Engine control INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2191 of 2395

6. If rack sliding force is not within specification, overhaul steer-

ing gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ªInspectionº, ªSTEERING WHEEL AND STEERING

COLUMNº, ST-14.

SST834-F

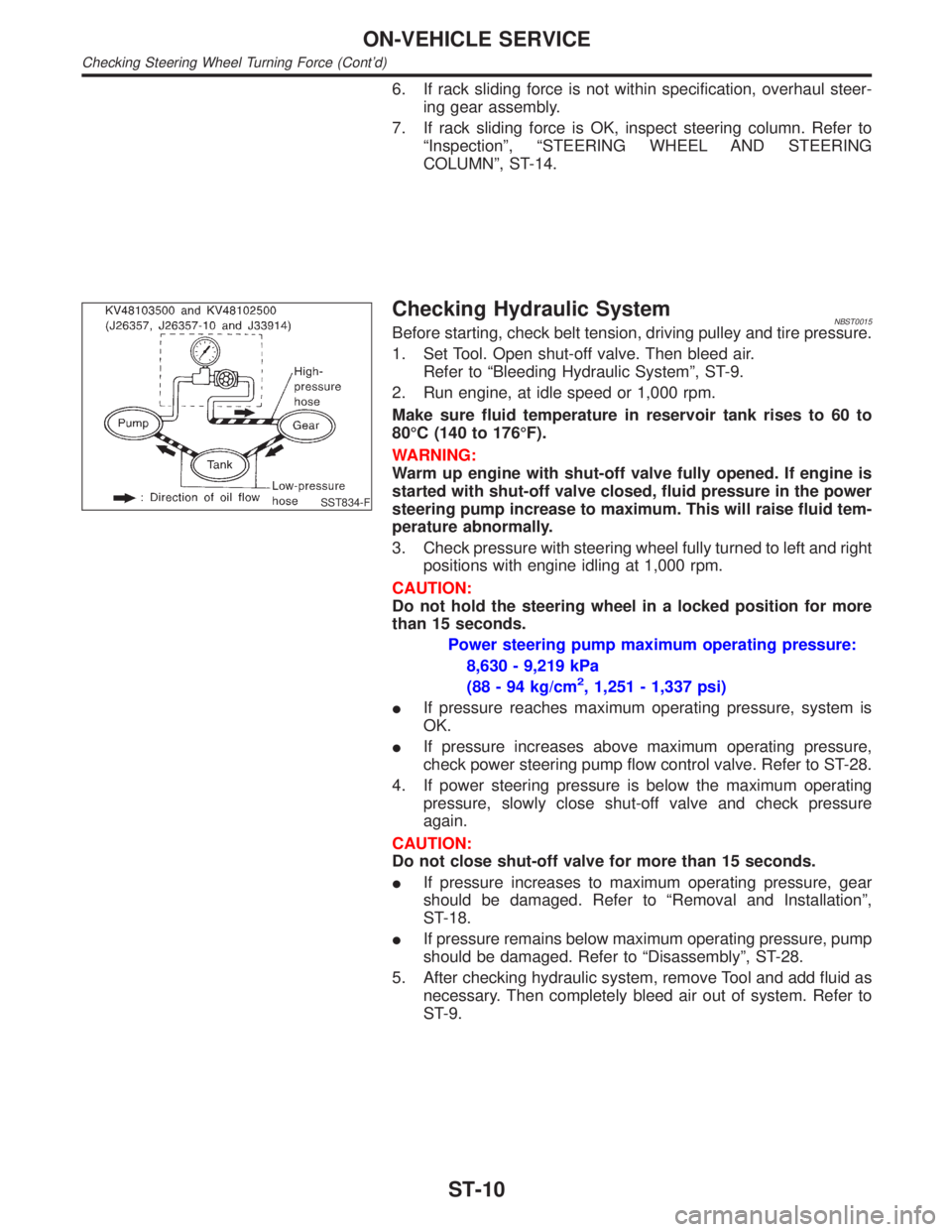

Checking Hydraulic SystemNBST0015Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air.

Refer to ªBleeding Hydraulic Systemº, ST-9.

2. Run engine, at idle speed or 1,000 rpm.

Make sure fluid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in the power

steering pump increase to maximum. This will raise fluid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,630 - 9,219 kPa

(88 - 94 kg/cm

2, 1,251 - 1,337 psi)

IIf pressure reaches maximum operating pressure, system is

OK.

IIf pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-28.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

IIf pressure increases to maximum operating pressure, gear

should be damaged. Refer to ªRemoval and Installationº,

ST-18.

IIf pressure remains below maximum operating pressure, pump

should be damaged. Refer to ªDisassemblyº, ST-28.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-9.

ON-VEHICLE SERVICE

Checking Steering Wheel Turning Force (Cont'd)

ST-10

Page 2236 of 2395

TRANSFER

SECTION

TF

CONTENTS

PRECAUTIONS...............................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............3

Precautions ..................................................................3

Service Notice..............................................................4

Wiring Diagrams and Trouble Diagnosis .....................4

PREPARATION...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools ...........................................9

ALL-MODE 4WD SYSTEM...........................................10

Cross-sectional View .................................................10

Control System .......................................................... 11

ALL-MODE 4WD TRANSFER BASIC CONTROL........12

HYDRAULIC CONTROL CIRCUITS...........................12

OUTLINE................................................................12

CONTROL SYSTEM DIAGRAM................................13

INDICATIONS OF 4WD WARNING LAMP..................13

Location of Electrical Parts ........................................14

Description of Electrical Parts ...................................15

TRANSFER MOTOR................................................15

WAIT DETECTION SWITCH.....................................15

2-4WD SHIFT SOLENOID VALVE.............................16

LINE PRESSURE SWITCH.......................................16

Circuit Diagram for Quick Pinpoint Check.................17

Wiring Diagram - TF -................................................18

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................27

Trouble Diagnosis without CONSULT-II ....................27

DESCRIPTION........................................................27

SELF-DIAGNOSTIC PROCEDURE............................28

INDICATIONS OF 4WD WARNING LAMP..................29

Trouble Diagnosis with CONSULT-II .........................30

SELF-DIAGNOSIS...................................................30

SELF-DIAGNOSTIC ITEMS......................................31

DATA MONITOR......................................................33

DATA MONITOR ITEMS...........................................34

REFERENCE VALUE IN DATA MONITOR MODE......36

WORK SUPPORT....................................................38

CLUTCH FORCE RELEASE LIMIT ADJUSTMENT.....39

TROUBLE DIAGNOSIS - INTRODUCTION..................41Introduction ................................................................41

DESCRIPTION........................................................41

DIAGNOSTIC WORKSHEET.....................................41

Work Flow ..................................................................43

HOW TO PERFORM TROUBLE DIAGNOSES FOR

QUICK AND ACCURATE REPAIR

.............................43

TROUBLE DIAGNOSIS - BASIC INSPECTION...........44

Listen to Customer Complaints .................................44

Transfer Fluid Check .................................................44

Road Test...................................................................44

PREPARATION FOR ROAD TEST............................44

1. CHECK BEFORE ENGINE IS STARTED...............45

2. CHECK AT IDLE..................................................47

3. CRUISE TEST.....................................................51

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................54

Transfer Control Unit Terminals and Reference

Value ..........................................................................54

REMOVAL AND INSTALLATION OF TRANSFER

CONTROL UNIT

......................................................54

INSPECTION OF TRANSFER CONTROL UNIT..........54

TRANSFER CONTROL UNIT INSPECTION TABLE....55

VEHICLE SPEED SENSOR (FRONT

REVOLUTION SENSOR)..............................................61

Diagnostic Procedure ................................................61

4WD SOLENOID VALVE...............................................64

Diagnostic Procedure ................................................64

2-4WD SHIFT SOLENOID VALVE AND 4WD

SHIFT SWITCH..............................................................66

Diagnostic Procedure ................................................66

TRANSFER MOTOR AND TRANSFER MOTOR

RELAY...........................................................................70

Diagnostic Procedure ................................................70

TRANSFER FLUID TEMPERATURE SENSOR............73

Diagnostic Procedure ................................................73

ATP SWITCH, WAIT DETECTION SWITCH AND

NEUTRAL-4LO SWITCH...............................................76

Diagnostic Procedure ................................................76

CLUTCH PRESSURE SWITCH....................................80

Diagnostic Procedure ................................................80

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2248 of 2395

CONTROL SYSTEM DIAGRAMNBTF0007S04

SMT763D

INDICATIONS OF 4WD WARNING LAMPNBTF0007S05

Condition Content 4WD warning lamp

During self-diagnosis Indicates the malfunction position by number of flickers. Flickers at malfunction mode.

Lamp check*Checks the lamp by turning ON during engine starting. After

engine starts, it turns OFF if there are no malfunctions.ON

Malfunction in 4WD system*Turns ON to indicate malfunction. When ignition switch is

turned to ªOFFº or the malfunction is corrected, it turns OFF.ON

When vehicle is driven with different

diameters of front and rear tiresFlickers once every 2 seconds.

Turns OFF when ignition switch is ªOFFº.Flickers once every 2 sec-

onds.

High fluid temperature in transfer

unitWhen fluid temperature is high or fluid temperature sensor

circuit is shorted, it flickers twice every second.

It turns OFF when fluid temperature becomes normal.Flickers twice a second.

Other than above (System is nor-

mal.)Lamp is OFF. OFF

*: When 4WD warning lamp is ON, all the 4WD shift indicator lamps turn OFF.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ALL-MODE 4WD SYSTEM

Control System (Cont'd)

TF-13

Page 2264 of 2395

INDICATIONS OF 4WD WARNING LAMPNBTF0011S03

Flickering pattern or flick-

ering conditionMalfunction Check items

1 Front revolution sensor circuit is shorted or open.Revolution sensor (front) circuit,

TF-61.

2 Rear revolution sensor circuit is shorted or open.Revolution sensor (rear) [Refer to

AT-111, ªDTC P0720 Vehicle Speed

Sensor´A/T (Revolution sensor)º.]

3 4WD solenoid valve circuit is shorted or open. 4WD solenoid valve circuit, TF-64.

42-4WD shift solenoid valve circuit is shorted or 2WD switch of

4WD shift switch is shorted.2-4WD shift solenoid valve circuit or

4WD shift switch circuit, TF-66.

5 Transfer motor relay circuit is shorted or open. Transfer motor relay circuit, TF-70.

8Power supply voltage of throttle position sensor is improper. Or

A/D converter of transfer control unit functions improperly.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle Posi-

tion Sensorº.)

9 Transfer fluid temperature sensor circuit is open.Transfer fluid temperature sensor

circuit, TF-73.

10 Neutral-4LO switch circuit is shorted or open. Neutral-4LO switch circuit, TF-76.

112-4WD shift solenoid valve circuit, 2WD switch of 4WD shift

switch circuit or clutch pressure switch circuit is shorted or open.2-4WD shift solenoid valve circuit,

4WD shift switch circuit or clutch

pressure switch circuit, TF-66, 80.

12 Line pressure switch circuit is shorted or open. Line pressure switch circuit, TF-83.

13 Engine speed signal circuit is shorted or open.Engine speed signal (Refer to

AT-116, ªDTC P0725 Engine Speed

Signalº.)

14 Throttle position sensor circuit is shorted or open.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle Posi-

tion Sensorº.)

15 Failure in power supply circuit of transfer control unit. Power supply of transfer control unit

16 4WD shift switch circuit is shorted. 4WD shift switch circuit, TF-66.

17 ABS operation signal circuit is shorted. ABS operation signal circuit, TF-86.

18ATP switch, wait detection switch or neutral-4LO switch circuit is

shorted or open.ATP switch, wait detection switch or

neutral-4LO switch circuit*, TF-76.

19Transfer control device actuator motor is faulty. (Abnormalities

are detected when actuator motor fails to operate while shifting

from ª4Hº to ª4LOº or vice versa.)Actuator motor and motor circuit,

TF-115, 89.

20Transfer control device actuator motor arm position sensing

switch is faulty.Actuator motor arm position sensing

switch and sensing switch circuit,

TF-115, 92.

21Transfer control device actuator circuit is faulty (Abnormalities

are detected when motor relay circuit is open/shorted or relay

monitor circuit is open/shorted.)Actuator motor, actuator motor arm

position sensing switch and their

associated circuits, TF-114, 115 and

94.

Repeats flickering every

2 to 5 sec.Circuits that the self-diagnosis covers have no malfunction. Ð

Repeats flickering every

0.25 sec.IPower supply failure of memory back-up.

IBattery is disconnected for a long time.

IBattery performance is poor.Data erase/display circuit, TF-88.GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis without CONSULT-II (Cont'd)

TF-29

Page 2269 of 2395

![INFINITI QX4 2001 Factory Service Manual SMT963D

12. Monitored data are displayed.

DATA MONITOR ITEMSNBTF0012S04q: StandardH: Option

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Revolution sensor-front [ INFINITI QX4 2001 Factory Service Manual SMT963D

12. Monitored data are displayed.

DATA MONITOR ITEMSNBTF0012S04q: StandardH: Option

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Revolution sensor-front [](/img/42/57027/w960_57027-2268.png)

SMT963D

12. Monitored data are displayed.

DATA MONITOR ITEMSNBTF0012S04q: StandardH: Option

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Revolution sensor-front [km/h (MPH)]qHRevolution sensor installed on T/F

Revolution sensor-rear [km/h (MPH)]qHVehicle speed sensor´A/T

Engine speed [rpm]qH

Throttle position sensor [V]qH

Transfer fluid temperature sensor [V]qH

Battery voltage [V]qH

2WD switch [ON-OFF]qH2WD switch of 4WD shift switch

AUTO switch [ON-OFF]qHAUTO switch of 4WD shift switch

Lock switch [ON-OFF]qH4H switch of 4WD shift switch

4L switch [ON-OFF]qH4LO switch of 4WD shift switch

N position switch TF [ON-OFF]qHN position switch of transfer

Line pressure switch [ON-OFF]qHLine pressure switch

Clutch pressure switch [ON-OFF]qHClutch pressure switch

ATP switch [ON-OFF]qH

N position switch [ON-OFF]qHªNº position on A/T PNP switch

R position switch [ON-OFF]qHªRº position on A/T PNP switch

P position switch [ON-OFF]qHªPº position on A/T PNP switch

Closed throttle position switch

[ON/OFF]qHIdle contact of throttle position switch

ABS operation switch [ON-OFF]qHABS operation switch

Wait detection switch [ON-OFF]qH

Throttle openingqHThrottle opening recognized by transfer control

unit

4WD-modeqH4WD-mode recognized by transfer control unit

(2W, AUTO, 4H & 4LO)

Vehicle speed comp [km/h (MPH)]qHVehicle speed recognized by transfer control

unit

*Control torque [N´m (kg-m, ft-lb)]qHCalculated torque recognized by transfer control

unit

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-34

Page 2271 of 2395

REFERENCE VALUE IN DATA MONITOR MODENBTF0012S09

Indicated items

(Screen terms for CONSULT, ªDATA

MONITORº mode)Display Conditions

Throttle position sensor

(THRTL POS SEN)Approx. 0.5 - 4.0V Throttle valve fully closed to fully open

Transfer fluid temperature sensor

(FLUID TEMP SE)Approx. 1.5 - 0.5VTransfer fluid temperature approx. 20 - 80ÉC (68 -

176ÉF)

Closed throttle position switch

(CLOSED THL/SW)ON After engine warm-up, accelerator pedal is released.

OFF After engine warm-up, accelerator pedal is depressed.

ABS operation switch

(ABS OPER SW)OFF ABS is not operating.

ON ABS is operating.

ABS control operation

(ABS CONT OPER)ONABS OPER SW is ªONº. Control operation is accom-

plished in combination with ABS.

OFFABS is not operating. When a message such as

ªimproper ABS operation signalº appears on the display

and ABS OPER SW is ªONº, control operation is not

accomplished in combination with ABS.

2WD position

(2WD SW)ON 4WD shift switch is in ª2WDº.

OFF Except the above condition

Lock position

(LOCK SWITCH)ON 4WD shift switch is in ª4Hº.

OFF Except the above condition

Neutral-4LO switch

(N POSI SW TF)

ATP switch

(ATP SWITCH)

Wait detection switch

(WAIT DETCT SW)4WD shift switch position2WD, AUTO,

4H(N) 4LO

ATP switch OFF ON OFF

Neutral-4LO switch OFF ON

Wait detection switchOFF ON

See Note.

Note: When shifting from ª4LOº to ª2WDº, ªAUTOº, ª4Hº, it turns ON when ªWaitº function

is operating (and it turns OFF when ªWaitº function is canceled).

Transfer motor relay

(MOTOR RELAY)Throttle valve4WD shift

switchA/T selector

leverMotor relay Remarks

Fully closed2WD Ð OFF

AUTO,

4LOP, N OFF

ON for approx. 2 sec. after

shifting to ªPº and ªNº

Others ON

4HP OFF

ON for approx. 2 sec. after

shifting to ªPº

Others ON

Line pressure switch

(LINE PRES SW)OFFThe vehicle has been left at room temperature for 5 min-

utes and more with ignition switch in ªOFFº position.

ONIgnition switch in ªONº, and 4WD shift switch in ªAUTOº

or ª4Hº and A/T selector lever in ªDº.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-36

Page 2272 of 2395

Indicated items

(Screen terms for CONSULT, ªDATA

MONITORº mode)Display Conditions

Clutch pressure switch

(CL PRES SW)OFFIgnition switch in ªONº, and 4WD shift switch in ª2WDº.

(ªWaitº function is not operating.)

ONIgnition switch in ªONº, and 4WD shift switch in ªAUTOº

or ª4Hº and A/T selector lever in ªDº. (ªWaitº function is

not operating.)

Control torque

(COMP CL TORQ)0 kg-m

4WD shift switch

(ªWaitº function is not oper-

ating.)In ª2WDº position

39 - 1,079 N´m

(4 - 110 kg-m, 29 - 796 ft-lb)In ªAUTOº position

1,079 N´m

(110 kg-m, 796 ft-lb)In ª4Hº or ª4LOº position

4WD solenoid

(DUTY SOLENOID)4% In ª2WDº position

94 - 4% In ªAUTOº position

4% In ª4Hº or ª4LOº position

2-4WD shift solenoid valve

(2-4WD SOL)OFF

4WD shift switchIn ª2WDº position

ON (ªWaitº function is not oper-

ating.)

In ªAUTOº position

OFF (ªWaitº function is operat-

ing.)

ON (ªWaitº function is not oper-

ating.)

In ª4Hº position

OFF (ªWaitº function is operat-

ing.)

ON In ª4LOº position

Indicated items Display Conditions

Battery voltage Approx. 12V Key switch ªONº and engine at rest

Approx. 13 - 14V During idling

AUTO switch OFF 4WD shift switch in other than ªAUTOº position

ON 4WD shift switch in ªAUTOº position

4L switch OFF 4WD shift switch in other than ª4LOº position

ON 4WD shift switch in ª4LOº position

N position switch OFF A/T selector lever in other than ªNº position

ON A/T selector lever in ªNº position

R position swtich OFF A/T selector lever in other than ªRº position

ON A/T selector lever in ªRº position

P position switch OFF A/T selector lever in other than ªPº position

ON A/T selector lever in ªPº position

Throttle opening 0.0/8 - 8.0/8 Throttle fully closed (0.0/8) or throttle fully open (8.0/8)

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-37

Page 2276 of 2395

IntroductionNBTF0013DESCRIPTIONNBTF0013S01When a malfunction (indicated by the 4WD warning lamp illumination) occurs, collect information first from the

customer about how the malfunction occurs. Then, proceed with the diagnosis presuming it is the cause. Also

inspect the electrical system, paying close attention to other possibilities such as fluid level and leaks.

All-mode 4WD transfer is controlled by transfer control unit and sensors.

If a malfunction occurs in the all-mode 4WD system, the 4WD warning lamp lights up to inform of the system

malfunction. There are two ways to identify the cause of the malfunction.

1) Performing the self-diagnosis. (The 4WD warning lamp will indicate what kind of malfunction has occurred

by flickering.)

2) Performing diagnosis using CONSULT-II.

DIAGNOSTIC WORKSHEETNBTF0013S02Information from CustomerNBTF0013S0201KEY POINTS

WHAT..... Vehicle model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Information sheet from customer

Customer name MR/MS Model & Year VIN

Transfer model

ATX14AEngine Mileage

Incident Date Manuf. Date In Service Date

FrequencylContinuouslIntermittent ( times a day)

Symptomsl4WD shift indicator lamp does not turn on.

l4WD warning lamp does not turn on.

l4WD shift indicator lamp does not turn off.

lATP warning lamp does not turn on.

l4LO indicator lamp does not turn on.

l4WD shift indicator lamp does not indicate ª4Hº.

l4WD shift indicator lamp repeats flicking.

lTight corner braking symptom occurs.

l4WD system does not operate.

lOthers.

4WD warning lamplContinuously litlNot lit

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction

TF-41

Page 2290 of 2395

SMT772D

TRANSFER CONTROL UNIT INSPECTION TABLENBTF0018S02(Data are reference values.)

Terminal

No.Item Condition Judgement standard

12-4WD shift solenoid

valve

&

4WD shift switch is set to ª2WDº

position.Less than 1V

4WD shift switch is set to any posi-

tion other than ª2WDº.Battery voltage

24WD shift indicator lamp

(2WD)

Lamp lights while system is operating

properly.Less than 1V

&

2WD indicator lamp does not come

on.Battery voltage

3 Ground Ð Ð

4Transfer shift relay

(High)While actuator is operating

(4H,4LO)Battery voltage

Actuator does not operate. Less than 1V

5 4WD warning lampLamp comes ON. (when engine is

stopped.)

(Fail-safe condition appears on

display, engine is stopped, actuator

position detection switch is

inoperative, oil temperature is too

high and/or tires of different size are

installed.)Less than 1V

Except above Battery voltage

6 Ground Ð Ð Ð

7 PNP switch (R position)

&

A/T selector lever is set to ªreverseº

position.Battery voltage

A/T selector lever is set to any posi-

tion other than ªreverseº.Less than 1V

8ÐÐÐÐ

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Transfer Control Unit Terminals and Reference Value (Cont'd)

TF-55

Page 2298 of 2395

5 CHECK INPUT SIGNAL

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector terminals 38 and 28.

(Measure it in AC range.)

Voltage:

0 km/h (0 MPH): 0V

30 km/h (19 MPH): More than 1V

(Voltage rises gradually in response to vehicle speed.)

SMT774D

OK or NG

OK©GO TO 6.

NG©GO TO 7.

6 PERFORM SELF-DIAGNOSIS AGAIN

After driving for a while, perform self-diagnosis again.

Refer to ªTrouble Diagnosis without CONSULT-IIº, TF-27.

OK or NG

OK©INSPECTION END

NG©1. Perform transfer control unit input/output signal inspection. Refer to ªTRANSFER

CONTROL UNIT INSPECTION TABLEº, ªTROUBLE DIAGNOSIS Ð GENERAL

DESCRIPTIONº, TF-55.

2. If NG, recheck transfer control unit pin terminals for damage or loose connection with

harness connector.

7 CHECK HARNESS CONTINUITY BETWEEN TRANSFER CONTROL UNIT AND FRONT REVOLUTION

SENSOR SUB-HARNESS CONNECTOR

OK or NG

OK©GO TO 6.

NG©Repair or replace sub-harness connector between transfer control unit and front revolu-

tion sensor.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

VEHICLE SPEED SENSOR (FRONT REVOLUTION SENSOR)

Diagnostic Procedure (Cont'd)

TF-63