................................................455

BULB SPECIFICATIONS............................................456

Headlamp.................................................................456

Exterior Lamp ..........................................................456

Interior Lamp............................................................456

WIRING DIAGRAM CODES (CELL CODES).............457GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CONTENTS(Cont'd)

EL-3

Page 1226 of 2395

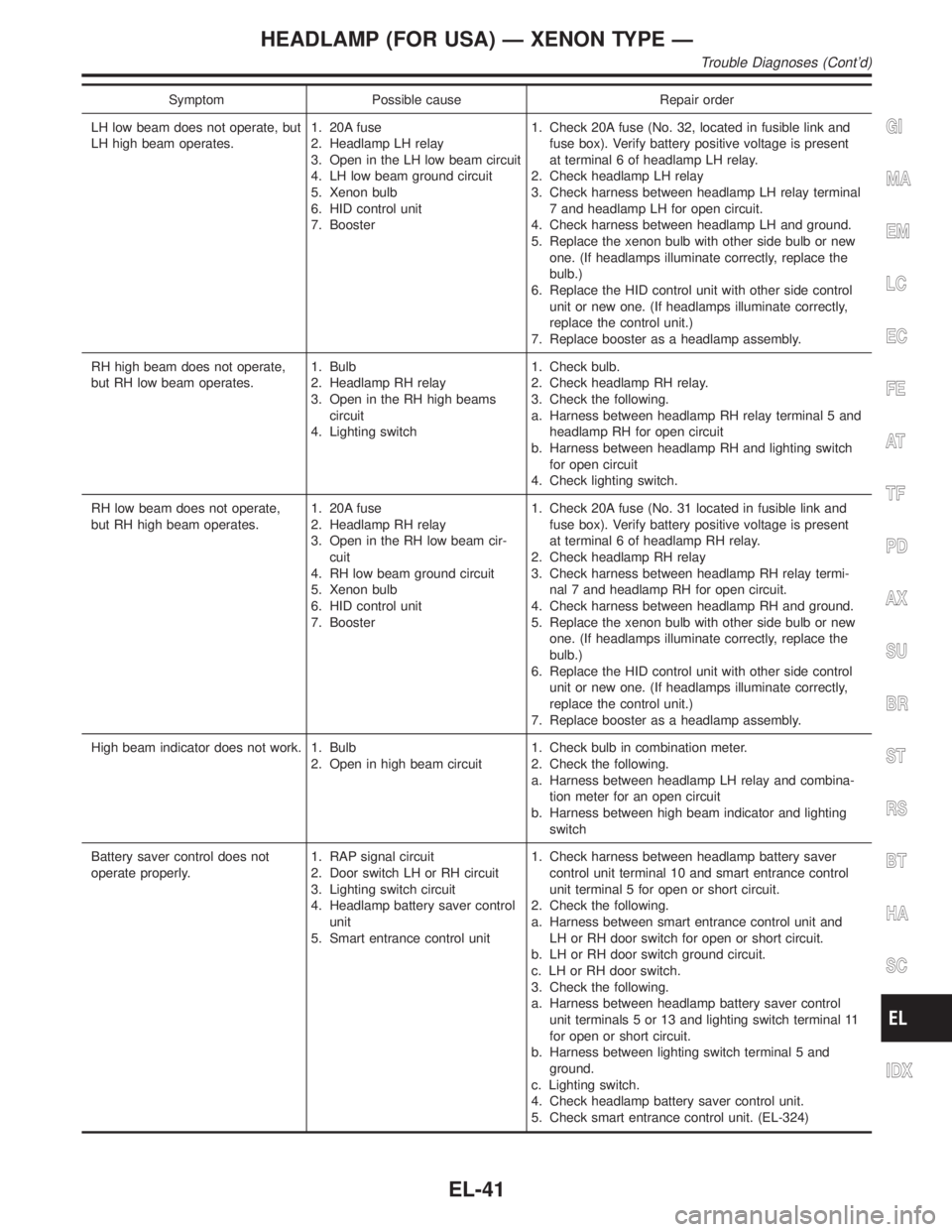

Symptom Possible cause Repair order

LH low beam does not operate, but

LH high beam operates.1. 20A fuse

2. Headlamp LH relay

3. Open in the LH low beam circuit

4. LH low beam ground circuit

5. Xenon bulb

6. HID control unit

7. Booster1. Check 20A fuse (No. 32, located in fusible link and

fuse box). Verify battery positive voltage is present

at terminal 6 of headlamp LH relay.

2. Check headlamp LH relay

3. Check harness between headlamp LH relay terminal

7 and headlamp LH for open circuit.

4. Check harness between headlamp LH and ground.

5. Replace the xenon bulb with other side bulb or new

one. (If headlamps illuminate correctly, replace the

bulb.)

6. Replace the HID control unit with other side control

unit or new one. (If headlamps illuminate correctly,

replace the control unit.)

7. Replace booster as a headlamp assembly.

RH high beam does not operate,

but RH low beam operates.1. Bulb

2. Headlamp RH relay

3. Open in the RH high beams

circuit

4. Lighting switch1. Check bulb.

2. Check headlamp RH relay.

3. Check the following.

a. Harness between headlamp RH relay terminal 5 and

headlamp RH for open circuit

b. Harness between headlamp RH and lighting switch

for open circuit

4. Check lighting switch.

RH low beam does not operate,

but RH high beam operates.1. 20A fuse

2. Headlamp RH relay

3. Open in the RH low beam cir-

cuit

4. RH low beam ground circuit

5. Xenon bulb

6. HID control unit

7. Booster1. Check 20A fuse (No. 31 located in fusible link and

fuse box). Verify battery positive voltage is present

at terminal 6 of headlamp RH relay.

2. Check headlamp RH relay

3. Check harness between headlamp RH relay termi-

nal 7 and headlamp RH for open circuit.

4. Check harness between headlamp RH and ground.

5. Replace the xenon bulb with other side bulb or new

one. (If headlamps illuminate correctly, replace the

bulb.)

6. Replace the HID control unit with other side control

unit or new one. (If headlamps illuminate correctly,

replace the control unit.)

7. Replace booster as a headlamp assembly.

High beam indicator does not work. 1. Bulb

2. Open in high beam circuit1. Check bulb in combination meter.

2. Check the following.

a. Harness between headlamp LH relay and combina-

tion meter for an open circuit

b. Harness between high beam indicator and lighting

switch

Battery saver control does not

operate properly.1. RAP signal circuit

2. Door switch LH or RH circuit

3. Lighting switch circuit

4. Headlamp battery saver control

unit

5. Smart entrance control unit1. Check harness between headlamp battery saver

control unit terminal 10 and smart entrance control

unit terminal 5 for open or short circuit.

2. Check the following.

a. Harness between smart entrance control unit and

LH or RH door switch for open or short circuit.

b. LH or RH door switch ground circuit.

c. LH or RH door switch.

3. Check the following.

a. Harness between headlamp battery saver control

unit terminals 5 or 13 and lighting switch terminal 11

for open or short circuit.

b. Harness between lighting switch terminal 5 and

ground.

c. Lighting switch.

4. Check headlamp battery saver control unit.

5. Check smart entrance control unit. (EL-324)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

HEADLAMP (FOR USA) Ð XENON TYPE Ð

Trouble Diagnoses (Cont'd)

EL-41

Page 1228 of 2395

Terminal No.Wire

colorItem ConditionVoltage

(Approximate value)

10 R/Y RAP signal Ignition switch OFF or ACC

(After more than 45 seconds with ignition

switch turned OFF or ACC)Less than 1V

ON or START Battery voltage

11 B Ground Ð Ð

13 G Tail lamp switch Lighting switch OFF Battery voltage

1ST or 2ND Less than 1V

14 R Tail lamp relay Ignition switch

(with lighting switch

1ST or 2ND)OFF or ACC More than 45 sec-

onds after ignition

switch is turned

OFF or ACCBattery voltage

Within 45 seconds

after ignition switch

is turned OFF or

ACCLess than 1V

ON or START Less than 1V

Headlamps illuminate by auto light control. Less than 1V

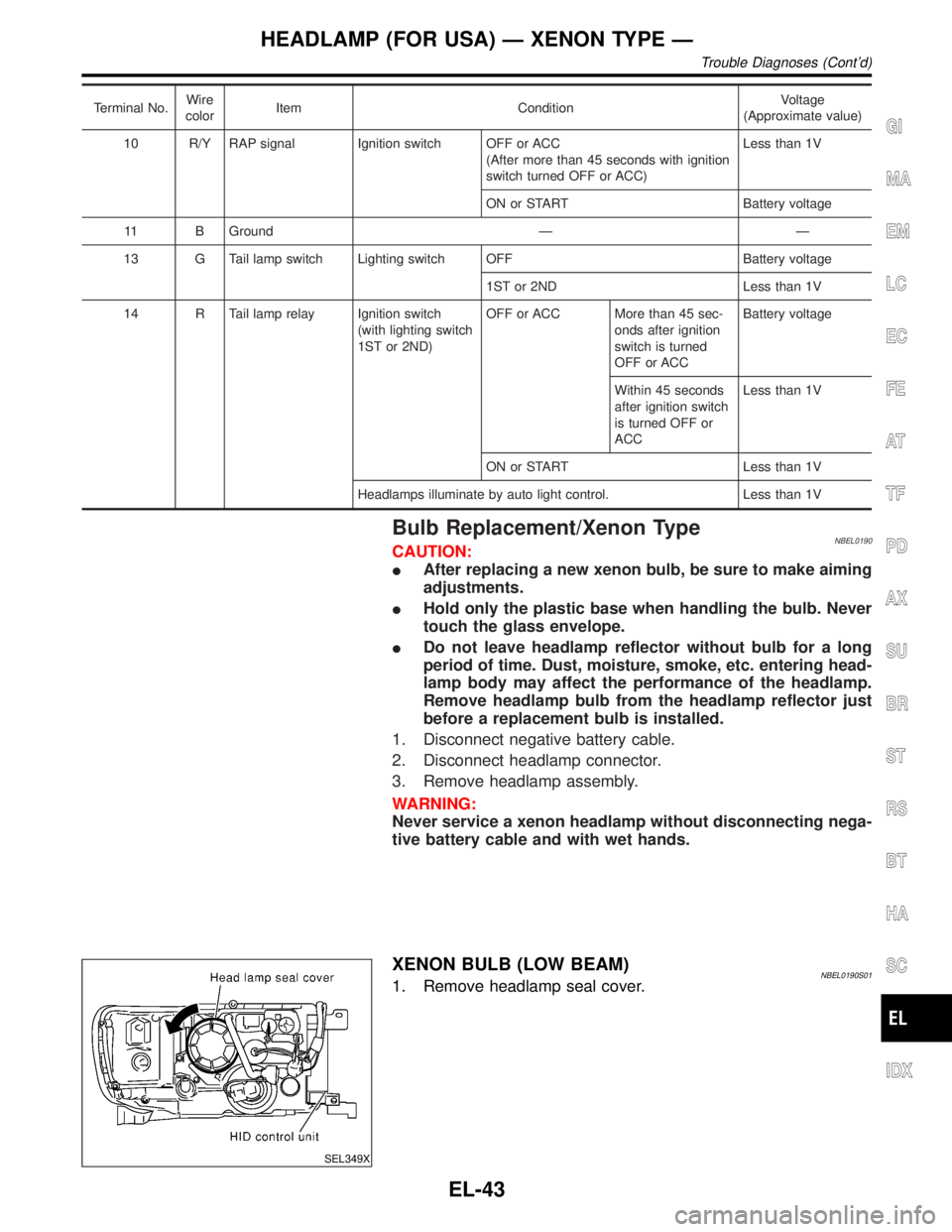

Bulb Replacement/Xenon TypeNBEL0190CAUTION:

IAfter replacing a new xenon bulb, be sure to make aiming

adjustments.

IHold only the plastic base when handling the bulb. Never

touch the glass envelope.

IDo not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

1. Disconnect negative battery cable.

2. Disconnect headlamp connector.

3. Remove headlamp assembly.

WARNING:

Never service a xenon headlamp without disconnecting nega-

tive battery cable and with wet hands.

SEL349X

XENON BULB (LOW BEAM)NBEL0190S011. Remove headlamp seal cover.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

HEADLAMP (FOR USA) Ð XENON TYPE Ð

Trouble Diagnoses (Cont'd)

EL-43

Page 1242 of 2395

Terminal

No.Wire

colorItem ConditionVoltage

(Approximate values)

7 L/R RH hi beam When lighting switch is turned to the 2ND position with

ªHI BEAMº positionBattery voltage

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

9 PU RH hi beam

(ground)When lighting switch is turned to the 2ND position with

ªHI BEAMº positionLess than 1V

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

10 GY LH hi beam

(ground)When lighting switch is turned to the 2ND position with

ªHI BEAMº positionLess than 1V

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

13

14L/W

W/RLighting switch

(Hi beam)When turning lighting switch to ªHI BEAMº Battery voltage

When turning lighting switch to ªFLASH TO PASSº Battery voltage

16 B Ground Ð Ð

17 L/G Parking brake

switch

When parking brake is released Battery voltage

When parking brake is set Less than 1.5V

BATTERY SAVER CONTROL UNIT INSPECTION TABLENBEL0193S02Refer to ªHEADLAMP (FOR USA)º, EL-42.

Bulb ReplacementNBEL0194Refer to ªHEADLAMP (FOR USA)º (EL-43).

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

HEADLAMP (FOR CANADA) Ð DAYTIME LIGHT SYSTEM Ð

Trouble Diagnoses (Cont'd)

EL-57

Page 1297 of 2395

Trouble DiagnosesNBEL0048PRELIMINARY CHECK FOR THERMOMETERNBEL0048S02

1 COOL DOWN CHECK

1. Turn the ignition key switch to the ªACCº position.

2. Cool down the ambient air temperature sensor with water or ice, so that the indicated temperature falls.

Does the indicated temperature fall?

Ye s©GO TO 2.

No©The system is malfunctioning. Check the system following ªINSPECTION/COMPASS

AND THERMOMETERº.

2 WARM UP CHECK

1. Leave the vehicle for 10 minutes, so that the indicated temperature rises.

2. With the ignition key in the ªACCº position, disconnect and reconnect the ambient air temperature sensor connector.

Does the indicated temperature rise?

Ye s©The system is OK.

No©The system is malfunctioning. Check the system following ªINSPECTION/COMPASS

AND THERMOMETERº.

NOTE:

IWhen the outside temperature is between 55ÉC (130ÉF) and 70ÉC (158ÉF), the display shows 55ÉC

(130ÉF). When the outside temperature is lower than þ30ÉC (þ20ÉF) or higher than 70ÉC (158ÉF), the dis-

play shows only ª---º.

IThe indicated temperature on the thermometer is not readily affected by engine heat. It changes only when

one of the following conditions is present.

a) The temperature detected by the ambient air temperature sensor is lower than the indicated temperature

on the thermometer.

b) The difference in temperature detected during a period of 40 seconds is less than 1ÉC (1.8ÉF) when vehicle

speed has been greater than 24 km/h (15 MPH) for more than 100 seconds.

(This is to prevent the indicated temperature from being affected by engine heat or cooling fan operation

during low-speed driving.)

c) The ignition key has been turned to the ªOFFº position for more than 4 hours. (The engine is cold.)

INSPECTION/COMPASS AND THERMOMETERNBEL0048S01

Symptom Possible causes Repair order

No display at all 1. 10A fuse

2. Ground circuit

3. Compass and thermometer1. Check 10A fuse [No. 9, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminal 7 of compass and thermometer.

2. Check ground circuit for compass and thermometer.

3. Replace compass and thermometer.

Forward direction indi-

cation slips off the

mark or incorrect.1. In manual correction mode (Bar

and display vanish.)

2. Zone variation change is not done.1. Drive the vehicle and turn at an angle of 90É.

2. Perform the zone variation change.

Compass reading

remains unchanged.1. Vehicle speed sensor is not

entered.

2. Compass and thermometer1. Check harness for open or short between combination meter

terminal 13 and compass and thermometer terminal 1.

2. Replace compass and thermometer.

Displays wrong tem-

perature when ambient

temperature is between

þ30ÉC (þ20ÉF) and

55ÉC (130ÉF). (See

NOTE above.)1. Check operation

2. Ambient air temperature sensor

circuit

3. Vehicle speed sensor is not

entered.

4. Ambient air temperature sensor

5. Compass and thermometer1. Perform preliminary check shown above.

2. Check harness for open or short between ambient air tem-

perature sensor and compass and thermometer.

3. Check harness for open or short between combination meter

terminal 13 and compass and thermometer terminal 1.

4. Replace ambient air temperature sensor.

5. Replace compass and thermometer.

COMPASS AND THERMOMETER

Trouble Diagnoses

EL-112

Page 1316 of 2395

LIGHTING SWITCH INPUT SIGNAL CHECK=NBEL0055S03

1 CHECK LIGHTING SWITCH INPUT SIGNAL

Check voltage between smart entrance control unit terminal 34 and ground.

SEL377X

OK or NG

OK©Lighting switch is OK.

NG©GO TO 2.

2 CHECK FUSE

Is 10A fuse (No. 61, located in the fuse and fusible link box) OK?

OK or NG

OK©GO TO 3.

NG©Replace fuse.

3 CHECK TAIL LAMP RELAY CIRCUIT

Check voltage between headlamp battery saver control unit terminal 6, 14 and ground.

SEL378X

OK or NG

OK©Check the following.

ITail lamp relay

IHarness for open or short between smart entrance control unit and tail lamp relay.

NG©GO TO 4.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WARNING CHIME

Trouble Diagnoses (Cont'd)

EL-131

Page 1351 of 2395

Trouble DiagnosesNBEL0082AUDIO UNITNBEL0082S01

Symptom Possible causes Repair order

Audio unit inoperative (no

digital display and no

sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 10, located in fuse block (J/B)].

Turn ignition switch ON and verify that battery posi-

tive voltage is present at terminal 10 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost

when ignition switch is

turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 4, located in fuse block (J/B)]

and verify that battery positive voltage is present at

terminal 6 of audio unit.

2. Remove audio unit for repair.

AM stations are weak or

noisy (FM stations OK).1. Antenna

2. Poor audio unit ground

3. Audio unit1. Check antenna.

2. Check audio unit ground.

3. Remove audio unit for repair.

FM stations are weak or

noisy (AM stations OK).1. Window antenna

2. Audio unit1. Check window antenna.

2. Remove audio unit for repair.

Audio unit generates noise

in AM and FM modes with

engine running.1. Poor audio unit ground

2. Loose or missing ground bonding

straps

3. Ignition condenser or rear window

defogger noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger

noise suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove audio unit for repair.

Audio unit generates noise

in AM and FM modes with

accessories on (switch

pops and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

Audio unit controls are

operational, but no sound

is heard from any speaker.1. 15A fuse

2. Audio unit output

3. Audio unit1. Check 15A fuse [No. 4, located in fuse block (J/B)].

Verify battery positive voltage is present at terminal 3

of audio amp. relay.

2. Check audio unit output voltage (Terminal 12).

3. Remove audio unit for repair.

All front speakers are inop-

erative.1. Audio amp. relay

2. Audio amp. relay ground

3. Amp. ON signal1. Check audio amp. relay.

2. Check audio amp. relay ground (Terminal 2).

3. Turn ignition switch ACC and audio unit ON. Verify

battery positive voltage is present at terminal 1 of

audio amp. relay.

Individual front speaker is

noisy or inoperative.1. Speaker ground

2. Power supply

3. Audio unit output

4. Speaker1. Check speaker ground (Terminal 5).

2. Check power supply for speaker (Terminal 4).

3. Check audio unit output voltage for speaker.

4. Replace speaker.

Both rear speakers are

inoperative.1. Poor rear speaker amp. ground

2. Power supply

3. Amp. ON signal

4. Rear speaker amp.1. Check rear speaker amp. ground circuit.

2. Check power supply for rear speaker amp. (Terminal

11).

3. Turn ignition switch ACC and audio unit ON. Verify

battery positive voltage is present at terminal 9 of

rear speaker amp.

4. Remove rear speaker amp. for repair.

Individual rear speaker is

noisy or inoperative.1. Speaker

2. Audio unit/amp. output

3. Speaker circuit

4. Audio unit1. Check speaker.

2. Check audio unit/amp. output.

3. Check wires for open or short between audio unit/

amp. and speakers.

4. Remove audio unit for repair.

AUDIO

Trouble Diagnoses

EL-166

Page 1356 of 2395

Trouble DiagnosesNBEL0086POWER ANTENNANBEL0086S01

Symptom Possible causes Repair order

Power antenna does not

operate.1. 7.5A fuse

2. Audio unit signal

3. Grounds M4, M66 and M1471. Check 7.5A fuse [No. 24, located in fuse block (J/B)].

Verify that battery positive voltage is present at termi-

nal 6 of power antenna.

2. Turn ignition switch and audio unit ON. Verify that

battery positive voltage is present at terminal 4 of

power antenna.

3. Check grounds M4, M66 and M147.

Location of AntennaNBEL0087

YEL067K

MEL036G

Antenna Rod ReplacementNBEL0088REMOVALNBEL0088S011. Remove antenna nut and antenna base.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

AUDIO ANTENNA

Trouble Diagnoses

EL-171